Decane's Interaction with Surfactants in Enhanced Oil Recovery

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EOR Decane-Surfactant Background and Objectives

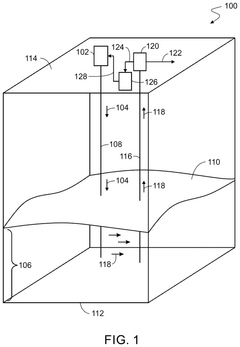

Enhanced Oil Recovery (EOR) has been a critical focus in the petroleum industry for decades, aiming to maximize oil production from existing reservoirs. Within this context, the interaction between decane and surfactants has emerged as a significant area of study. Decane, a straight-chain alkane with ten carbon atoms, serves as a model compound for understanding the behavior of longer-chain hydrocarbons in oil reservoirs.

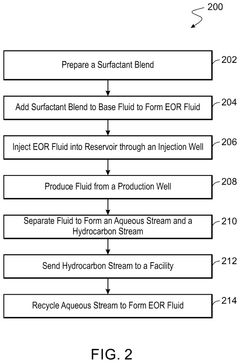

The evolution of EOR techniques has led to the development of various surfactant-based methods, which have shown promising results in improving oil recovery efficiency. Surfactants, amphiphilic molecules with both hydrophilic and hydrophobic components, play a crucial role in altering the interfacial properties between oil and water phases. This alteration can lead to reduced interfacial tension, improved wettability, and enhanced oil mobilization.

The study of decane's interaction with surfactants in EOR is rooted in the need to understand fundamental mechanisms that govern oil-surfactant-water systems at the molecular level. This understanding is essential for designing more effective and efficient EOR processes. The historical progression of this field has seen a shift from empirical approaches to more sophisticated molecular-level investigations, enabled by advancements in analytical techniques and computational modeling.

Recent technological advancements have allowed researchers to probe deeper into the molecular interactions between decane and various surfactants. These include the use of advanced spectroscopic methods, high-resolution microscopy, and molecular dynamics simulations. Such tools have provided unprecedented insights into the formation of microemulsions, the dynamics of surfactant adsorption at oil-water interfaces, and the mechanisms of oil droplet coalescence and breakup.

The primary objectives of studying decane-surfactant interactions in EOR are multifaceted. Firstly, there is a drive to optimize surfactant formulations for specific reservoir conditions, considering factors such as temperature, pressure, and brine composition. Secondly, researchers aim to develop predictive models that can accurately describe the behavior of oil-surfactant systems under various conditions, thereby reducing the need for extensive experimental work.

Furthermore, there is a growing emphasis on developing environmentally friendly and cost-effective surfactants for EOR applications. This objective aligns with the broader industry trend towards sustainable and responsible resource extraction. The ultimate goal is to translate the fundamental understanding of decane-surfactant interactions into practical, field-scale EOR solutions that can significantly enhance oil recovery rates while minimizing environmental impact.

The evolution of EOR techniques has led to the development of various surfactant-based methods, which have shown promising results in improving oil recovery efficiency. Surfactants, amphiphilic molecules with both hydrophilic and hydrophobic components, play a crucial role in altering the interfacial properties between oil and water phases. This alteration can lead to reduced interfacial tension, improved wettability, and enhanced oil mobilization.

The study of decane's interaction with surfactants in EOR is rooted in the need to understand fundamental mechanisms that govern oil-surfactant-water systems at the molecular level. This understanding is essential for designing more effective and efficient EOR processes. The historical progression of this field has seen a shift from empirical approaches to more sophisticated molecular-level investigations, enabled by advancements in analytical techniques and computational modeling.

Recent technological advancements have allowed researchers to probe deeper into the molecular interactions between decane and various surfactants. These include the use of advanced spectroscopic methods, high-resolution microscopy, and molecular dynamics simulations. Such tools have provided unprecedented insights into the formation of microemulsions, the dynamics of surfactant adsorption at oil-water interfaces, and the mechanisms of oil droplet coalescence and breakup.

