How Decane Augments Extraction Processes in Biorefineries

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Decane in Biorefineries: Background and Objectives

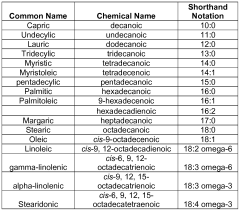

Decane, a versatile hydrocarbon, has emerged as a significant player in the evolving landscape of biorefinery processes. The journey of decane's integration into biorefineries traces back to the early 2000s when the push for sustainable and efficient extraction methods in biofuel production gained momentum. As the bioeconomy expanded, researchers and industry professionals recognized the potential of decane to enhance various extraction processes, particularly in the realm of lipid-based biofuels and high-value biochemicals.

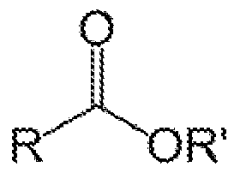

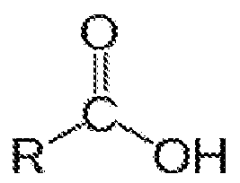

The primary objective of incorporating decane into biorefinery operations is to optimize the extraction efficiency of target compounds from biomass. This aligns with the broader goals of biorefineries to maximize resource utilization and minimize waste generation. Decane's unique properties, including its non-polar nature and relatively low boiling point, make it an ideal candidate for selective extraction of lipids and other hydrophobic compounds from complex biomass matrices.

In the context of biorefineries, decane serves multiple purposes. It acts as a co-solvent in extraction processes, enhancing the solubility of desired compounds and facilitating their separation from the biomass matrix. Additionally, decane can function as a phase separator in liquid-liquid extraction systems, enabling more efficient fractionation of biomolecules based on their polarity and solubility characteristics.

The evolution of decane's role in biorefineries has been driven by the increasing demand for sustainable alternatives to petroleum-based products. As biorefineries strive to develop integrated processes for the production of biofuels, biochemicals, and biomaterials, the need for effective extraction technologies has become paramount. Decane's compatibility with various biomass feedstocks and its potential for recycling within closed-loop systems make it an attractive option for modern biorefinery designs.

Recent technological advancements have further expanded the potential applications of decane in biorefineries. Innovations in process intensification, such as the development of continuous extraction systems and the integration of membrane technologies, have enhanced the efficiency and scalability of decane-based extraction processes. These developments aim to address key challenges in biorefinery operations, including energy consumption, solvent recovery, and product purity.

Looking ahead, the objectives for decane utilization in biorefineries are multifaceted. Researchers and industry stakeholders are focused on optimizing decane-based extraction protocols for a wider range of biomass feedstocks, including algal biomass and lignocellulosic materials. There is also a growing interest in exploring synergistic effects between decane and other green solvents to create more environmentally friendly and efficient extraction systems.

The primary objective of incorporating decane into biorefinery operations is to optimize the extraction efficiency of target compounds from biomass. This aligns with the broader goals of biorefineries to maximize resource utilization and minimize waste generation. Decane's unique properties, including its non-polar nature and relatively low boiling point, make it an ideal candidate for selective extraction of lipids and other hydrophobic compounds from complex biomass matrices.

In the context of biorefineries, decane serves multiple purposes. It acts as a co-solvent in extraction processes, enhancing the solubility of desired compounds and facilitating their separation from the biomass matrix. Additionally, decane can function as a phase separator in liquid-liquid extraction systems, enabling more efficient fractionation of biomolecules based on their polarity and solubility characteristics.

The evolution of decane's role in biorefineries has been driven by the increasing demand for sustainable alternatives to petroleum-based products. As biorefineries strive to develop integrated processes for the production of biofuels, biochemicals, and biomaterials, the need for effective extraction technologies has become paramount. Decane's compatibility with various biomass feedstocks and its potential for recycling within closed-loop systems make it an attractive option for modern biorefinery designs.

Recent technological advancements have further expanded the potential applications of decane in biorefineries. Innovations in process intensification, such as the development of continuous extraction systems and the integration of membrane technologies, have enhanced the efficiency and scalability of decane-based extraction processes. These developments aim to address key challenges in biorefinery operations, including energy consumption, solvent recovery, and product purity.

Looking ahead, the objectives for decane utilization in biorefineries are multifaceted. Researchers and industry stakeholders are focused on optimizing decane-based extraction protocols for a wider range of biomass feedstocks, including algal biomass and lignocellulosic materials. There is also a growing interest in exploring synergistic effects between decane and other green solvents to create more environmentally friendly and efficient extraction systems.

