What are the sustainability challenges in zinc coating waste management

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zinc Coating Waste Management Background and Objectives

Zinc coating, primarily in the form of galvanization, has been a cornerstone industrial process for corrosion protection since its commercial development in the 19th century. This technology has evolved significantly over decades, from early hot-dip galvanizing methods to modern continuous galvanizing lines and electroplating techniques. The fundamental principle remains unchanged: applying zinc layers to steel and iron products creates a sacrificial barrier that protects the base metal from environmental degradation.

The waste management challenges associated with zinc coating processes have intensified as global production has expanded. Currently, the global zinc coating industry generates an estimated 1.5-2 million tons of waste annually, including zinc ash, zinc dross, spent pickling solutions, and wastewater containing dissolved zinc compounds. These waste streams present significant environmental hazards if improperly managed, including soil contamination, groundwater pollution, and potential ecological damage.

Historical approaches to zinc coating waste management have predominantly relied on landfill disposal, which fails to address the long-term sustainability concerns and represents a significant loss of valuable zinc resources. The zinc recovery rate from industrial processes globally averages only 30-40%, indicating substantial room for improvement in resource efficiency and circular economy implementation.

The technological evolution in this field is now driven by increasing regulatory pressure, resource scarcity concerns, and growing corporate sustainability commitments. Environmental regulations worldwide, particularly in the EU, North America, and increasingly in Asia, have established stricter parameters for zinc-containing waste disposal, pushing the industry toward more sustainable practices.

The primary objectives of advancing zinc coating waste management technologies include: reducing the environmental footprint of galvanizing operations; increasing zinc recovery rates to above 80%; developing economically viable recycling processes that can be implemented across various scales of operation; and creating closed-loop systems that minimize external waste outputs.

Key technological targets involve the development of more efficient zinc recovery methods from various waste streams, particularly from zinc ash and dross; implementation of advanced filtration and precipitation techniques for zinc-containing wastewater; exploration of novel applications for recovered zinc compounds beyond traditional recycling pathways; and integration of digital monitoring systems to optimize waste management processes in real-time.

The achievement of these objectives would represent a significant shift toward sustainability in an industry that has historically prioritized production efficiency over environmental considerations. The transition requires not only technological innovation but also new business models that recognize recovered zinc and treated waste streams as valuable resources rather than disposal challenges.

The waste management challenges associated with zinc coating processes have intensified as global production has expanded. Currently, the global zinc coating industry generates an estimated 1.5-2 million tons of waste annually, including zinc ash, zinc dross, spent pickling solutions, and wastewater containing dissolved zinc compounds. These waste streams present significant environmental hazards if improperly managed, including soil contamination, groundwater pollution, and potential ecological damage.

Historical approaches to zinc coating waste management have predominantly relied on landfill disposal, which fails to address the long-term sustainability concerns and represents a significant loss of valuable zinc resources. The zinc recovery rate from industrial processes globally averages only 30-40%, indicating substantial room for improvement in resource efficiency and circular economy implementation.

The technological evolution in this field is now driven by increasing regulatory pressure, resource scarcity concerns, and growing corporate sustainability commitments. Environmental regulations worldwide, particularly in the EU, North America, and increasingly in Asia, have established stricter parameters for zinc-containing waste disposal, pushing the industry toward more sustainable practices.

The primary objectives of advancing zinc coating waste management technologies include: reducing the environmental footprint of galvanizing operations; increasing zinc recovery rates to above 80%; developing economically viable recycling processes that can be implemented across various scales of operation; and creating closed-loop systems that minimize external waste outputs.

Key technological targets involve the development of more efficient zinc recovery methods from various waste streams, particularly from zinc ash and dross; implementation of advanced filtration and precipitation techniques for zinc-containing wastewater; exploration of novel applications for recovered zinc compounds beyond traditional recycling pathways; and integration of digital monitoring systems to optimize waste management processes in real-time.

The achievement of these objectives would represent a significant shift toward sustainability in an industry that has historically prioritized production efficiency over environmental considerations. The transition requires not only technological innovation but also new business models that recognize recovered zinc and treated waste streams as valuable resources rather than disposal challenges.