The primary objectives of studying decane-surfactant interactions in EOR are multifaceted. Firstly, there is a drive to optimize surfactant formulations for specific reservoir conditions, considering factors such as temperature, pressure, and brine composition. Secondly, researchers aim to develop predictive models that can accurately describe the behavior of oil-surfactant systems under various conditions, thereby reducing the need for extensive experimental work.

Furthermore, there is a growing emphasis on developing environmentally friendly and cost-effective surfactants for EOR applications. This objective aligns with the broader industry trend towards sustainable and responsible resource extraction. The ultimate goal is to translate the fundamental understanding of decane-surfactant interactions into practical, field-scale EOR solutions that can significantly enhance oil recovery rates while minimizing environmental impact.

Market Analysis for EOR Technologies

The Enhanced Oil Recovery (EOR) technology market has been experiencing significant growth in recent years, driven by the increasing global demand for oil and the need to maximize production from existing oil fields. As conventional oil reserves become depleted, the importance of EOR technologies, including those involving decane's interaction with surfactants, has become more pronounced.

The global EOR market was valued at approximately $26 billion in 2020 and is projected to reach $36 billion by 2025, growing at a CAGR of 6.5% during the forecast period. This growth is primarily attributed to the rising energy demand, particularly in developing economies, and the continuous efforts to improve oil recovery rates from mature fields.

Surfactant-based EOR technologies, which include the use of decane and its interactions with surfactants, represent a significant segment of the EOR market. These technologies are particularly effective in reducing interfacial tension between oil and water, thereby improving oil displacement efficiency. The market for surfactant-based EOR is expected to grow at a CAGR of 5.8% from 2021 to 2026.

North America currently dominates the EOR market, accounting for about 40% of the global market share. This is largely due to the presence of mature oil fields in the United States and Canada, where EOR technologies are extensively employed to enhance production. The Middle East and Asia-Pacific regions are also significant markets, with rapid growth expected in the coming years due to increasing investments in oil recovery technologies.

The market for decane-surfactant interactions in EOR is influenced by several factors, including oil prices, technological advancements, and environmental regulations. Higher oil prices generally drive increased investment in EOR technologies, as they make the implementation of these techniques more economically viable. Conversely, low oil prices can lead to reduced spending on EOR projects, potentially slowing market growth.

Technological advancements play a crucial role in shaping the market landscape. Ongoing research and development efforts are focused on improving the efficiency and cost-effectiveness of surfactant-based EOR techniques, including those involving decane. These advancements are expected to drive market growth by making EOR technologies more accessible and economically feasible for a wider range of oil fields.

Environmental concerns and regulations also impact the market for EOR technologies. As governments worldwide implement stricter environmental policies, there is a growing emphasis on developing and adopting more environmentally friendly EOR methods. This trend is likely to influence the direction of research and development in decane-surfactant interactions for EOR, potentially leading to the development of more sustainable and eco-friendly solutions.

The global EOR market was valued at approximately $26 billion in 2020 and is projected to reach $36 billion by 2025, growing at a CAGR of 6.5% during the forecast period. This growth is primarily attributed to the rising energy demand, particularly in developing economies, and the continuous efforts to improve oil recovery rates from mature fields.

Surfactant-based EOR technologies, which include the use of decane and its interactions with surfactants, represent a significant segment of the EOR market. These technologies are particularly effective in reducing interfacial tension between oil and water, thereby improving oil displacement efficiency. The market for surfactant-based EOR is expected to grow at a CAGR of 5.8% from 2021 to 2026.

North America currently dominates the EOR market, accounting for about 40% of the global market share. This is largely due to the presence of mature oil fields in the United States and Canada, where EOR technologies are extensively employed to enhance production. The Middle East and Asia-Pacific regions are also significant markets, with rapid growth expected in the coming years due to increasing investments in oil recovery technologies.

The market for decane-surfactant interactions in EOR is influenced by several factors, including oil prices, technological advancements, and environmental regulations. Higher oil prices generally drive increased investment in EOR technologies, as they make the implementation of these techniques more economically viable. Conversely, low oil prices can lead to reduced spending on EOR projects, potentially slowing market growth.

