Advanced Materials in Solar Inverter Manufacturing

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Inverter Materials Evolution and Objectives

Solar inverter technology has undergone significant evolution since its inception, driven by the growing demand for efficient and reliable renewable energy systems. The development of advanced materials has played a crucial role in this progression, enabling improvements in performance, durability, and cost-effectiveness of solar inverters.

In the early stages, solar inverters primarily utilized silicon-based semiconductors and conventional copper wiring. However, as the industry matured, the focus shifted towards more advanced materials to address key challenges such as power density, thermal management, and overall efficiency.

The introduction of wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), marked a significant milestone in solar inverter technology. These materials offer superior electrical properties, including higher breakdown voltage, faster switching speeds, and lower on-resistance compared to traditional silicon. As a result, inverters incorporating these advanced semiconductors can operate at higher frequencies and temperatures, leading to improved efficiency and reduced cooling requirements.

Advancements in magnetic materials have also contributed to the evolution of solar inverters. The development of nanocrystalline and amorphous soft magnetic materials has enabled the creation of more compact and efficient transformers and inductors. These materials exhibit lower core losses and higher saturation flux density, allowing for smaller component sizes and improved power density in inverter designs.

Thermal management has been another area of focus, with the introduction of advanced thermal interface materials and novel heat sink designs. Graphene-based composites and phase-change materials have shown promise in enhancing heat dissipation, crucial for maintaining optimal performance and longevity of inverter components.

The objectives of current research in advanced materials for solar inverter manufacturing are multifaceted. Primarily, there is a drive to further improve efficiency, with a target of achieving inverter efficiencies exceeding 99%. This goal necessitates the development of materials with even lower losses and higher temperature capabilities.

Another key objective is to enhance the reliability and lifespan of solar inverters. This involves research into materials that can withstand harsh environmental conditions, resist degradation, and maintain performance over extended periods. Advanced encapsulation materials and corrosion-resistant coatings are areas of active investigation.

Cost reduction remains a critical goal, driving research into materials that are not only high-performing but also economically viable for large-scale production. This includes exploring alternative materials that can match or exceed the properties of current advanced materials at a lower cost.

Lastly, there is a growing emphasis on sustainability and environmental impact. Research is being conducted on biodegradable and recyclable materials for inverter components, as well as materials with a lower carbon footprint in their production and lifecycle.

In the early stages, solar inverters primarily utilized silicon-based semiconductors and conventional copper wiring. However, as the industry matured, the focus shifted towards more advanced materials to address key challenges such as power density, thermal management, and overall efficiency.

The introduction of wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), marked a significant milestone in solar inverter technology. These materials offer superior electrical properties, including higher breakdown voltage, faster switching speeds, and lower on-resistance compared to traditional silicon. As a result, inverters incorporating these advanced semiconductors can operate at higher frequencies and temperatures, leading to improved efficiency and reduced cooling requirements.

Advancements in magnetic materials have also contributed to the evolution of solar inverters. The development of nanocrystalline and amorphous soft magnetic materials has enabled the creation of more compact and efficient transformers and inductors. These materials exhibit lower core losses and higher saturation flux density, allowing for smaller component sizes and improved power density in inverter designs.

Thermal management has been another area of focus, with the introduction of advanced thermal interface materials and novel heat sink designs. Graphene-based composites and phase-change materials have shown promise in enhancing heat dissipation, crucial for maintaining optimal performance and longevity of inverter components.

The objectives of current research in advanced materials for solar inverter manufacturing are multifaceted. Primarily, there is a drive to further improve efficiency, with a target of achieving inverter efficiencies exceeding 99%. This goal necessitates the development of materials with even lower losses and higher temperature capabilities.

Another key objective is to enhance the reliability and lifespan of solar inverters. This involves research into materials that can withstand harsh environmental conditions, resist degradation, and maintain performance over extended periods. Advanced encapsulation materials and corrosion-resistant coatings are areas of active investigation.

Cost reduction remains a critical goal, driving research into materials that are not only high-performing but also economically viable for large-scale production. This includes exploring alternative materials that can match or exceed the properties of current advanced materials at a lower cost.

Lastly, there is a growing emphasis on sustainability and environmental impact. Research is being conducted on biodegradable and recyclable materials for inverter components, as well as materials with a lower carbon footprint in their production and lifecycle.

