Decane in Advanced Treatment of Carbon Nanotube Growth

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CNT Growth Background

Carbon nanotubes (CNTs) have emerged as a revolutionary material in the field of nanotechnology since their discovery in 1991. These cylindrical structures of carbon atoms exhibit exceptional mechanical, electrical, and thermal properties, making them highly attractive for various applications across industries. The growth of CNTs has been a subject of intense research and development over the past three decades, with significant advancements in synthesis techniques and control over their properties.

The background of CNT growth is rooted in the broader context of carbon-based nanomaterials, including fullerenes and graphene. Early methods of CNT synthesis included arc discharge and laser ablation, which produced limited quantities of nanotubes with varying quality. The breakthrough came with the development of chemical vapor deposition (CVD) techniques in the late 1990s, which allowed for more controlled and scalable production of CNTs.

CVD-based growth methods involve the decomposition of carbon-containing precursors over metal catalysts at elevated temperatures. This process enables the formation of both single-walled and multi-walled CNTs with varying diameters, lengths, and chiralities. The choice of catalyst, carbon source, and growth conditions plays a crucial role in determining the characteristics of the resulting nanotubes.

As research progressed, scientists and engineers focused on optimizing growth parameters to enhance CNT quality, yield, and selectivity. This led to the development of various CVD techniques, including thermal CVD, plasma-enhanced CVD, and floating catalyst CVD. Each method offers distinct advantages in terms of growth rate, purity, and control over CNT properties.

The use of hydrocarbon precursors, such as methane, ethylene, and acetylene, has been widely explored in CNT growth. However, the introduction of decane as a carbon source represents an advanced approach in CNT synthesis. Decane, a linear alkane with ten carbon atoms, offers several potential benefits in the growth process, including a higher carbon yield and the possibility of producing longer and more aligned CNTs.

The exploration of decane in CNT growth aligns with the ongoing efforts to develop more efficient and sustainable synthesis methods. As researchers continue to unravel the complexities of CNT growth mechanisms, the use of advanced precursors like decane opens up new avenues for tailoring CNT properties and expanding their potential applications in fields such as electronics, energy storage, and advanced materials.

Understanding the background of CNT growth, including the evolution of synthesis techniques and the introduction of novel precursors like decane, is crucial for advancing the field and realizing the full potential of these remarkable nanomaterials in technological applications.

The background of CNT growth is rooted in the broader context of carbon-based nanomaterials, including fullerenes and graphene. Early methods of CNT synthesis included arc discharge and laser ablation, which produced limited quantities of nanotubes with varying quality. The breakthrough came with the development of chemical vapor deposition (CVD) techniques in the late 1990s, which allowed for more controlled and scalable production of CNTs.

CVD-based growth methods involve the decomposition of carbon-containing precursors over metal catalysts at elevated temperatures. This process enables the formation of both single-walled and multi-walled CNTs with varying diameters, lengths, and chiralities. The choice of catalyst, carbon source, and growth conditions plays a crucial role in determining the characteristics of the resulting nanotubes.

As research progressed, scientists and engineers focused on optimizing growth parameters to enhance CNT quality, yield, and selectivity. This led to the development of various CVD techniques, including thermal CVD, plasma-enhanced CVD, and floating catalyst CVD. Each method offers distinct advantages in terms of growth rate, purity, and control over CNT properties.

The use of hydrocarbon precursors, such as methane, ethylene, and acetylene, has been widely explored in CNT growth. However, the introduction of decane as a carbon source represents an advanced approach in CNT synthesis. Decane, a linear alkane with ten carbon atoms, offers several potential benefits in the growth process, including a higher carbon yield and the possibility of producing longer and more aligned CNTs.

The exploration of decane in CNT growth aligns with the ongoing efforts to develop more efficient and sustainable synthesis methods. As researchers continue to unravel the complexities of CNT growth mechanisms, the use of advanced precursors like decane opens up new avenues for tailoring CNT properties and expanding their potential applications in fields such as electronics, energy storage, and advanced materials.

Understanding the background of CNT growth, including the evolution of synthesis techniques and the introduction of novel precursors like decane, is crucial for advancing the field and realizing the full potential of these remarkable nanomaterials in technological applications.

