Decane-Derived Oligomers in Innovative Material Design

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Decane Oligomers Background and Objectives

Decane-derived oligomers have emerged as a promising field of study in innovative material design, offering unique properties that bridge the gap between small molecules and polymers. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the potential of oligomeric structures derived from long-chain hydrocarbons. Decane, a ten-carbon alkane, has since become a focal point due to its abundance, stability, and versatility as a precursor for oligomer synthesis.

The primary objective of research in this area is to harness the structural and functional characteristics of decane-derived oligomers to create novel materials with enhanced performance and sustainability. These oligomers offer a balance between the processability of small molecules and the robust mechanical properties of polymers, making them ideal candidates for a wide range of applications, from advanced coatings to high-performance composites.

One of the key drivers behind the growing interest in decane-derived oligomers is the push towards more sustainable and environmentally friendly materials. As the world grapples with the challenges of climate change and resource depletion, there is an increasing demand for materials that can be produced from renewable or abundant feedstocks, with minimal environmental impact. Decane, being a component of many natural and synthetic hydrocarbon mixtures, presents an attractive starting point for developing such materials.

The technological trajectory of decane-derived oligomers has seen significant advancements in synthesis methods, characterization techniques, and application development. Early research focused primarily on understanding the fundamental chemistry of oligomerization processes and exploring basic structure-property relationships. As the field progressed, attention shifted towards developing more controlled and efficient synthesis routes, enabling the production of oligomers with precise molecular weights, architectures, and functionalities.

Recent years have witnessed a surge in interdisciplinary collaborations, bringing together chemists, materials scientists, and engineers to unlock the full potential of decane-derived oligomers. This collaborative approach has led to breakthroughs in areas such as self-healing materials, stimuli-responsive coatings, and high-performance adhesives. The integration of computational modeling and machine learning techniques has further accelerated the discovery and optimization of new oligomeric structures with tailored properties.

Looking ahead, the research on decane-derived oligomers aims to address several critical challenges and opportunities. These include developing scalable and cost-effective production methods, expanding the range of achievable properties through molecular design, and exploring novel applications in emerging fields such as flexible electronics, energy storage, and biomedical devices. Additionally, there is a growing emphasis on understanding and optimizing the entire lifecycle of these materials, from production to end-of-life management, to ensure their long-term sustainability and environmental compatibility.

The primary objective of research in this area is to harness the structural and functional characteristics of decane-derived oligomers to create novel materials with enhanced performance and sustainability. These oligomers offer a balance between the processability of small molecules and the robust mechanical properties of polymers, making them ideal candidates for a wide range of applications, from advanced coatings to high-performance composites.

One of the key drivers behind the growing interest in decane-derived oligomers is the push towards more sustainable and environmentally friendly materials. As the world grapples with the challenges of climate change and resource depletion, there is an increasing demand for materials that can be produced from renewable or abundant feedstocks, with minimal environmental impact. Decane, being a component of many natural and synthetic hydrocarbon mixtures, presents an attractive starting point for developing such materials.

The technological trajectory of decane-derived oligomers has seen significant advancements in synthesis methods, characterization techniques, and application development. Early research focused primarily on understanding the fundamental chemistry of oligomerization processes and exploring basic structure-property relationships. As the field progressed, attention shifted towards developing more controlled and efficient synthesis routes, enabling the production of oligomers with precise molecular weights, architectures, and functionalities.

Recent years have witnessed a surge in interdisciplinary collaborations, bringing together chemists, materials scientists, and engineers to unlock the full potential of decane-derived oligomers. This collaborative approach has led to breakthroughs in areas such as self-healing materials, stimuli-responsive coatings, and high-performance adhesives. The integration of computational modeling and machine learning techniques has further accelerated the discovery and optimization of new oligomeric structures with tailored properties.

Looking ahead, the research on decane-derived oligomers aims to address several critical challenges and opportunities. These include developing scalable and cost-effective production methods, expanding the range of achievable properties through molecular design, and exploring novel applications in emerging fields such as flexible electronics, energy storage, and biomedical devices. Additionally, there is a growing emphasis on understanding and optimizing the entire lifecycle of these materials, from production to end-of-life management, to ensure their long-term sustainability and environmental compatibility.

