Decane’s Interaction with Ionic Liquids in Separative Processes

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Decane-Ionic Liquid Interaction Background

Decane, a straight-chain alkane with ten carbon atoms, has been a subject of significant interest in the field of separative processes, particularly in its interaction with ionic liquids. This interaction forms the foundation for various separation techniques, including liquid-liquid extraction, absorption, and membrane separation processes. The study of decane's behavior in ionic liquid systems has gained prominence due to the increasing demand for efficient and environmentally friendly separation methods in the petrochemical industry.

Ionic liquids, often referred to as designer solvents, are salts that remain liquid at room temperature. Their unique properties, such as negligible vapor pressure, high thermal stability, and tunable physicochemical characteristics, make them attractive alternatives to conventional organic solvents. The interaction between decane and ionic liquids is primarily governed by van der Waals forces and electrostatic interactions, which are influenced by the structure and composition of the ionic liquid.

The historical context of decane-ionic liquid interactions can be traced back to the early 2000s when researchers began exploring the potential of ionic liquids for hydrocarbon separation. Initial studies focused on understanding the solubility and partitioning behavior of decane in various ionic liquids. These investigations laid the groundwork for developing more sophisticated separation techniques and provided insights into the molecular-level interactions between non-polar hydrocarbons and ionic liquids.

Over the past two decades, significant advancements have been made in elucidating the mechanisms of decane-ionic liquid interactions. Researchers have employed a combination of experimental techniques, such as NMR spectroscopy, molecular dynamics simulations, and thermodynamic measurements, to gain a comprehensive understanding of these systems. These studies have revealed that factors such as the alkyl chain length of the ionic liquid, the nature of the anion, and the presence of functional groups play crucial roles in determining the extent and nature of the interaction with decane.

The technological evolution in this field has led to the development of task-specific ionic liquids designed to enhance the selectivity and efficiency of decane separation. For instance, fluorinated ionic liquids have shown promising results in extracting decane from complex hydrocarbon mixtures. Additionally, the concept of supported ionic liquid membranes has emerged as a potential solution for continuous separation processes involving decane and other hydrocarbons.

As research in this area continues to progress, new frontiers are being explored, including the use of deep eutectic solvents as alternatives to traditional ionic liquids and the integration of ionic liquid-based separation techniques with other emerging technologies such as microfluidics and nanotechnology. These advancements are expected to further enhance the efficiency and applicability of decane separation processes across various industrial sectors.

Ionic liquids, often referred to as designer solvents, are salts that remain liquid at room temperature. Their unique properties, such as negligible vapor pressure, high thermal stability, and tunable physicochemical characteristics, make them attractive alternatives to conventional organic solvents. The interaction between decane and ionic liquids is primarily governed by van der Waals forces and electrostatic interactions, which are influenced by the structure and composition of the ionic liquid.

The historical context of decane-ionic liquid interactions can be traced back to the early 2000s when researchers began exploring the potential of ionic liquids for hydrocarbon separation. Initial studies focused on understanding the solubility and partitioning behavior of decane in various ionic liquids. These investigations laid the groundwork for developing more sophisticated separation techniques and provided insights into the molecular-level interactions between non-polar hydrocarbons and ionic liquids.

Over the past two decades, significant advancements have been made in elucidating the mechanisms of decane-ionic liquid interactions. Researchers have employed a combination of experimental techniques, such as NMR spectroscopy, molecular dynamics simulations, and thermodynamic measurements, to gain a comprehensive understanding of these systems. These studies have revealed that factors such as the alkyl chain length of the ionic liquid, the nature of the anion, and the presence of functional groups play crucial roles in determining the extent and nature of the interaction with decane.

The technological evolution in this field has led to the development of task-specific ionic liquids designed to enhance the selectivity and efficiency of decane separation. For instance, fluorinated ionic liquids have shown promising results in extracting decane from complex hydrocarbon mixtures. Additionally, the concept of supported ionic liquid membranes has emerged as a potential solution for continuous separation processes involving decane and other hydrocarbons.

As research in this area continues to progress, new frontiers are being explored, including the use of deep eutectic solvents as alternatives to traditional ionic liquids and the integration of ionic liquid-based separation techniques with other emerging technologies such as microfluidics and nanotechnology. These advancements are expected to further enhance the efficiency and applicability of decane separation processes across various industrial sectors.

