Research on microstructure evolution in hot-dip zinc coatings

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hot-Dip Zinc Coating Background and Objectives

Hot-dip galvanizing technology has evolved significantly since its initial industrial application in the 19th century. This surface treatment process, which involves immersing steel components in molten zinc to form protective coatings, has become fundamental to corrosion prevention across multiple industries. The historical progression of this technology has been marked by continuous improvements in bath composition, process parameters, and understanding of the underlying metallurgical reactions.

The microstructure evolution in hot-dip zinc coatings represents a complex interplay of thermodynamics, kinetics, and diffusion phenomena. Initially viewed as a simple dipping process, modern understanding reveals sophisticated phase transformations occurring at the steel-zinc interface. These transformations critically influence coating properties including adhesion strength, corrosion resistance, and mechanical performance.

Recent technological trends indicate a shift toward more sophisticated control of the coating microstructure through precise manipulation of bath chemistry, immersion parameters, and post-treatment processes. The addition of alloying elements such as aluminum, magnesium, and silicon has emerged as a significant advancement, enabling tailored coating properties for specific applications.

The global push toward sustainability and reduced environmental impact has also influenced the evolution of hot-dip galvanizing technology. Research efforts increasingly focus on developing zinc coatings that maintain or enhance performance while reducing zinc consumption and minimizing environmental footprint. This includes exploration of thinner coatings with optimized microstructures that maintain equivalent protection.

The primary technical objectives in this field include developing comprehensive models of microstructure evolution during the coating process, understanding the influence of process parameters on phase formation and distribution, and establishing correlations between microstructural features and coating performance. Additionally, there is significant interest in real-time monitoring and control systems that can adapt process parameters to achieve consistent microstructural outcomes.

Another critical objective involves addressing challenges related to coating high-strength steels and advanced materials, where traditional galvanizing processes may lead to undesirable microstructural features or hydrogen embrittlement. The development of specialized processes for these materials represents a frontier in hot-dip coating technology.

The convergence of computational modeling, advanced characterization techniques, and in-situ monitoring capabilities has created unprecedented opportunities for understanding and controlling microstructure evolution in zinc coatings, potentially leading to next-generation protective systems with enhanced performance and sustainability profiles.

The microstructure evolution in hot-dip zinc coatings represents a complex interplay of thermodynamics, kinetics, and diffusion phenomena. Initially viewed as a simple dipping process, modern understanding reveals sophisticated phase transformations occurring at the steel-zinc interface. These transformations critically influence coating properties including adhesion strength, corrosion resistance, and mechanical performance.

Recent technological trends indicate a shift toward more sophisticated control of the coating microstructure through precise manipulation of bath chemistry, immersion parameters, and post-treatment processes. The addition of alloying elements such as aluminum, magnesium, and silicon has emerged as a significant advancement, enabling tailored coating properties for specific applications.

The global push toward sustainability and reduced environmental impact has also influenced the evolution of hot-dip galvanizing technology. Research efforts increasingly focus on developing zinc coatings that maintain or enhance performance while reducing zinc consumption and minimizing environmental footprint. This includes exploration of thinner coatings with optimized microstructures that maintain equivalent protection.

The primary technical objectives in this field include developing comprehensive models of microstructure evolution during the coating process, understanding the influence of process parameters on phase formation and distribution, and establishing correlations between microstructural features and coating performance. Additionally, there is significant interest in real-time monitoring and control systems that can adapt process parameters to achieve consistent microstructural outcomes.

Another critical objective involves addressing challenges related to coating high-strength steels and advanced materials, where traditional galvanizing processes may lead to undesirable microstructural features or hydrogen embrittlement. The development of specialized processes for these materials represents a frontier in hot-dip coating technology.

The convergence of computational modeling, advanced characterization techniques, and in-situ monitoring capabilities has created unprecedented opportunities for understanding and controlling microstructure evolution in zinc coatings, potentially leading to next-generation protective systems with enhanced performance and sustainability profiles.

