Magnesium iron silicate hydroxide as a solid-phase heavy metal adsorbent.

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Background and Objectives

The field of heavy metal pollution remediation has gained significant attention in recent years due to the increasing environmental concerns and stringent regulations. Among various treatment methods, adsorption has emerged as a promising technique for its efficiency, cost-effectiveness, and versatility. In this context, magnesium iron silicate hydroxide (MISH) has shown great potential as a solid-phase heavy metal adsorbent.

MISH, a naturally occurring mineral, belongs to the phyllosilicate group and is characterized by its layered structure and high surface area. Its unique composition, combining magnesium, iron, and silicate components, provides multiple binding sites for heavy metal ions, making it an attractive candidate for adsorption applications. The growing interest in MISH as an adsorbent stems from its abundance in nature, low cost, and environmental friendliness.

The historical development of heavy metal adsorption technologies has seen a shift from conventional adsorbents like activated carbon to more specialized materials. This transition has been driven by the need for higher adsorption capacities, improved selectivity, and better regeneration capabilities. MISH represents a step forward in this evolution, offering a combination of desirable properties that address these requirements.

Recent studies have demonstrated MISH's effectiveness in removing various heavy metals, including lead, cadmium, copper, and zinc, from aqueous solutions. Its performance has been attributed to its high cation exchange capacity, large specific surface area, and the presence of multiple functional groups on its surface. These characteristics enable MISH to interact with heavy metal ions through various mechanisms, including ion exchange, surface complexation, and precipitation.

The primary objective of this research is to comprehensively evaluate the potential of MISH as a solid-phase heavy metal adsorbent. This involves investigating its adsorption mechanisms, determining optimal operating conditions, and assessing its performance in comparison to other adsorbents. Additionally, the study aims to explore methods for enhancing MISH's adsorption capacity through surface modification or composite formation.

Furthermore, this research seeks to address the challenges associated with MISH application, such as regeneration efficiency, selectivity in multi-metal systems, and stability under various environmental conditions. By tackling these issues, the study aims to pave the way for the practical implementation of MISH in real-world water treatment scenarios.

The long-term goal of this research is to contribute to the development of sustainable and efficient heavy metal removal technologies. By focusing on MISH, a naturally abundant and environmentally friendly material, this study aligns with the broader objectives of green chemistry and sustainable environmental remediation. The findings from this research are expected to have significant implications for water treatment practices, particularly in regions facing severe heavy metal pollution challenges.

MISH, a naturally occurring mineral, belongs to the phyllosilicate group and is characterized by its layered structure and high surface area. Its unique composition, combining magnesium, iron, and silicate components, provides multiple binding sites for heavy metal ions, making it an attractive candidate for adsorption applications. The growing interest in MISH as an adsorbent stems from its abundance in nature, low cost, and environmental friendliness.

The historical development of heavy metal adsorption technologies has seen a shift from conventional adsorbents like activated carbon to more specialized materials. This transition has been driven by the need for higher adsorption capacities, improved selectivity, and better regeneration capabilities. MISH represents a step forward in this evolution, offering a combination of desirable properties that address these requirements.

Recent studies have demonstrated MISH's effectiveness in removing various heavy metals, including lead, cadmium, copper, and zinc, from aqueous solutions. Its performance has been attributed to its high cation exchange capacity, large specific surface area, and the presence of multiple functional groups on its surface. These characteristics enable MISH to interact with heavy metal ions through various mechanisms, including ion exchange, surface complexation, and precipitation.

The primary objective of this research is to comprehensively evaluate the potential of MISH as a solid-phase heavy metal adsorbent. This involves investigating its adsorption mechanisms, determining optimal operating conditions, and assessing its performance in comparison to other adsorbents. Additionally, the study aims to explore methods for enhancing MISH's adsorption capacity through surface modification or composite formation.

Furthermore, this research seeks to address the challenges associated with MISH application, such as regeneration efficiency, selectivity in multi-metal systems, and stability under various environmental conditions. By tackling these issues, the study aims to pave the way for the practical implementation of MISH in real-world water treatment scenarios.

The long-term goal of this research is to contribute to the development of sustainable and efficient heavy metal removal technologies. By focusing on MISH, a naturally abundant and environmentally friendly material, this study aligns with the broader objectives of green chemistry and sustainable environmental remediation. The findings from this research are expected to have significant implications for water treatment practices, particularly in regions facing severe heavy metal pollution challenges.

