Role of Decane in Thin Film Deposition Techniques

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Decane in Thin Films: Background and Objectives

Thin film deposition techniques have been a cornerstone of modern materials science and engineering, playing a crucial role in the development of advanced technologies across various industries. The use of decane in these techniques has emerged as a significant area of interest due to its unique properties and potential applications. Decane, a straight-chain alkane hydrocarbon with ten carbon atoms, has garnered attention for its role as a precursor and solvent in thin film deposition processes.

The evolution of thin film deposition techniques has been driven by the increasing demand for high-performance materials in electronics, optics, and energy sectors. As the complexity of devices and structures continues to grow, so does the need for precise control over film thickness, composition, and morphology. In this context, decane has become a valuable tool for researchers and engineers seeking to optimize thin film properties and expand the range of materials that can be deposited.

The primary objective of investigating decane's role in thin film deposition is to enhance the quality and functionality of deposited films while potentially simplifying or improving existing deposition processes. Researchers aim to exploit decane's low vapor pressure, high boiling point, and chemical stability to achieve better control over film growth kinetics and surface interactions. These properties make decane particularly attractive for solution-based deposition methods and certain vapor deposition techniques.

One of the key goals in this field is to understand how decane influences the nucleation and growth mechanisms of thin films. This knowledge is essential for tailoring film properties such as crystallinity, grain size, and surface roughness, which directly impact the performance of devices incorporating these films. Additionally, researchers are exploring how decane can be used to modify the surface energy of substrates or act as a templating agent to guide the self-assembly of nanostructures during film formation.

Another important objective is to investigate the potential of decane as an environmentally friendly alternative to more hazardous solvents commonly used in thin film deposition. As sustainability becomes an increasingly critical consideration in materials processing, the use of safer, less toxic compounds like decane aligns with broader efforts to develop greener manufacturing technologies.

Furthermore, the research community is focused on expanding the range of materials that can be effectively deposited using decane-based techniques. This includes exploring its applicability in the deposition of organic semiconductors, metal oxides, and hybrid organic-inorganic materials. By leveraging decane's unique properties, scientists hope to overcome limitations in existing deposition methods and enable the fabrication of novel thin film structures with enhanced functionality.

The evolution of thin film deposition techniques has been driven by the increasing demand for high-performance materials in electronics, optics, and energy sectors. As the complexity of devices and structures continues to grow, so does the need for precise control over film thickness, composition, and morphology. In this context, decane has become a valuable tool for researchers and engineers seeking to optimize thin film properties and expand the range of materials that can be deposited.

The primary objective of investigating decane's role in thin film deposition is to enhance the quality and functionality of deposited films while potentially simplifying or improving existing deposition processes. Researchers aim to exploit decane's low vapor pressure, high boiling point, and chemical stability to achieve better control over film growth kinetics and surface interactions. These properties make decane particularly attractive for solution-based deposition methods and certain vapor deposition techniques.

One of the key goals in this field is to understand how decane influences the nucleation and growth mechanisms of thin films. This knowledge is essential for tailoring film properties such as crystallinity, grain size, and surface roughness, which directly impact the performance of devices incorporating these films. Additionally, researchers are exploring how decane can be used to modify the surface energy of substrates or act as a templating agent to guide the self-assembly of nanostructures during film formation.

Another important objective is to investigate the potential of decane as an environmentally friendly alternative to more hazardous solvents commonly used in thin film deposition. As sustainability becomes an increasingly critical consideration in materials processing, the use of safer, less toxic compounds like decane aligns with broader efforts to develop greener manufacturing technologies.

Furthermore, the research community is focused on expanding the range of materials that can be effectively deposited using decane-based techniques. This includes exploring its applicability in the deposition of organic semiconductors, metal oxides, and hybrid organic-inorganic materials. By leveraging decane's unique properties, scientists hope to overcome limitations in existing deposition methods and enable the fabrication of novel thin film structures with enhanced functionality.

Market Analysis for Decane-Based Deposition

The market for decane-based thin film deposition techniques has shown significant growth in recent years, driven by increasing demand for advanced electronic devices and semiconductor technologies. This market segment is closely tied to the broader thin film deposition industry, which was valued at approximately $70 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of around 8% through 2026.