Market Analysis of Zinc Coating Applications

The global zinc coating market has demonstrated robust growth over the past decade, with a market value reaching $25.6 billion in 2022. This growth trajectory is expected to continue, with projections indicating a compound annual growth rate (CAGR) of 5.2% through 2030. The automotive industry remains the largest consumer of hot-dip galvanized products, accounting for approximately 30% of total market share, followed by construction (25%), infrastructure (20%), and consumer appliances (15%).

Regional analysis reveals that Asia-Pacific dominates the zinc coating market, representing 45% of global consumption, with China alone accounting for 28% of worldwide demand. North America and Europe follow with 22% and 20% market shares respectively. Emerging economies in South America and Africa are showing accelerated adoption rates, with annual growth exceeding 7% in these regions.

The market demand for advanced zinc coatings is increasingly driven by stringent anti-corrosion requirements across industries. Automotive manufacturers, particularly in premium segments, are demanding zinc coatings with enhanced microstructural properties that can withstand more aggressive environmental conditions while maintaining aesthetic appeal. The construction sector's shift toward longer-lasting building materials has similarly boosted demand for high-performance zinc coatings with controlled microstructure.

Environmental regulations have become a significant market driver, with regulations like the EU's REACH and similar frameworks in North America and Asia pushing for more environmentally sustainable coating processes. This has accelerated research into zinc coating microstructures that can deliver equivalent or superior performance with reduced coating thickness and lower energy consumption during application.

The market is witnessing a notable trend toward value-added zinc coatings with specialized microstructures. Premium zinc-aluminum-magnesium coatings, which offer superior corrosion resistance through optimized microstructural properties, have seen a market growth rate of 8.3% annually, outpacing traditional galvanized products. These advanced coatings command price premiums of 15-20% over conventional alternatives.

Industry surveys indicate that end-users are increasingly willing to pay premium prices for zinc coatings with documented microstructural optimization that translates to extended service life. This trend is particularly pronounced in marine applications, where the cost of maintenance and replacement is exceptionally high, creating a specialized market segment growing at 9.1% annually.

The competitive landscape shows increasing investment in research capabilities focused on microstructure control technologies, with major steel producers allocating an average of 3.7% of revenue to R&D in coating technologies, up from 2.5% five years ago.

Regional analysis reveals that Asia-Pacific dominates the zinc coating market, representing 45% of global consumption, with China alone accounting for 28% of worldwide demand. North America and Europe follow with 22% and 20% market shares respectively. Emerging economies in South America and Africa are showing accelerated adoption rates, with annual growth exceeding 7% in these regions.

The market demand for advanced zinc coatings is increasingly driven by stringent anti-corrosion requirements across industries. Automotive manufacturers, particularly in premium segments, are demanding zinc coatings with enhanced microstructural properties that can withstand more aggressive environmental conditions while maintaining aesthetic appeal. The construction sector's shift toward longer-lasting building materials has similarly boosted demand for high-performance zinc coatings with controlled microstructure.

Environmental regulations have become a significant market driver, with regulations like the EU's REACH and similar frameworks in North America and Asia pushing for more environmentally sustainable coating processes. This has accelerated research into zinc coating microstructures that can deliver equivalent or superior performance with reduced coating thickness and lower energy consumption during application.

The market is witnessing a notable trend toward value-added zinc coatings with specialized microstructures. Premium zinc-aluminum-magnesium coatings, which offer superior corrosion resistance through optimized microstructural properties, have seen a market growth rate of 8.3% annually, outpacing traditional galvanized products. These advanced coatings command price premiums of 15-20% over conventional alternatives.

Industry surveys indicate that end-users are increasingly willing to pay premium prices for zinc coatings with documented microstructural optimization that translates to extended service life. This trend is particularly pronounced in marine applications, where the cost of maintenance and replacement is exceptionally high, creating a specialized market segment growing at 9.1% annually.

The competitive landscape shows increasing investment in research capabilities focused on microstructure control technologies, with major steel producers allocating an average of 3.7% of revenue to R&D in coating technologies, up from 2.5% five years ago.