Technological advancements play a crucial role in shaping the market landscape. Ongoing research and development efforts are focused on improving the efficiency and cost-effectiveness of surfactant-based EOR techniques, including those involving decane. These advancements are expected to drive market growth by making EOR technologies more accessible and economically feasible for a wider range of oil fields.

Environmental concerns and regulations also impact the market for EOR technologies. As governments worldwide implement stricter environmental policies, there is a growing emphasis on developing and adopting more environmentally friendly EOR methods. This trend is likely to influence the direction of research and development in decane-surfactant interactions for EOR, potentially leading to the development of more sustainable and eco-friendly solutions.

Current Challenges in Decane-Surfactant Interactions

The interaction between decane and surfactants in enhanced oil recovery (EOR) presents several significant challenges that hinder the optimization of oil extraction processes. One of the primary issues is the complex nature of the interfacial phenomena occurring between the oil phase (represented by decane) and the aqueous surfactant solutions. The dynamic behavior of these interfaces, influenced by factors such as temperature, pressure, and salinity, makes it difficult to predict and control the efficiency of oil displacement.

Another challenge lies in the molecular-level understanding of surfactant adsorption at the oil-water interface. The adsorption kinetics and equilibrium states of surfactants on the decane surface are not fully elucidated, leading to uncertainties in designing effective surfactant formulations. This knowledge gap impedes the development of tailored surfactant systems that can maximize oil recovery while minimizing surfactant consumption.

The stability of surfactant-stabilized emulsions in the presence of decane poses another significant challenge. These emulsions play a crucial role in mobilizing trapped oil, but their long-term stability under reservoir conditions is often compromised. Factors such as coalescence, Ostwald ripening, and phase separation can lead to emulsion breakdown, reducing the effectiveness of the EOR process.

Furthermore, the interaction between decane and surfactants is heavily influenced by the presence of other components in the reservoir, such as brine, rock minerals, and other hydrocarbons. These multi-component interactions create a complex system that is difficult to model and predict accurately. The synergistic or antagonistic effects of these components on surfactant performance remain poorly understood, limiting the ability to optimize surfactant formulations for specific reservoir conditions.

The environmental impact of surfactant-decane interactions in EOR also presents challenges. The potential for surfactant retention in the reservoir and subsequent contamination of groundwater resources is a significant concern. Developing environmentally friendly surfactants that maintain their effectiveness in decane displacement while minimizing ecological risks is an ongoing challenge in the field.

Lastly, the economic viability of surfactant-based EOR processes involving decane interactions remains a critical challenge. The high cost of surfactants, coupled with the uncertainty in their performance under varying reservoir conditions, makes it difficult to justify their large-scale application in many oil fields. Balancing the cost of surfactant implementation against the incremental oil recovery achieved is an ongoing struggle for the industry.

Another challenge lies in the molecular-level understanding of surfactant adsorption at the oil-water interface. The adsorption kinetics and equilibrium states of surfactants on the decane surface are not fully elucidated, leading to uncertainties in designing effective surfactant formulations. This knowledge gap impedes the development of tailored surfactant systems that can maximize oil recovery while minimizing surfactant consumption.

The stability of surfactant-stabilized emulsions in the presence of decane poses another significant challenge. These emulsions play a crucial role in mobilizing trapped oil, but their long-term stability under reservoir conditions is often compromised. Factors such as coalescence, Ostwald ripening, and phase separation can lead to emulsion breakdown, reducing the effectiveness of the EOR process.

Furthermore, the interaction between decane and surfactants is heavily influenced by the presence of other components in the reservoir, such as brine, rock minerals, and other hydrocarbons. These multi-component interactions create a complex system that is difficult to model and predict accurately. The synergistic or antagonistic effects of these components on surfactant performance remain poorly understood, limiting the ability to optimize surfactant formulations for specific reservoir conditions.