Market Demand Analysis for Advanced Solar Inverters

The global solar inverter market is experiencing significant growth, driven by the increasing adoption of renewable energy sources and the push for sustainable power generation. Advanced materials play a crucial role in enhancing the performance, efficiency, and reliability of solar inverters, leading to a surge in demand for innovative solutions in this sector.

The market for advanced solar inverters is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 10% through 2026. This growth is primarily attributed to the rising installation of solar photovoltaic (PV) systems worldwide, coupled with government initiatives and incentives promoting clean energy adoption. Residential, commercial, and utility-scale solar projects are all contributing to this increased demand for high-performance inverters.

One of the key drivers of market demand is the need for improved efficiency in solar energy conversion. Advanced materials, such as wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), are gaining traction due to their ability to operate at higher temperatures and frequencies, resulting in more compact and efficient inverter designs. These materials enable higher power density, reduced cooling requirements, and improved overall system performance.

Another significant factor influencing market demand is the growing emphasis on grid stability and power quality. As the penetration of solar energy in the power grid increases, there is a rising need for inverters that can provide advanced grid support functions, such as reactive power control and low voltage ride-through capabilities. Advanced materials and components that enable these features are becoming increasingly important to meet evolving grid codes and regulations.

The trend towards smart and connected solar systems is also driving demand for advanced inverters. Integration of Internet of Things (IoT) technologies and advanced monitoring capabilities requires inverters with sophisticated control systems and communication interfaces. This has led to increased interest in materials and components that can support these smart functionalities while maintaining high reliability and performance.

Durability and longevity are becoming critical factors in the solar inverter market. End-users are seeking inverters with extended lifespans to maximize their return on investment. This has created a demand for advanced materials that can withstand harsh environmental conditions, thermal cycling, and electrical stress over long periods. Manufacturers are focusing on developing robust packaging materials, thermal management solutions, and protective coatings to enhance the reliability and longevity of inverters.

The global shift towards decentralized energy systems and microgrids is also influencing the demand for advanced solar inverters. These applications require inverters with enhanced flexibility, modularity, and the ability to operate in various configurations. Advanced materials that enable more versatile and adaptable inverter designs are gaining prominence in this segment of the market.

The market for advanced solar inverters is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 10% through 2026. This growth is primarily attributed to the rising installation of solar photovoltaic (PV) systems worldwide, coupled with government initiatives and incentives promoting clean energy adoption. Residential, commercial, and utility-scale solar projects are all contributing to this increased demand for high-performance inverters.

One of the key drivers of market demand is the need for improved efficiency in solar energy conversion. Advanced materials, such as wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), are gaining traction due to their ability to operate at higher temperatures and frequencies, resulting in more compact and efficient inverter designs. These materials enable higher power density, reduced cooling requirements, and improved overall system performance.

Another significant factor influencing market demand is the growing emphasis on grid stability and power quality. As the penetration of solar energy in the power grid increases, there is a rising need for inverters that can provide advanced grid support functions, such as reactive power control and low voltage ride-through capabilities. Advanced materials and components that enable these features are becoming increasingly important to meet evolving grid codes and regulations.

The trend towards smart and connected solar systems is also driving demand for advanced inverters. Integration of Internet of Things (IoT) technologies and advanced monitoring capabilities requires inverters with sophisticated control systems and communication interfaces. This has led to increased interest in materials and components that can support these smart functionalities while maintaining high reliability and performance.

Durability and longevity are becoming critical factors in the solar inverter market. End-users are seeking inverters with extended lifespans to maximize their return on investment. This has created a demand for advanced materials that can withstand harsh environmental conditions, thermal cycling, and electrical stress over long periods. Manufacturers are focusing on developing robust packaging materials, thermal management solutions, and protective coatings to enhance the reliability and longevity of inverters.

The global shift towards decentralized energy systems and microgrids is also influencing the demand for advanced solar inverters. These applications require inverters with enhanced flexibility, modularity, and the ability to operate in various configurations. Advanced materials that enable more versatile and adaptable inverter designs are gaining prominence in this segment of the market.

Current State and Challenges in Inverter Materials

The current state of materials used in solar inverter manufacturing is characterized by a continuous pursuit of higher efficiency, reliability, and cost-effectiveness. Silicon carbide (SiC) and gallium nitride (GaN) have emerged as leading wide-bandgap semiconductors, offering significant advantages over traditional silicon-based materials. These advanced materials enable higher switching frequencies, lower power losses, and improved thermal management, resulting in more compact and efficient inverter designs.