Market Demand for Sustainable Zinc Coating Solutions

The global market for sustainable zinc coating solutions is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability initiatives. The zinc coating industry, valued at approximately $20 billion globally, faces mounting pressure to address waste management challenges. Traditional zinc coating processes generate substantial hazardous waste, including spent acid solutions, zinc-rich sludges, and contaminated rinse waters that pose serious environmental risks when improperly managed.

Industrial sectors including automotive, construction, and infrastructure development represent the largest demand segments for zinc coatings, collectively accounting for over 70% of market consumption. These industries are increasingly seeking sustainable alternatives that minimize environmental impact while maintaining corrosion protection performance. Market research indicates that companies implementing sustainable zinc coating technologies can achieve up to 30% reduction in waste disposal costs and significant improvements in regulatory compliance.

Regulatory frameworks worldwide are becoming more stringent regarding zinc-containing waste disposal. The European Union's Industrial Emissions Directive and the U.S. EPA's Resource Conservation and Recovery Act have established strict guidelines for zinc waste management, creating market pressure for innovative solutions. Countries in Asia, particularly China and India, are also implementing tighter environmental regulations, expanding the global market for sustainable zinc coating technologies.

Consumer and stakeholder expectations are reshaping market dynamics, with sustainability performance increasingly influencing purchasing decisions. Major end-users of zinc-coated products are extending sustainability requirements throughout their supply chains, creating market pull for environmentally responsible coating processes. This trend is particularly evident in the automotive sector, where OEMs are establishing specific sustainability targets for their suppliers.

Emerging market opportunities exist in closed-loop zinc recovery systems, which can reclaim up to 95% of zinc from waste streams for reuse. The market for such recovery technologies is projected to grow at a CAGR of 8.5% through 2028. Additionally, water-based zinc coating formulations are gaining market share, with demand increasing approximately 12% annually as industries seek to reduce volatile organic compound emissions.

Economic factors further support market growth for sustainable solutions, as rising disposal costs for hazardous waste make waste reduction technologies increasingly cost-effective. The return on investment period for advanced zinc recovery systems has decreased from 5-7 years to 2-3 years in many applications, accelerating adoption rates across industrial sectors.

Industrial sectors including automotive, construction, and infrastructure development represent the largest demand segments for zinc coatings, collectively accounting for over 70% of market consumption. These industries are increasingly seeking sustainable alternatives that minimize environmental impact while maintaining corrosion protection performance. Market research indicates that companies implementing sustainable zinc coating technologies can achieve up to 30% reduction in waste disposal costs and significant improvements in regulatory compliance.

Regulatory frameworks worldwide are becoming more stringent regarding zinc-containing waste disposal. The European Union's Industrial Emissions Directive and the U.S. EPA's Resource Conservation and Recovery Act have established strict guidelines for zinc waste management, creating market pressure for innovative solutions. Countries in Asia, particularly China and India, are also implementing tighter environmental regulations, expanding the global market for sustainable zinc coating technologies.

Consumer and stakeholder expectations are reshaping market dynamics, with sustainability performance increasingly influencing purchasing decisions. Major end-users of zinc-coated products are extending sustainability requirements throughout their supply chains, creating market pull for environmentally responsible coating processes. This trend is particularly evident in the automotive sector, where OEMs are establishing specific sustainability targets for their suppliers.

Emerging market opportunities exist in closed-loop zinc recovery systems, which can reclaim up to 95% of zinc from waste streams for reuse. The market for such recovery technologies is projected to grow at a CAGR of 8.5% through 2028. Additionally, water-based zinc coating formulations are gaining market share, with demand increasing approximately 12% annually as industries seek to reduce volatile organic compound emissions.

Economic factors further support market growth for sustainable solutions, as rising disposal costs for hazardous waste make waste reduction technologies increasingly cost-effective. The return on investment period for advanced zinc recovery systems has decreased from 5-7 years to 2-3 years in many applications, accelerating adoption rates across industrial sectors.