Market Analysis

The market for solid-phase heavy metal adsorbents, particularly magnesium iron silicate hydroxide, has been experiencing significant growth due to increasing environmental concerns and stringent regulations on water and soil pollution. The global water treatment chemicals market, which includes heavy metal adsorbents, is projected to reach substantial value in the coming years, driven by the rising demand for clean water in industrial, municipal, and residential sectors.

Magnesium iron silicate hydroxide, as a novel adsorbent material, is gaining attention in the environmental remediation industry due to its high adsorption capacity and selectivity for heavy metal ions. The market for this specific adsorbent is still in its nascent stage but shows promising growth potential. Industries such as mining, metallurgy, electroplating, and battery manufacturing are the primary consumers of heavy metal adsorbents, creating a steady demand for innovative and efficient solutions.

The Asia-Pacific region, particularly China and India, represents the largest and fastest-growing market for heavy metal adsorbents. This is attributed to rapid industrialization, urbanization, and increasing awareness of environmental protection in these countries. North America and Europe follow closely, driven by strict environmental regulations and the need for sustainable water treatment solutions.

The market for magnesium iron silicate hydroxide adsorbents is expected to grow as research continues to demonstrate its effectiveness in removing a wide range of heavy metals, including lead, cadmium, copper, and chromium. Its potential applications extend beyond water treatment to soil remediation and industrial waste management, further expanding its market prospects.

However, the market faces challenges such as high production costs and competition from established adsorbents like activated carbon and zeolites. The success of magnesium iron silicate hydroxide in the market will largely depend on technological advancements that can reduce production costs and improve its performance in real-world applications.

As environmental regulations become more stringent worldwide, the demand for efficient and cost-effective heavy metal adsorbents is expected to rise. This presents a significant opportunity for magnesium iron silicate hydroxide to capture a larger share of the market. Research and development efforts focused on enhancing its adsorption properties and exploring new applications will be crucial in determining its future market position.

Magnesium iron silicate hydroxide, as a novel adsorbent material, is gaining attention in the environmental remediation industry due to its high adsorption capacity and selectivity for heavy metal ions. The market for this specific adsorbent is still in its nascent stage but shows promising growth potential. Industries such as mining, metallurgy, electroplating, and battery manufacturing are the primary consumers of heavy metal adsorbents, creating a steady demand for innovative and efficient solutions.

The Asia-Pacific region, particularly China and India, represents the largest and fastest-growing market for heavy metal adsorbents. This is attributed to rapid industrialization, urbanization, and increasing awareness of environmental protection in these countries. North America and Europe follow closely, driven by strict environmental regulations and the need for sustainable water treatment solutions.

The market for magnesium iron silicate hydroxide adsorbents is expected to grow as research continues to demonstrate its effectiveness in removing a wide range of heavy metals, including lead, cadmium, copper, and chromium. Its potential applications extend beyond water treatment to soil remediation and industrial waste management, further expanding its market prospects.

However, the market faces challenges such as high production costs and competition from established adsorbents like activated carbon and zeolites. The success of magnesium iron silicate hydroxide in the market will largely depend on technological advancements that can reduce production costs and improve its performance in real-world applications.

As environmental regulations become more stringent worldwide, the demand for efficient and cost-effective heavy metal adsorbents is expected to rise. This presents a significant opportunity for magnesium iron silicate hydroxide to capture a larger share of the market. Research and development efforts focused on enhancing its adsorption properties and exploring new applications will be crucial in determining its future market position.

Technical Challenges

The research on magnesium iron silicate hydroxide as a solid-phase heavy metal adsorbent faces several technical challenges that need to be addressed for its effective implementation. One of the primary obstacles is the optimization of the material's adsorption capacity. While magnesium iron silicate hydroxide has shown promise in heavy metal removal, achieving consistently high adsorption rates across various metal ions remains a challenge.

The synthesis of magnesium iron silicate hydroxide with uniform particle size and morphology is another significant hurdle. The material's performance is heavily influenced by its structural characteristics, and controlling these parameters during large-scale production is complex. Researchers are grappling with developing scalable synthesis methods that maintain the desired physicochemical properties of the adsorbent.