Market Analysis for Separation Processes

The market for separation processes involving decane and ionic liquids is experiencing significant growth, driven by the increasing demand for efficient and environmentally friendly separation technologies in various industries. The global market for ionic liquids in separation processes is projected to expand at a compound annual growth rate of 8.5% from 2021 to 2026, with a substantial portion attributed to applications involving hydrocarbons like decane.

The oil and gas industry remains the primary driver for decane-ionic liquid separation processes, as the need for more effective and sustainable methods of hydrocarbon purification continues to rise. Refineries and petrochemical plants are increasingly adopting ionic liquid-based technologies to improve the efficiency of their separation processes, reduce energy consumption, and minimize environmental impact. This trend is particularly pronounced in regions with stringent environmental regulations, such as Europe and North America.

Emerging applications in the pharmaceutical and fine chemical industries are also contributing to market growth. The ability of ionic liquids to selectively extract and purify organic compounds, including decane and its derivatives, has led to increased adoption in these high-value sectors. The market is seeing a surge in demand for customized ionic liquids tailored to specific separation requirements, offering opportunities for specialized chemical manufacturers.

The Asia-Pacific region is expected to witness the fastest growth in the market for decane-ionic liquid separation processes. Rapid industrialization, coupled with increasing environmental concerns, is driving the adoption of advanced separation technologies in countries like China and India. Additionally, the region's growing focus on clean energy and bio-based chemicals is creating new avenues for ionic liquid applications in separating and purifying hydrocarbons.

Technological advancements in ionic liquid design and process optimization are further fueling market expansion. Research and development efforts are focused on developing novel ionic liquids with enhanced selectivity and stability for decane separation. These innovations are expected to improve process efficiency and reduce operational costs, making ionic liquid-based separation more competitive compared to traditional methods.

However, the market faces challenges related to the high initial costs of implementing ionic liquid-based separation systems and the need for specialized expertise in handling these materials. Despite these obstacles, the long-term benefits of improved separation efficiency and reduced environmental impact are driving continued investment and adoption across industries.

The oil and gas industry remains the primary driver for decane-ionic liquid separation processes, as the need for more effective and sustainable methods of hydrocarbon purification continues to rise. Refineries and petrochemical plants are increasingly adopting ionic liquid-based technologies to improve the efficiency of their separation processes, reduce energy consumption, and minimize environmental impact. This trend is particularly pronounced in regions with stringent environmental regulations, such as Europe and North America.

Emerging applications in the pharmaceutical and fine chemical industries are also contributing to market growth. The ability of ionic liquids to selectively extract and purify organic compounds, including decane and its derivatives, has led to increased adoption in these high-value sectors. The market is seeing a surge in demand for customized ionic liquids tailored to specific separation requirements, offering opportunities for specialized chemical manufacturers.

The Asia-Pacific region is expected to witness the fastest growth in the market for decane-ionic liquid separation processes. Rapid industrialization, coupled with increasing environmental concerns, is driving the adoption of advanced separation technologies in countries like China and India. Additionally, the region's growing focus on clean energy and bio-based chemicals is creating new avenues for ionic liquid applications in separating and purifying hydrocarbons.

Technological advancements in ionic liquid design and process optimization are further fueling market expansion. Research and development efforts are focused on developing novel ionic liquids with enhanced selectivity and stability for decane separation. These innovations are expected to improve process efficiency and reduce operational costs, making ionic liquid-based separation more competitive compared to traditional methods.

However, the market faces challenges related to the high initial costs of implementing ionic liquid-based separation systems and the need for specialized expertise in handling these materials. Despite these obstacles, the long-term benefits of improved separation efficiency and reduced environmental impact are driving continued investment and adoption across industries.

Current Challenges in Decane-IL Separation

The separation of decane from ionic liquids (ILs) presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary issues is the strong intermolecular interactions between decane and certain ionic liquids, which can make the separation process energy-intensive and less efficient. These interactions are often governed by complex molecular dynamics that are not yet fully understood, necessitating further research to optimize separation techniques.

Another challenge lies in the selection of appropriate ionic liquids for decane separation. While some ILs show promising selectivity for decane, they may also exhibit unfavorable properties such as high viscosity or poor thermal stability, which can hinder their practical application in industrial settings. The trade-off between selectivity and other physicochemical properties of ILs remains a significant hurdle in developing effective separation processes.

The scalability of decane-IL separation processes also poses a considerable challenge. Many of the current methods that show promise at the laboratory scale face difficulties when scaled up to industrial levels. Issues such as increased energy consumption, reduced separation efficiency, and higher operational costs often emerge during scale-up attempts, highlighting the need for innovative engineering solutions and process optimizations.