Market Analysis for Decane-Enhanced Biorefinery Products

The market for decane-enhanced biorefinery products is experiencing significant growth, driven by the increasing demand for sustainable and efficient extraction processes in the biofuel and biochemical industries. Decane, a hydrocarbon solvent, has emerged as a valuable tool in augmenting extraction processes, particularly in biorefineries focused on producing renewable fuels and high-value chemicals from biomass.

The global biorefinery market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 10% through 2030. This growth is fueled by the rising adoption of renewable energy sources and the push for reducing carbon emissions across various industries. Within this broader market, the demand for decane-enhanced extraction processes is expected to show even stronger growth, as biorefineries seek to optimize their production efficiency and product quality.

Key market segments that are likely to benefit from decane-enhanced extraction include biodiesel production, cellulosic ethanol manufacturing, and the extraction of specialty chemicals from biomass. The biodiesel sector, in particular, is showing robust demand for improved extraction methods, as producers aim to increase yield and reduce processing costs. Decane's ability to enhance the separation of oils from biomass feedstocks makes it an attractive option for this segment.

Geographically, North America and Europe are currently the leading markets for decane-enhanced biorefinery products, owing to their advanced biofuel industries and supportive regulatory environments. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing investments in biorefinery technologies and the region's rapidly expanding renewable energy sector.

The market is also seeing a trend towards the development of integrated biorefineries that can produce a wide range of products from biomass feedstocks. This trend is expected to further boost the demand for efficient extraction processes, including those enhanced by decane. Additionally, the growing focus on circular economy principles is likely to create new opportunities for decane-enhanced extraction in the recovery and valorization of waste biomass.

Despite the positive outlook, the market faces challenges such as the volatility of feedstock prices and the need for significant capital investments in biorefinery infrastructure. However, ongoing research and development efforts aimed at improving extraction efficiencies and reducing costs are expected to mitigate these challenges and drive further market growth.

The global biorefinery market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 10% through 2030. This growth is fueled by the rising adoption of renewable energy sources and the push for reducing carbon emissions across various industries. Within this broader market, the demand for decane-enhanced extraction processes is expected to show even stronger growth, as biorefineries seek to optimize their production efficiency and product quality.

Key market segments that are likely to benefit from decane-enhanced extraction include biodiesel production, cellulosic ethanol manufacturing, and the extraction of specialty chemicals from biomass. The biodiesel sector, in particular, is showing robust demand for improved extraction methods, as producers aim to increase yield and reduce processing costs. Decane's ability to enhance the separation of oils from biomass feedstocks makes it an attractive option for this segment.

Geographically, North America and Europe are currently the leading markets for decane-enhanced biorefinery products, owing to their advanced biofuel industries and supportive regulatory environments. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing investments in biorefinery technologies and the region's rapidly expanding renewable energy sector.

The market is also seeing a trend towards the development of integrated biorefineries that can produce a wide range of products from biomass feedstocks. This trend is expected to further boost the demand for efficient extraction processes, including those enhanced by decane. Additionally, the growing focus on circular economy principles is likely to create new opportunities for decane-enhanced extraction in the recovery and valorization of waste biomass.

Despite the positive outlook, the market faces challenges such as the volatility of feedstock prices and the need for significant capital investments in biorefinery infrastructure. However, ongoing research and development efforts aimed at improving extraction efficiencies and reducing costs are expected to mitigate these challenges and drive further market growth.

Current Challenges in Biorefinery Extraction Processes

Biorefinery extraction processes face several significant challenges that hinder their efficiency and widespread adoption. One of the primary issues is the complexity of biomass feedstocks, which often contain a diverse array of compounds with varying chemical properties. This heterogeneity makes it difficult to develop universal extraction methods that can effectively isolate target molecules without compromising their quality or yield.

The recalcitrance of lignocellulosic biomass presents another major obstacle. The strong bonds between cellulose, hemicellulose, and lignin components require harsh pretreatment conditions, which can lead to the degradation of valuable compounds and the formation of inhibitory by-products. This not only reduces the overall yield but also necessitates additional purification steps, increasing process complexity and cost.

Energy efficiency remains a critical concern in biorefinery extraction processes. Many current techniques, such as steam explosion or supercritical fluid extraction, demand significant energy inputs, which can offset the environmental benefits of bio-based products. Balancing energy consumption with extraction efficiency is an ongoing challenge that requires innovative solutions and process optimizations.