Decane, as a precursor in thin film deposition processes, has gained traction due to its unique properties that contribute to improved film quality and process efficiency. The market for decane-based deposition techniques is particularly strong in the semiconductor industry, where it is used in the production of advanced integrated circuits and memory devices. The global semiconductor market, which reached $556 billion in 2021, serves as a key driver for the adoption of decane-based deposition technologies.

The automotive and aerospace industries are also emerging as significant consumers of decane-based thin film deposition techniques. These sectors require high-performance coatings for various applications, including wear-resistant surfaces, thermal barriers, and optical coatings. The growing emphasis on lightweight materials and fuel efficiency in these industries is expected to further boost the demand for advanced thin film technologies.

In the renewable energy sector, decane-based deposition techniques are finding applications in the production of solar cells and energy storage devices. The global solar energy market, which was valued at $184 billion in 2021, presents a substantial opportunity for growth in decane-based thin film technologies, particularly in the development of more efficient and cost-effective photovoltaic cells.

Geographically, Asia-Pacific dominates the market for decane-based thin film deposition, accounting for over 40% of the global market share. This is primarily due to the region's strong presence in semiconductor manufacturing and electronics production. North America and Europe follow, with significant investments in research and development driving innovation in thin film technologies.

The market landscape is characterized by a mix of established players and innovative start-ups. Major companies in the thin film deposition equipment market, such as Applied Materials, Lam Research, and Tokyo Electron, are increasingly incorporating decane-based processes into their product offerings. Additionally, specialized chemical suppliers are emerging to meet the growing demand for high-purity decane precursors.

Looking ahead, the market for decane-based thin film deposition techniques is expected to continue its growth trajectory. Factors such as the increasing miniaturization of electronic devices, the development of 5G and IoT technologies, and the push for more sustainable manufacturing processes are likely to drive further adoption of these advanced deposition techniques across various industries.

Decane, as a precursor in thin film deposition processes, has gained traction due to its unique properties that contribute to improved film quality and process efficiency. The market for decane-based deposition techniques is particularly strong in the semiconductor industry, where it is used in the production of advanced integrated circuits and memory devices. The global semiconductor market, which reached $556 billion in 2021, serves as a key driver for the adoption of decane-based deposition technologies.

The automotive and aerospace industries are also emerging as significant consumers of decane-based thin film deposition techniques. These sectors require high-performance coatings for various applications, including wear-resistant surfaces, thermal barriers, and optical coatings. The growing emphasis on lightweight materials and fuel efficiency in these industries is expected to further boost the demand for advanced thin film technologies.

In the renewable energy sector, decane-based deposition techniques are finding applications in the production of solar cells and energy storage devices. The global solar energy market, which was valued at $184 billion in 2021, presents a substantial opportunity for growth in decane-based thin film technologies, particularly in the development of more efficient and cost-effective photovoltaic cells.

Geographically, Asia-Pacific dominates the market for decane-based thin film deposition, accounting for over 40% of the global market share. This is primarily due to the region's strong presence in semiconductor manufacturing and electronics production. North America and Europe follow, with significant investments in research and development driving innovation in thin film technologies.

The market landscape is characterized by a mix of established players and innovative start-ups. Major companies in the thin film deposition equipment market, such as Applied Materials, Lam Research, and Tokyo Electron, are increasingly incorporating decane-based processes into their product offerings. Additionally, specialized chemical suppliers are emerging to meet the growing demand for high-purity decane precursors.

Looking ahead, the market for decane-based thin film deposition techniques is expected to continue its growth trajectory. Factors such as the increasing miniaturization of electronic devices, the development of 5G and IoT technologies, and the push for more sustainable manufacturing processes are likely to drive further adoption of these advanced deposition techniques across various industries.

Current Challenges in Decane-Assisted Deposition

Despite the promising potential of decane in thin film deposition techniques, several challenges currently hinder its widespread adoption and optimal utilization. One of the primary obstacles is the precise control of decane vapor pressure during the deposition process. The volatility of decane can lead to inconsistent film growth rates and non-uniform thickness across the substrate surface, particularly in large-area depositions.

Another significant challenge lies in managing the thermal decomposition of decane at elevated temperatures. As the substrate temperature increases, decane molecules may break down into smaller hydrocarbon fragments, potentially introducing impurities into the growing film. This thermal instability can compromise the purity and structural integrity of the deposited layers, especially in applications requiring high-temperature processing.

The interaction between decane and various precursor materials presents yet another hurdle. While decane serves as an effective carrier solvent for many precursors, it may also react undesirably with certain compounds, altering their chemical properties or deposition behavior. This reactivity can limit the range of compatible materials and constrain the versatility of decane-assisted deposition techniques.