Environmental concerns and sustainability considerations add another layer of complexity to the challenges in decane-IL separation. While ionic liquids are often touted as green solvents, their potential environmental impact and recyclability in large-scale operations remain subjects of ongoing research. Ensuring that separation processes are not only efficient but also environmentally friendly is crucial for their long-term viability and acceptance.

Furthermore, the economic feasibility of decane-IL separation processes is a significant challenge. The high cost of many ionic liquids, coupled with the energy requirements for separation and purification, can make these processes economically unattractive compared to traditional separation methods. Developing cost-effective synthesis routes for ILs and improving the overall economics of the separation process are critical areas that require attention.

Lastly, the lack of comprehensive data on the behavior of decane-IL systems under various operating conditions hampers the development of predictive models and simulation tools. This knowledge gap makes it difficult to optimize process parameters and design efficient separation systems without extensive experimental work. Addressing this challenge through systematic studies and the development of reliable predictive tools is essential for advancing the field of decane-IL separation.

Another challenge lies in the selection of appropriate ionic liquids for decane separation. While some ILs show promising selectivity for decane, they may also exhibit unfavorable properties such as high viscosity or poor thermal stability, which can hinder their practical application in industrial settings. The trade-off between selectivity and other physicochemical properties of ILs remains a significant hurdle in developing effective separation processes.

The scalability of decane-IL separation processes also poses a considerable challenge. Many of the current methods that show promise at the laboratory scale face difficulties when scaled up to industrial levels. Issues such as increased energy consumption, reduced separation efficiency, and higher operational costs often emerge during scale-up attempts, highlighting the need for innovative engineering solutions and process optimizations.

Environmental concerns and sustainability considerations add another layer of complexity to the challenges in decane-IL separation. While ionic liquids are often touted as green solvents, their potential environmental impact and recyclability in large-scale operations remain subjects of ongoing research. Ensuring that separation processes are not only efficient but also environmentally friendly is crucial for their long-term viability and acceptance.

Furthermore, the economic feasibility of decane-IL separation processes is a significant challenge. The high cost of many ionic liquids, coupled with the energy requirements for separation and purification, can make these processes economically unattractive compared to traditional separation methods. Developing cost-effective synthesis routes for ILs and improving the overall economics of the separation process are critical areas that require attention.

Lastly, the lack of comprehensive data on the behavior of decane-IL systems under various operating conditions hampers the development of predictive models and simulation tools. This knowledge gap makes it difficult to optimize process parameters and design efficient separation systems without extensive experimental work. Addressing this challenge through systematic studies and the development of reliable predictive tools is essential for advancing the field of decane-IL separation.

Existing Decane-IL Separation Methods

01 Decane as a solvent or reaction medium

Decane is often used as a solvent or reaction medium in various chemical processes. Its non-polar nature makes it suitable for dissolving organic compounds and facilitating reactions. It can be used in extraction processes, as a diluent, or as a medium for chemical transformations.- Decane as a solvent or reaction medium: Decane is often used as a solvent or reaction medium in various chemical processes. Its non-polar nature makes it suitable for dissolving organic compounds and facilitating reactions. It can be used in extraction processes, as a diluent, or as a medium for carrying out organic syntheses.

- Decane in polymer synthesis and processing: Decane plays a role in polymer synthesis and processing. It can be used as a chain transfer agent in polymerization reactions, affecting the molecular weight and properties of the resulting polymers. Additionally, it may serve as a plasticizer or processing aid in polymer formulations.

- Decane in fuel and lubricant applications: Decane is a component in various fuel and lubricant formulations. It can be used as a fuel additive to improve combustion properties or as a base oil in lubricant compositions. Its properties contribute to the overall performance of these products in terms of viscosity, volatility, and thermal stability.

- Decane in pharmaceutical and cosmetic applications: Decane finds applications in pharmaceutical and cosmetic formulations. It can be used as a carrier or vehicle for active ingredients, enhancing their delivery and absorption. In cosmetics, it may serve as an emollient or contribute to the texture and spreadability of products.

- Decane in chemical synthesis and transformations: Decane is involved in various chemical synthesis and transformation processes. It can undergo reactions such as dehydrogenation, isomerization, or functionalization to produce valuable chemical intermediates or end products. These transformations are important in the production of specialty chemicals and fine chemicals.