Market Analysis for Decane-Derived Materials

The market for decane-derived materials is experiencing significant growth, driven by the increasing demand for innovative and sustainable materials across various industries. These materials, particularly decane-derived oligomers, offer unique properties that make them attractive for a wide range of applications, from advanced polymers to specialty chemicals.

In the polymer industry, decane-derived materials are gaining traction due to their potential to enhance the performance of existing products and enable the development of new, high-value materials. The market for these materials in polymer applications is expected to grow steadily over the next five years, with a focus on improving durability, thermal stability, and chemical resistance of end products.

The automotive sector represents a key market for decane-derived materials, particularly in the development of lightweight components and high-performance coatings. As automakers strive to meet stringent fuel efficiency and emissions standards, the demand for innovative materials that can reduce vehicle weight without compromising safety or performance is on the rise.

In the construction industry, decane-derived materials are finding applications in advanced insulation systems and high-performance adhesives. The growing emphasis on energy-efficient buildings and sustainable construction practices is driving the adoption of these materials, with the market showing promising growth potential in both residential and commercial sectors.

The electronics industry is another significant market for decane-derived materials, particularly in the development of advanced packaging solutions and protective coatings for electronic components. As consumer electronics become increasingly sophisticated and miniaturized, the demand for materials that can provide enhanced protection and performance is growing rapidly.

Geographically, North America and Europe currently lead the market for decane-derived materials, owing to their strong research and development capabilities and the presence of key industry players. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing investments in advanced materials research, and growing demand from end-use industries.

The market for decane-derived materials faces some challenges, including the need for further research to fully understand and optimize their properties, as well as the development of cost-effective production methods. However, the potential benefits of these materials in terms of performance, sustainability, and versatility are expected to drive continued investment and market growth.

In the polymer industry, decane-derived materials are gaining traction due to their potential to enhance the performance of existing products and enable the development of new, high-value materials. The market for these materials in polymer applications is expected to grow steadily over the next five years, with a focus on improving durability, thermal stability, and chemical resistance of end products.

The automotive sector represents a key market for decane-derived materials, particularly in the development of lightweight components and high-performance coatings. As automakers strive to meet stringent fuel efficiency and emissions standards, the demand for innovative materials that can reduce vehicle weight without compromising safety or performance is on the rise.

In the construction industry, decane-derived materials are finding applications in advanced insulation systems and high-performance adhesives. The growing emphasis on energy-efficient buildings and sustainable construction practices is driving the adoption of these materials, with the market showing promising growth potential in both residential and commercial sectors.

The electronics industry is another significant market for decane-derived materials, particularly in the development of advanced packaging solutions and protective coatings for electronic components. As consumer electronics become increasingly sophisticated and miniaturized, the demand for materials that can provide enhanced protection and performance is growing rapidly.

Geographically, North America and Europe currently lead the market for decane-derived materials, owing to their strong research and development capabilities and the presence of key industry players. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing investments in advanced materials research, and growing demand from end-use industries.

The market for decane-derived materials faces some challenges, including the need for further research to fully understand and optimize their properties, as well as the development of cost-effective production methods. However, the potential benefits of these materials in terms of performance, sustainability, and versatility are expected to drive continued investment and market growth.

Current Challenges in Oligomer Synthesis

The synthesis of decane-derived oligomers presents several significant challenges that researchers and material scientists are currently grappling with. One of the primary obstacles is achieving precise control over the molecular weight and polydispersity of the oligomers. The polymerization process of decane-based monomers often results in a broad distribution of chain lengths, making it difficult to obtain uniform oligomers with specific properties.

Another major challenge lies in the selective functionalization of the oligomers. Decane, being a linear alkane, lacks reactive functional groups along its backbone. This limitation makes it challenging to introduce desired functionalities at specific positions without compromising the overall structure or properties of the oligomers. Researchers are exploring various catalytic systems and reaction conditions to overcome this hurdle and achieve site-specific modifications.