Current Challenges in Microstructure Control

Despite significant advancements in hot-dip galvanizing technology, controlling the microstructure evolution in zinc coatings remains a formidable challenge for researchers and industry practitioners. One of the primary difficulties lies in the complex intermetallic phase formation at the steel-zinc interface, which significantly influences coating properties but is notoriously difficult to predict and control. The Fe-Zn intermetallic compounds (Γ, Γ1, δ, and ζ phases) form rapidly during the immersion process, with their growth kinetics being highly sensitive to multiple processing parameters.

Temperature fluctuations during the galvanizing process present another substantial challenge. Even minor deviations from optimal dipping temperatures can dramatically alter the microstructure development, leading to inconsistent coating quality across production batches. This temperature sensitivity is particularly problematic in industrial settings where maintaining precise thermal conditions throughout large galvanizing baths is technically demanding.

The chemical composition of the zinc bath introduces additional complexity to microstructure control. Modern galvanizing operations frequently incorporate alloying elements such as aluminum, magnesium, and silicon to enhance specific coating properties. However, these additions create intricate thermodynamic and kinetic interactions that can produce unexpected microstructural features. The synergistic effects between multiple alloying elements remain inadequately understood, limiting the ability to design optimal bath compositions for specific applications.

Surface condition of the steel substrate represents another critical challenge. Pre-existing oxides, surface roughness variations, and chemical contaminants can significantly alter nucleation and growth patterns during zinc coating formation. These substrate-related factors often lead to heterogeneous microstructure development across the coated surface, compromising coating uniformity and performance consistency.

Cooling rate control after withdrawal from the zinc bath constitutes a frequently overlooked challenge. The solidification behavior of the coating during this stage substantially influences the final grain structure, texture development, and defect formation. Current industrial practices typically lack sophisticated cooling control mechanisms, resulting in microstructural variations that affect coating ductility and corrosion resistance.

Advanced characterization limitations further impede progress in this field. While techniques like electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM) provide valuable insights, they often require extensive sample preparation and offer limited in-situ capabilities. This creates a significant gap between laboratory understanding and real-time industrial process monitoring, making it difficult to implement knowledge-based microstructure control strategies in production environments.

Temperature fluctuations during the galvanizing process present another substantial challenge. Even minor deviations from optimal dipping temperatures can dramatically alter the microstructure development, leading to inconsistent coating quality across production batches. This temperature sensitivity is particularly problematic in industrial settings where maintaining precise thermal conditions throughout large galvanizing baths is technically demanding.

The chemical composition of the zinc bath introduces additional complexity to microstructure control. Modern galvanizing operations frequently incorporate alloying elements such as aluminum, magnesium, and silicon to enhance specific coating properties. However, these additions create intricate thermodynamic and kinetic interactions that can produce unexpected microstructural features. The synergistic effects between multiple alloying elements remain inadequately understood, limiting the ability to design optimal bath compositions for specific applications.

Surface condition of the steel substrate represents another critical challenge. Pre-existing oxides, surface roughness variations, and chemical contaminants can significantly alter nucleation and growth patterns during zinc coating formation. These substrate-related factors often lead to heterogeneous microstructure development across the coated surface, compromising coating uniformity and performance consistency.

Cooling rate control after withdrawal from the zinc bath constitutes a frequently overlooked challenge. The solidification behavior of the coating during this stage substantially influences the final grain structure, texture development, and defect formation. Current industrial practices typically lack sophisticated cooling control mechanisms, resulting in microstructural variations that affect coating ductility and corrosion resistance.

Advanced characterization limitations further impede progress in this field. While techniques like electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM) provide valuable insights, they often require extensive sample preparation and offer limited in-situ capabilities. This creates a significant gap between laboratory understanding and real-time industrial process monitoring, making it difficult to implement knowledge-based microstructure control strategies in production environments.

Current Methodologies for Microstructure Analysis

01 Microstructure control in hot-dip zinc coatings

The microstructure of hot-dip zinc coatings can be controlled through various processing parameters such as bath composition, immersion time, and cooling rate. Controlling these parameters allows for the formation of specific intermetallic phases and grain structures that influence the coating's properties. Proper microstructure control can lead to improved corrosion resistance, adhesion, and mechanical properties of the zinc coating.- Microstructure control in hot-dip zinc coatings: The microstructure of hot-dip zinc coatings can be controlled through various processing parameters such as bath composition, immersion time, and cooling rate. By manipulating these parameters, specific microstructural features can be achieved, including grain size, phase distribution, and intermetallic compound formation. Controlled microstructure leads to improved coating properties such as corrosion resistance, adhesion, and mechanical performance.