02 Decane in polymer synthesis and processing

Decane plays a role in polymer synthesis and processing. It can be used as a chain transfer agent in polymerization reactions, affecting the molecular weight and properties of the resulting polymers. Additionally, it may serve as a processing aid or plasticizer in polymer formulations.Expand Specific Solutions03 Decane in fuel and lubricant applications

Decane is a component in various fuel and lubricant formulations. It can be used as a fuel additive to improve combustion properties or as a base oil in lubricant compositions. Its properties contribute to the overall performance of these products in automotive and industrial applications.Expand Specific Solutions04 Decane interactions in catalytic processes

Decane interactions are studied in catalytic processes, particularly in the petroleum and petrochemical industries. It can serve as a model compound for understanding hydrocarbon reactions on catalyst surfaces, such as isomerization, cracking, and reforming processes.Expand Specific Solutions05 Decane in separation and purification techniques

Decane is utilized in various separation and purification techniques. It can be employed in liquid-liquid extraction processes, as a mobile phase in chromatography, or as a component in distillation processes. Its physical properties make it suitable for separating and purifying organic compounds.Expand Specific Solutions

Key Players in IL Separation Industry

The interaction between decane and ionic liquids in separative processes represents an emerging field at the intersection of chemical engineering and materials science. This technology is in its early development stage, with significant potential for growth in industrial applications. The market size is expanding as industries seek more efficient and environmentally friendly separation methods. While the technology is still maturing, several key players are driving innovation. Companies like BASF, Shell Oil, and ExxonMobil are investing in research and development, leveraging their expertise in petrochemicals and process engineering. Academic institutions such as the University of South Alabama and Zhejiang University are contributing fundamental research. The collaboration between industry and academia is accelerating the technology's advancement, with a focus on improving efficiency and scalability for commercial applications.

BASF Corp.

Technical Solution: BASF has developed innovative ionic liquid-based separation processes for decane and other hydrocarbons. Their approach utilizes task-specific ionic liquids with tailored physicochemical properties to achieve selective extraction of decane from complex mixtures. The process involves a liquid-liquid extraction step where the ionic liquid selectively absorbs decane, followed by a recovery step using mild heating or vacuum stripping to separate the decane from the ionic liquid [1][3]. BASF has optimized the ionic liquid composition to maximize decane selectivity while minimizing viscosity and cost. Their system achieves separation factors over 100 for decane/aromatic mixtures and can handle feed streams with up to 50% decane content [2].

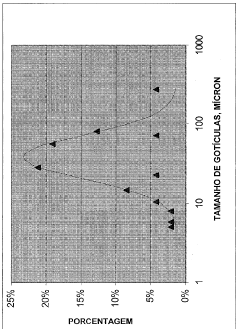

Strengths: High selectivity, mild operating conditions, recyclable solvent. Weaknesses: Relatively high ionic liquid costs, potential for emulsion formation.

UOP LLC

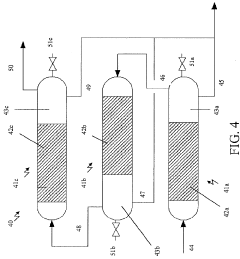

Technical Solution: UOP has developed an advanced ionic liquid-based extraction technology for separating decane and other aliphatic hydrocarbons from aromatic compounds. Their process utilizes a proprietary blend of imidazolium-based ionic liquids with carefully tuned cation and anion structures to achieve high decane selectivity. The extraction is carried out in a multi-stage countercurrent column, allowing for efficient mass transfer and separation [4]. UOP's system incorporates a novel ionic liquid regeneration step using supercritical CO2, which enables nearly complete recovery and recycling of the ionic liquid solvent [5]. The process can achieve decane purities over 99.5% with yields exceeding 98% for feed streams containing 20-80% decane [6].

Strengths: High purity and yield, efficient solvent recycling, flexible feed composition. Weaknesses: High capital costs, complex process control requirements.

Core Innovations in IL-Hydrocarbon Interactions

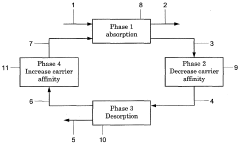

Processes for separation of gases using ionic liquids

PatentWO2009011577A1

Innovation

- The use of ionic liquids with metal ions as a complexing agent allows for efficient gas separation by forming reversible complexes, enabling faster operating speeds, reduced equipment size, and eliminating the need for additional drying steps due to the high concentration and electrochemical stability of the ionic liquid solutions.