Market Analysis

The market for decane in advanced treatment of carbon nanotube growth is experiencing significant expansion, driven by the increasing demand for high-quality carbon nanotubes across various industries. Carbon nanotubes have found applications in electronics, aerospace, energy storage, and biomedical fields, among others, due to their exceptional mechanical, electrical, and thermal properties. The use of decane as a carbon source in the chemical vapor deposition (CVD) process for carbon nanotube growth has gained traction due to its ability to produce high-quality, well-aligned nanotubes with controlled properties.

The global carbon nanotube market is projected to grow substantially in the coming years, with a compound annual growth rate (CAGR) expected to be in the double digits. This growth is primarily attributed to the increasing adoption of carbon nanotubes in emerging technologies and the continuous improvement in production techniques. The demand for decane in this specific application is closely tied to the overall carbon nanotube market growth, as it represents a crucial component in the advanced treatment process.

Key industries driving the demand for high-quality carbon nanotubes include electronics and semiconductors, where nanotubes are used in the development of next-generation transistors, sensors, and conductive films. The aerospace and automotive sectors are also significant consumers, utilizing carbon nanotubes for lightweight, high-strength composite materials. Additionally, the energy storage industry is exploring the potential of carbon nanotubes in improving battery and supercapacitor performance.

The market for decane in carbon nanotube growth is characterized by a relatively small number of specialized suppliers, as the purity and quality requirements for this application are stringent. This has created opportunities for companies that can provide high-grade decane specifically tailored for nanotube synthesis. The market is also influenced by ongoing research and development efforts aimed at optimizing the CVD process and exploring alternative carbon sources.

Geographically, the market for decane in carbon nanotube growth is concentrated in regions with advanced manufacturing capabilities and strong research institutions. North America, Europe, and East Asia are the primary markets, with countries like the United States, Japan, South Korea, and Germany leading in both production and consumption. Emerging economies, particularly China and India, are also showing increased interest and investment in carbon nanotube technologies, potentially expanding the market for decane and other precursor materials.

As the demand for more sophisticated and tailored carbon nanotubes grows, the market for decane in advanced treatment processes is expected to evolve. There is a trend towards developing more efficient and environmentally friendly production methods, which may impact the choice of carbon sources and catalysts used in nanotube synthesis. This presents both challenges and opportunities for suppliers of decane and related materials in the carbon nanotube growth market.

The global carbon nanotube market is projected to grow substantially in the coming years, with a compound annual growth rate (CAGR) expected to be in the double digits. This growth is primarily attributed to the increasing adoption of carbon nanotubes in emerging technologies and the continuous improvement in production techniques. The demand for decane in this specific application is closely tied to the overall carbon nanotube market growth, as it represents a crucial component in the advanced treatment process.

Key industries driving the demand for high-quality carbon nanotubes include electronics and semiconductors, where nanotubes are used in the development of next-generation transistors, sensors, and conductive films. The aerospace and automotive sectors are also significant consumers, utilizing carbon nanotubes for lightweight, high-strength composite materials. Additionally, the energy storage industry is exploring the potential of carbon nanotubes in improving battery and supercapacitor performance.

The market for decane in carbon nanotube growth is characterized by a relatively small number of specialized suppliers, as the purity and quality requirements for this application are stringent. This has created opportunities for companies that can provide high-grade decane specifically tailored for nanotube synthesis. The market is also influenced by ongoing research and development efforts aimed at optimizing the CVD process and exploring alternative carbon sources.

Geographically, the market for decane in carbon nanotube growth is concentrated in regions with advanced manufacturing capabilities and strong research institutions. North America, Europe, and East Asia are the primary markets, with countries like the United States, Japan, South Korea, and Germany leading in both production and consumption. Emerging economies, particularly China and India, are also showing increased interest and investment in carbon nanotube technologies, potentially expanding the market for decane and other precursor materials.

As the demand for more sophisticated and tailored carbon nanotubes grows, the market for decane in advanced treatment processes is expected to evolve. There is a trend towards developing more efficient and environmentally friendly production methods, which may impact the choice of carbon sources and catalysts used in nanotube synthesis. This presents both challenges and opportunities for suppliers of decane and related materials in the carbon nanotube growth market.

Technical Challenges

The advanced treatment of carbon nanotube growth using decane faces several significant technical challenges that researchers and engineers are actively working to overcome. One of the primary obstacles is achieving precise control over the growth process to produce carbon nanotubes with specific characteristics, such as diameter, length, and chirality. The complexity of the growth mechanism, involving the interaction between the carbon source (decane), catalyst particles, and growth conditions, makes it difficult to maintain consistent quality and properties across large-scale production.