The use of organic solvents in traditional extraction methods poses environmental and safety risks. While effective in isolating target compounds, these solvents are often toxic, flammable, and difficult to recycle. The search for green solvents that are both environmentally friendly and efficient in extraction is an active area of research, but finding suitable alternatives that match the performance of conventional solvents remains challenging.

Scalability is another significant hurdle in biorefinery extraction processes. Many promising techniques developed at the laboratory scale face difficulties when scaled up to industrial levels. Issues such as heat and mass transfer limitations, equipment design, and process control become more pronounced at larger scales, affecting the consistency and quality of extracted products.

Water consumption in extraction processes is a growing concern, particularly in regions facing water scarcity. Many biorefinery operations require substantial amounts of water for extraction and subsequent purification steps. Developing water-efficient extraction technologies and implementing effective water recycling systems are crucial for the sustainability of biorefinery operations.

Lastly, the variability in biomass feedstock quality and composition poses challenges for maintaining consistent extraction performance. Seasonal changes, geographic differences, and storage conditions can all affect the chemical makeup of biomass, requiring flexible extraction processes that can adapt to these variations while maintaining product quality and yield.

The recalcitrance of lignocellulosic biomass presents another major obstacle. The strong bonds between cellulose, hemicellulose, and lignin components require harsh pretreatment conditions, which can lead to the degradation of valuable compounds and the formation of inhibitory by-products. This not only reduces the overall yield but also necessitates additional purification steps, increasing process complexity and cost.

Energy efficiency remains a critical concern in biorefinery extraction processes. Many current techniques, such as steam explosion or supercritical fluid extraction, demand significant energy inputs, which can offset the environmental benefits of bio-based products. Balancing energy consumption with extraction efficiency is an ongoing challenge that requires innovative solutions and process optimizations.

The use of organic solvents in traditional extraction methods poses environmental and safety risks. While effective in isolating target compounds, these solvents are often toxic, flammable, and difficult to recycle. The search for green solvents that are both environmentally friendly and efficient in extraction is an active area of research, but finding suitable alternatives that match the performance of conventional solvents remains challenging.

Scalability is another significant hurdle in biorefinery extraction processes. Many promising techniques developed at the laboratory scale face difficulties when scaled up to industrial levels. Issues such as heat and mass transfer limitations, equipment design, and process control become more pronounced at larger scales, affecting the consistency and quality of extracted products.

Water consumption in extraction processes is a growing concern, particularly in regions facing water scarcity. Many biorefinery operations require substantial amounts of water for extraction and subsequent purification steps. Developing water-efficient extraction technologies and implementing effective water recycling systems are crucial for the sustainability of biorefinery operations.

Lastly, the variability in biomass feedstock quality and composition poses challenges for maintaining consistent extraction performance. Seasonal changes, geographic differences, and storage conditions can all affect the chemical makeup of biomass, requiring flexible extraction processes that can adapt to these variations while maintaining product quality and yield.

Decane-Based Extraction Methods in Biorefineries

01 Solvent extraction of decane

Decane can be extracted using various solvents, such as hydrocarbons or polar solvents. The choice of solvent depends on the specific application and desired purity of the extracted decane. This process often involves mixing the source material with the solvent, allowing for separation, and then recovering the decane through distillation or other separation techniques.- Solvent extraction of decane: Decane can be extracted using various solvents, such as hydrocarbons or polar solvents. The choice of solvent depends on the specific application and desired purity of the extracted decane. This process often involves mixing the source material with the solvent, allowing for separation, and then recovering the decane through distillation or other separation techniques.

- Supercritical fluid extraction of decane: Supercritical fluid extraction, particularly using carbon dioxide, can be employed to extract decane from various matrices. This method offers advantages such as high selectivity, low environmental impact, and the ability to operate at relatively low temperatures. The process involves using supercritical CO2 as a solvent to selectively extract decane from complex mixtures.

- Membrane-based separation of decane: Membrane technology can be used for the separation and purification of decane from mixtures. This process involves the use of selective membranes that allow decane to pass through while retaining other components. Various types of membranes, such as polymeric or inorganic membranes, can be employed depending on the specific separation requirements.

- Adsorption-based extraction of decane: Adsorption processes can be utilized to extract decane from complex mixtures. This method involves the use of adsorbents such as activated carbon, zeolites, or molecular sieves to selectively adsorb decane from a mixture. The adsorbed decane can then be recovered through desorption processes, such as temperature or pressure swing adsorption.