- Influence of alloying elements on zinc coating microstructure: Alloying elements added to the zinc bath significantly affect the resulting coating microstructure. Elements such as aluminum, magnesium, silicon, and rare earth metals can modify the growth and morphology of intermetallic phases. These additions can refine grain structure, inhibit undesirable phase formation, and promote the development of beneficial microstructural features that enhance coating performance and durability.

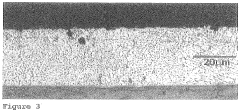

- Intermetallic phase formation in zinc coatings: During the hot-dip galvanizing process, various intermetallic phases form at the interface between the zinc coating and the steel substrate. These phases, including Fe-Zn compounds like gamma, delta, and zeta phases, have distinct crystallographic structures and properties. The distribution, thickness, and morphology of these intermetallic layers significantly influence the coating's adhesion, formability, and corrosion protection capabilities.

- Effect of substrate composition and surface preparation on coating microstructure: The composition and surface condition of the steel substrate play crucial roles in determining the microstructure of hot-dip zinc coatings. Factors such as carbon content, presence of alloying elements in the steel, surface roughness, and pre-treatment processes affect the nucleation and growth of zinc crystals and intermetallic compounds. Proper surface preparation ensures uniform coating microstructure and optimal adhesion.

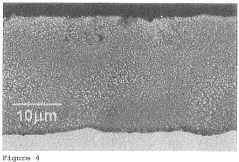

- Advanced characterization techniques for zinc coating microstructure: Various analytical techniques are employed to characterize the microstructure of hot-dip zinc coatings. These include scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), and electron backscatter diffraction (EBSD). These methods provide detailed information about grain size, phase distribution, crystallographic orientation, and chemical composition, enabling better understanding and optimization of coating microstructures for specific applications.

02 Alloying elements effect on zinc coating microstructure

The addition of alloying elements such as aluminum, magnesium, silicon, and rare earth metals to the zinc bath significantly influences the microstructure of hot-dip coatings. These elements can modify the growth of intermetallic phases, refine grain size, and alter the morphology of the coating. Different alloying elements produce distinct microstructural features that can be tailored for specific applications and performance requirements.Expand Specific Solutions03 Intermetallic phase formation in zinc coatings

Hot-dip zinc coatings typically form multiple intermetallic phases at the interface between the zinc coating and the steel substrate. These phases include eta (pure zinc), zeta (FeZn13), delta (FeZn10), and gamma (Fe3Zn10) layers. The thickness, continuity, and morphology of these intermetallic phases significantly impact the coating's performance characteristics, including corrosion resistance, formability, and weldability.Expand Specific Solutions04 Heat treatment effects on zinc coating microstructure

Post-coating heat treatments can significantly modify the microstructure of hot-dip zinc coatings. Annealing processes promote diffusion between the zinc coating and the steel substrate, altering the thickness and composition of intermetallic phases. Controlled heating and cooling cycles can be used to optimize the microstructure for specific performance requirements, such as improved formability or enhanced corrosion resistance.Expand Specific Solutions05 Surface preparation influence on coating microstructure

The surface condition of the steel substrate before hot-dip galvanizing significantly affects the resulting zinc coating microstructure. Proper cleaning, degreasing, pickling, and fluxing treatments ensure uniform wetting and reaction between the molten zinc and the steel surface. Surface roughness, chemical composition, and presence of contaminants can all influence nucleation and growth of zinc crystals, affecting the final microstructure and adhesion of the coating.Expand Specific Solutions