Another major challenge lies in the optimization of catalyst performance and longevity. The catalysts used in decane-based carbon nanotube growth, typically transition metal nanoparticles, can become deactivated or poisoned over time, leading to reduced growth efficiency and inconsistent nanotube structures. Developing more robust and long-lasting catalysts that can withstand the harsh growth conditions while maintaining their activity is crucial for improving the overall process.

The formation of amorphous carbon and other unwanted byproducts during the growth process presents an additional hurdle. These impurities can interfere with the growth of high-quality nanotubes and contaminate the final product. Researchers are exploring various approaches to minimize the formation of these byproducts, including fine-tuning growth parameters and developing more selective catalysts.

Scaling up the production of carbon nanotubes using decane as a precursor also poses significant challenges. While laboratory-scale experiments have shown promising results, translating these findings into large-scale, industrial production processes remains difficult. Issues such as maintaining uniform growth conditions, ensuring consistent precursor delivery, and managing heat transfer in larger reactors need to be addressed to achieve economically viable production rates.

The environmental and safety concerns associated with the use of decane and other hydrocarbons in carbon nanotube growth also present technical challenges. Developing safer and more environmentally friendly processes, including the recovery and recycling of unused precursors and the treatment of exhaust gases, is essential for the widespread adoption of this technology.

Lastly, the characterization and quality control of carbon nanotubes produced using decane-based methods remain challenging. Developing rapid, accurate, and non-destructive techniques for assessing the structural and electronic properties of the nanotubes is crucial for ensuring product consistency and meeting the stringent requirements of various applications.

Another major challenge lies in the optimization of catalyst performance and longevity. The catalysts used in decane-based carbon nanotube growth, typically transition metal nanoparticles, can become deactivated or poisoned over time, leading to reduced growth efficiency and inconsistent nanotube structures. Developing more robust and long-lasting catalysts that can withstand the harsh growth conditions while maintaining their activity is crucial for improving the overall process.

The formation of amorphous carbon and other unwanted byproducts during the growth process presents an additional hurdle. These impurities can interfere with the growth of high-quality nanotubes and contaminate the final product. Researchers are exploring various approaches to minimize the formation of these byproducts, including fine-tuning growth parameters and developing more selective catalysts.

Scaling up the production of carbon nanotubes using decane as a precursor also poses significant challenges. While laboratory-scale experiments have shown promising results, translating these findings into large-scale, industrial production processes remains difficult. Issues such as maintaining uniform growth conditions, ensuring consistent precursor delivery, and managing heat transfer in larger reactors need to be addressed to achieve economically viable production rates.

The environmental and safety concerns associated with the use of decane and other hydrocarbons in carbon nanotube growth also present technical challenges. Developing safer and more environmentally friendly processes, including the recovery and recycling of unused precursors and the treatment of exhaust gases, is essential for the widespread adoption of this technology.

Lastly, the characterization and quality control of carbon nanotubes produced using decane-based methods remain challenging. Developing rapid, accurate, and non-destructive techniques for assessing the structural and electronic properties of the nanotubes is crucial for ensuring product consistency and meeting the stringent requirements of various applications.

Decane-based Solutions

01 Chemical vapor deposition (CVD) methods

CVD is a common method for growing carbon nanotubes. It involves the decomposition of carbon-containing gases on catalytic metal particles at high temperatures. This process allows for controlled growth of nanotubes with various structures and properties.- Chemical vapor deposition (CVD) methods: CVD is a common method for growing carbon nanotubes. It involves the decomposition of carbon-containing gases on catalyst particles at high temperatures. This process can be optimized by controlling factors such as gas composition, catalyst type, and reaction conditions to produce nanotubes with desired properties.

- Catalyst preparation and optimization: The preparation and optimization of catalysts play a crucial role in carbon nanotube growth. This includes selecting appropriate catalyst materials, controlling particle size and distribution, and developing methods to enhance catalyst activity and selectivity for specific nanotube structures.

- Growth on substrates and templates: Carbon nanotubes can be grown on various substrates and templates to control their orientation, alignment, and properties. This approach involves preparing suitable substrates, patterning catalyst particles, and optimizing growth conditions to achieve desired nanotube architectures.

