Cellophane Coatings for Improved Barrier Properties

JUL 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Coating Evolution and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging since its invention in the early 20th century. The evolution of cellophane coatings has been driven by the continuous demand for improved barrier properties, particularly against moisture, gases, and odors. This research aims to explore and advance the development of cellophane coatings to enhance its protective capabilities, thereby extending the shelf life of packaged products and reducing food waste.

The journey of cellophane coatings began with simple moisture-resistant treatments, progressing to more sophisticated multi-layer structures. Early coatings focused primarily on moisture resistance, using materials like nitrocellulose and waxes. As technology advanced, the focus shifted to creating more comprehensive barrier properties, incorporating materials such as polyvinylidene chloride (PVDC) and polyvinyl alcohol (PVOH) to improve gas and aroma barriers.

Recent developments in cellophane coatings have seen the integration of nanotechnology and bio-based materials. Nanocomposite coatings, utilizing materials like nanoclays and metal oxide nanoparticles, have shown promise in significantly enhancing barrier properties while maintaining the film's transparency. Simultaneously, the push towards sustainability has led to increased research in bio-based and biodegradable coating materials, aligning with global efforts to reduce plastic waste.

The primary objective of this research is to develop advanced cellophane coatings that provide superior barrier properties against oxygen, water vapor, and aromatic compounds. These improvements aim to extend the shelf life of packaged foods and pharmaceuticals, reduce spoilage, and maintain product quality for longer periods. Additionally, the research seeks to achieve these enhancements while adhering to principles of sustainability and eco-friendliness.

Another crucial goal is to optimize the coating process for improved efficiency and cost-effectiveness. This includes exploring new application methods, such as plasma-enhanced chemical vapor deposition (PECVD) and atomic layer deposition (ALD), which offer the potential for ultra-thin, highly effective barrier layers. The research also aims to investigate the scalability of these advanced coating technologies for industrial applications.

Furthermore, this study will explore the potential of smart and active coatings for cellophane. These innovative coatings could incorporate features such as oxygen scavenging, antimicrobial properties, or even intelligent indicators for freshness and quality. Such advancements would not only improve the protective qualities of cellophane packaging but also add value through enhanced functionality and consumer interaction.

In conclusion, the evolution of cellophane coatings represents a continuous journey towards improved performance and sustainability. This research aims to push the boundaries of what is possible with cellophane coatings, addressing current limitations and anticipating future needs in the packaging industry. By focusing on advanced materials, innovative processes, and multifunctional properties, the objective is to position cellophane as a cutting-edge, sustainable packaging solution for the 21st century.

The journey of cellophane coatings began with simple moisture-resistant treatments, progressing to more sophisticated multi-layer structures. Early coatings focused primarily on moisture resistance, using materials like nitrocellulose and waxes. As technology advanced, the focus shifted to creating more comprehensive barrier properties, incorporating materials such as polyvinylidene chloride (PVDC) and polyvinyl alcohol (PVOH) to improve gas and aroma barriers.

Recent developments in cellophane coatings have seen the integration of nanotechnology and bio-based materials. Nanocomposite coatings, utilizing materials like nanoclays and metal oxide nanoparticles, have shown promise in significantly enhancing barrier properties while maintaining the film's transparency. Simultaneously, the push towards sustainability has led to increased research in bio-based and biodegradable coating materials, aligning with global efforts to reduce plastic waste.

The primary objective of this research is to develop advanced cellophane coatings that provide superior barrier properties against oxygen, water vapor, and aromatic compounds. These improvements aim to extend the shelf life of packaged foods and pharmaceuticals, reduce spoilage, and maintain product quality for longer periods. Additionally, the research seeks to achieve these enhancements while adhering to principles of sustainability and eco-friendliness.

Another crucial goal is to optimize the coating process for improved efficiency and cost-effectiveness. This includes exploring new application methods, such as plasma-enhanced chemical vapor deposition (PECVD) and atomic layer deposition (ALD), which offer the potential for ultra-thin, highly effective barrier layers. The research also aims to investigate the scalability of these advanced coating technologies for industrial applications.

Furthermore, this study will explore the potential of smart and active coatings for cellophane. These innovative coatings could incorporate features such as oxygen scavenging, antimicrobial properties, or even intelligent indicators for freshness and quality. Such advancements would not only improve the protective qualities of cellophane packaging but also add value through enhanced functionality and consumer interaction.

In conclusion, the evolution of cellophane coatings represents a continuous journey towards improved performance and sustainability. This research aims to push the boundaries of what is possible with cellophane coatings, addressing current limitations and anticipating future needs in the packaging industry. By focusing on advanced materials, innovative processes, and multifunctional properties, the objective is to position cellophane as a cutting-edge, sustainable packaging solution for the 21st century.

Market Demand for Enhanced Barrier Packaging

The global packaging industry has witnessed a significant shift towards enhanced barrier properties in recent years, driven by increasing consumer demand for fresher, longer-lasting products and growing environmental concerns. This trend has created a substantial market opportunity for cellophane coatings with improved barrier characteristics.