Leading Companies in Zinc Coating Industry

The hot-dip zinc coating microstructure evolution research field is currently in a growth phase, with increasing market demand driven by automotive, construction, and renewable energy sectors. The global market for galvanized steel products is expanding at approximately 5% annually, reaching over $200 billion. Technologically, major steel producers like thyssenkrupp Steel Europe, Baoshan Iron & Steel, Nippon Steel, and JFE Steel are leading innovation through advanced characterization techniques and process optimization. Research institutions including Shanghai Jiao Tong University and Colorado School of Mines are contributing fundamental knowledge, while coating specialists such as Hempel A/S and Wacker Chemie AG are developing enhanced formulations. The field is transitioning from empirical to simulation-based approaches, with digital twin technologies emerging as competitive differentiators.

thyssenkrupp Steel Europe AG

Technical Solution: Thyssenkrupp Steel Europe has developed the "ZincEvolution" technology platform focused on controlling microstructure evolution in hot-dip galvanized coatings. Their approach centers on manipulating the Fe-Zn reaction kinetics through precise control of bath chemistry and immersion parameters. Their research has established critical relationships between substrate steel composition (particularly Si and P content) and the resulting zinc coating microstructure[2]. Thyssenkrupp's innovation includes a proprietary pre-galvanizing annealing process that creates an optimized substrate surface condition with controlled oxide formation, promoting uniform zinc wetting and adhesion[4]. Their technology incorporates carefully calibrated additions of nickel (0.05-0.15%) and vanadium (0.01-0.03%) to the zinc bath, which significantly alters the nucleation and growth behavior of Fe-Zn intermetallic phases, particularly inhibiting the formation of brittle Γ phase while promoting more ductile δ and ζ phases at the coating-substrate interface.

Strengths: Exceptional understanding of the relationship between substrate composition and coating microstructure, allowing for tailored solutions for different steel grades. Their approach enables excellent coating adhesion even on difficult-to-coat high-silicon steels. Weaknesses: Their specialized bath chemistry requires frequent monitoring and adjustment, potentially increasing operational complexity and maintenance requirements.

Baoshan Iron & Steel Co., Ltd.

Technical Solution: Baosteel has developed innovative approaches to microstructure control in hot-dip galvanized coatings through their "Controlled Intermetallic Formation" (CIF) technology. Their research focuses on manipulating the Fe-Zn reaction kinetics by precise control of bath temperature gradients and immersion parameters. Baosteel's proprietary pre-annealing process creates optimized substrate surface conditions that promote uniform nucleation of zinc crystals during immersion[2]. Their technology incorporates carefully calibrated additions of aluminum (0.15-0.25%) and antimony (0.03-0.08%) to the zinc bath to control intermetallic compound growth, particularly targeting the suppression of brittle Fe-Zn phases while promoting the formation of more ductile phases[4]. Baosteel has also pioneered the use of post-galvanizing heat treatments at specific temperature ranges (250-350°C) to transform the coating microstructure, enhancing both corrosion resistance and mechanical properties through controlled phase transformation of the Fe-Zn intermetallics.

Strengths: Exceptional control over Fe-Zn intermetallic compound formation through innovative bath chemistry and post-treatment processes, resulting in superior coating adhesion and formability. Weaknesses: Their approach requires precise control of multiple process variables, making it challenging to maintain consistent quality across different production lines and substrate types.

Key Research Breakthroughs in Zinc Coating

Treating al/ZN-based alloy coated products

PatentActiveNZ573913A

Innovation

- Rapid intense heating of the alloy coating at a rate of at least 500°C/s for a short duration, followed by rapid cooling at a rate of at least 100°C/s, using the substrate as a heat sink to form a modified crystalline microstructure, which can be a single phase or a uniform dispersion of fine particles, thereby minimizing element redistribution and promoting a refined microstructure.

Corrosion Resistance Performance Metrics

Corrosion resistance is a critical performance parameter for hot-dip zinc coatings, directly influencing the service life and reliability of coated steel products. The microstructure evolution during hot-dip galvanizing significantly impacts these corrosion resistance properties, necessitating comprehensive metrics for evaluation and comparison.

Standard accelerated corrosion tests, including salt spray testing (ASTM B117), cyclic corrosion testing (ASTM G85), and electrochemical impedance spectroscopy (EIS), provide quantitative measures of coating performance. These tests evaluate time-to-failure, corrosion rate, and impedance characteristics, offering comparative data across different coating microstructures. The correlation between zinc coating microstructure and these metrics reveals that finer, more uniform intermetallic phases typically demonstrate superior corrosion resistance.