- Fractional distillation for decane separation: Fractional distillation is a common method for separating decane from other hydrocarbons or mixtures. This process exploits the differences in boiling points between decane and other components. By carefully controlling temperature and pressure conditions, decane can be separated and collected as a distinct fraction during the distillation process.

02 Supercritical fluid extraction of decane

Supercritical fluid extraction, particularly using carbon dioxide, can be employed to extract decane from various matrices. This method offers advantages such as high selectivity, low environmental impact, and the ability to operate at relatively low temperatures. The process involves using supercritical CO2 as a solvent to selectively extract decane from complex mixtures.Expand Specific Solutions03 Membrane-based separation for decane extraction

Membrane technology can be used for the selective extraction of decane from mixtures. This process involves the use of specialized membranes that allow for the preferential passage of decane while retaining other components. The efficiency of this method depends on factors such as membrane material, pore size, and operating conditions.Expand Specific Solutions04 Adsorption-based decane extraction

Adsorption techniques can be employed to extract decane from various sources. This method utilizes adsorbent materials with high affinity for decane, such as activated carbon or zeolites. The process typically involves passing the source material through an adsorbent bed, followed by desorption to recover the extracted decane.Expand Specific Solutions05 Fractional distillation for decane separation

Fractional distillation can be used to separate and extract decane from complex hydrocarbon mixtures. This process exploits the differences in boiling points between decane and other components. The mixture is heated, and the vapors are collected at different temperature ranges, allowing for the isolation of decane based on its specific boiling point.Expand Specific Solutions

Key Players in Biorefinery and Decane Production

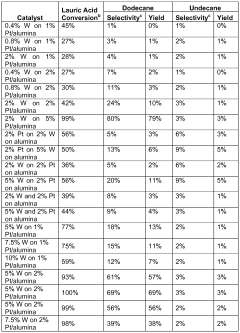

The competitive landscape for decane augmentation in biorefinery extraction processes is evolving rapidly, with the industry in its early growth stage. The market size is expanding as biorefineries seek more efficient extraction methods, driven by the increasing demand for sustainable biofuels and biochemicals. Technologically, the field is advancing, with companies like DuPont de Nemours, ENEOS Corp., and ExxonMobil Chemical Patents leading research efforts. Academic institutions such as Harbin Institute of Technology and Zhejiang University are also contributing to technological advancements. While the technology is promising, it is still in the development phase, with ongoing research to optimize decane's effectiveness in various biorefinery applications.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed an innovative biorefinery process that utilizes decane as a co-solvent in the extraction of valuable compounds from biomass. Their approach involves a two-phase extraction system, where decane is mixed with an aqueous phase containing the target molecules. This method enhances the efficiency of extracting lipids, terpenes, and other hydrophobic compounds from plant materials[1]. The process incorporates a continuous counter-current extraction setup, allowing for optimal mass transfer and separation of desired products. DuPont's technology also includes a novel recycling system for the decane solvent, minimizing waste and improving overall process economics[3].

Strengths: Enhanced extraction efficiency, improved product purity, and reduced environmental impact due to solvent recycling. Weaknesses: Potential high initial capital costs and the need for specialized equipment for handling volatile organic solvents.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has pioneered a decane-based extraction technology for biorefineries that focuses on the recovery of high-value chemicals from lignocellulosic biomass. Their process utilizes supercritical decane as an extraction medium, which allows for selective separation of lignin and other aromatic compounds from cellulose and hemicellulose fractions[2]. The supercritical state of decane enables deeper penetration into the biomass structure, resulting in higher yields of target molecules. ExxonMobil's system also incorporates advanced heat integration and pressure recovery mechanisms, significantly reducing energy consumption in the extraction process[4]. Additionally, they have developed proprietary catalysts that work synergistically with decane to convert extracted lignin into valuable chemical precursors[5].

Strengths: High selectivity for aromatic compounds, energy-efficient process, and value-added conversion of lignin. Weaknesses: Complexity of supercritical fluid handling and potential safety concerns associated with high-pressure operations.

Innovative Decane Applications in Biorefinery Processes

Process for making linear long-chain alkanes from renewable feedstocks using catalysts comprising heteropolyacids

PatentWO2014159484A1

Innovation

- A hydrodeoxygenation process using a catalyst comprising Group IB, VIB, or VIII metals and heteropolyacids or their salts at temperatures between 150 °C to 250 °C and hydrogen gas pressures of at least 300 psig, which converts C10-18 oxygenates to linear alkanes without significant carbon chain shortening.