SiC-based inverters have gained substantial traction in the market, with major manufacturers incorporating this technology into their product lines. The superior thermal conductivity and higher breakdown voltage of SiC allow for reduced cooling requirements and increased power density. However, the widespread adoption of SiC faces challenges related to material costs and manufacturing complexities, which are gradually being addressed through improved production techniques and economies of scale.

GaN technology, while less mature than SiC in the context of solar inverters, shows promising potential for future applications. Its ability to operate at even higher frequencies than SiC could lead to further reductions in inverter size and weight. However, GaN currently faces limitations in terms of voltage handling capabilities and reliability concerns, particularly in high-power applications typical of utility-scale solar installations.

In addition to semiconductor materials, advancements in passive components are also crucial for inverter performance. High-frequency magnetic materials, such as nanocrystalline and amorphous alloys, are being developed to reduce core losses and improve power density in transformers and inductors. These materials enable the design of more compact and efficient magnetic components, which are essential for high-frequency operation.

Thermal management remains a critical challenge in inverter design, driving research into advanced thermal interface materials and novel cooling solutions. Developments in phase-change materials, graphene-based composites, and microfluidic cooling systems are being explored to enhance heat dissipation and maintain optimal operating temperatures for sensitive electronic components.

Despite these advancements, several challenges persist in the field of inverter materials. The long-term reliability and degradation mechanisms of wide-bandgap semiconductors under typical operating conditions of solar inverters are not yet fully understood, necessitating extensive reliability testing and modeling. Additionally, the integration of these advanced materials into existing manufacturing processes presents technical and economic hurdles that must be overcome to achieve widespread adoption.

SiC-based inverters have gained substantial traction in the market, with major manufacturers incorporating this technology into their product lines. The superior thermal conductivity and higher breakdown voltage of SiC allow for reduced cooling requirements and increased power density. However, the widespread adoption of SiC faces challenges related to material costs and manufacturing complexities, which are gradually being addressed through improved production techniques and economies of scale.

GaN technology, while less mature than SiC in the context of solar inverters, shows promising potential for future applications. Its ability to operate at even higher frequencies than SiC could lead to further reductions in inverter size and weight. However, GaN currently faces limitations in terms of voltage handling capabilities and reliability concerns, particularly in high-power applications typical of utility-scale solar installations.

In addition to semiconductor materials, advancements in passive components are also crucial for inverter performance. High-frequency magnetic materials, such as nanocrystalline and amorphous alloys, are being developed to reduce core losses and improve power density in transformers and inductors. These materials enable the design of more compact and efficient magnetic components, which are essential for high-frequency operation.

Thermal management remains a critical challenge in inverter design, driving research into advanced thermal interface materials and novel cooling solutions. Developments in phase-change materials, graphene-based composites, and microfluidic cooling systems are being explored to enhance heat dissipation and maintain optimal operating temperatures for sensitive electronic components.

Despite these advancements, several challenges persist in the field of inverter materials. The long-term reliability and degradation mechanisms of wide-bandgap semiconductors under typical operating conditions of solar inverters are not yet fully understood, necessitating extensive reliability testing and modeling. Additionally, the integration of these advanced materials into existing manufacturing processes presents technical and economic hurdles that must be overcome to achieve widespread adoption.

Existing Advanced Material Solutions

01 Advanced materials for construction and infrastructure

Development of innovative materials for construction and infrastructure applications, focusing on improved durability, strength, and sustainability. These materials may include advanced composites, high-performance concrete, and smart materials that can adapt to environmental conditions.- Advanced materials for construction and infrastructure: Development of innovative materials for construction and infrastructure applications, focusing on improved durability, strength, and sustainability. These materials may include advanced composites, smart materials, and eco-friendly alternatives to traditional construction materials.

- Nanotechnology-based advanced materials: Utilization of nanotechnology to create advanced materials with enhanced properties, such as improved strength, conductivity, or reactivity. These materials can be applied in various fields, including electronics, energy storage, and biomedical applications.

- Advanced materials for energy applications: Development of materials for energy generation, storage, and conversion, including advanced battery materials, solar cell materials, and thermoelectric materials. These innovations aim to improve energy efficiency and support the transition to renewable energy sources.

- Biomaterials and biocompatible advanced materials: Creation of advanced materials for medical and biological applications, such as tissue engineering, drug delivery systems, and implantable devices. These materials are designed to be biocompatible and may incorporate smart or responsive properties.