Furthermore, the environmental and safety concerns associated with decane usage pose challenges in industrial settings. As a volatile organic compound (VOC), decane emissions must be carefully managed to comply with stringent environmental regulations. This necessitates the implementation of sophisticated vapor recovery systems and emission control measures, adding complexity and cost to the deposition process.

The optimization of decane flow dynamics in deposition chambers remains a complex task. Achieving uniform vapor distribution and controlled gas-phase reactions requires precise engineering of gas delivery systems and chamber geometries. Any inhomogeneities in the decane vapor flow can result in thickness variations and compositional gradients across the deposited films.

Lastly, the long-term stability of decane-deposited films under various environmental conditions is an ongoing area of investigation. Potential issues such as film degradation, delamination, or changes in physical properties over time need to be thoroughly addressed to ensure the reliability and longevity of devices incorporating these thin films.

Addressing these challenges requires a multidisciplinary approach, combining advances in process engineering, materials science, and analytical techniques. Overcoming these hurdles will be crucial for realizing the full potential of decane in next-generation thin film deposition technologies.

Another significant challenge lies in managing the thermal decomposition of decane at elevated temperatures. As the substrate temperature increases, decane molecules may break down into smaller hydrocarbon fragments, potentially introducing impurities into the growing film. This thermal instability can compromise the purity and structural integrity of the deposited layers, especially in applications requiring high-temperature processing.

The interaction between decane and various precursor materials presents yet another hurdle. While decane serves as an effective carrier solvent for many precursors, it may also react undesirably with certain compounds, altering their chemical properties or deposition behavior. This reactivity can limit the range of compatible materials and constrain the versatility of decane-assisted deposition techniques.

Furthermore, the environmental and safety concerns associated with decane usage pose challenges in industrial settings. As a volatile organic compound (VOC), decane emissions must be carefully managed to comply with stringent environmental regulations. This necessitates the implementation of sophisticated vapor recovery systems and emission control measures, adding complexity and cost to the deposition process.

The optimization of decane flow dynamics in deposition chambers remains a complex task. Achieving uniform vapor distribution and controlled gas-phase reactions requires precise engineering of gas delivery systems and chamber geometries. Any inhomogeneities in the decane vapor flow can result in thickness variations and compositional gradients across the deposited films.

Lastly, the long-term stability of decane-deposited films under various environmental conditions is an ongoing area of investigation. Potential issues such as film degradation, delamination, or changes in physical properties over time need to be thoroughly addressed to ensure the reliability and longevity of devices incorporating these thin films.

Addressing these challenges requires a multidisciplinary approach, combining advances in process engineering, materials science, and analytical techniques. Overcoming these hurdles will be crucial for realizing the full potential of decane in next-generation thin film deposition technologies.

Existing Decane-Based Deposition Methods

01 Synthesis and production of decane

Decane can be synthesized through various chemical processes, including the hydrogenation of olefins or the reduction of fatty acids. It is also produced as a byproduct in petroleum refining. The production methods often involve catalytic reactions and specific reaction conditions to achieve high yields and purity.- Synthesis and applications of decane derivatives: Decane and its derivatives are used in various chemical processes and applications. These include the synthesis of organic compounds, use as solvents, and in the production of polymers and other materials. The versatility of decane-based compounds makes them valuable in industrial and research settings.

- Decane in fuel and energy applications: Decane is an important component in fuel formulations and energy-related applications. It is used in the production of diesel fuel, jet fuel, and other petroleum products. Research is ongoing to optimize the use of decane and its derivatives in improving fuel efficiency and reducing emissions.

- Decane in pharmaceutical and cosmetic industries: Decane and its derivatives find applications in the pharmaceutical and cosmetic industries. They are used as ingredients in various formulations, including drug delivery systems, topical treatments, and personal care products. The properties of decane make it suitable for enhancing the stability and efficacy of certain compounds.

- Decane in material science and polymer chemistry: Decane plays a role in material science and polymer chemistry. It is used in the synthesis of various polymers and copolymers, contributing to the development of new materials with specific properties. Decane-based compounds are also utilized in the modification of existing materials to enhance their performance characteristics.

- Environmental and safety considerations of decane: The use of decane in various applications necessitates consideration of its environmental impact and safety profile. Research is conducted to assess the toxicity, biodegradability, and potential environmental effects of decane and its derivatives. Efforts are made to develop safer and more environmentally friendly alternatives or improved handling methods.