- Post-growth processing and purification: After growth, carbon nanotubes often require post-processing and purification steps to remove impurities, separate different types of nanotubes, and enhance their properties. This may include techniques such as acid treatment, oxidation, and functionalization to prepare nanotubes for specific applications.

- Continuous production and scaling up: Developing methods for continuous production and scaling up carbon nanotube growth is essential for industrial applications. This involves designing and optimizing reactor systems, improving process efficiency, and addressing challenges related to large-scale production while maintaining nanotube quality and yield.

02 Catalyst preparation and optimization

The preparation and optimization of catalysts play a crucial role in carbon nanotube growth. This includes selecting appropriate catalyst materials, controlling particle size and distribution, and modifying catalyst support structures to enhance growth efficiency and nanotube quality.Expand Specific Solutions03 Growth parameter control

Controlling various growth parameters such as temperature, pressure, gas flow rates, and reaction time is essential for optimizing carbon nanotube growth. These parameters significantly influence the structure, quality, and yield of the nanotubes produced.Expand Specific Solutions04 Post-growth treatment and purification

After growth, carbon nanotubes often require post-treatment and purification processes to remove impurities, amorphous carbon, and catalyst residues. These processes may include acid treatment, oxidation, annealing, or functionalization to enhance the nanotubes' properties and suitability for various applications.Expand Specific Solutions05 Vertically aligned nanotube growth

Growing vertically aligned carbon nanotubes is a specialized technique that produces highly ordered nanotube arrays. This method often involves careful control of catalyst deposition, substrate preparation, and growth conditions to achieve uniform alignment and desired nanotube length.Expand Specific Solutions

Industry Leaders

The competitive landscape for "Decane in Advanced Treatment of Carbon Nanotube Growth" is characterized by a mix of academic institutions, research organizations, and industrial players. The market is in a growth phase, with increasing demand for advanced carbon nanotube applications. Key players include Tsinghua University, Samsung Electronics, and MIT, indicating a global distribution of expertise. The technology is maturing, with companies like Nori (Shenzhen) New Technology and AIXTRON SE developing specialized equipment and processes. However, the field remains research-intensive, with organizations like CNRS and NIMS contributing to fundamental advancements. The market size is expanding as carbon nanotubes find applications in electronics, energy storage, and advanced materials.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed an innovative approach to carbon nanotube growth using decane as a precursor in a plasma-enhanced chemical vapor deposition (PECVD) system. Their method employs a low-temperature process (around 600°C) which is compatible with existing semiconductor manufacturing processes [4]. Samsung's technique utilizes a thin nickel catalyst layer on silicon wafers, with decane vapor introduced into the chamber along with hydrogen and argon gases. The plasma activation allows for efficient decomposition of decane and promotes vertical growth of carbon nanotubes. This process has achieved growth rates of up to 5 μm/min, with the ability to produce dense arrays of vertically aligned multi-walled carbon nanotubes with diameters ranging from 10-50 nm [5]. Samsung has also developed in-situ purification techniques to remove amorphous carbon during growth, resulting in high-purity nanotubes suitable for electronic applications [6].

Strengths: Low-temperature process compatible with semiconductor manufacturing, high growth rates. Weaknesses: Limited control over single-walled nanotube production, potential for plasma damage to nanotubes.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel approach for advanced treatment of carbon nanotube growth using decane as a carbon source. Their method involves a chemical vapor deposition (CVD) process with precise control over temperature and gas flow rates. They have achieved highly aligned carbon nanotube forests with lengths exceeding 1 mm and diameters of 1-3 nm [1]. The process utilizes a thin iron catalyst layer on silicon substrates, with decane vapor carried by argon and hydrogen gases. MIT's technique allows for fine-tuning of nanotube properties by adjusting growth parameters such as temperature (typically 750-850°C) and gas ratios [2]. This method has demonstrated the ability to produce both single-walled and multi-walled carbon nanotubes with high purity and controlled chirality [3].

Strengths: High degree of control over nanotube properties, ability to produce long and aligned nanotubes. Weaknesses: Complex setup and potentially high energy requirements for the CVD process.