Current Challenges in Zinc Waste Treatment Technologies

The zinc coating industry faces significant waste management challenges that threaten environmental sustainability and economic viability. Current zinc waste treatment technologies exhibit several critical limitations that impede effective resource recovery and environmental protection. Traditional hydrometallurgical processes, while common, consume substantial amounts of chemicals and generate secondary waste streams containing heavy metals and acidic compounds that require additional treatment.

Physical separation methods such as filtration and sedimentation demonstrate inadequate efficiency for complex zinc-containing waste matrices, particularly when dealing with mixed metal contaminants. These methods often fail to achieve the purity levels required for zinc recovery and reuse in industrial applications, resulting in downcycling rather than true circular economy solutions.

Pyrometallurgical approaches, including thermal treatment and incineration, present concerning energy consumption profiles with substantial carbon footprints. The high-temperature operations necessary for zinc recovery from coating waste demand significant energy inputs, contradicting sustainability objectives. Additionally, these processes can release harmful emissions including volatile organic compounds and particulate matter containing heavy metals.

Chemical precipitation techniques currently employed face challenges in selectivity when treating mixed-metal waste streams typical in zinc coating operations. The resulting sludge often contains multiple metal hydroxides that complicate downstream processing and limit the economic value of recovered materials. Furthermore, these processes typically require precise pH control and substantial chemical inputs.

Electrochemical recovery methods show promise but remain limited by high electricity consumption and electrode fouling issues when processing complex industrial waste streams. Current electrode materials and cell designs have not achieved the durability and efficiency required for widespread industrial implementation, particularly at scales relevant to large coating operations.

Biological treatment approaches using microorganisms for zinc recovery demonstrate slow kinetics and sensitivity to process conditions that restrict their industrial applicability. While laboratory studies show potential, scaling these technologies to handle industrial volumes of zinc coating waste remains challenging due to variable waste composition and the presence of inhibitory compounds.

Regulatory compliance presents another significant challenge, as increasingly stringent environmental standards worldwide require more comprehensive treatment solutions. Many existing technologies fail to meet emerging limits for effluent quality and solid waste characteristics, creating compliance risks for zinc coating operations. This regulatory landscape is driving the need for more advanced, integrated treatment approaches that can address multiple contaminants simultaneously while recovering valuable resources.

Physical separation methods such as filtration and sedimentation demonstrate inadequate efficiency for complex zinc-containing waste matrices, particularly when dealing with mixed metal contaminants. These methods often fail to achieve the purity levels required for zinc recovery and reuse in industrial applications, resulting in downcycling rather than true circular economy solutions.

Pyrometallurgical approaches, including thermal treatment and incineration, present concerning energy consumption profiles with substantial carbon footprints. The high-temperature operations necessary for zinc recovery from coating waste demand significant energy inputs, contradicting sustainability objectives. Additionally, these processes can release harmful emissions including volatile organic compounds and particulate matter containing heavy metals.

Chemical precipitation techniques currently employed face challenges in selectivity when treating mixed-metal waste streams typical in zinc coating operations. The resulting sludge often contains multiple metal hydroxides that complicate downstream processing and limit the economic value of recovered materials. Furthermore, these processes typically require precise pH control and substantial chemical inputs.

Electrochemical recovery methods show promise but remain limited by high electricity consumption and electrode fouling issues when processing complex industrial waste streams. Current electrode materials and cell designs have not achieved the durability and efficiency required for widespread industrial implementation, particularly at scales relevant to large coating operations.

Biological treatment approaches using microorganisms for zinc recovery demonstrate slow kinetics and sensitivity to process conditions that restrict their industrial applicability. While laboratory studies show potential, scaling these technologies to handle industrial volumes of zinc coating waste remains challenging due to variable waste composition and the presence of inhibitory compounds.

Regulatory compliance presents another significant challenge, as increasingly stringent environmental standards worldwide require more comprehensive treatment solutions. Many existing technologies fail to meet emerging limits for effluent quality and solid waste characteristics, creating compliance risks for zinc coating operations. This regulatory landscape is driving the need for more advanced, integrated treatment approaches that can address multiple contaminants simultaneously while recovering valuable resources.