The environmental impact of surfactant-decane interactions in EOR also presents challenges. The potential for surfactant retention in the reservoir and subsequent contamination of groundwater resources is a significant concern. Developing environmentally friendly surfactants that maintain their effectiveness in decane displacement while minimizing ecological risks is an ongoing challenge in the field.

Lastly, the economic viability of surfactant-based EOR processes involving decane interactions remains a critical challenge. The high cost of surfactants, coupled with the uncertainty in their performance under varying reservoir conditions, makes it difficult to justify their large-scale application in many oil fields. Balancing the cost of surfactant implementation against the incremental oil recovery achieved is an ongoing struggle for the industry.

Existing Decane-Surfactant Interaction Models

01 Decane as a solvent or reaction medium

Decane is often used as a solvent or reaction medium in various chemical processes. Its non-polar nature makes it suitable for dissolving organic compounds and facilitating reactions. It can be used in extraction processes, as a diluent, or as a medium for chemical transformations.- Decane as a solvent in chemical reactions: Decane is utilized as a solvent in various chemical reactions, particularly in organic synthesis. Its non-polar nature makes it suitable for dissolving and facilitating reactions involving hydrophobic compounds. The use of decane as a solvent can influence reaction rates, product yields, and selectivity in certain chemical processes.

- Decane in polymer synthesis and processing: Decane plays a role in polymer synthesis and processing. It can be used as a diluent or dispersing agent in polymerization reactions, affecting the molecular weight and properties of the resulting polymers. Additionally, decane may be employed in polymer modification processes or as a component in polymer formulations to enhance specific characteristics.

- Decane in fuel and lubricant applications: Decane is a component in various fuel and lubricant formulations. Its presence can influence the combustion properties of fuels and the performance characteristics of lubricants. Research focuses on understanding decane's interactions with other hydrocarbons and additives to optimize fuel efficiency and lubricant effectiveness.

- Decane in separation and purification processes: Decane is utilized in separation and purification processes, particularly in the petrochemical industry. Its physical properties make it suitable for liquid-liquid extraction, distillation, and other separation techniques. Understanding decane's interactions with other hydrocarbons is crucial for developing efficient separation methods.

- Decane interactions in biological systems: The interactions of decane with biological systems are studied for various applications, including drug delivery, membrane research, and toxicology. Its hydrophobic nature influences its behavior in lipid bilayers and cellular environments. Research in this area aims to understand the impact of decane on biological processes and potential applications in pharmaceutical and biomedical fields.

02 Decane in polymer synthesis and processing

Decane plays a role in polymer synthesis and processing. It can be used as a chain transfer agent in polymerization reactions, affecting the molecular weight and properties of the resulting polymers. Additionally, it may serve as a processing aid or plasticizer in polymer formulations.Expand Specific Solutions03 Decane in fuel and lubricant applications

Decane is a component in various fuel and lubricant formulations. It can be used as a fuel additive to improve combustion properties or as a base oil in lubricant compositions. Its properties contribute to the overall performance of these products in automotive and industrial applications.Expand Specific Solutions04 Decane in pharmaceutical and cosmetic formulations

Decane finds applications in pharmaceutical and cosmetic formulations. It can be used as a carrier or solvent for active ingredients, enhancing their delivery and efficacy. Its low toxicity and skin compatibility make it suitable for topical applications and personal care products.Expand Specific Solutions05 Decane in chemical synthesis and reactions

Decane is involved in various chemical synthesis and reactions. It can serve as a starting material or intermediate in the production of other chemicals. Its reactivity and structural properties make it useful in organic synthesis, including alkylation, dehydrogenation, and isomerization reactions.Expand Specific Solutions