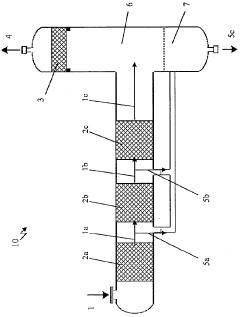

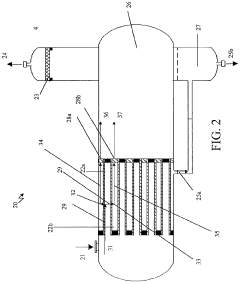

PROCESS FOR SEPARATING AN IONIC LIQUID FROM HYDROCARBONS, AND FOR REGENERATING AN IONIC LIQUID CATALYST, AND ALKYLATION PROCESS.

PatentInactiveBRPI0921681A2

Innovation

- A coalescer process is used, where a coalescer material with a stronger affinity for ionic liquids than hydrocarbons captures and coalesces ionic liquid droplets, allowing them to separate from the hydrocarbon phase through gravitational settling, enabling the recovery of ionic liquid catalysts for recycling.

Environmental Impact of IL-based Processes

The environmental impact of ionic liquid (IL)-based processes in the context of decane separation is a critical consideration for sustainable industrial practices. ILs have gained attention as potential replacements for conventional organic solvents due to their unique properties, including low volatility and high thermal stability. However, their environmental implications must be carefully evaluated.

One of the primary environmental advantages of IL-based processes for decane separation is the reduction of volatile organic compound (VOC) emissions. Traditional separation methods often involve the use of volatile organic solvents, which can contribute to air pollution and ozone depletion. ILs, being non-volatile, significantly mitigate this issue, leading to improved air quality and reduced atmospheric impact.

Water pollution is another area where IL-based processes show potential benefits. Unlike many conventional solvents, ILs have negligible vapor pressure and are generally immiscible with water. This characteristic reduces the risk of contaminating water sources through evaporation or direct contact. However, it is crucial to note that some ILs may still pose risks to aquatic ecosystems if released, necessitating proper handling and disposal protocols.

The lifecycle assessment of IL-based processes for decane separation reveals both advantages and challenges. On one hand, the longevity and recyclability of ILs can lead to reduced waste generation and resource consumption compared to traditional methods. This aspect aligns well with circular economy principles and can contribute to overall sustainability. On the other hand, the synthesis of ILs often involves complex processes that may have their own environmental footprint, including energy consumption and the use of precursor chemicals.

Biodegradability is a key factor in assessing the long-term environmental impact of ILs. While some ILs have been designed to be biodegradable, others may persist in the environment, potentially accumulating in ecosystems. Research into the development of more environmentally friendly ILs, such as those derived from renewable resources or with enhanced biodegradability, is ongoing and crucial for improving the sustainability profile of IL-based separation processes.

Energy efficiency is another important aspect of the environmental impact assessment. IL-based processes for decane separation can potentially offer energy savings compared to conventional distillation methods, particularly for mixtures with close boiling points. This reduced energy demand translates to lower greenhouse gas emissions associated with power generation, contributing to climate change mitigation efforts.

In conclusion, while IL-based processes for decane separation offer several environmental benefits, particularly in terms of VOC reduction and potential energy efficiency, careful consideration must be given to their full lifecycle impact, including synthesis, use, and disposal. Ongoing research and development efforts are essential to optimize the environmental performance of these processes and ensure their sustainable implementation in industrial applications.

One of the primary environmental advantages of IL-based processes for decane separation is the reduction of volatile organic compound (VOC) emissions. Traditional separation methods often involve the use of volatile organic solvents, which can contribute to air pollution and ozone depletion. ILs, being non-volatile, significantly mitigate this issue, leading to improved air quality and reduced atmospheric impact.

Water pollution is another area where IL-based processes show potential benefits. Unlike many conventional solvents, ILs have negligible vapor pressure and are generally immiscible with water. This characteristic reduces the risk of contaminating water sources through evaporation or direct contact. However, it is crucial to note that some ILs may still pose risks to aquatic ecosystems if released, necessitating proper handling and disposal protocols.

The lifecycle assessment of IL-based processes for decane separation reveals both advantages and challenges. On one hand, the longevity and recyclability of ILs can lead to reduced waste generation and resource consumption compared to traditional methods. This aspect aligns well with circular economy principles and can contribute to overall sustainability. On the other hand, the synthesis of ILs often involves complex processes that may have their own environmental footprint, including energy consumption and the use of precursor chemicals.

Biodegradability is a key factor in assessing the long-term environmental impact of ILs. While some ILs have been designed to be biodegradable, others may persist in the environment, potentially accumulating in ecosystems. Research into the development of more environmentally friendly ILs, such as those derived from renewable resources or with enhanced biodegradability, is ongoing and crucial for improving the sustainability profile of IL-based separation processes.