Selectivity in metal ion adsorption presents another technical challenge. In real-world applications, wastewater often contains multiple heavy metal species. Enhancing the selectivity of magnesium iron silicate hydroxide towards specific high-priority contaminants while maintaining overall adsorption efficiency is a critical area of ongoing research.

The stability and regeneration of the adsorbent material pose additional challenges. Long-term stability under various pH conditions and in the presence of competing ions is crucial for practical applications. Moreover, developing efficient regeneration processes that allow for multiple adsorption-desorption cycles without significant loss of performance is essential for economic viability.

Environmental concerns and regulatory compliance add another layer of complexity. Ensuring that the adsorbent itself does not introduce secondary contamination and meets stringent environmental standards is paramount. This includes addressing potential leaching of magnesium or iron ions from the adsorbent during the treatment process.

The kinetics of adsorption, particularly in continuous flow systems, present technical hurdles. Optimizing the contact time and flow rates to achieve maximum adsorption efficiency while maintaining practical throughput rates is a delicate balance that researchers are striving to achieve.

Lastly, the integration of magnesium iron silicate hydroxide into existing water treatment systems poses engineering challenges. Developing effective methods for incorporating the adsorbent into filtration systems, managing pressure drops, and preventing clogging or channeling effects are areas that require innovative solutions.

The synthesis of magnesium iron silicate hydroxide with uniform particle size and morphology is another significant hurdle. The material's performance is heavily influenced by its structural characteristics, and controlling these parameters during large-scale production is complex. Researchers are grappling with developing scalable synthesis methods that maintain the desired physicochemical properties of the adsorbent.

Selectivity in metal ion adsorption presents another technical challenge. In real-world applications, wastewater often contains multiple heavy metal species. Enhancing the selectivity of magnesium iron silicate hydroxide towards specific high-priority contaminants while maintaining overall adsorption efficiency is a critical area of ongoing research.

The stability and regeneration of the adsorbent material pose additional challenges. Long-term stability under various pH conditions and in the presence of competing ions is crucial for practical applications. Moreover, developing efficient regeneration processes that allow for multiple adsorption-desorption cycles without significant loss of performance is essential for economic viability.

Environmental concerns and regulatory compliance add another layer of complexity. Ensuring that the adsorbent itself does not introduce secondary contamination and meets stringent environmental standards is paramount. This includes addressing potential leaching of magnesium or iron ions from the adsorbent during the treatment process.

The kinetics of adsorption, particularly in continuous flow systems, present technical hurdles. Optimizing the contact time and flow rates to achieve maximum adsorption efficiency while maintaining practical throughput rates is a delicate balance that researchers are striving to achieve.

Lastly, the integration of magnesium iron silicate hydroxide into existing water treatment systems poses engineering challenges. Developing effective methods for incorporating the adsorbent into filtration systems, managing pressure drops, and preventing clogging or channeling effects are areas that require innovative solutions.

Current Solutions

01 Adsorption capacity enhancement through modification

The adsorption capacity of magnesium iron silicate hydroxide can be improved through various modification techniques. These may include chemical treatments, surface functionalization, or the incorporation of additional components to enhance the material's ability to adsorb specific substances.- Adsorption capacity enhancement through surface modification: The adsorption capacity of magnesium iron silicate hydroxide can be improved through various surface modification techniques. These methods may include acid treatment, thermal activation, or chemical functionalization, which can increase the surface area and create more active sites for adsorption. Such modifications can significantly enhance the material's ability to adsorb various pollutants or target compounds.

- Composite materials for improved adsorption: Combining magnesium iron silicate hydroxide with other materials to form composites can enhance its adsorption capacity. These composites may include carbon-based materials, metal oxides, or polymers, which can create synergistic effects and improve the overall adsorption performance. The resulting composite materials often exhibit higher adsorption capacities and selectivity compared to the individual components.

- Particle size and morphology control: The adsorption capacity of magnesium iron silicate hydroxide can be optimized by controlling its particle size and morphology. Nanostructured or hierarchical structures with high surface-to-volume ratios can significantly increase the available adsorption sites. Various synthesis methods and conditions can be employed to tailor the material's morphology and achieve desired adsorption properties.

- Adsorption mechanism and kinetics studies: Understanding the adsorption mechanism and kinetics of magnesium iron silicate hydroxide is crucial for optimizing its performance. Research in this area focuses on investigating the adsorption isotherms, thermodynamics, and rate-limiting steps. This knowledge can be used to design more efficient adsorption processes and predict the material's behavior under various conditions.