The food and beverage sector, in particular, has shown a strong appetite for advanced barrier packaging solutions. As consumers become more health-conscious and demand convenience, there is a growing need for packaging that can extend shelf life, preserve nutritional value, and maintain product quality. Cellophane coatings with enhanced barrier properties offer an attractive solution to these challenges, potentially reducing food waste and improving product safety.

In the pharmaceutical industry, the demand for high-performance barrier packaging is also on the rise. Stringent regulations and the need to protect sensitive medications from moisture, oxygen, and light have led to increased interest in advanced coating technologies. Cellophane coatings that can provide superior barrier properties are well-positioned to capture a significant share of this market.

The cosmetics and personal care sector represents another key area of growth for enhanced barrier packaging. With the increasing popularity of natural and organic products, which often have shorter shelf lives, there is a pressing need for packaging solutions that can protect these formulations from degradation. Cellophane coatings with improved barrier properties can help extend product life and maintain efficacy, addressing a critical market need.

E-commerce has emerged as a major driver of demand for enhanced barrier packaging. As online shopping continues to grow, especially in the wake of the global pandemic, there is an increased need for packaging that can withstand the rigors of shipping and handling while maintaining product integrity. Cellophane coatings that offer superior protection against moisture, oxygen, and physical damage are well-suited to meet these challenges.

The sustainability aspect of cellophane coatings also aligns well with current market trends. As consumers and regulators push for more environmentally friendly packaging solutions, there is growing interest in biodegradable and compostable materials. Cellophane, being derived from renewable resources, has the potential to meet these sustainability requirements while still providing enhanced barrier properties.

Market research indicates that the global barrier packaging market is expected to experience robust growth in the coming years. This growth is driven by factors such as urbanization, changing lifestyles, and increasing disposable incomes in emerging economies. The Asia-Pacific region, in particular, is anticipated to be a key growth market for enhanced barrier packaging, presenting significant opportunities for cellophane coating technologies.

The food and beverage sector, in particular, has shown a strong appetite for advanced barrier packaging solutions. As consumers become more health-conscious and demand convenience, there is a growing need for packaging that can extend shelf life, preserve nutritional value, and maintain product quality. Cellophane coatings with enhanced barrier properties offer an attractive solution to these challenges, potentially reducing food waste and improving product safety.

In the pharmaceutical industry, the demand for high-performance barrier packaging is also on the rise. Stringent regulations and the need to protect sensitive medications from moisture, oxygen, and light have led to increased interest in advanced coating technologies. Cellophane coatings that can provide superior barrier properties are well-positioned to capture a significant share of this market.

The cosmetics and personal care sector represents another key area of growth for enhanced barrier packaging. With the increasing popularity of natural and organic products, which often have shorter shelf lives, there is a pressing need for packaging solutions that can protect these formulations from degradation. Cellophane coatings with improved barrier properties can help extend product life and maintain efficacy, addressing a critical market need.

E-commerce has emerged as a major driver of demand for enhanced barrier packaging. As online shopping continues to grow, especially in the wake of the global pandemic, there is an increased need for packaging that can withstand the rigors of shipping and handling while maintaining product integrity. Cellophane coatings that offer superior protection against moisture, oxygen, and physical damage are well-suited to meet these challenges.

The sustainability aspect of cellophane coatings also aligns well with current market trends. As consumers and regulators push for more environmentally friendly packaging solutions, there is growing interest in biodegradable and compostable materials. Cellophane, being derived from renewable resources, has the potential to meet these sustainability requirements while still providing enhanced barrier properties.

Market research indicates that the global barrier packaging market is expected to experience robust growth in the coming years. This growth is driven by factors such as urbanization, changing lifestyles, and increasing disposable incomes in emerging economies. The Asia-Pacific region, in particular, is anticipated to be a key growth market for enhanced barrier packaging, presenting significant opportunities for cellophane coating technologies.

Current Limitations in Cellophane Barrier Properties

Cellophane, a biodegradable and transparent film derived from regenerated cellulose, has been widely used in packaging applications due to its excellent clarity, gloss, and printability. However, despite its many advantages, cellophane faces significant limitations in its barrier properties, particularly against moisture and gases, which restrict its use in certain packaging applications.

One of the primary limitations of cellophane is its poor moisture barrier. While cellophane exhibits good barrier properties against oxygen and other gases when dry, its performance deteriorates rapidly in humid conditions. This hygroscopic nature causes cellophane to absorb moisture from the environment, leading to swelling and a significant reduction in its barrier effectiveness. As a result, cellophane packaging may fail to protect moisture-sensitive products adequately, limiting its use in applications where moisture control is critical.

Another major limitation is cellophane's inadequate barrier against certain gases, particularly carbon dioxide. This limitation is especially problematic in food packaging applications, where carbon dioxide permeability can lead to premature spoilage of packaged products. The inability to effectively contain carbon dioxide also restricts cellophane's use in modified atmosphere packaging (MAP) systems, which are increasingly important in extending the shelf life of fresh produce and other perishable goods.