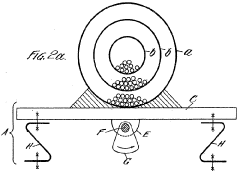

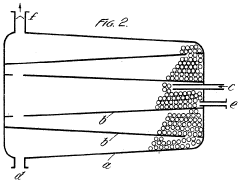

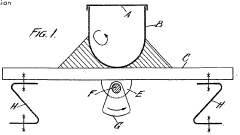

Method of carrying out chemical reactions and extraction processes

PatentInactiveGB457552A

Innovation

- The process involves oscillating the vessel containing the reacting components at a frequency of hundreds to thousands of cycles per minute with an amplitude of several millimeters, using grinding bodies if necessary, to continuously renew the reaction surface and intensify mixing, allowing for reactions to occur without heat and in water, thus avoiding by-reactions and achieving high yields.

Environmental Impact of Decane Use in Biorefineries

The use of decane in biorefinery extraction processes has significant environmental implications that warrant careful consideration. While decane enhances the efficiency of biomass extraction, its environmental impact must be thoroughly assessed to ensure sustainable practices in the biorefinery industry.

One of the primary environmental concerns associated with decane use is its potential for air pollution. As a volatile organic compound (VOC), decane can contribute to the formation of ground-level ozone and smog when released into the atmosphere. This can have detrimental effects on air quality, particularly in urban areas or regions with high industrial activity. To mitigate these impacts, biorefineries must implement robust emission control systems and adhere to strict air quality regulations.

Water pollution is another critical environmental issue related to decane use in biorefineries. Accidental spills or improper disposal of decane-containing waste can contaminate surface and groundwater sources. Given decane's low water solubility and tendency to form a separate phase, it can persist in aquatic environments and potentially harm aquatic ecosystems. Biorefineries must therefore implement comprehensive wastewater treatment systems and spill prevention measures to protect water resources.

The production and use of decane also contribute to greenhouse gas emissions, both directly and indirectly. The manufacturing process of decane, typically derived from petroleum, involves energy-intensive operations that release carbon dioxide and other greenhouse gases. Additionally, the transportation and storage of decane for biorefinery use further contribute to the carbon footprint of the extraction process. To address these concerns, biorefineries should explore more sustainable sourcing options for decane or consider alternative, bio-based solvents with lower environmental impacts.

Soil contamination is another potential environmental risk associated with decane use in biorefineries. Spills or leaks can lead to soil pollution, affecting soil quality and potentially impacting local flora and fauna. The persistence of decane in soil can also lead to long-term environmental degradation if not properly remediated. Biorefineries must implement rigorous soil monitoring programs and have effective cleanup protocols in place to address any contamination incidents promptly.

To minimize the environmental impact of decane use, biorefineries should adopt a comprehensive approach to environmental management. This includes implementing best practices for handling and storage, investing in state-of-the-art pollution control technologies, and continuously monitoring environmental indicators. Additionally, research into more environmentally friendly alternatives to decane should be prioritized to reduce the overall ecological footprint of biorefinery operations.

One of the primary environmental concerns associated with decane use is its potential for air pollution. As a volatile organic compound (VOC), decane can contribute to the formation of ground-level ozone and smog when released into the atmosphere. This can have detrimental effects on air quality, particularly in urban areas or regions with high industrial activity. To mitigate these impacts, biorefineries must implement robust emission control systems and adhere to strict air quality regulations.

Water pollution is another critical environmental issue related to decane use in biorefineries. Accidental spills or improper disposal of decane-containing waste can contaminate surface and groundwater sources. Given decane's low water solubility and tendency to form a separate phase, it can persist in aquatic environments and potentially harm aquatic ecosystems. Biorefineries must therefore implement comprehensive wastewater treatment systems and spill prevention measures to protect water resources.

The production and use of decane also contribute to greenhouse gas emissions, both directly and indirectly. The manufacturing process of decane, typically derived from petroleum, involves energy-intensive operations that release carbon dioxide and other greenhouse gases. Additionally, the transportation and storage of decane for biorefinery use further contribute to the carbon footprint of the extraction process. To address these concerns, biorefineries should explore more sustainable sourcing options for decane or consider alternative, bio-based solvents with lower environmental impacts.