Key Decane Innovations

Carbon nanotube grown on catalyst and manufacture method

PatentActiveUS7932510B2

Innovation

- A method involving the deposition of catalytic fine particles containing Al—Fe, Zr—Co, or Hf—Co on a base body, followed by growing carbon nanotubes using Chemical Vapor Deposition (CVD), where the catalytic fine particles are formed through laser ablation and classified by a differential mobility analyzer to achieve uniform diameter and controlled growth.

Carbon nanotube growth method

PatentWO2004094690A1

Innovation

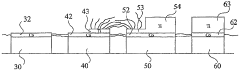

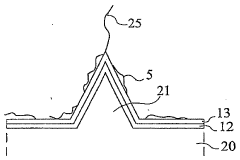

- A chemical vapor deposition process assisted by a hot filament, using a bilayer of titanium and cobalt with specific thickness ratios (titanium between 0.5-5 nm and cobalt between 0.25-10 nm, where cobalt thickness is between half and twice the titanium thickness), applied to a silicon oxide substrate with features like tips, to control nanotube growth on both upper and lateral surfaces.

Environmental Impact

The environmental impact of using decane in advanced treatment of carbon nanotube growth is a critical consideration in the development and application of this technology. Decane, a hydrocarbon compound, plays a significant role in enhancing the growth and quality of carbon nanotubes. However, its use raises several environmental concerns that must be carefully evaluated and addressed.

One of the primary environmental issues associated with decane use is its potential for air pollution. During the carbon nanotube growth process, decane may be vaporized and released into the atmosphere. This can contribute to the formation of ground-level ozone and other air pollutants, potentially impacting local air quality and human health. Additionally, as a volatile organic compound (VOC), decane emissions may contribute to the overall burden of atmospheric pollutants.

Water contamination is another significant environmental concern. If not properly managed, decane can leach into groundwater or surface water systems. This contamination can have detrimental effects on aquatic ecosystems and potentially impact drinking water sources. The persistence of decane in water bodies may lead to long-term environmental consequences, necessitating extensive remediation efforts.

The production and disposal of decane also present environmental challenges. The manufacturing process of decane, typically derived from petroleum, contributes to carbon emissions and energy consumption. Furthermore, the disposal of decane-contaminated waste materials from carbon nanotube production facilities requires careful handling to prevent soil and water pollution.

From a broader perspective, the use of decane in carbon nanotube growth raises questions about the overall sustainability of the technology. While carbon nanotubes offer numerous benefits in various applications, including potential environmental benefits through improved energy efficiency and lightweight materials, the environmental cost of their production using hydrocarbon-based precursors like decane must be carefully weighed against these advantages.

To mitigate these environmental impacts, research efforts are focusing on developing more environmentally friendly alternatives to decane or improving the efficiency of its use in carbon nanotube growth. This includes exploring bio-based precursors, implementing closed-loop systems to minimize emissions and waste, and developing advanced filtration and treatment technologies to reduce the environmental footprint of the production process.

In conclusion, while decane plays a crucial role in advanced carbon nanotube growth, its environmental impact necessitates ongoing research and development of sustainable practices. Balancing the technological benefits of carbon nanotubes with environmental stewardship remains a key challenge in this field, driving innovation towards more eco-friendly production methods.

One of the primary environmental issues associated with decane use is its potential for air pollution. During the carbon nanotube growth process, decane may be vaporized and released into the atmosphere. This can contribute to the formation of ground-level ozone and other air pollutants, potentially impacting local air quality and human health. Additionally, as a volatile organic compound (VOC), decane emissions may contribute to the overall burden of atmospheric pollutants.

Water contamination is another significant environmental concern. If not properly managed, decane can leach into groundwater or surface water systems. This contamination can have detrimental effects on aquatic ecosystems and potentially impact drinking water sources. The persistence of decane in water bodies may lead to long-term environmental consequences, necessitating extensive remediation efforts.

The production and disposal of decane also present environmental challenges. The manufacturing process of decane, typically derived from petroleum, contributes to carbon emissions and energy consumption. Furthermore, the disposal of decane-contaminated waste materials from carbon nanotube production facilities requires careful handling to prevent soil and water pollution.

From a broader perspective, the use of decane in carbon nanotube growth raises questions about the overall sustainability of the technology. While carbon nanotubes offer numerous benefits in various applications, including potential environmental benefits through improved energy efficiency and lightweight materials, the environmental cost of their production using hydrocarbon-based precursors like decane must be carefully weighed against these advantages.