Cellophane also exhibits limited resistance to oils and fats, which can penetrate the film and compromise its structural integrity. This weakness is particularly problematic in packaging applications for fatty foods or cosmetic products, where oil resistance is crucial for maintaining product quality and preventing package failure.

The thermal stability of cellophane is another area of concern. At high temperatures, cellophane can lose its dimensional stability and barrier properties, limiting its use in hot-fill applications or in packaging products that require heat sterilization. This thermal sensitivity also restricts the use of cellophane in certain food packaging applications where heat sealing or hot-filling processes are common.

Furthermore, cellophane's barrier properties are significantly affected by mechanical stress. Flexing, stretching, or other forms of mechanical manipulation can create micro-cracks or other defects in the film structure, compromising its barrier effectiveness. This sensitivity to mechanical stress limits cellophane's use in applications where the packaging may undergo significant handling or physical stress during distribution and use.

Lastly, while cellophane is biodegradable, its production process involves the use of chemicals that can be environmentally problematic. This aspect, combined with the need for additional coatings or laminates to improve its barrier properties, can complicate recycling efforts and reduce its overall environmental sustainability.

These limitations highlight the need for innovative approaches to enhance cellophane's barrier properties, driving research into advanced coating technologies and material modifications to overcome these challenges and expand the potential applications of this versatile packaging material.

One of the primary limitations of cellophane is its poor moisture barrier. While cellophane exhibits good barrier properties against oxygen and other gases when dry, its performance deteriorates rapidly in humid conditions. This hygroscopic nature causes cellophane to absorb moisture from the environment, leading to swelling and a significant reduction in its barrier effectiveness. As a result, cellophane packaging may fail to protect moisture-sensitive products adequately, limiting its use in applications where moisture control is critical.

Another major limitation is cellophane's inadequate barrier against certain gases, particularly carbon dioxide. This limitation is especially problematic in food packaging applications, where carbon dioxide permeability can lead to premature spoilage of packaged products. The inability to effectively contain carbon dioxide also restricts cellophane's use in modified atmosphere packaging (MAP) systems, which are increasingly important in extending the shelf life of fresh produce and other perishable goods.

Cellophane also exhibits limited resistance to oils and fats, which can penetrate the film and compromise its structural integrity. This weakness is particularly problematic in packaging applications for fatty foods or cosmetic products, where oil resistance is crucial for maintaining product quality and preventing package failure.

The thermal stability of cellophane is another area of concern. At high temperatures, cellophane can lose its dimensional stability and barrier properties, limiting its use in hot-fill applications or in packaging products that require heat sterilization. This thermal sensitivity also restricts the use of cellophane in certain food packaging applications where heat sealing or hot-filling processes are common.

Furthermore, cellophane's barrier properties are significantly affected by mechanical stress. Flexing, stretching, or other forms of mechanical manipulation can create micro-cracks or other defects in the film structure, compromising its barrier effectiveness. This sensitivity to mechanical stress limits cellophane's use in applications where the packaging may undergo significant handling or physical stress during distribution and use.

Lastly, while cellophane is biodegradable, its production process involves the use of chemicals that can be environmentally problematic. This aspect, combined with the need for additional coatings or laminates to improve its barrier properties, can complicate recycling efforts and reduce its overall environmental sustainability.

These limitations highlight the need for innovative approaches to enhance cellophane's barrier properties, driving research into advanced coating technologies and material modifications to overcome these challenges and expand the potential applications of this versatile packaging material.

Existing Cellophane Barrier Enhancement Solutions

01 Barrier properties of cellophane coatings

Cellophane coatings are known for their excellent barrier properties against gases, moisture, and other environmental factors. These coatings can be applied to various substrates to enhance their protective capabilities. The barrier properties of cellophane coatings can be further improved through modifications or combinations with other materials.- Barrier properties enhancement techniques: Various techniques are employed to enhance the barrier properties of cellophane coatings. These may include the application of additional layers, incorporation of nanoparticles, or chemical modifications to the cellophane structure. Such enhancements can improve resistance to moisture, gases, and other environmental factors, making the coatings more effective for packaging and preservation purposes.