02 Applications of decane in chemical industry

Decane finds applications in various sectors of the chemical industry. It is used as a solvent, a component in fuel blends, and as a raw material for the production of other chemicals. Its properties make it suitable for use in lubricants, hydraulic fluids, and as a heat transfer medium in certain industrial processes.Expand Specific Solutions03 Decane in pharmaceutical and cosmetic formulations

Decane is utilized in pharmaceutical and cosmetic formulations due to its properties as a non-polar solvent and emollient. It can be incorporated into topical preparations, creams, and lotions to improve texture and enhance the delivery of active ingredients. Its low toxicity makes it suitable for use in various personal care products.Expand Specific Solutions04 Decane derivatives and their applications

Various derivatives of decane, such as decanol and decanal, have been developed and find applications in different industries. These derivatives are used in the production of plasticizers, surfactants, and fragrances. They also serve as intermediates in the synthesis of more complex organic compounds.Expand Specific Solutions05 Environmental and safety considerations of decane

The use and handling of decane require consideration of environmental and safety aspects. Its low water solubility and potential for bioaccumulation necessitate proper disposal methods. Safety measures are important when working with decane due to its flammability and potential for forming explosive mixtures with air. Regulations and guidelines exist for its safe storage, transport, and use in industrial settings.Expand Specific Solutions

Key Players in Thin Film Industry

The role of decane in thin film deposition techniques is part of an evolving competitive landscape in the semiconductor industry. This field is currently in a growth phase, with increasing market size driven by demand for advanced electronic devices. The technology is maturing but still has room for innovation. Key players like Tokyo Electron, Applied Materials, and NAURA Microelectronics are investing heavily in research and development to improve thin film deposition processes. These companies are focusing on enhancing efficiency, precision, and scalability of deposition techniques using decane and other materials. As the technology advances, we can expect to see further consolidation among major players and the emergence of specialized niche providers.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron has incorporated decane into their TELTM Trias™ ALD system for advanced thin film deposition. Their approach utilizes decane as a reducing agent in the deposition of metal films, particularly for copper and cobalt interconnects in advanced logic devices. The company's proprietary pulsed flow technique allows for uniform film growth with thicknesses controllable to within 0.1 nm [2]. Tokyo Electron has also developed a hybrid ALD/CVD process using decane, which enables conformal coating of high aspect ratio structures with deposition rates up to 5 nm/min [4]. Furthermore, they have explored the use of decane in selective area deposition techniques, achieving selective growth on metal surfaces while inhibiting deposition on dielectric areas [6].

Strengths: High conformality in complex structures, excellent thickness control, and potential for selective deposition. Weaknesses: Process complexity and potential for increased cost due to specialized equipment requirements.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced thin film deposition techniques utilizing decane as a precursor. Their approach involves a modified atomic layer deposition (ALD) process where decane is used as a carbon source for depositing carbon-doped silicon oxide films. This method allows for precise control of film thickness and composition, with deposition rates up to 2 nm/min [1]. The company has also integrated decane-based processes into their Endura® platform, enabling high-volume manufacturing of advanced semiconductor devices with feature sizes below 5 nm [3]. Additionally, Applied Materials has explored the use of decane in plasma-enhanced chemical vapor deposition (PECVD) for low-k dielectric films, achieving a dielectric constant as low as 2.2 [5].

Strengths: Precise control over film properties, high throughput, and compatibility with existing manufacturing equipment. Weaknesses: Potential for carbon contamination in some applications and the need for careful process optimization to maintain film quality.

Innovations in Decane-Assisted Thin Film Growth

Film deposition method using atomic layer deposition

PatentWO2024177008A1

Innovation

- The method involves vaporizing a raw material liquid in an evaporator with a stirring mechanism to increase the contact area with the gas phase, maintaining a temperature of 400°C or less, and using a connection system to maintain consistent partial pressure, allowing for stable film formation by ALD while minimizing decomposition products and impurities.