Key Players in EOR Surfactant Development

The interaction between decane and surfactants in Enhanced Oil Recovery (EOR) represents a mature yet evolving field within the oil and gas industry. The market is characterized by established players like China Petroleum & Chemical Corp., Shell Oil Co., and Saudi Arabian Oil Co., alongside specialized research institutions. The technology's maturity is evident in its widespread application, but ongoing research by companies such as DuPont de Nemours, Inc. and universities like The University of Texas System indicates potential for further optimization. The global EOR market size, valued at billions of dollars, is expected to grow steadily due to increasing demand for efficient oil extraction methods. However, the competitive landscape is intensifying as companies strive to develop more effective and environmentally friendly surfactant formulations for EOR applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach for decane's interaction with surfactants in enhanced oil recovery (EOR). Their method involves using a combination of anionic and nonionic surfactants to create a synergistic effect that enhances the solubilization of decane in the aqueous phase. The company has implemented a multi-component surfactant system that includes alkyl benzene sulfonates and ethoxylated alcohols, which work together to reduce interfacial tension between oil and water phases[1]. This approach has shown significant improvements in oil recovery rates, with laboratory tests demonstrating up to 15% additional oil recovery compared to conventional methods[2].

Strengths: Improved oil recovery rates, synergistic surfactant system, reduced interfacial tension. Weaknesses: Potential environmental concerns, higher cost of specialized surfactants.

Shell Oil Co.

Technical Solution: Shell Oil Co. has pioneered an innovative technique for optimizing decane's interaction with surfactants in EOR operations. Their approach utilizes advanced molecular dynamics simulations to design tailored surfactant formulations that maximize decane solubilization and mobilization. Shell's research has led to the development of smart surfactants that can adapt to varying reservoir conditions, including temperature and salinity fluctuations[3]. These adaptive surfactants contain both hydrophilic and lipophilic components that can rearrange their molecular structure to maintain optimal performance in different environments. Field trials have shown that this technology can increase oil recovery by up to 20% in decane-rich reservoirs compared to traditional surfactant flooding techniques[4].

Strengths: Adaptive surfactant technology, enhanced performance in varying conditions, significant increase in oil recovery. Weaknesses: High development costs, complexity in implementation.

Innovative Approaches in Surfactant Design

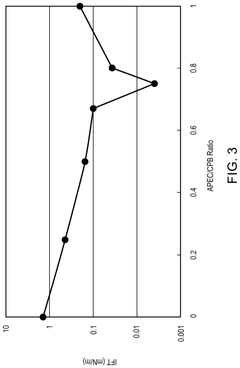

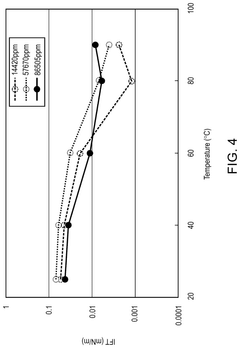

Surfactant mixtures for enhanced oil recovery

PatentPendingUS20250019586A1

Innovation

- A surfactant blend comprising anionic-nonionic surfactants like sodium alkylphenol ethoxylate carboxylate and cationic surfactants such as alkyl pyridine salts is used, which maintains ultra-low interfacial tension across a wide range of temperatures and salinities, enhancing oil recovery by forming a close packing adsorption layer on the interface.

Formulation of surfactant to enhance crude oil recovery

PatentInactiveCA2872775A1

Innovation

- A surfactant formulation comprising a mixture of C16-C22 fatty acids and their salts with monoethanolamine (MEA) is injected into the reservoir, reducing petroleum-water interfacial tension and viscosity, maintaining effectiveness in the presence of divalent metals, and activating natural surfactants with an organic base like MEA to enhance oil mobility and recovery.

Environmental Impact of Surfactant-Based EOR

The environmental impact of surfactant-based Enhanced Oil Recovery (EOR) is a critical consideration in the oil and gas industry. Surfactants used in EOR processes can have significant effects on ecosystems, water resources, and soil quality. These chemicals, when released into the environment, may persist for extended periods and potentially contaminate groundwater and surface water sources.

One of the primary concerns is the toxicity of surfactants to aquatic organisms. Many surfactants used in EOR can disrupt the natural balance of aquatic ecosystems, affecting fish, algae, and other marine life. The bioaccumulation of these substances in the food chain can lead to long-term ecological consequences, impacting biodiversity and ecosystem health.