Existing Zinc Waste Recovery and Treatment Methods

01 Recycling and recovery of zinc from coating waste

Various methods for recycling and recovering zinc from coating waste streams to reduce environmental impact and conserve resources. These processes involve collection, separation, and treatment of zinc-containing waste materials from galvanizing operations. The recovered zinc can be reused in new coating applications, creating a circular economy approach that significantly reduces the need for virgin zinc mining and processing.- Recycling and recovery of zinc from coating waste: Various methods for recycling and recovering zinc from coating waste streams to reduce environmental impact and conserve resources. These processes involve collection, separation, and treatment of zinc-containing waste to extract and reuse the valuable metal, thereby reducing the need for virgin zinc mining and processing. The recovered zinc can be reintroduced into the manufacturing process, creating a circular economy approach to zinc coating operations.

- Sustainable zinc coating processes and formulations: Development of environmentally friendly zinc coating processes and formulations that reduce waste generation and environmental impact. These innovations include water-based coating systems, powder coating technologies, and formulations with reduced volatile organic compounds. The sustainable processes often incorporate energy-efficient application methods and curing techniques that minimize resource consumption while maintaining or improving coating performance and durability.

- Waste treatment and detoxification systems: Specialized systems and methods for treating and detoxifying zinc coating waste before disposal or discharge. These systems typically involve chemical, physical, or biological treatment processes to neutralize harmful components, reduce toxicity, and ensure compliance with environmental regulations. Advanced treatment technologies may include precipitation, filtration, ion exchange, and membrane separation to remove zinc and other heavy metals from wastewater and solid waste streams.

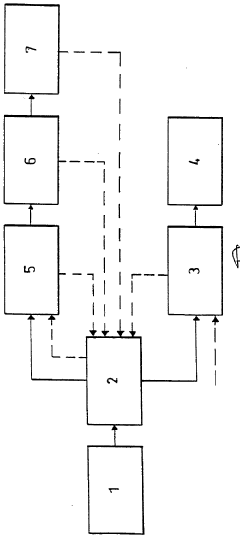

- Monitoring and management systems for zinc waste: Digital solutions and management systems for tracking, monitoring, and optimizing zinc waste handling throughout the coating process. These systems incorporate sensors, data analytics, and automation to provide real-time monitoring of waste generation, treatment efficiency, and environmental compliance. Advanced management approaches may include predictive maintenance, process optimization algorithms, and decision support tools to minimize waste generation and maximize resource efficiency.

- Life cycle assessment and sustainability metrics for zinc coating: Methodologies and frameworks for evaluating the environmental impact and sustainability of zinc coating processes throughout their life cycle. These approaches consider raw material extraction, manufacturing, use phase, and end-of-life management to quantify environmental footprints and identify improvement opportunities. Sustainability metrics may include carbon footprint, water usage, waste generation, and resource efficiency indicators that help manufacturers benchmark performance and communicate environmental benefits to stakeholders.

02 Sustainable zinc coating processes and formulations

Development of environmentally friendly zinc coating processes and formulations that minimize waste generation and reduce environmental impact. These innovations include water-based zinc coating systems, powder coating technologies, and low-VOC formulations that maintain performance while reducing hazardous waste. Advanced application methods also help optimize zinc usage and minimize overspray and material waste during the coating process.Expand Specific Solutions03 Treatment and disposal of zinc coating waste

Methods for treating and safely disposing of zinc coating waste that cannot be recycled. These approaches include chemical stabilization, solidification, and encapsulation techniques to prevent zinc leaching into the environment. Advanced waste treatment systems neutralize hazardous components and convert waste into less harmful forms before disposal in specially designed landfills or containment facilities that prevent environmental contamination.Expand Specific Solutions04 Monitoring and management systems for zinc waste

Digital systems and technologies for monitoring and managing zinc coating waste throughout its lifecycle. These include tracking systems, data analytics platforms, and integrated management software that help companies monitor waste generation, optimize collection processes, and ensure regulatory compliance. Real-time monitoring capabilities allow for immediate intervention when waste parameters exceed acceptable thresholds, preventing environmental incidents.Expand Specific Solutions05 Zero-waste and circular economy approaches for zinc coating