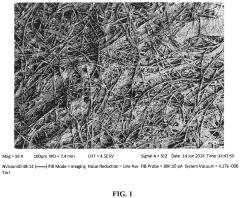

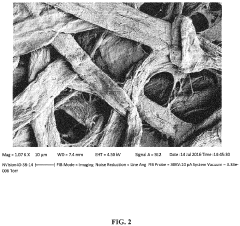

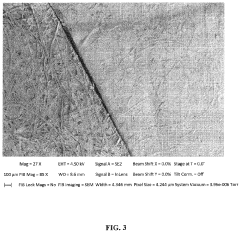

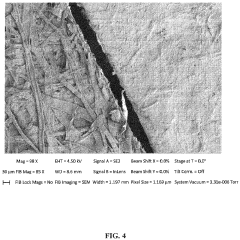

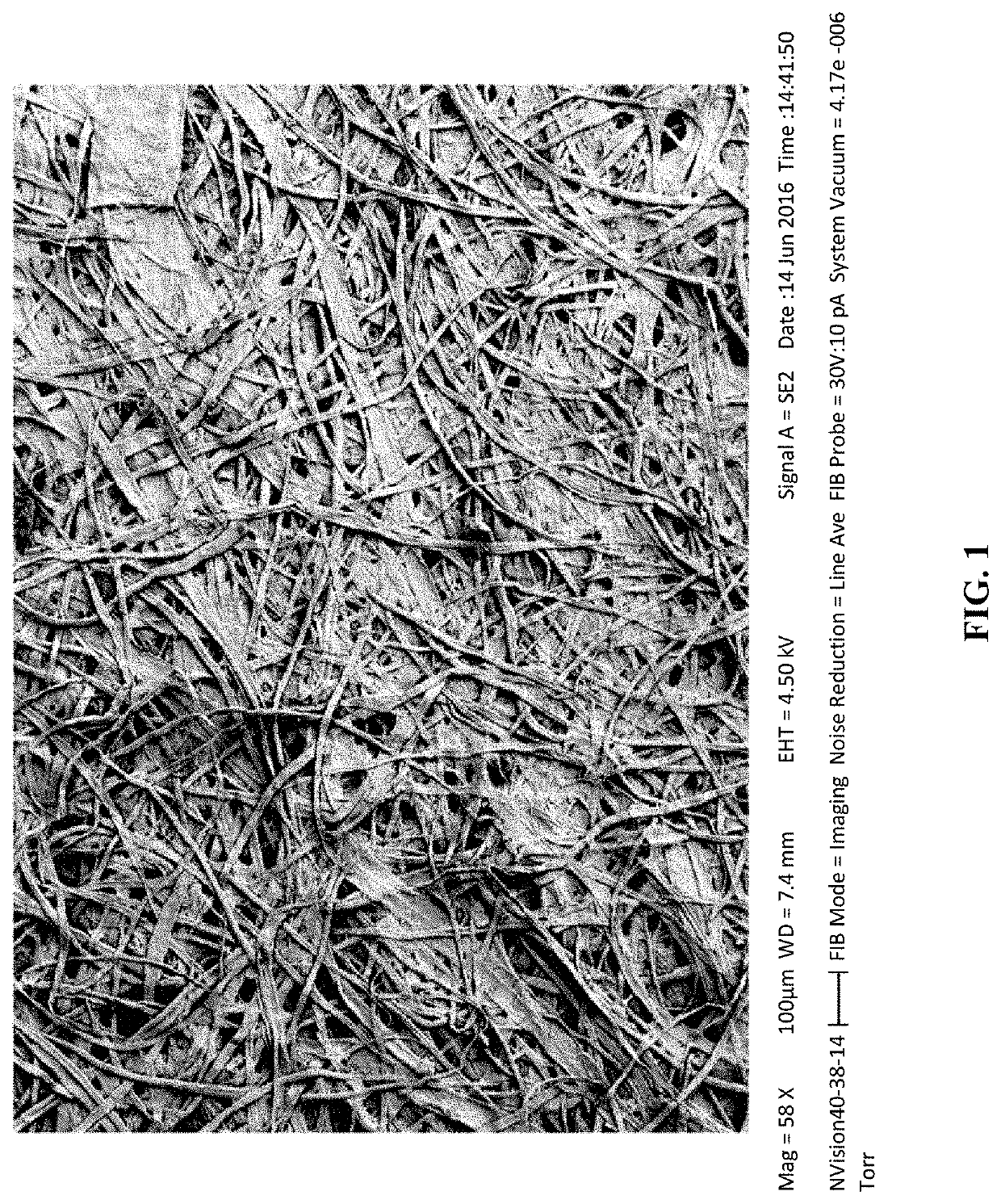

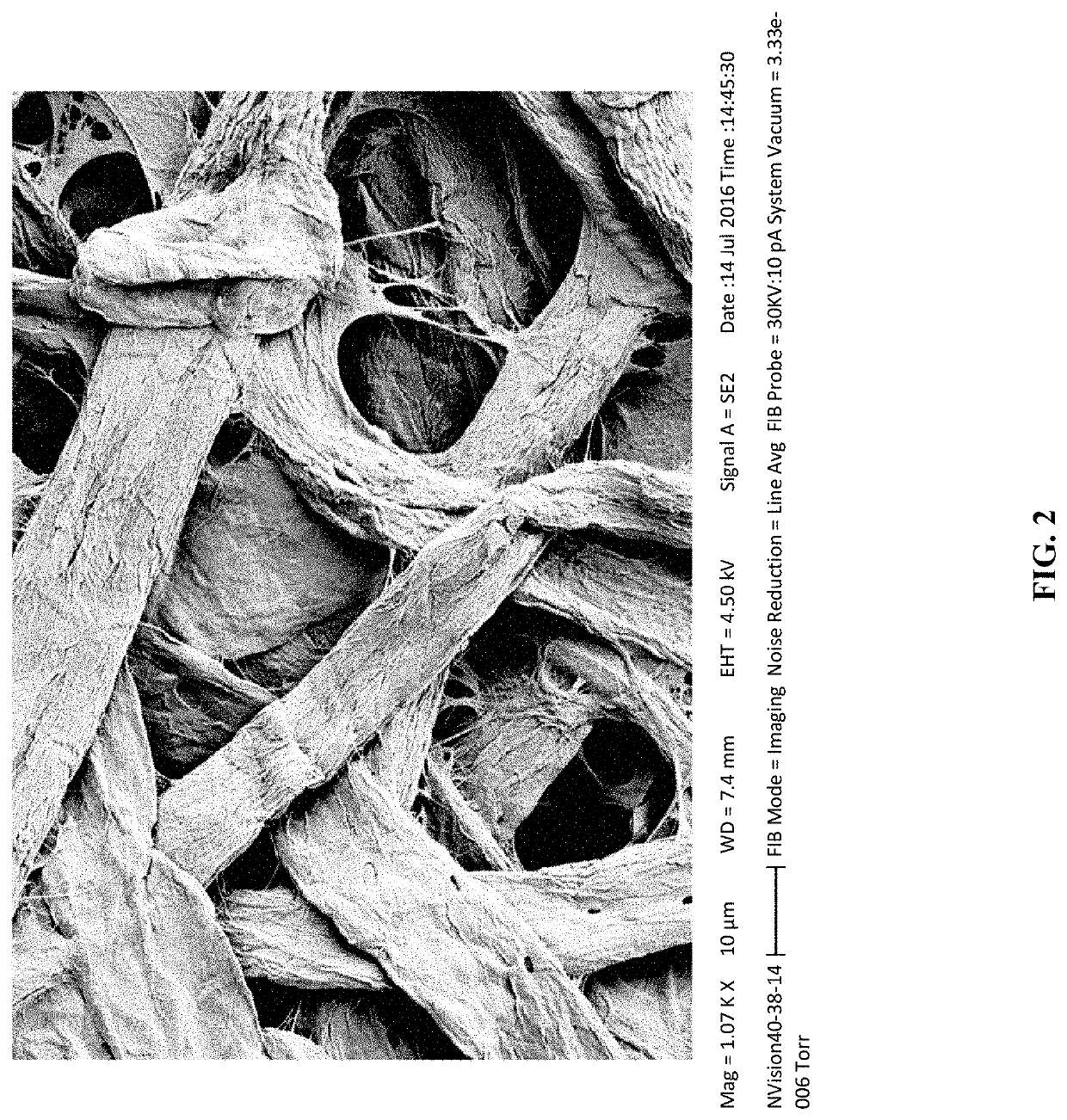

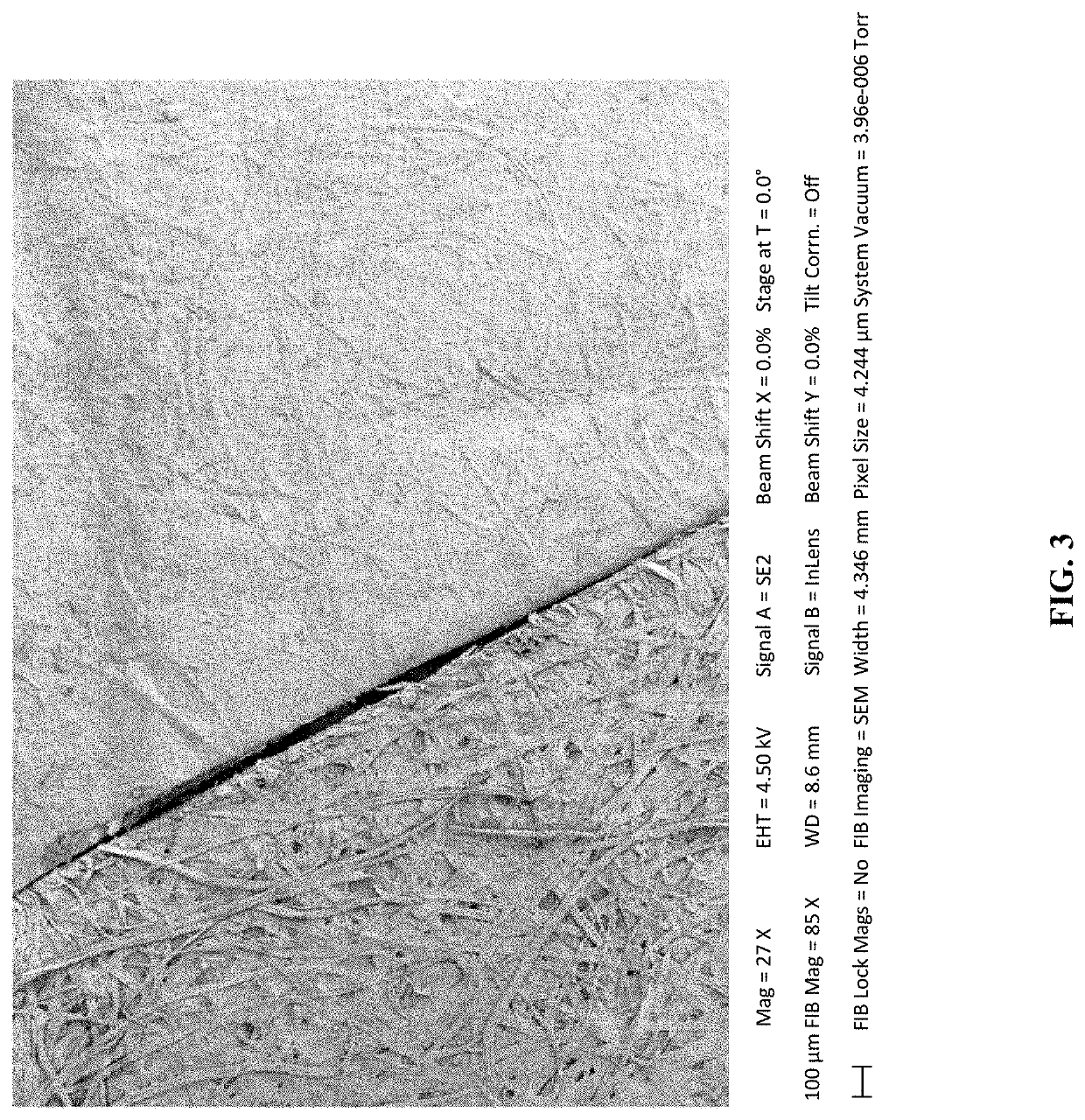

- Measurement and characterization of barrier properties: Advanced methods and instruments are used to measure and characterize the barrier properties of cellophane coatings. These may include permeability tests, spectroscopic analysis, and microscopy techniques. Accurate measurement is crucial for quality control and optimization of coating formulations to achieve desired barrier performance.

- Biodegradable and eco-friendly cellophane coatings: Development of biodegradable and eco-friendly cellophane coatings with enhanced barrier properties is a growing area of research. These coatings aim to provide effective protection while minimizing environmental impact. Approaches may include the use of natural additives or modified cellulose derivatives to improve barrier function without compromising biodegradability.

- Multi-layer cellophane coating systems: Multi-layer coating systems incorporating cellophane are designed to provide superior barrier properties. These systems may combine cellophane with other materials such as polymers or metals to create a composite structure with enhanced resistance to moisture, oxygen, and other permeants. The layered approach allows for customization of barrier properties for specific applications.

- Smart and active cellophane coatings: Development of smart and active cellophane coatings that can respond to environmental changes or actively maintain barrier properties over time. These may include coatings with self-healing capabilities, moisture-responsive elements, or incorporated active agents that enhance preservation. Such advanced coatings aim to provide dynamic barrier protection for various applications.