Soil contamination is another significant issue associated with surfactant-based EOR. The chemicals can alter soil properties, affecting its fertility and microbial communities. This can lead to reduced agricultural productivity in affected areas and changes in local vegetation patterns. Furthermore, the potential for soil erosion may increase due to the alteration of soil structure by surfactants.

The production and disposal of surfactants used in EOR also contribute to environmental concerns. The manufacturing process of these chemicals often involves energy-intensive procedures and the use of potentially harmful precursors. Proper disposal of waste surfactants and contaminated water from EOR operations presents additional challenges, as improper handling can lead to further environmental degradation.

Air quality can be affected by volatile organic compounds (VOCs) released during surfactant-based EOR operations. These emissions can contribute to smog formation and have adverse effects on human health, particularly in areas with high concentrations of oil extraction activities.

Efforts to mitigate the environmental impact of surfactant-based EOR include the development of more environmentally friendly surfactants, such as biosurfactants derived from natural sources. These alternatives aim to reduce toxicity and improve biodegradability. Additionally, advanced treatment technologies for produced water and improved waste management practices are being implemented to minimize the release of harmful substances into the environment.

Regulatory frameworks and industry standards play a crucial role in addressing the environmental concerns associated with surfactant-based EOR. Stricter regulations on chemical use, disposal methods, and monitoring requirements are being implemented in many regions to ensure responsible practices and minimize ecological damage.

One of the primary concerns is the toxicity of surfactants to aquatic organisms. Many surfactants used in EOR can disrupt the natural balance of aquatic ecosystems, affecting fish, algae, and other marine life. The bioaccumulation of these substances in the food chain can lead to long-term ecological consequences, impacting biodiversity and ecosystem health.

Soil contamination is another significant issue associated with surfactant-based EOR. The chemicals can alter soil properties, affecting its fertility and microbial communities. This can lead to reduced agricultural productivity in affected areas and changes in local vegetation patterns. Furthermore, the potential for soil erosion may increase due to the alteration of soil structure by surfactants.

The production and disposal of surfactants used in EOR also contribute to environmental concerns. The manufacturing process of these chemicals often involves energy-intensive procedures and the use of potentially harmful precursors. Proper disposal of waste surfactants and contaminated water from EOR operations presents additional challenges, as improper handling can lead to further environmental degradation.

Air quality can be affected by volatile organic compounds (VOCs) released during surfactant-based EOR operations. These emissions can contribute to smog formation and have adverse effects on human health, particularly in areas with high concentrations of oil extraction activities.

Efforts to mitigate the environmental impact of surfactant-based EOR include the development of more environmentally friendly surfactants, such as biosurfactants derived from natural sources. These alternatives aim to reduce toxicity and improve biodegradability. Additionally, advanced treatment technologies for produced water and improved waste management practices are being implemented to minimize the release of harmful substances into the environment.

Regulatory frameworks and industry standards play a crucial role in addressing the environmental concerns associated with surfactant-based EOR. Stricter regulations on chemical use, disposal methods, and monitoring requirements are being implemented in many regions to ensure responsible practices and minimize ecological damage.

Economic Feasibility of Decane-Surfactant EOR

The economic feasibility of decane-surfactant enhanced oil recovery (EOR) is a critical consideration for oil companies seeking to maximize their production from mature fields. This analysis examines the financial viability of implementing decane-surfactant EOR techniques, taking into account various economic factors and market conditions.

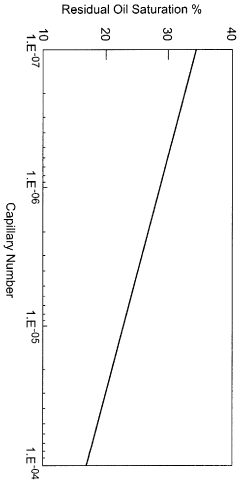

The primary economic driver for decane-surfactant EOR is the potential for increased oil recovery from existing reservoirs. By reducing interfacial tension between oil and water, this technique can mobilize previously trapped oil, potentially increasing recovery rates by 5-15% of original oil in place. This additional recovery can significantly extend the productive life of mature fields and improve overall project economics.