Comprehensive strategies and systems designed to achieve zero-waste goals in zinc coating operations through circular economy principles. These approaches integrate product design, process optimization, waste minimization, and material recovery to create closed-loop systems. By redesigning products and processes to facilitate disassembly and material recovery, these systems maximize the value of zinc resources while minimizing environmental impact throughout the entire product lifecycle.Expand Specific Solutions

Key Industry Players in Zinc Coating Recycling

The zinc coating waste management sector is currently in a growth phase, with increasing market size driven by stringent environmental regulations and sustainability concerns. The global market is expanding as industries seek efficient waste management solutions to reduce environmental impact and recover valuable materials. Leading companies like Umicore Building Products, Glencore Technology, and Trez SA are advancing mature recycling technologies, while research institutions such as Xiamen University, Central South University, and Tongji University are developing innovative approaches to zinc waste treatment. Companies including Kobe Steel, Henkel, and HBIS are implementing integrated waste management systems, focusing on circular economy principles. The competitive landscape features established industrial players alongside specialized waste management firms, with collaboration between academic and industrial sectors accelerating technological advancement.

Central South University

Technical Solution: Central South University has developed a comprehensive zinc coating waste management system based on their pioneering research in hydrometallurgical recovery processes. Their technology employs a multi-stage leaching approach using environmentally benign organic acids that can selectively dissolve zinc from complex waste matrices with efficiency rates exceeding 92%. The university's research team has engineered novel adsorbent materials derived from agricultural waste that can capture dissolved zinc ions from dilute solutions, enabling recovery from even low-concentration waste streams. Their process incorporates electrochemical recovery cells with specialized membrane technology that reduces energy consumption by approximately 40% compared to conventional electrowinning. The system also features advanced oxidation processes that degrade organic contaminants in wastewater, producing effluent that meets stringent discharge standards. Central South University's integrated approach includes waste valorization pathways that convert zinc-depleted residues into geopolymer construction materials, achieving near-complete utilization of input materials.

Strengths: Cutting-edge research with novel recovery mechanisms; holistic approach addressing multiple waste streams; low environmental footprint with minimal chemical inputs. Weaknesses: Some technologies still at laboratory or pilot scale; requires technology transfer for industrial implementation; may face challenges in scaling up complex processes.

Glencore Technology Pty Ltd.

Technical Solution: Glencore Technology has developed the ISASMELTTM and ISAPROCESSTM technologies that address zinc coating waste management through innovative pyrometallurgical and hydrometallurgical approaches. Their system can process diverse zinc-bearing wastes including galvanizing dross, zinc ash, and EAF dust with recovery efficiencies exceeding 95%. The technology employs a top-submerged lance furnace that reduces energy consumption by approximately 25% compared to conventional rotary kilns. Glencore's process incorporates sophisticated off-gas handling systems that capture particulates and volatile compounds, reducing atmospheric emissions by over 99%. Their integrated flowsheet includes jarosite precipitation control mechanisms that transform problematic iron-bearing residues into stable compounds suitable for safe disposal or utilization in construction materials. The company has implemented these technologies at industrial scale, processing over 150,000 tons of zinc-bearing waste annually across multiple facilities worldwide.

Strengths: Proven at industrial scale with high throughput capacity; versatile in handling multiple waste types; excellent recovery rates with minimal environmental impact. Weaknesses: High capital expenditure requirements; complex operation requiring specialized expertise; energy-intensive process despite efficiency improvements.

Critical Technologies for Zinc Coating Waste Valorization

Method for upgrading waste material comprising sheet metal with a zinc plating on at least one side thereof

PatentWO1997006283A1

Innovation

- A process involving mechanical treatment to increase zinc layer accessibility, followed by immersion in a sodium hydroxide solution for complete zinc dissolution, and subsequent washing and densification of the sheet metal, with zinc recovery through electrolysis, allowing for the reuse of both zinc-free sheet metal and pure zinc.

Method for separating and recovering zinc from zinc plating waste liquid

PatentActiveJP2012082458A

Innovation

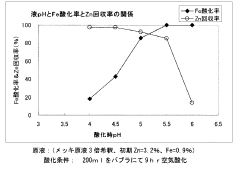

- A method involving dilution, pH adjustment, and air oxidation to convert divalent iron to trivalent iron, followed by precipitation of ferric hydroxide and zinc hydroxide, with optional sulfide precipitation to enhance zinc recovery, using inexpensive alkalis and sulfiding agents to manage high salt concentrations and improve zinc concentration.