Soil contamination is another potential environmental risk associated with decane use in biorefineries. Spills or leaks can lead to soil pollution, affecting soil quality and potentially impacting local flora and fauna. The persistence of decane in soil can also lead to long-term environmental degradation if not properly remediated. Biorefineries must implement rigorous soil monitoring programs and have effective cleanup protocols in place to address any contamination incidents promptly.

To minimize the environmental impact of decane use, biorefineries should adopt a comprehensive approach to environmental management. This includes implementing best practices for handling and storage, investing in state-of-the-art pollution control technologies, and continuously monitoring environmental indicators. Additionally, research into more environmentally friendly alternatives to decane should be prioritized to reduce the overall ecological footprint of biorefinery operations.

Economic Feasibility of Decane-Enhanced Biorefining

The economic feasibility of decane-enhanced biorefining is a critical consideration for the implementation of this technology in industrial settings. Decane, a hydrocarbon solvent, has shown promising results in augmenting extraction processes within biorefineries, potentially leading to improved efficiency and cost-effectiveness.

One of the primary economic advantages of incorporating decane into biorefining processes is the potential for increased yield of valuable bio-based products. By enhancing the extraction of target compounds from biomass feedstocks, decane can help maximize the recovery of high-value molecules, thereby improving the overall economic output of the biorefinery.

The use of decane in extraction processes may also lead to reduced energy consumption. Traditional extraction methods often require high temperatures or pressures, which can be energy-intensive and costly. Decane-based extraction techniques can potentially operate under milder conditions, resulting in lower energy requirements and associated cost savings.

Furthermore, decane's selectivity in extraction processes can contribute to improved product purity. This can reduce downstream processing costs by minimizing the need for extensive purification steps, ultimately leading to more streamlined and cost-effective production processes.

However, the economic feasibility of decane-enhanced biorefining must also consider the initial investment required for implementing this technology. This may include costs associated with modifying existing equipment or installing new systems designed specifically for decane-based extraction processes.

The recyclability of decane is another crucial factor in assessing its economic viability. Efficient solvent recovery and reuse can significantly reduce operational costs and environmental impact, making the process more sustainable and economically attractive in the long term.

Market demand for bio-based products extracted using decane-enhanced processes will play a vital role in determining the economic feasibility. If the resulting products command premium prices due to improved quality or sustainability credentials, this could offset implementation costs and drive profitability.

Regulatory considerations must also be factored into the economic analysis. Compliance with environmental and safety regulations may require additional investments, but could also potentially open up new market opportunities for products derived from more sustainable extraction processes.

In conclusion, while decane-enhanced biorefining shows promise in terms of improved yields, energy efficiency, and product quality, a comprehensive economic analysis must weigh these benefits against implementation costs, market dynamics, and regulatory requirements to determine its overall feasibility in industrial applications.

One of the primary economic advantages of incorporating decane into biorefining processes is the potential for increased yield of valuable bio-based products. By enhancing the extraction of target compounds from biomass feedstocks, decane can help maximize the recovery of high-value molecules, thereby improving the overall economic output of the biorefinery.

The use of decane in extraction processes may also lead to reduced energy consumption. Traditional extraction methods often require high temperatures or pressures, which can be energy-intensive and costly. Decane-based extraction techniques can potentially operate under milder conditions, resulting in lower energy requirements and associated cost savings.

Furthermore, decane's selectivity in extraction processes can contribute to improved product purity. This can reduce downstream processing costs by minimizing the need for extensive purification steps, ultimately leading to more streamlined and cost-effective production processes.

However, the economic feasibility of decane-enhanced biorefining must also consider the initial investment required for implementing this technology. This may include costs associated with modifying existing equipment or installing new systems designed specifically for decane-based extraction processes.

The recyclability of decane is another crucial factor in assessing its economic viability. Efficient solvent recovery and reuse can significantly reduce operational costs and environmental impact, making the process more sustainable and economically attractive in the long term.

Market demand for bio-based products extracted using decane-enhanced processes will play a vital role in determining the economic feasibility. If the resulting products command premium prices due to improved quality or sustainability credentials, this could offset implementation costs and drive profitability.

Regulatory considerations must also be factored into the economic analysis. Compliance with environmental and safety regulations may require additional investments, but could also potentially open up new market opportunities for products derived from more sustainable extraction processes.

In conclusion, while decane-enhanced biorefining shows promise in terms of improved yields, energy efficiency, and product quality, a comprehensive economic analysis must weigh these benefits against implementation costs, market dynamics, and regulatory requirements to determine its overall feasibility in industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!