02 Measurement and testing of cellophane coating properties

Various methods and apparatus are used to measure and test the barrier properties of cellophane coatings. These include techniques for assessing gas permeability, moisture vapor transmission rate, and other relevant parameters. Advanced analytical tools and standardized testing procedures help in evaluating the effectiveness of cellophane coatings.Expand Specific Solutions03 Modifications to enhance cellophane coating performance

Researchers have developed methods to modify cellophane coatings to enhance their barrier properties. These modifications may include the incorporation of nanoparticles, chemical treatments, or the creation of multi-layer structures. Such improvements aim to extend the shelf life of packaged products and increase the overall effectiveness of the coating.Expand Specific Solutions04 Applications of cellophane coatings in packaging

Cellophane coatings find extensive use in the packaging industry due to their barrier properties. They are applied to various materials such as paper, plastic films, and metal foils to create protective packaging for food, pharmaceuticals, and other sensitive products. The coatings help preserve product quality and extend shelf life.Expand Specific Solutions05 Environmental considerations and biodegradability

As environmental concerns grow, there is increasing focus on developing biodegradable cellophane coatings with improved barrier properties. Research is being conducted to create eco-friendly alternatives that maintain the protective qualities of traditional cellophane coatings while reducing environmental impact. This includes exploring bio-based materials and sustainable production methods.Expand Specific Solutions