To mitigate these environmental impacts, research efforts are focusing on developing more environmentally friendly alternatives to decane or improving the efficiency of its use in carbon nanotube growth. This includes exploring bio-based precursors, implementing closed-loop systems to minimize emissions and waste, and developing advanced filtration and treatment technologies to reduce the environmental footprint of the production process.

In conclusion, while decane plays a crucial role in advanced carbon nanotube growth, its environmental impact necessitates ongoing research and development of sustainable practices. Balancing the technological benefits of carbon nanotubes with environmental stewardship remains a key challenge in this field, driving innovation towards more eco-friendly production methods.

Scalability Prospects

The scalability prospects for decane in advanced treatment of carbon nanotube growth are promising, with several key factors contributing to its potential for large-scale implementation. Decane, as a carbon precursor, offers significant advantages in terms of scalability due to its availability, stability, and ease of handling.

One of the primary factors supporting the scalability of decane-based carbon nanotube growth is its liquid state at room temperature. This characteristic allows for easier storage, transportation, and integration into existing industrial processes. Unlike gaseous precursors, which require specialized handling and storage equipment, decane can be readily incorporated into existing liquid-based manufacturing systems.

The relatively low cost and abundance of decane also contribute to its scalability potential. As a byproduct of petroleum refining, decane is readily available in large quantities, making it an economically viable option for large-scale carbon nanotube production. This availability ensures a stable supply chain, which is crucial for industrial-scale manufacturing processes.

Furthermore, decane's chemical stability and low reactivity at room temperature enhance its scalability prospects. These properties allow for safer handling and storage, reducing the need for complex safety measures and specialized equipment. This simplification of the production process can lead to reduced costs and increased efficiency in large-scale operations.

The versatility of decane in various carbon nanotube growth methods also supports its scalability. It can be used in both thermal and plasma-enhanced chemical vapor deposition processes, providing flexibility in manufacturing approaches. This adaptability allows for the optimization of growth conditions and the potential for integration into different production lines.

Another aspect contributing to the scalability of decane-based carbon nanotube growth is its potential for continuous production processes. Unlike batch processes, continuous production can significantly increase output and efficiency, making it more suitable for large-scale manufacturing. The liquid nature of decane facilitates its use in continuous flow reactors, which can lead to higher throughput and more consistent product quality.

However, challenges remain in scaling up decane-based carbon nanotube growth. These include optimizing growth parameters for large-scale production, ensuring uniform nanotube quality across larger substrate areas, and developing efficient purification and post-processing techniques. Addressing these challenges will be crucial for realizing the full scalability potential of decane in advanced carbon nanotube growth.

One of the primary factors supporting the scalability of decane-based carbon nanotube growth is its liquid state at room temperature. This characteristic allows for easier storage, transportation, and integration into existing industrial processes. Unlike gaseous precursors, which require specialized handling and storage equipment, decane can be readily incorporated into existing liquid-based manufacturing systems.

The relatively low cost and abundance of decane also contribute to its scalability potential. As a byproduct of petroleum refining, decane is readily available in large quantities, making it an economically viable option for large-scale carbon nanotube production. This availability ensures a stable supply chain, which is crucial for industrial-scale manufacturing processes.

Furthermore, decane's chemical stability and low reactivity at room temperature enhance its scalability prospects. These properties allow for safer handling and storage, reducing the need for complex safety measures and specialized equipment. This simplification of the production process can lead to reduced costs and increased efficiency in large-scale operations.

The versatility of decane in various carbon nanotube growth methods also supports its scalability. It can be used in both thermal and plasma-enhanced chemical vapor deposition processes, providing flexibility in manufacturing approaches. This adaptability allows for the optimization of growth conditions and the potential for integration into different production lines.

Another aspect contributing to the scalability of decane-based carbon nanotube growth is its potential for continuous production processes. Unlike batch processes, continuous production can significantly increase output and efficiency, making it more suitable for large-scale manufacturing. The liquid nature of decane facilitates its use in continuous flow reactors, which can lead to higher throughput and more consistent product quality.

However, challenges remain in scaling up decane-based carbon nanotube growth. These include optimizing growth parameters for large-scale production, ensuring uniform nanotube quality across larger substrate areas, and developing efficient purification and post-processing techniques. Addressing these challenges will be crucial for realizing the full scalability potential of decane in advanced carbon nanotube growth.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!