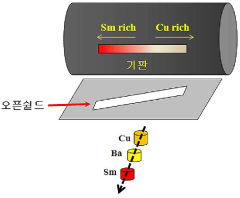

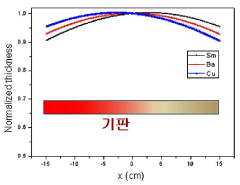

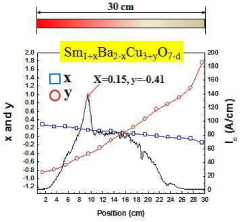

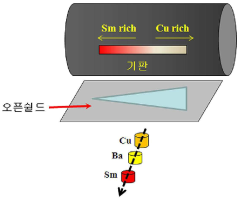

Deposition method of thin film with gradient compositional ratio and thickness

PatentInactiveKR1020120111124A

Innovation

- A double chamber deposition method with a material supply unit perpendicular to the drum axis and an open shield between the supply unit and substrate, allowing for composition and thickness gradients in the thin film, enabling easy measurement of physical properties.

Environmental Impact of Decane in Deposition

The use of decane in thin film deposition techniques raises significant environmental concerns that warrant careful consideration. Decane, a hydrocarbon compound, is widely employed as a solvent or precursor in various deposition processes. However, its volatile nature and potential for atmospheric release pose challenges to environmental sustainability.

One of the primary environmental impacts of decane in deposition processes is its contribution to air pollution. When released into the atmosphere, decane can react with other pollutants to form ground-level ozone and particulate matter, both of which are harmful to human health and ecosystems. These reactions can exacerbate smog formation in urban areas and contribute to respiratory issues in exposed populations.

Furthermore, decane's persistence in the environment is a cause for concern. As a relatively stable compound, it can remain in the atmosphere for extended periods, potentially traveling long distances and affecting areas far from its point of origin. This persistence increases the likelihood of bioaccumulation in various organisms, potentially disrupting food chains and ecosystems.

Water pollution is another significant environmental risk associated with decane use in deposition techniques. Improper handling or disposal of decane-containing waste can lead to contamination of water bodies. Once in aquatic environments, decane can form a film on the water surface, impeding oxygen transfer and harming aquatic life. Its low water solubility also makes it challenging to remove through conventional water treatment methods.

The production and transportation of decane for industrial use also contribute to its environmental footprint. The extraction and refining processes of hydrocarbons, from which decane is derived, are energy-intensive and often associated with greenhouse gas emissions. Additionally, the risk of spills during transportation poses threats to soil and water quality in affected areas.

To mitigate these environmental impacts, industries employing decane in thin film deposition are increasingly focusing on developing closed-loop systems and improved waste management practices. Efforts are being made to recover and recycle decane, reducing its release into the environment. Additionally, research into alternative, more environmentally friendly solvents and precursors is gaining momentum, aiming to replace decane in various deposition processes.

Regulatory bodies worldwide are also tightening controls on volatile organic compound (VOC) emissions, including decane. This has led to the implementation of stricter handling and disposal protocols in industries utilizing decane for thin film deposition. Such regulations are driving innovation in emission control technologies and encouraging the adoption of more sustainable practices in the field.

One of the primary environmental impacts of decane in deposition processes is its contribution to air pollution. When released into the atmosphere, decane can react with other pollutants to form ground-level ozone and particulate matter, both of which are harmful to human health and ecosystems. These reactions can exacerbate smog formation in urban areas and contribute to respiratory issues in exposed populations.

Furthermore, decane's persistence in the environment is a cause for concern. As a relatively stable compound, it can remain in the atmosphere for extended periods, potentially traveling long distances and affecting areas far from its point of origin. This persistence increases the likelihood of bioaccumulation in various organisms, potentially disrupting food chains and ecosystems.

Water pollution is another significant environmental risk associated with decane use in deposition techniques. Improper handling or disposal of decane-containing waste can lead to contamination of water bodies. Once in aquatic environments, decane can form a film on the water surface, impeding oxygen transfer and harming aquatic life. Its low water solubility also makes it challenging to remove through conventional water treatment methods.

The production and transportation of decane for industrial use also contribute to its environmental footprint. The extraction and refining processes of hydrocarbons, from which decane is derived, are energy-intensive and often associated with greenhouse gas emissions. Additionally, the risk of spills during transportation poses threats to soil and water quality in affected areas.

To mitigate these environmental impacts, industries employing decane in thin film deposition are increasingly focusing on developing closed-loop systems and improved waste management practices. Efforts are being made to recover and recycle decane, reducing its release into the environment. Additionally, research into alternative, more environmentally friendly solvents and precursors is gaining momentum, aiming to replace decane in various deposition processes.