Key Players in Barrier Coating Industry

The research on cellophane coatings for improved barrier properties is in a mature stage, with a competitive landscape dominated by established players. The market size is substantial, driven by increasing demand for sustainable packaging solutions. Companies like Tetra Laval, PPG Industries, and Stora Enso are at the forefront, leveraging their extensive R&D capabilities and global presence. The technology's maturity is evident in the diverse applications across industries, with firms like Henkel and SCHOTT AG contributing to advancements. However, emerging players such as Melodea Ltd. are introducing innovative approaches, potentially disrupting the market with eco-friendly alternatives. The industry is characterized by ongoing research and development efforts to enhance performance and sustainability.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has developed innovative cellophane coatings that focus on improving barrier properties while maintaining transparency and flexibility. Their approach utilizes a proprietary blend of acrylic and polyester resins, combined with specialized additives to enhance moisture and oxygen resistance[2]. The coating is applied using advanced precision coating techniques, ensuring uniform coverage and optimal performance. PPG's technology also incorporates UV-resistant compounds, extending the coating's durability and protecting the underlying cellophane from degradation[4]. Furthermore, the company has invested in water-based coating formulations, reducing VOC emissions and improving the environmental profile of their products[6]. PPG's coatings are designed to be compatible with various printing and converting processes, making them versatile for different packaging applications.