- Advanced materials for aerospace and defense: Development of high-performance materials for aerospace and defense applications, focusing on lightweight, high-strength materials, heat-resistant materials, and advanced coatings. These materials aim to improve the performance and durability of aircraft, spacecraft, and military equipment.

02 Nanomaterials and nanocomposites

Research and development of nanomaterials and nanocomposites with unique properties and applications. These materials can be used in various fields, including electronics, energy storage, and biomedical applications, offering enhanced performance and functionality at the nanoscale.Expand Specific Solutions03 Advanced materials for energy applications

Development of materials for energy generation, storage, and conversion. This includes advanced battery materials, solar cell materials, thermoelectric materials, and materials for hydrogen storage and fuel cells, aimed at improving energy efficiency and sustainability.Expand Specific Solutions04 Biomaterials and biocompatible materials

Research on advanced materials for medical and biological applications, including tissue engineering, drug delivery systems, and implantable devices. These materials are designed to interact with biological systems, offering improved biocompatibility and functionality in medical treatments.Expand Specific Solutions05 Smart and responsive materials

Development of materials that can respond to external stimuli such as temperature, light, or electrical fields. These materials have applications in sensors, actuators, and adaptive structures, offering new possibilities for creating responsive and intelligent systems in various industries.Expand Specific Solutions

Key Players in Solar Inverter Manufacturing

The research on advanced materials in solar inverter manufacturing is in a growth phase, with the market expanding rapidly due to increasing demand for renewable energy solutions. The global solar inverter market is projected to reach significant size in the coming years, driven by technological advancements and government initiatives. The technology maturity varies across different aspects of inverter materials, with some areas more established and others still evolving. Key players like SolAero Technologies, Eni SpA, and Silicon Genesis Corp. are driving innovation in materials science, focusing on improving efficiency, durability, and cost-effectiveness. Universities and research institutions, such as École Polytechnique Fédérale de Lausanne and the University of Massachusetts, are contributing to fundamental research, while companies like LG Chem and GlobalFoundries are applying advanced materials in commercial production, indicating a competitive and collaborative landscape in this field.

Silicon Genesis Corp.

Technical Solution: Silicon Genesis Corp. specializes in advanced silicon materials for solar applications, including inverter manufacturing. Their proprietary PolyMax™ technology enables the production of ultra-thin crystalline silicon wafers, which can significantly reduce material costs in solar cell production[8]. They have also developed a novel kerf-free wafering process that minimizes silicon waste during manufacturing, potentially lowering the overall cost of solar inverters[9]. Silicon Genesis is researching advanced surface texturing techniques that could improve the light absorption properties of silicon, potentially increasing the efficiency of solar cells used in inverters.

Strengths: Expertise in silicon wafer technology, cost-effective manufacturing processes, potential for significant efficiency improvements. Weaknesses: Limited focus on non-silicon materials, may face challenges as the industry moves towards alternative technologies.

Dow Global Technologies LLC

Technical Solution: Dow has been at the forefront of developing advanced materials for solar inverter manufacturing. Their research focuses on silicone-based materials that enhance the reliability and performance of solar inverters. Dow has developed specialized silicone gels and elastomers that provide excellent thermal management and electrical insulation properties[6]. These materials can withstand extreme temperatures and UV exposure, crucial for long-term outdoor performance. Dow's ENLIGHT™ polyolefin encapsulant films have shown to increase power output by up to 3% compared to traditional EVA films[7]. They are also exploring conductive inks and coatings that could revolutionize the manufacturing process of solar inverters, potentially reducing costs and improving efficiency.

Strengths: Expertise in silicone-based materials, proven track record in enhancing solar panel performance, diverse range of solutions for different inverter components. Weaknesses: May face competition from emerging non-silicon based technologies, potential environmental concerns with some synthetic materials.

Core Innovations in Inverter Materials

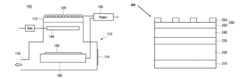

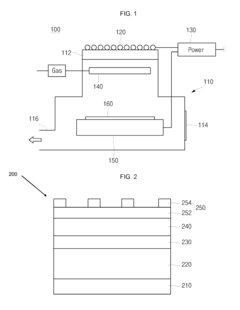

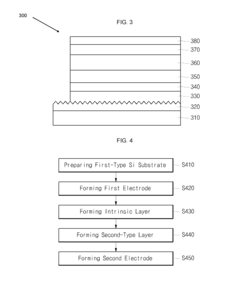

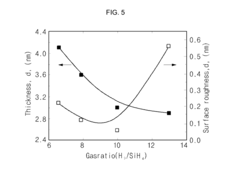

Method for fabricating solar cell using inductively coupled plasma chemical vapor deposition

PatentActiveUS8268714B2

Innovation

- The method employs inductively coupled plasma chemical vapor deposition (ICP-CVD) to form layers in solar cells, using specific gas ratios and processing conditions to create hydrogenated amorphous silicon and microcrystallized intrinsic layers, enabling the fabrication of solar cells with improved efficiency and reduced material requirements.