The purification and isolation of decane-derived oligomers pose additional difficulties. Traditional separation techniques often struggle to effectively distinguish between oligomers of similar chain lengths, leading to mixtures with varying degrees of purity. This challenge is particularly pronounced when attempting to isolate oligomers with specific molecular weights or narrow polydispersity indices.

Scalability and cost-effectiveness of oligomer synthesis remain significant concerns for industrial applications. Current methods often involve multiple steps, expensive catalysts, or harsh reaction conditions, limiting their viability for large-scale production. Developing more efficient and economical synthetic routes is crucial for the widespread adoption of decane-derived oligomers in innovative material design.

Environmental considerations also present challenges in oligomer synthesis. Many traditional polymerization methods rely on toxic solvents or generate significant waste products. There is a growing need for greener synthesis approaches that minimize environmental impact while maintaining the desired oligomer properties.

Lastly, the characterization of decane-derived oligomers can be complex, particularly for higher molecular weight species. Advanced analytical techniques are required to accurately determine the structure, composition, and properties of these oligomers. Developing more robust and accessible characterization methods is essential for advancing research in this field and ensuring the reproducibility of synthetic processes.

Another major challenge lies in the selective functionalization of the oligomers. Decane, being a linear alkane, lacks reactive functional groups along its backbone. This limitation makes it challenging to introduce desired functionalities at specific positions without compromising the overall structure or properties of the oligomers. Researchers are exploring various catalytic systems and reaction conditions to overcome this hurdle and achieve site-specific modifications.

The purification and isolation of decane-derived oligomers pose additional difficulties. Traditional separation techniques often struggle to effectively distinguish between oligomers of similar chain lengths, leading to mixtures with varying degrees of purity. This challenge is particularly pronounced when attempting to isolate oligomers with specific molecular weights or narrow polydispersity indices.

Scalability and cost-effectiveness of oligomer synthesis remain significant concerns for industrial applications. Current methods often involve multiple steps, expensive catalysts, or harsh reaction conditions, limiting their viability for large-scale production. Developing more efficient and economical synthetic routes is crucial for the widespread adoption of decane-derived oligomers in innovative material design.

Environmental considerations also present challenges in oligomer synthesis. Many traditional polymerization methods rely on toxic solvents or generate significant waste products. There is a growing need for greener synthesis approaches that minimize environmental impact while maintaining the desired oligomer properties.

Lastly, the characterization of decane-derived oligomers can be complex, particularly for higher molecular weight species. Advanced analytical techniques are required to accurately determine the structure, composition, and properties of these oligomers. Developing more robust and accessible characterization methods is essential for advancing research in this field and ensuring the reproducibility of synthetic processes.

Existing Decane Oligomer Synthesis Methods

01 Synthesis of decane-derived oligomers

Methods for synthesizing oligomers derived from decane, including polymerization techniques and reaction conditions. These processes aim to create oligomers with specific properties for various applications in materials science and chemistry.- Synthesis of decane-derived oligomers: Methods for synthesizing oligomers derived from decane, including polymerization techniques and reaction conditions. These processes aim to create oligomers with specific properties for various applications in materials science and chemistry.

- Applications in electrical and electronic components: Decane-derived oligomers are utilized in the production of electrical and electronic components, such as insulation materials, dielectrics, and conductive polymers. These materials offer improved performance and durability in various electronic applications.

- Use in lubricants and hydraulic fluids: Oligomers derived from decane are incorporated into lubricants and hydraulic fluids to enhance their properties. These additives can improve viscosity, thermal stability, and wear resistance in industrial and automotive applications.

- Biomedical and pharmaceutical applications: Decane-derived oligomers find use in biomedical and pharmaceutical fields, including drug delivery systems, biocompatible materials, and diagnostic tools. These materials offer unique properties that can enhance the efficacy and safety of medical treatments.