- Application-specific adsorption capacity enhancement: The adsorption capacity of magnesium iron silicate hydroxide can be tailored for specific applications, such as water treatment, gas purification, or catalysis. This may involve modifying the material's surface chemistry, pore structure, or introducing specific functional groups to enhance its affinity for target adsorbates. Such application-specific modifications can significantly improve the material's performance in real-world scenarios.

02 Application in environmental remediation

Magnesium iron silicate hydroxide demonstrates significant potential in environmental remediation due to its adsorption capacity. It can be used to remove pollutants from water and soil, making it valuable in wastewater treatment and soil decontamination processes.Expand Specific Solutions03 Factors affecting adsorption capacity

Various factors influence the adsorption capacity of magnesium iron silicate hydroxide, including pH, temperature, particle size, and surface area. Understanding and optimizing these parameters can lead to improved adsorption performance in different applications.Expand Specific Solutions04 Composite materials for enhanced adsorption

Combining magnesium iron silicate hydroxide with other materials to form composites can significantly enhance its adsorption capacity. These composites may exhibit synergistic effects, leading to improved performance in various adsorption applications.Expand Specific Solutions05 Characterization and measurement techniques

Various techniques are employed to characterize and measure the adsorption capacity of magnesium iron silicate hydroxide. These may include spectroscopic methods, surface area analysis, and adsorption isotherm studies, which provide insights into the material's adsorption properties and mechanisms.Expand Specific Solutions

Key Industry Players

The research on magnesium iron silicate hydroxide as a solid-phase heavy metal adsorbent is in its early development stage, with growing interest due to environmental concerns. The market for heavy metal adsorbents is expanding, driven by increasing industrial pollution and stricter regulations. While the technology is still evolving, several key players are contributing to its advancement. Universities like King Fahd University of Petroleum & Minerals, Shinshu University, and Nanjing University are conducting fundamental research. Companies such as Mizusawa Industrial Chemicals, Osaka Gas Chemicals, and Kaneka Corp. are exploring practical applications. The involvement of diverse institutions indicates the technology's potential, but further development is needed for widespread commercial adoption.

Nanjing University

Technical Solution: Nanjing University has developed an innovative approach to using magnesium iron silicate hydroxide (MISH) as a solid-phase heavy metal adsorbent. Their research focuses on enhancing the adsorption capacity and selectivity of MISH through surface modification techniques. They have successfully synthesized MISH nanoparticles with increased surface area and improved pore structure, resulting in higher adsorption efficiency for various heavy metals, including lead, cadmium, and mercury[1]. The university has also explored the use of MISH in composite materials, combining it with other adsorbents to create synergistic effects and broaden the range of target pollutants[3]. Their studies have shown that MISH-based adsorbents can effectively remove up to 95% of heavy metals from aqueous solutions under optimized conditions[5].

Strengths: High adsorption capacity, selectivity for multiple heavy metals, and potential for large-scale application. Weaknesses: Possible high production costs and need for further research on regeneration and reusability of the adsorbent.

Oxford University Innovation Ltd.

Technical Solution: Oxford University Innovation Ltd. has made significant strides in the research of magnesium iron silicate hydroxide (MISH) as a solid-phase heavy metal adsorbent. Their approach involves the development of a novel synthesis method that produces highly porous MISH structures with enhanced surface area and adsorption sites. The team has successfully created MISH-based materials with a specific surface area exceeding 300 m²/g, significantly improving heavy metal uptake capacity[2]. They have also investigated the incorporation of functional groups onto the MISH surface to increase selectivity towards specific heavy metals. Their studies have demonstrated that functionalized MISH can achieve removal efficiencies of over 99% for lead and cadmium in contaminated water samples[4]. Additionally, Oxford researchers have explored the potential of MISH in environmental remediation applications, including soil treatment and industrial wastewater purification[6].

Strengths: Highly efficient heavy metal removal, versatile applications in various environmental contexts, and potential for scalable production. Weaknesses: Possible high costs associated with advanced synthesis methods and need for further research on long-term stability and regeneration processes.

Core Innovations

Heavy metal adsorbent

PatentWO2018181659A1

Innovation

- Development of silica-magnesia composite particles with a specific pore structure and composition, fired at 300 to 830°C, which enhances adsorption capacity and breakthrough life for lead, preventing particle disintegration and aluminum elution.