Capital expenditure (CAPEX) for implementing decane-surfactant EOR is relatively low compared to other EOR methods, as it often utilizes existing infrastructure. The main CAPEX components include surfactant manufacturing or procurement, injection equipment, and potential modifications to production facilities. These costs typically range from $5-15 million for a medium-sized field, depending on reservoir characteristics and existing infrastructure.

Operating expenses (OPEX) for decane-surfactant EOR are primarily driven by the cost of chemicals and increased water handling. Surfactant costs can vary widely, from $2-10 per kilogram, depending on the specific formulation and market conditions. Water handling costs may increase due to higher water cut in produced fluids, potentially adding $0.5-2 per barrel of total fluid produced.

The economic viability of decane-surfactant EOR is highly sensitive to oil prices. At current oil prices (assuming $60-70 per barrel), many projects show positive net present value (NPV) and internal rates of return (IRR) exceeding 15%. However, sustained low oil prices below $40 per barrel may challenge the economic feasibility of some projects, particularly in fields with higher operating costs or lower incremental recovery potential.

Technological advancements in surfactant formulations and injection strategies continue to improve the economic outlook for decane-surfactant EOR. Developments in low-cost, high-performance surfactants and optimized injection protocols are reducing chemical costs and improving recovery efficiencies, potentially lowering the break-even oil price for these projects.

Environmental regulations and carbon pricing mechanisms may impact the economic feasibility of decane-surfactant EOR in the future. While this technique generally has a lower environmental footprint compared to thermal EOR methods, potential restrictions on chemical use or increased costs associated with water management could affect project economics.

In conclusion, decane-surfactant EOR demonstrates promising economic feasibility in many scenarios, particularly for mature fields with significant remaining oil in place. However, careful economic analysis, considering field-specific factors, oil price forecasts, and evolving regulatory landscapes, is essential for determining the viability of individual projects.

The primary economic driver for decane-surfactant EOR is the potential for increased oil recovery from existing reservoirs. By reducing interfacial tension between oil and water, this technique can mobilize previously trapped oil, potentially increasing recovery rates by 5-15% of original oil in place. This additional recovery can significantly extend the productive life of mature fields and improve overall project economics.

Capital expenditure (CAPEX) for implementing decane-surfactant EOR is relatively low compared to other EOR methods, as it often utilizes existing infrastructure. The main CAPEX components include surfactant manufacturing or procurement, injection equipment, and potential modifications to production facilities. These costs typically range from $5-15 million for a medium-sized field, depending on reservoir characteristics and existing infrastructure.

Operating expenses (OPEX) for decane-surfactant EOR are primarily driven by the cost of chemicals and increased water handling. Surfactant costs can vary widely, from $2-10 per kilogram, depending on the specific formulation and market conditions. Water handling costs may increase due to higher water cut in produced fluids, potentially adding $0.5-2 per barrel of total fluid produced.

The economic viability of decane-surfactant EOR is highly sensitive to oil prices. At current oil prices (assuming $60-70 per barrel), many projects show positive net present value (NPV) and internal rates of return (IRR) exceeding 15%. However, sustained low oil prices below $40 per barrel may challenge the economic feasibility of some projects, particularly in fields with higher operating costs or lower incremental recovery potential.

Technological advancements in surfactant formulations and injection strategies continue to improve the economic outlook for decane-surfactant EOR. Developments in low-cost, high-performance surfactants and optimized injection protocols are reducing chemical costs and improving recovery efficiencies, potentially lowering the break-even oil price for these projects.

Environmental regulations and carbon pricing mechanisms may impact the economic feasibility of decane-surfactant EOR in the future. While this technique generally has a lower environmental footprint compared to thermal EOR methods, potential restrictions on chemical use or increased costs associated with water management could affect project economics.

In conclusion, decane-surfactant EOR demonstrates promising economic feasibility in many scenarios, particularly for mature fields with significant remaining oil in place. However, careful economic analysis, considering field-specific factors, oil price forecasts, and evolving regulatory landscapes, is essential for determining the viability of individual projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!