- Environmental and sustainability aspects: Research on the environmental impact and sustainability of decane-derived oligomers, including biodegradability, eco-friendly production methods, and potential applications in green technologies. This area focuses on developing more sustainable alternatives to traditional petroleum-based materials.

02 Applications in electrical and electronic components

Decane-derived oligomers are utilized in the production of electrical and electronic components, such as insulation materials, dielectric fluids, and conductive polymers. These materials offer improved performance and durability in various electronic applications.Expand Specific Solutions03 Use in lubricants and hydraulic fluids

Oligomers derived from decane are employed as base oils or additives in lubricants and hydraulic fluids. These materials provide enhanced thermal stability, viscosity control, and wear resistance in industrial and automotive applications.Expand Specific Solutions04 Incorporation in polymer composites

Decane-derived oligomers are used as components in polymer composites, enhancing properties such as flexibility, impact resistance, and thermal stability. These composites find applications in automotive, aerospace, and construction industries.Expand Specific Solutions05 Environmental and biodegradation studies

Research on the environmental impact and biodegradability of decane-derived oligomers, including studies on their degradation pathways, toxicity, and potential for use in eco-friendly products. This research aims to develop more sustainable materials for various applications.Expand Specific Solutions

Key Players in Oligomer Research and Production

The research on decane-derived oligomers in innovative material design is in an emerging phase, with growing interest from both academia and industry. The market size is expanding as these oligomers show promise in various applications, particularly in advanced materials and polymer science. The technology is still developing, with companies like BASF Corp., Covestro Deutschland AG, and DSM IP Assets BV leading the way in research and development. While not yet fully mature, the technology is progressing rapidly, with major chemical companies investing in its potential. Universities such as Rutgers and Dalian University of Technology are also contributing to the field, indicating a collaborative approach between industry and academia to advance this innovative material design.

BASF Corp.

Technical Solution: BASF Corp. has developed innovative approaches to decane-derived oligomers for material design. Their research focuses on creating high-performance polymers with enhanced thermal and mechanical properties. BASF's technology involves controlled oligomerization of decane to produce oligomers with specific chain lengths and functionalities[1]. These oligomers are then incorporated into polymer matrices to improve characteristics such as heat resistance, impact strength, and chemical stability. The company has also explored the use of catalysts to optimize the oligomerization process, resulting in more uniform oligomer distributions and better control over final material properties[3].

Strengths: Extensive expertise in polymer chemistry, large-scale production capabilities, and a strong R&D infrastructure. Weaknesses: Potential high costs associated with specialized oligomer production and integration into existing manufacturing processes.

Covestro Deutschland AG

Technical Solution: Covestro has made significant strides in utilizing decane-derived oligomers for innovative material design, particularly in the field of polyurethanes and polycarbonates. Their approach involves incorporating these oligomers as soft segments in block copolymers, resulting in materials with improved flexibility, impact resistance, and low-temperature performance[2]. Covestro's research has also focused on developing bio-based alternatives to traditional petroleum-derived decane oligomers, aligning with sustainability goals. The company has successfully demonstrated the use of these oligomers in applications such as automotive interiors, consumer electronics, and high-performance coatings[4].

Strengths: Strong focus on sustainability and bio-based materials, extensive experience in polyurethane and polycarbonate technologies. Weaknesses: Potential challenges in scaling up production of bio-based decane oligomers and ensuring consistent quality.

Innovative Approaches in Oligomer Design

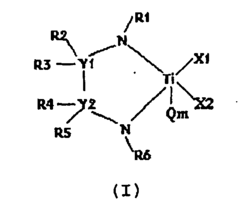

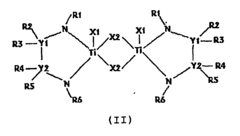

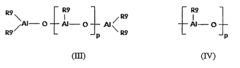

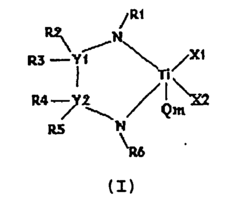

Process for the preparation of oligomers

PatentInactiveEP1397329B1

Innovation

- A catalyst system based on a titanium bisamide compound with specific silicon, germanium, or tin atoms, combined with activating boron-containing cocatalysts and optionally aluminoxanes, which selectively produces vinyl group-terminated oligomers and a high proportion of linear dimers by altering the termination mechanism during oligomerization.