Weight loss measurements during exposure testing represent another fundamental metric, with results typically expressed in grams per square meter per year (g/m²/yr). Research indicates that coatings with optimized Fe-Zn intermetallic distribution can achieve corrosion rates below 5 g/m²/yr in moderate environments, significantly outperforming conventional coatings that may exhibit rates of 15-20 g/m²/yr.

Barrier protection efficiency, measured through porosity assessments and permeability testing, directly correlates with microstructure density and uniformity. Advanced imaging techniques including focused ion beam (FIB) sectioning combined with SEM analysis enable quantification of coating defect density, with high-performance coatings demonstrating defect densities below 5 per cm².

Galvanic protection capacity, a unique property of zinc coatings, can be quantified through sacrificial area ratio measurements and polarization studies. The microstructure evolution during hot-dip processing significantly influences this property, with research showing that controlled cooling rates can enhance sacrificial protection by up to 40% through optimization of active zinc phase distribution.

Environmental performance metrics have gained importance, with coating durability in specific environments (marine, industrial, rural) now standardized through ISO 9223 classification. Microstructure-specific performance mapping reveals that coatings with balanced η-ζ phase distributions demonstrate superior versatility across diverse environmental conditions.

Advanced characterization techniques including localized electrochemical impedance spectroscopy (LEIS) and scanning Kelvin probe force microscopy (SKPFM) now enable site-specific corrosion resistance mapping, providing unprecedented insights into how specific microstructural features contribute to overall protection performance. These techniques have revealed that phase boundary regions often initiate corrosion, highlighting the importance of boundary engineering in next-generation coating development.

Standard accelerated corrosion tests, including salt spray testing (ASTM B117), cyclic corrosion testing (ASTM G85), and electrochemical impedance spectroscopy (EIS), provide quantitative measures of coating performance. These tests evaluate time-to-failure, corrosion rate, and impedance characteristics, offering comparative data across different coating microstructures. The correlation between zinc coating microstructure and these metrics reveals that finer, more uniform intermetallic phases typically demonstrate superior corrosion resistance.

Weight loss measurements during exposure testing represent another fundamental metric, with results typically expressed in grams per square meter per year (g/m²/yr). Research indicates that coatings with optimized Fe-Zn intermetallic distribution can achieve corrosion rates below 5 g/m²/yr in moderate environments, significantly outperforming conventional coatings that may exhibit rates of 15-20 g/m²/yr.

Barrier protection efficiency, measured through porosity assessments and permeability testing, directly correlates with microstructure density and uniformity. Advanced imaging techniques including focused ion beam (FIB) sectioning combined with SEM analysis enable quantification of coating defect density, with high-performance coatings demonstrating defect densities below 5 per cm².

Galvanic protection capacity, a unique property of zinc coatings, can be quantified through sacrificial area ratio measurements and polarization studies. The microstructure evolution during hot-dip processing significantly influences this property, with research showing that controlled cooling rates can enhance sacrificial protection by up to 40% through optimization of active zinc phase distribution.

Environmental performance metrics have gained importance, with coating durability in specific environments (marine, industrial, rural) now standardized through ISO 9223 classification. Microstructure-specific performance mapping reveals that coatings with balanced η-ζ phase distributions demonstrate superior versatility across diverse environmental conditions.

Advanced characterization techniques including localized electrochemical impedance spectroscopy (LEIS) and scanning Kelvin probe force microscopy (SKPFM) now enable site-specific corrosion resistance mapping, providing unprecedented insights into how specific microstructural features contribute to overall protection performance. These techniques have revealed that phase boundary regions often initiate corrosion, highlighting the importance of boundary engineering in next-generation coating development.

Environmental Impact and Sustainability Considerations

The environmental impact of hot-dip galvanizing processes has become increasingly significant as industries worldwide strive for more sustainable manufacturing practices. The zinc coating process, while providing excellent corrosion protection, involves several environmental considerations that must be addressed through comprehensive lifecycle assessment and sustainable innovation.