Strengths: High transparency, improved UV resistance, environmentally friendly formulations, versatility in application. Weaknesses: May require specialized application equipment, potential for higher costs compared to traditional coatings.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed advanced cellophane coatings with enhanced barrier properties. Their approach involves using a multi-layer coating system that combines different polymers to create a synergistic effect. The base layer typically consists of a modified cellulose material, while subsequent layers incorporate specialized barrier polymers such as ethylene vinyl alcohol (EVOH) or polyvinyl alcohol (PVOH)[1]. This multi-layer structure significantly improves oxygen and moisture barrier properties, extending the shelf life of packaged products. Additionally, Dow has implemented nanotechnology in their coatings, incorporating nanoparticles like clay or silica to further enhance barrier performance[3]. The company has also focused on developing bio-based and compostable coating options to address sustainability concerns in the packaging industry[5].

Strengths: Superior barrier properties, customizable multi-layer approach, incorporation of nanotechnology, focus on sustainability. Weaknesses: Potentially higher production costs, complexity in recycling multi-layer materials.

Innovative Coating Technologies for Cellophane

Biobased barrier coatings

PatentPendingEP4403698A2

Innovation

- Application of a barrier coating comprising a prolamine, such as zein, combined with a polyol fatty acid ester (PFAE) on cellulose-based materials, which provides lipophobicity while maintaining biodegradability and recyclability, using natural sources for fatty acid moieties and avoiding secondary lipophobes.

Biobased carrier coatings

PatentActiveUS20200002572A1

Innovation

- Application of a barrier coating comprising a prolamine and a polyol fatty acid ester (PFAE) on cellulose-based materials, such as zein and saccharide fatty acid esters, to create a surface resistant to oil and grease without lowering surface energy, using natural sources for fatty acids and allowing biodegradability and recyclability.

Environmental Impact of Cellophane Coatings

The environmental impact of cellophane coatings is a critical consideration in the development and application of this technology. Cellophane, a biodegradable material derived from cellulose, has been widely used in packaging due to its transparency and barrier properties. However, the coatings applied to enhance its performance can significantly alter its environmental footprint.

Traditional cellophane coatings often incorporate synthetic polymers or chemical additives to improve moisture resistance and extend shelf life. These additives can potentially hinder the biodegradability of cellophane, leading to increased environmental persistence. As a result, coated cellophane may take longer to decompose in landfills or natural environments, contributing to plastic pollution concerns.

The production process of cellophane coatings also raises environmental questions. Many coating formulations require the use of solvents or energy-intensive manufacturing techniques, which can contribute to air pollution and greenhouse gas emissions. Additionally, the extraction and processing of raw materials for these coatings may have associated environmental impacts, including habitat disruption and resource depletion.

Water pollution is another potential consequence of cellophane coating production and disposal. Some coating materials may leach harmful chemicals into aquatic ecosystems if not properly managed during manufacturing or after disposal. This can affect water quality and pose risks to aquatic life.

On the positive side, advancements in eco-friendly coating technologies are addressing some of these environmental concerns. Bio-based coatings derived from renewable resources are being developed as alternatives to petroleum-based options. These sustainable coatings aim to maintain the barrier properties of cellophane while reducing its overall environmental impact.

Recyclability is a key factor in assessing the environmental performance of coated cellophane. Some coatings may interfere with recycling processes, making it challenging to recover and reuse the material. Research is ongoing to develop coatings that are compatible with existing recycling infrastructure or can be easily separated from the cellophane substrate.

The end-of-life management of coated cellophane products is crucial for minimizing environmental harm. Proper disposal and recycling systems need to be in place to ensure that these materials do not contribute to litter or accumulate in natural environments. Education and awareness campaigns can play a vital role in promoting responsible consumer behavior regarding the disposal of coated cellophane products.

As regulations around packaging materials become more stringent, the environmental impact of cellophane coatings is likely to face increased scrutiny. This may drive further innovation in coating technologies that prioritize sustainability without compromising performance. The challenge lies in balancing the functional requirements of packaging with the urgent need for environmentally friendly solutions.

Traditional cellophane coatings often incorporate synthetic polymers or chemical additives to improve moisture resistance and extend shelf life. These additives can potentially hinder the biodegradability of cellophane, leading to increased environmental persistence. As a result, coated cellophane may take longer to decompose in landfills or natural environments, contributing to plastic pollution concerns.

The production process of cellophane coatings also raises environmental questions. Many coating formulations require the use of solvents or energy-intensive manufacturing techniques, which can contribute to air pollution and greenhouse gas emissions. Additionally, the extraction and processing of raw materials for these coatings may have associated environmental impacts, including habitat disruption and resource depletion.

Water pollution is another potential consequence of cellophane coating production and disposal. Some coating materials may leach harmful chemicals into aquatic ecosystems if not properly managed during manufacturing or after disposal. This can affect water quality and pose risks to aquatic life.