Environmental Impact of Oligomer Production

The production of decane-derived oligomers, while offering innovative material design possibilities, also raises significant environmental concerns. The synthesis process typically involves petrochemical feedstocks and energy-intensive reactions, contributing to greenhouse gas emissions and resource depletion. The use of organic solvents and catalysts in oligomer production can lead to hazardous waste generation, requiring careful management and disposal practices to minimize environmental contamination.

Furthermore, the persistence of these oligomers in the environment is a growing concern. Unlike their monomeric counterparts, oligomers often exhibit increased resistance to biodegradation due to their complex molecular structures. This persistence can lead to accumulation in ecosystems, potentially affecting wildlife and disrupting natural processes. Aquatic environments are particularly vulnerable, as oligomers may leach from products and enter water systems, where they can adsorb to sediments or be ingested by marine organisms.

The production scale of decane-derived oligomers also plays a crucial role in their environmental impact. As demand for these materials increases in various industries, the cumulative effect of large-scale production becomes more pronounced. This includes not only direct emissions and waste from manufacturing processes but also indirect impacts such as increased transportation and energy consumption throughout the supply chain.

However, it is important to note that the environmental impact of oligomer production is not uniformly negative. In some applications, these materials can contribute to sustainability efforts. For instance, when used in high-performance coatings or advanced composites, decane-derived oligomers can enhance product durability and longevity, potentially reducing overall material consumption and waste generation over time.

Efforts to mitigate the environmental impact of oligomer production are ongoing. Research into green chemistry approaches, such as the use of bio-based feedstocks and environmentally benign solvents, shows promise in reducing the carbon footprint of oligomer synthesis. Additionally, advancements in process efficiency and waste reduction techniques are helping to minimize resource consumption and pollutant emissions associated with production.

As the field of innovative material design continues to evolve, there is a growing emphasis on life cycle assessment (LCA) for decane-derived oligomers. This holistic approach considers environmental impacts from raw material extraction through production, use, and eventual disposal or recycling. By identifying hotspots in the product life cycle, researchers and manufacturers can target areas for improvement, potentially leading to more sustainable oligomer production practices in the future.

Furthermore, the persistence of these oligomers in the environment is a growing concern. Unlike their monomeric counterparts, oligomers often exhibit increased resistance to biodegradation due to their complex molecular structures. This persistence can lead to accumulation in ecosystems, potentially affecting wildlife and disrupting natural processes. Aquatic environments are particularly vulnerable, as oligomers may leach from products and enter water systems, where they can adsorb to sediments or be ingested by marine organisms.

The production scale of decane-derived oligomers also plays a crucial role in their environmental impact. As demand for these materials increases in various industries, the cumulative effect of large-scale production becomes more pronounced. This includes not only direct emissions and waste from manufacturing processes but also indirect impacts such as increased transportation and energy consumption throughout the supply chain.

However, it is important to note that the environmental impact of oligomer production is not uniformly negative. In some applications, these materials can contribute to sustainability efforts. For instance, when used in high-performance coatings or advanced composites, decane-derived oligomers can enhance product durability and longevity, potentially reducing overall material consumption and waste generation over time.

Efforts to mitigate the environmental impact of oligomer production are ongoing. Research into green chemistry approaches, such as the use of bio-based feedstocks and environmentally benign solvents, shows promise in reducing the carbon footprint of oligomer synthesis. Additionally, advancements in process efficiency and waste reduction techniques are helping to minimize resource consumption and pollutant emissions associated with production.

As the field of innovative material design continues to evolve, there is a growing emphasis on life cycle assessment (LCA) for decane-derived oligomers. This holistic approach considers environmental impacts from raw material extraction through production, use, and eventual disposal or recycling. By identifying hotspots in the product life cycle, researchers and manufacturers can target areas for improvement, potentially leading to more sustainable oligomer production practices in the future.