Regulatory bodies worldwide are also tightening controls on volatile organic compound (VOC) emissions, including decane. This has led to the implementation of stricter handling and disposal protocols in industries utilizing decane for thin film deposition. Such regulations are driving innovation in emission control technologies and encouraging the adoption of more sustainable practices in the field.

Scalability of Decane-Based Techniques

The scalability of decane-based thin film deposition techniques is a critical factor in their potential for widespread industrial adoption. As the demand for advanced materials and coatings continues to grow across various sectors, the ability to scale up these processes becomes increasingly important.

One of the key advantages of decane-based techniques is their potential for large-area deposition. The low vapor pressure and high boiling point of decane allow for stable and controlled deposition over extended periods, which is crucial for scaling up to larger substrate sizes. This characteristic makes decane-based methods particularly attractive for applications in solar cells, displays, and protective coatings where uniform coverage over large areas is essential.

However, scaling up decane-based techniques also presents several challenges. The primary concern is maintaining consistent film quality and thickness across larger substrates. As the deposition area increases, ensuring uniform temperature distribution and precursor delivery becomes more complex. This may require the development of advanced reactor designs and precise control systems to manage the process parameters effectively.

Another aspect of scalability is the throughput of the deposition process. While decane-based techniques can offer good film quality, their deposition rates may be slower compared to some other methods. Improving the deposition rate without compromising film quality is an ongoing area of research and development. Strategies such as optimizing precursor chemistry, enhancing vapor delivery systems, and exploring hybrid approaches combining decane with other solvents or techniques are being investigated to address this challenge.

The economic feasibility of scaling up decane-based techniques is also a crucial consideration. As production scales increase, the cost-effectiveness of the process becomes more critical. This includes not only the raw material costs but also energy consumption, equipment requirements, and process efficiency. Researchers and engineers are working on optimizing these factors to make decane-based techniques more competitive at industrial scales.

Environmental and safety considerations play a significant role in the scalability of decane-based techniques. While decane is generally considered less hazardous than many other solvents used in thin film deposition, scaling up its use requires careful assessment of potential environmental impacts and implementation of appropriate safety measures. This includes developing efficient solvent recovery and recycling systems to minimize waste and reduce operational costs.

In conclusion, the scalability of decane-based thin film deposition techniques shows promise but also faces several challenges. Ongoing research and development efforts are focused on addressing these challenges to unlock the full potential of these techniques for large-scale industrial applications. The success of these efforts could significantly impact the future landscape of thin film deposition technologies across various industries.

One of the key advantages of decane-based techniques is their potential for large-area deposition. The low vapor pressure and high boiling point of decane allow for stable and controlled deposition over extended periods, which is crucial for scaling up to larger substrate sizes. This characteristic makes decane-based methods particularly attractive for applications in solar cells, displays, and protective coatings where uniform coverage over large areas is essential.

However, scaling up decane-based techniques also presents several challenges. The primary concern is maintaining consistent film quality and thickness across larger substrates. As the deposition area increases, ensuring uniform temperature distribution and precursor delivery becomes more complex. This may require the development of advanced reactor designs and precise control systems to manage the process parameters effectively.

Another aspect of scalability is the throughput of the deposition process. While decane-based techniques can offer good film quality, their deposition rates may be slower compared to some other methods. Improving the deposition rate without compromising film quality is an ongoing area of research and development. Strategies such as optimizing precursor chemistry, enhancing vapor delivery systems, and exploring hybrid approaches combining decane with other solvents or techniques are being investigated to address this challenge.

The economic feasibility of scaling up decane-based techniques is also a crucial consideration. As production scales increase, the cost-effectiveness of the process becomes more critical. This includes not only the raw material costs but also energy consumption, equipment requirements, and process efficiency. Researchers and engineers are working on optimizing these factors to make decane-based techniques more competitive at industrial scales.

Environmental and safety considerations play a significant role in the scalability of decane-based techniques. While decane is generally considered less hazardous than many other solvents used in thin film deposition, scaling up its use requires careful assessment of potential environmental impacts and implementation of appropriate safety measures. This includes developing efficient solvent recovery and recycling systems to minimize waste and reduce operational costs.

In conclusion, the scalability of decane-based thin film deposition techniques shows promise but also faces several challenges. Ongoing research and development efforts are focused on addressing these challenges to unlock the full potential of these techniques for large-scale industrial applications. The success of these efforts could significantly impact the future landscape of thin film deposition technologies across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!