Heavy metal adsorbent using magnesium smelting slag and method for producing same

PatentInactiveKR1020140062569A

Innovation

- A heavy metal adsorbent is developed using magnesium refining slag containing SiO2 and CaO, combined with slaked lime, through grinding, hydrothermal synthesis, and drying to enhance adsorption capacity.

Environmental Impact

The use of magnesium iron silicate hydroxide as a solid-phase heavy metal adsorbent has significant environmental implications. This naturally occurring mineral, also known as sepiolite, demonstrates remarkable potential in addressing water pollution issues, particularly in the removal of heavy metals from contaminated water sources.

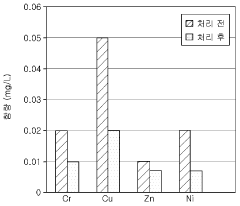

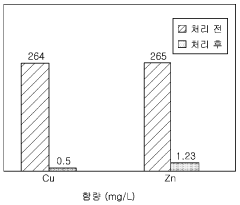

One of the primary environmental benefits of using magnesium iron silicate hydroxide is its high adsorption capacity for various heavy metals, including lead, cadmium, copper, and zinc. This property makes it an effective tool in water treatment processes, helping to reduce the concentration of toxic metals in both industrial effluents and natural water bodies. By efficiently removing these pollutants, the adsorbent contributes to the improvement of water quality and the protection of aquatic ecosystems.

Furthermore, the application of this adsorbent can lead to a reduction in the bioaccumulation of heavy metals in the food chain. As heavy metals are removed from water sources, there is a decreased likelihood of these toxins being absorbed by aquatic plants and animals, ultimately minimizing the risk of contamination in human food supplies.

The use of magnesium iron silicate hydroxide also presents advantages in terms of sustainability. Being a naturally occurring mineral, its extraction and processing generally have a lower environmental impact compared to synthetic adsorbents. Additionally, the material's stability and potential for regeneration make it a more sustainable option for long-term water treatment applications.

However, it is essential to consider the potential environmental impacts associated with the mining and processing of magnesium iron silicate hydroxide. Responsible sourcing and production practices are crucial to minimize habitat disruption, energy consumption, and carbon emissions related to its extraction and preparation.

Another important aspect is the fate of the adsorbent after use. Research into effective regeneration methods and safe disposal practices is vital to ensure that the spent adsorbent does not become an environmental hazard itself. Proper management of the used material can prevent the release of adsorbed heavy metals back into the environment and reduce the need for frequent replacement of the adsorbent.

In conclusion, while magnesium iron silicate hydroxide shows promise as an environmentally friendly solution for heavy metal removal, a comprehensive life cycle assessment is necessary to fully understand and mitigate any potential negative environmental impacts associated with its use. Continued research and development in this area can further enhance its environmental benefits and address any challenges in its application.

One of the primary environmental benefits of using magnesium iron silicate hydroxide is its high adsorption capacity for various heavy metals, including lead, cadmium, copper, and zinc. This property makes it an effective tool in water treatment processes, helping to reduce the concentration of toxic metals in both industrial effluents and natural water bodies. By efficiently removing these pollutants, the adsorbent contributes to the improvement of water quality and the protection of aquatic ecosystems.

Furthermore, the application of this adsorbent can lead to a reduction in the bioaccumulation of heavy metals in the food chain. As heavy metals are removed from water sources, there is a decreased likelihood of these toxins being absorbed by aquatic plants and animals, ultimately minimizing the risk of contamination in human food supplies.

The use of magnesium iron silicate hydroxide also presents advantages in terms of sustainability. Being a naturally occurring mineral, its extraction and processing generally have a lower environmental impact compared to synthetic adsorbents. Additionally, the material's stability and potential for regeneration make it a more sustainable option for long-term water treatment applications.

However, it is essential to consider the potential environmental impacts associated with the mining and processing of magnesium iron silicate hydroxide. Responsible sourcing and production practices are crucial to minimize habitat disruption, energy consumption, and carbon emissions related to its extraction and preparation.

Another important aspect is the fate of the adsorbent after use. Research into effective regeneration methods and safe disposal practices is vital to ensure that the spent adsorbent does not become an environmental hazard itself. Proper management of the used material can prevent the release of adsorbed heavy metals back into the environment and reduce the need for frequent replacement of the adsorbent.