Scalability and Industrial Applications

The scalability and industrial applications of decane-derived oligomers in innovative material design present significant opportunities and challenges. These oligomers offer unique properties that make them attractive for various industrial sectors, including aerospace, automotive, and consumer goods manufacturing.

One of the primary advantages of decane-derived oligomers is their potential for large-scale production. The relatively simple and cost-effective synthesis process allows for scalable manufacturing, which is crucial for meeting industrial demands. This scalability is particularly important in sectors requiring high-volume production, such as automotive parts or packaging materials.

In the aerospace industry, decane-derived oligomers show promise in developing lightweight yet durable materials. Their ability to form strong, heat-resistant polymers makes them ideal for aircraft components that must withstand extreme conditions. The scalability of production ensures a steady supply for this demanding sector.

The automotive industry stands to benefit greatly from these materials. As vehicle manufacturers increasingly focus on fuel efficiency and sustainability, lightweight materials derived from decane oligomers could play a crucial role. Their scalable production allows for integration into mass-produced vehicles, potentially revolutionizing automotive design and performance.

In the realm of consumer goods, decane-derived oligomers offer possibilities for creating innovative packaging solutions. Their unique properties can be harnessed to develop materials that are both durable and environmentally friendly. The ability to scale production to meet consumer market demands is a significant advantage in this sector.

However, challenges remain in fully realizing the industrial potential of these materials. One key issue is the need for consistent quality across large-scale production. Ensuring uniform properties in oligomer-based materials produced in industrial quantities requires sophisticated quality control measures and potentially new manufacturing technologies.

Another challenge lies in the integration of these new materials into existing industrial processes. Many industries have established manufacturing methods optimized for traditional materials. Adapting these processes to accommodate decane-derived oligomers may require significant investment in new equipment and training.

Despite these challenges, the potential benefits of decane-derived oligomers in industrial applications are substantial. Their unique properties, combined with scalable production methods, position them as a promising material for future innovations across multiple industries. As research continues and manufacturing processes evolve, these materials are likely to play an increasingly important role in industrial design and production.

One of the primary advantages of decane-derived oligomers is their potential for large-scale production. The relatively simple and cost-effective synthesis process allows for scalable manufacturing, which is crucial for meeting industrial demands. This scalability is particularly important in sectors requiring high-volume production, such as automotive parts or packaging materials.

In the aerospace industry, decane-derived oligomers show promise in developing lightweight yet durable materials. Their ability to form strong, heat-resistant polymers makes them ideal for aircraft components that must withstand extreme conditions. The scalability of production ensures a steady supply for this demanding sector.

The automotive industry stands to benefit greatly from these materials. As vehicle manufacturers increasingly focus on fuel efficiency and sustainability, lightweight materials derived from decane oligomers could play a crucial role. Their scalable production allows for integration into mass-produced vehicles, potentially revolutionizing automotive design and performance.

In the realm of consumer goods, decane-derived oligomers offer possibilities for creating innovative packaging solutions. Their unique properties can be harnessed to develop materials that are both durable and environmentally friendly. The ability to scale production to meet consumer market demands is a significant advantage in this sector.

However, challenges remain in fully realizing the industrial potential of these materials. One key issue is the need for consistent quality across large-scale production. Ensuring uniform properties in oligomer-based materials produced in industrial quantities requires sophisticated quality control measures and potentially new manufacturing technologies.

Another challenge lies in the integration of these new materials into existing industrial processes. Many industries have established manufacturing methods optimized for traditional materials. Adapting these processes to accommodate decane-derived oligomers may require significant investment in new equipment and training.

Despite these challenges, the potential benefits of decane-derived oligomers in industrial applications are substantial. Their unique properties, combined with scalable production methods, position them as a promising material for future innovations across multiple industries. As research continues and manufacturing processes evolve, these materials are likely to play an increasingly important role in industrial design and production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!