Energy efficiency is another important aspect of the environmental impact assessment. IL-based processes for decane separation can potentially offer energy savings compared to conventional distillation methods, particularly for mixtures with close boiling points. This reduced energy demand translates to lower greenhouse gas emissions associated with power generation, contributing to climate change mitigation efforts.

In conclusion, while IL-based processes for decane separation offer several environmental benefits, particularly in terms of VOC reduction and potential energy efficiency, careful consideration must be given to their full lifecycle impact, including synthesis, use, and disposal. Ongoing research and development efforts are essential to optimize the environmental performance of these processes and ensure their sustainable implementation in industrial applications.

Economic Feasibility of IL Separations

The economic feasibility of ionic liquid (IL) separations in the context of decane interactions is a critical consideration for industrial applications. The cost-effectiveness of IL-based separation processes largely depends on the efficiency of decane extraction, the recyclability of the ILs, and the overall process economics.

Initial capital investment for IL-based separation systems can be substantial due to the high cost of ionic liquids themselves. However, the long-term economic benefits may outweigh these upfront costs. ILs have shown superior selectivity and capacity for decane extraction compared to conventional organic solvents, potentially leading to reduced equipment sizes and lower operational costs.

The recyclability of ILs is a key factor in their economic viability. Most ILs can be regenerated and reused multiple times without significant loss of performance, which significantly reduces the need for continuous replenishment. This characteristic can lead to substantial savings in material costs over time, especially when compared to traditional volatile organic solvents that may require frequent replacement due to evaporative losses.

Energy consumption is another crucial aspect of economic feasibility. IL-based separations often operate at lower temperatures than conventional distillation processes, potentially resulting in reduced energy costs. However, the higher viscosity of some ILs may necessitate additional energy input for pumping and mixing, which must be factored into the overall energy balance.

The scalability of IL separation processes is an important consideration for industrial implementation. While lab-scale studies have demonstrated promising results, the economic viability of large-scale operations needs careful evaluation. Factors such as mass transfer limitations, mixing efficiency, and heat transfer characteristics at industrial scales can significantly impact the overall process economics.

Market dynamics also play a role in the economic feasibility of IL separations. The increasing demand for high-purity hydrocarbons in various industries, coupled with stricter environmental regulations, may create favorable conditions for the adoption of IL-based technologies. However, the volatility of decane prices and the availability of alternative separation technologies must be considered in long-term economic projections.

Lastly, the potential for process intensification and integration with existing systems can enhance the economic attractiveness of IL separations. For instance, combining IL-based extraction with membrane technologies or using ILs in hybrid separation processes could lead to synergistic effects that improve overall process efficiency and reduce costs.

Initial capital investment for IL-based separation systems can be substantial due to the high cost of ionic liquids themselves. However, the long-term economic benefits may outweigh these upfront costs. ILs have shown superior selectivity and capacity for decane extraction compared to conventional organic solvents, potentially leading to reduced equipment sizes and lower operational costs.

The recyclability of ILs is a key factor in their economic viability. Most ILs can be regenerated and reused multiple times without significant loss of performance, which significantly reduces the need for continuous replenishment. This characteristic can lead to substantial savings in material costs over time, especially when compared to traditional volatile organic solvents that may require frequent replacement due to evaporative losses.

Energy consumption is another crucial aspect of economic feasibility. IL-based separations often operate at lower temperatures than conventional distillation processes, potentially resulting in reduced energy costs. However, the higher viscosity of some ILs may necessitate additional energy input for pumping and mixing, which must be factored into the overall energy balance.

The scalability of IL separation processes is an important consideration for industrial implementation. While lab-scale studies have demonstrated promising results, the economic viability of large-scale operations needs careful evaluation. Factors such as mass transfer limitations, mixing efficiency, and heat transfer characteristics at industrial scales can significantly impact the overall process economics.

Market dynamics also play a role in the economic feasibility of IL separations. The increasing demand for high-purity hydrocarbons in various industries, coupled with stricter environmental regulations, may create favorable conditions for the adoption of IL-based technologies. However, the volatility of decane prices and the availability of alternative separation technologies must be considered in long-term economic projections.

Lastly, the potential for process intensification and integration with existing systems can enhance the economic attractiveness of IL separations. For instance, combining IL-based extraction with membrane technologies or using ILs in hybrid separation processes could lead to synergistic effects that improve overall process efficiency and reduce costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!