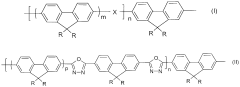

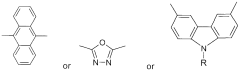

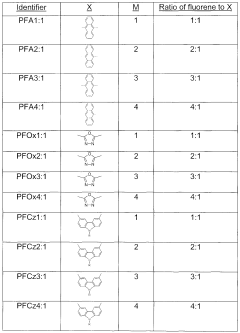

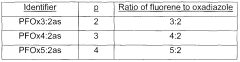

Hybrid nanocomposite semiconductor material and method of producing inorganic semiconductor therefor

PatentWO2007006136A1

Innovation

- A hybrid nanocomposite semiconductor material is developed, comprising nanometer-sized inorganic semiconductor particles incorporated into a hole-conductive fluorene copolymer film, where the particle size and energy levels are tunable to optimize electron-hole pathways, using a microwave-assisted method that reduces costs and enhances scalability and stability.

Environmental Impact of Advanced Inverter Materials

The environmental impact of advanced materials used in solar inverter manufacturing is a critical consideration in the ongoing development of sustainable energy technologies. As the solar industry continues to grow, the materials used in inverter production play a significant role in determining the overall environmental footprint of solar energy systems.

Advanced materials such as silicon carbide (SiC) and gallium nitride (GaN) are increasingly being utilized in solar inverters due to their superior electrical properties. These wide-bandgap semiconductors offer higher efficiency and power density compared to traditional silicon-based components. However, their environmental impact throughout the lifecycle must be carefully assessed.

The production of SiC and GaN materials typically requires high-temperature processes and energy-intensive manufacturing techniques. This can lead to increased carbon emissions during the manufacturing phase compared to conventional silicon-based inverters. Nevertheless, the improved efficiency of these advanced materials in operation may offset the initial environmental costs over the lifetime of the inverter.

Recycling and end-of-life management of solar inverters containing advanced materials present both challenges and opportunities. While some components may be more difficult to recycle due to their complex composition, the higher value of materials like SiC and GaN could incentivize the development of more efficient recycling processes.

The use of advanced materials in solar inverters also contributes to reducing the overall size and weight of the components. This can lead to decreased material usage and transportation-related emissions throughout the supply chain. Additionally, the improved durability and longer lifespan of inverters made with these materials can reduce the frequency of replacements, further minimizing environmental impact.

Water usage and potential contamination during the manufacturing of advanced inverter materials are important environmental considerations. Proper water management and treatment systems are essential to mitigate any negative impacts on local ecosystems and water resources.

As the solar industry continues to evolve, ongoing research into the environmental impact of advanced inverter materials is crucial. Life cycle assessments (LCAs) and environmental product declarations (EPDs) are becoming increasingly important tools for evaluating and comparing the sustainability of different inverter technologies. These assessments help manufacturers and consumers make informed decisions about the environmental trade-offs associated with various material choices.

In conclusion, while advanced materials in solar inverter manufacturing offer significant performance benefits, their environmental impact must be carefully managed throughout the entire product lifecycle. Continued innovation in material science and manufacturing processes will be key to further improving the sustainability of solar energy systems.

Advanced materials such as silicon carbide (SiC) and gallium nitride (GaN) are increasingly being utilized in solar inverters due to their superior electrical properties. These wide-bandgap semiconductors offer higher efficiency and power density compared to traditional silicon-based components. However, their environmental impact throughout the lifecycle must be carefully assessed.

The production of SiC and GaN materials typically requires high-temperature processes and energy-intensive manufacturing techniques. This can lead to increased carbon emissions during the manufacturing phase compared to conventional silicon-based inverters. Nevertheless, the improved efficiency of these advanced materials in operation may offset the initial environmental costs over the lifetime of the inverter.