In conclusion, while magnesium iron silicate hydroxide shows promise as an environmentally friendly solution for heavy metal removal, a comprehensive life cycle assessment is necessary to fully understand and mitigate any potential negative environmental impacts associated with its use. Continued research and development in this area can further enhance its environmental benefits and address any challenges in its application.

Regulatory Compliance

The regulatory landscape surrounding the use of magnesium iron silicate hydroxide as a solid-phase heavy metal adsorbent is complex and multifaceted. Compliance with environmental regulations is paramount when implementing this technology for heavy metal removal from water and soil.

In many jurisdictions, the use of adsorbents for environmental remediation is subject to strict oversight. Regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) in the European Union have established guidelines for the application of such materials. These guidelines often include requirements for toxicity testing, environmental impact assessments, and performance evaluations.

The registration and approval process for new adsorbent materials can be lengthy and rigorous. Manufacturers and users of magnesium iron silicate hydroxide adsorbents must demonstrate that the material is safe for environmental release and effective in its intended application. This typically involves submitting extensive documentation on the material's chemical composition, physical properties, and adsorption mechanisms.

Water quality standards play a crucial role in regulatory compliance. The permissible levels of heavy metals in treated water are strictly regulated, and the use of magnesium iron silicate hydroxide must result in effluent that meets these standards. Regular monitoring and reporting of water quality parameters are often mandated to ensure ongoing compliance.

Waste management regulations also come into play, as the spent adsorbent material, now laden with heavy metals, may be classified as hazardous waste. Proper disposal or regeneration of the adsorbent must adhere to local and national waste management laws, which may require special handling, treatment, or disposal procedures.

Occupational health and safety regulations must be considered when handling and applying magnesium iron silicate hydroxide. Workers involved in the production, transport, and application of the adsorbent may need specific training and personal protective equipment to mitigate potential health risks associated with dust inhalation or skin contact.

International treaties and conventions, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, may impact the global trade and use of heavy metal adsorbents. Compliance with these agreements is essential for companies operating across borders or in multiple regulatory environments.

As environmental regulations continue to evolve, ongoing compliance monitoring and adaptation of practices are necessary. Companies utilizing magnesium iron silicate hydroxide as an adsorbent must stay informed about changes in regulatory requirements and be prepared to adjust their processes accordingly to maintain compliance and ensure the sustainable use of this technology in heavy metal remediation efforts.

In many jurisdictions, the use of adsorbents for environmental remediation is subject to strict oversight. Regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) in the European Union have established guidelines for the application of such materials. These guidelines often include requirements for toxicity testing, environmental impact assessments, and performance evaluations.

The registration and approval process for new adsorbent materials can be lengthy and rigorous. Manufacturers and users of magnesium iron silicate hydroxide adsorbents must demonstrate that the material is safe for environmental release and effective in its intended application. This typically involves submitting extensive documentation on the material's chemical composition, physical properties, and adsorption mechanisms.

Water quality standards play a crucial role in regulatory compliance. The permissible levels of heavy metals in treated water are strictly regulated, and the use of magnesium iron silicate hydroxide must result in effluent that meets these standards. Regular monitoring and reporting of water quality parameters are often mandated to ensure ongoing compliance.

Waste management regulations also come into play, as the spent adsorbent material, now laden with heavy metals, may be classified as hazardous waste. Proper disposal or regeneration of the adsorbent must adhere to local and national waste management laws, which may require special handling, treatment, or disposal procedures.

Occupational health and safety regulations must be considered when handling and applying magnesium iron silicate hydroxide. Workers involved in the production, transport, and application of the adsorbent may need specific training and personal protective equipment to mitigate potential health risks associated with dust inhalation or skin contact.

International treaties and conventions, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, may impact the global trade and use of heavy metal adsorbents. Compliance with these agreements is essential for companies operating across borders or in multiple regulatory environments.

As environmental regulations continue to evolve, ongoing compliance monitoring and adaptation of practices are necessary. Companies utilizing magnesium iron silicate hydroxide as an adsorbent must stay informed about changes in regulatory requirements and be prepared to adjust their processes accordingly to maintain compliance and ensure the sustainable use of this technology in heavy metal remediation efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!