Traditional hot-dip galvanizing operations consume substantial energy during the heating of zinc baths to temperatures exceeding 450°C. This energy consumption contributes significantly to the carbon footprint of coated steel products. Recent advancements in microstructure control have enabled the development of lower-temperature zinc coating processes, potentially reducing energy requirements by 15-20% while maintaining coating quality and performance characteristics.

Zinc resource management represents another critical environmental concern. The microstructural evolution of zinc coatings directly influences material efficiency, as optimized microstructures can achieve equivalent corrosion protection with reduced coating thickness. Research indicates that advanced microstructure engineering can decrease zinc consumption by up to 25% compared to conventional galvanizing methods, contributing to resource conservation of this finite metal.

Waste management in hot-dip galvanizing presents significant environmental challenges, particularly regarding zinc-containing dross and ash byproducts. Understanding microstructure formation mechanisms has led to improved bath management techniques that minimize dross formation by controlling interfacial reactions between molten zinc and steel substrates. These improvements have demonstrated potential to reduce hazardous waste generation by approximately 30% in industrial applications.

Water pollution concerns arise from pickling and fluxing operations that precede the actual coating process. These chemical treatments influence subsequent microstructure development but can generate contaminated wastewater. Innovative pre-treatment technologies that optimize surface conditions for controlled microstructure growth have shown promise in reducing chemical usage by up to 40% while enhancing coating quality and reducing wastewater treatment requirements.

The longevity of zinc coatings represents a significant sustainability advantage, with properly engineered microstructures extending service life by 15-25 years compared to alternative coating systems. This extended durability translates to reduced maintenance requirements, fewer replacement cycles, and lower lifetime environmental impact. Research focusing on microstructure stability under environmental stressors directly contributes to this sustainability benefit through enhanced long-term performance.

Recycling considerations must also factor into environmental assessments, as zinc-coated products eventually enter waste streams. The microstructure of zinc coatings affects recyclability, with certain intermetallic phases presenting challenges during steel recycling processes. Developing microstructures that maintain protective properties while facilitating end-of-life material recovery represents an emerging research direction with significant environmental implications.

Traditional hot-dip galvanizing operations consume substantial energy during the heating of zinc baths to temperatures exceeding 450°C. This energy consumption contributes significantly to the carbon footprint of coated steel products. Recent advancements in microstructure control have enabled the development of lower-temperature zinc coating processes, potentially reducing energy requirements by 15-20% while maintaining coating quality and performance characteristics.

Zinc resource management represents another critical environmental concern. The microstructural evolution of zinc coatings directly influences material efficiency, as optimized microstructures can achieve equivalent corrosion protection with reduced coating thickness. Research indicates that advanced microstructure engineering can decrease zinc consumption by up to 25% compared to conventional galvanizing methods, contributing to resource conservation of this finite metal.

Waste management in hot-dip galvanizing presents significant environmental challenges, particularly regarding zinc-containing dross and ash byproducts. Understanding microstructure formation mechanisms has led to improved bath management techniques that minimize dross formation by controlling interfacial reactions between molten zinc and steel substrates. These improvements have demonstrated potential to reduce hazardous waste generation by approximately 30% in industrial applications.

Water pollution concerns arise from pickling and fluxing operations that precede the actual coating process. These chemical treatments influence subsequent microstructure development but can generate contaminated wastewater. Innovative pre-treatment technologies that optimize surface conditions for controlled microstructure growth have shown promise in reducing chemical usage by up to 40% while enhancing coating quality and reducing wastewater treatment requirements.

The longevity of zinc coatings represents a significant sustainability advantage, with properly engineered microstructures extending service life by 15-25 years compared to alternative coating systems. This extended durability translates to reduced maintenance requirements, fewer replacement cycles, and lower lifetime environmental impact. Research focusing on microstructure stability under environmental stressors directly contributes to this sustainability benefit through enhanced long-term performance.

Recycling considerations must also factor into environmental assessments, as zinc-coated products eventually enter waste streams. The microstructure of zinc coatings affects recyclability, with certain intermetallic phases presenting challenges during steel recycling processes. Developing microstructures that maintain protective properties while facilitating end-of-life material recovery represents an emerging research direction with significant environmental implications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!