On the positive side, advancements in eco-friendly coating technologies are addressing some of these environmental concerns. Bio-based coatings derived from renewable resources are being developed as alternatives to petroleum-based options. These sustainable coatings aim to maintain the barrier properties of cellophane while reducing its overall environmental impact.

Recyclability is a key factor in assessing the environmental performance of coated cellophane. Some coatings may interfere with recycling processes, making it challenging to recover and reuse the material. Research is ongoing to develop coatings that are compatible with existing recycling infrastructure or can be easily separated from the cellophane substrate.

The end-of-life management of coated cellophane products is crucial for minimizing environmental harm. Proper disposal and recycling systems need to be in place to ensure that these materials do not contribute to litter or accumulate in natural environments. Education and awareness campaigns can play a vital role in promoting responsible consumer behavior regarding the disposal of coated cellophane products.

As regulations around packaging materials become more stringent, the environmental impact of cellophane coatings is likely to face increased scrutiny. This may drive further innovation in coating technologies that prioritize sustainability without compromising performance. The challenge lies in balancing the functional requirements of packaging with the urgent need for environmentally friendly solutions.

Regulatory Compliance for Food Packaging Materials

Regulatory compliance is a critical aspect of food packaging materials, including cellophane coatings with improved barrier properties. The use of such materials in food packaging is subject to stringent regulations to ensure consumer safety and product integrity. In the United States, the Food and Drug Administration (FDA) oversees the regulatory framework for food contact materials, including cellophane and its coatings.

The FDA's regulations for food packaging materials are primarily outlined in Title 21 of the Code of Federal Regulations (CFR), specifically in parts 170-199. These regulations establish the requirements for the composition, manufacturing processes, and intended use of food contact materials. For cellophane coatings, manufacturers must ensure compliance with 21 CFR 177.1200, which covers cellophane as a food contact substance.

In addition to FDA regulations, manufacturers must also consider the requirements set forth by other regulatory bodies, such as the European Food Safety Authority (EFSA) for products intended for the European market. The EFSA's guidelines on food contact materials are outlined in Regulation (EC) No 1935/2004, which establishes general principles of safety and inertness for all food contact materials.

To demonstrate regulatory compliance, manufacturers of cellophane coatings must conduct extensive testing and provide documentation on the safety and suitability of their products for food contact applications. This typically involves migration testing to assess the potential transfer of substances from the packaging material to the food. The results of these tests must fall within the established limits for specific migration and overall migration as defined by the relevant regulatory bodies.

Furthermore, manufacturers must ensure that all raw materials used in the production of cellophane coatings are approved for food contact applications. This includes any additives, monomers, or other substances used in the coating formulation. The FDA maintains a list of approved substances in the Form FDA 1572, while the EFSA provides a similar list in its Union List of authorized substances.

Compliance with Good Manufacturing Practices (GMPs) is another crucial aspect of regulatory requirements for food packaging materials. These practices ensure that the manufacturing process maintains the safety and quality of the packaging material throughout production. For cellophane coatings, this may include specific guidelines on handling, processing, and quality control measures.

As regulations evolve to address emerging concerns and new scientific findings, manufacturers must stay informed about changes in regulatory requirements. This may involve ongoing monitoring of regulatory updates, participation in industry associations, and regular consultation with regulatory experts to ensure continued compliance.

The FDA's regulations for food packaging materials are primarily outlined in Title 21 of the Code of Federal Regulations (CFR), specifically in parts 170-199. These regulations establish the requirements for the composition, manufacturing processes, and intended use of food contact materials. For cellophane coatings, manufacturers must ensure compliance with 21 CFR 177.1200, which covers cellophane as a food contact substance.

In addition to FDA regulations, manufacturers must also consider the requirements set forth by other regulatory bodies, such as the European Food Safety Authority (EFSA) for products intended for the European market. The EFSA's guidelines on food contact materials are outlined in Regulation (EC) No 1935/2004, which establishes general principles of safety and inertness for all food contact materials.

To demonstrate regulatory compliance, manufacturers of cellophane coatings must conduct extensive testing and provide documentation on the safety and suitability of their products for food contact applications. This typically involves migration testing to assess the potential transfer of substances from the packaging material to the food. The results of these tests must fall within the established limits for specific migration and overall migration as defined by the relevant regulatory bodies.

Furthermore, manufacturers must ensure that all raw materials used in the production of cellophane coatings are approved for food contact applications. This includes any additives, monomers, or other substances used in the coating formulation. The FDA maintains a list of approved substances in the Form FDA 1572, while the EFSA provides a similar list in its Union List of authorized substances.

Compliance with Good Manufacturing Practices (GMPs) is another crucial aspect of regulatory requirements for food packaging materials. These practices ensure that the manufacturing process maintains the safety and quality of the packaging material throughout production. For cellophane coatings, this may include specific guidelines on handling, processing, and quality control measures.

As regulations evolve to address emerging concerns and new scientific findings, manufacturers must stay informed about changes in regulatory requirements. This may involve ongoing monitoring of regulatory updates, participation in industry associations, and regular consultation with regulatory experts to ensure continued compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!