Recycling and end-of-life management of solar inverters containing advanced materials present both challenges and opportunities. While some components may be more difficult to recycle due to their complex composition, the higher value of materials like SiC and GaN could incentivize the development of more efficient recycling processes.

The use of advanced materials in solar inverters also contributes to reducing the overall size and weight of the components. This can lead to decreased material usage and transportation-related emissions throughout the supply chain. Additionally, the improved durability and longer lifespan of inverters made with these materials can reduce the frequency of replacements, further minimizing environmental impact.

Water usage and potential contamination during the manufacturing of advanced inverter materials are important environmental considerations. Proper water management and treatment systems are essential to mitigate any negative impacts on local ecosystems and water resources.

As the solar industry continues to evolve, ongoing research into the environmental impact of advanced inverter materials is crucial. Life cycle assessments (LCAs) and environmental product declarations (EPDs) are becoming increasingly important tools for evaluating and comparing the sustainability of different inverter technologies. These assessments help manufacturers and consumers make informed decisions about the environmental trade-offs associated with various material choices.

In conclusion, while advanced materials in solar inverter manufacturing offer significant performance benefits, their environmental impact must be carefully managed throughout the entire product lifecycle. Continued innovation in material science and manufacturing processes will be key to further improving the sustainability of solar energy systems.

Standardization and Certification Requirements

Standardization and certification requirements play a crucial role in the development and adoption of advanced materials for solar inverter manufacturing. These requirements ensure the quality, safety, and reliability of solar inverters, while also promoting industry-wide consistency and interoperability.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), have established specific guidelines for solar inverter materials and components. These standards cover various aspects, including electrical safety, electromagnetic compatibility, and environmental performance.

One of the key certification requirements for advanced materials in solar inverter manufacturing is compliance with IEC 62109, which outlines safety standards for power converters used in photovoltaic systems. This standard addresses the electrical, mechanical, and thermal safety aspects of inverter materials and components.

Additionally, the UL 1741 standard, developed by Underwriters Laboratories, is widely recognized in North America for certifying inverters and other grid-connected distributed energy resources. Manufacturers must ensure that their advanced materials meet these stringent requirements to obtain certification.

Environmental considerations are also addressed through standards such as IEC 61730, which focuses on the safety qualification of photovoltaic modules. This standard includes requirements for materials used in inverter enclosures and other components exposed to environmental factors.

Certification processes often involve rigorous testing procedures to verify the performance and durability of advanced materials under various operating conditions. These tests may include accelerated aging, thermal cycling, and humidity resistance to simulate real-world scenarios and ensure long-term reliability.

As the solar industry continues to evolve, standardization and certification requirements are regularly updated to keep pace with technological advancements. Manufacturers and researchers must stay informed about these changes to ensure their materials and products remain compliant and competitive in the market.

Compliance with these standards and obtaining necessary certifications not only ensures product quality but also facilitates market entry and customer acceptance. It provides assurance to end-users, installers, and regulatory bodies that the advanced materials used in solar inverters meet established safety and performance criteria.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), have established specific guidelines for solar inverter materials and components. These standards cover various aspects, including electrical safety, electromagnetic compatibility, and environmental performance.

One of the key certification requirements for advanced materials in solar inverter manufacturing is compliance with IEC 62109, which outlines safety standards for power converters used in photovoltaic systems. This standard addresses the electrical, mechanical, and thermal safety aspects of inverter materials and components.

Additionally, the UL 1741 standard, developed by Underwriters Laboratories, is widely recognized in North America for certifying inverters and other grid-connected distributed energy resources. Manufacturers must ensure that their advanced materials meet these stringent requirements to obtain certification.

Environmental considerations are also addressed through standards such as IEC 61730, which focuses on the safety qualification of photovoltaic modules. This standard includes requirements for materials used in inverter enclosures and other components exposed to environmental factors.

Certification processes often involve rigorous testing procedures to verify the performance and durability of advanced materials under various operating conditions. These tests may include accelerated aging, thermal cycling, and humidity resistance to simulate real-world scenarios and ensure long-term reliability.

As the solar industry continues to evolve, standardization and certification requirements are regularly updated to keep pace with technological advancements. Manufacturers and researchers must stay informed about these changes to ensure their materials and products remain compliant and competitive in the market.

Compliance with these standards and obtaining necessary certifications not only ensures product quality but also facilitates market entry and customer acceptance. It provides assurance to end-users, installers, and regulatory bodies that the advanced materials used in solar inverters meet established safety and performance criteria.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!