Environmental Regulations Impacting Zinc Waste Management

The regulatory landscape governing zinc coating waste management has evolved significantly over the past decades, reflecting growing environmental concerns and sustainability imperatives. At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal classifies certain zinc-containing wastes as hazardous, imposing strict controls on their cross-border movement and disposal. This framework has been instrumental in preventing the dumping of zinc-laden waste in countries with less stringent environmental protections.

In the European Union, the Waste Framework Directive (2008/98/EC) establishes a waste hierarchy that prioritizes prevention, reuse, and recycling over disposal, directly impacting how zinc coating waste must be managed. Additionally, the Industrial Emissions Directive (2010/75/EU) imposes strict emission limits for zinc and its compounds, requiring Best Available Techniques (BAT) implementation in galvanizing facilities. The REACH Regulation further controls the use of zinc compounds, influencing waste generation upstream in the production process.

The United States Environmental Protection Agency regulates zinc waste under the Resource Conservation and Recovery Act (RCRA), with specific provisions for F006 waste from electroplating operations. The Clean Water Act also establishes discharge limits for zinc in industrial effluents, while the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) addresses historical zinc contamination at brownfield sites.

Emerging economies are rapidly strengthening their regulatory frameworks. China's revised Environmental Protection Law and Solid Waste Law have introduced stricter penalties for improper waste disposal, including zinc-containing waste. India's Hazardous and Other Wastes (Management and Transboundary Movement) Rules similarly regulate zinc waste management with increasing stringency.

A notable trend is the shift toward circular economy principles in regulatory frameworks. The EU's Circular Economy Action Plan explicitly targets metal waste streams, including zinc, promoting recovery and recycling. Extended Producer Responsibility (EPR) schemes are increasingly being applied to galvanized products, making manufacturers partially responsible for end-of-life waste management.

Compliance costs have risen substantially, with facilities reporting 15-30% increases in waste management expenditures over the past five years. However, these regulations have also driven innovation in waste treatment technologies and recycling processes, creating new market opportunities. Companies that have proactively invested in advanced waste management systems report competitive advantages through reduced compliance risks and access to environmentally conscious markets.

In the European Union, the Waste Framework Directive (2008/98/EC) establishes a waste hierarchy that prioritizes prevention, reuse, and recycling over disposal, directly impacting how zinc coating waste must be managed. Additionally, the Industrial Emissions Directive (2010/75/EU) imposes strict emission limits for zinc and its compounds, requiring Best Available Techniques (BAT) implementation in galvanizing facilities. The REACH Regulation further controls the use of zinc compounds, influencing waste generation upstream in the production process.

The United States Environmental Protection Agency regulates zinc waste under the Resource Conservation and Recovery Act (RCRA), with specific provisions for F006 waste from electroplating operations. The Clean Water Act also establishes discharge limits for zinc in industrial effluents, while the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) addresses historical zinc contamination at brownfield sites.

Emerging economies are rapidly strengthening their regulatory frameworks. China's revised Environmental Protection Law and Solid Waste Law have introduced stricter penalties for improper waste disposal, including zinc-containing waste. India's Hazardous and Other Wastes (Management and Transboundary Movement) Rules similarly regulate zinc waste management with increasing stringency.

A notable trend is the shift toward circular economy principles in regulatory frameworks. The EU's Circular Economy Action Plan explicitly targets metal waste streams, including zinc, promoting recovery and recycling. Extended Producer Responsibility (EPR) schemes are increasingly being applied to galvanized products, making manufacturers partially responsible for end-of-life waste management.

Compliance costs have risen substantially, with facilities reporting 15-30% increases in waste management expenditures over the past five years. However, these regulations have also driven innovation in waste treatment technologies and recycling processes, creating new market opportunities. Companies that have proactively invested in advanced waste management systems report competitive advantages through reduced compliance risks and access to environmentally conscious markets.

Economic Feasibility of Zinc Recovery Systems

The economic viability of zinc recovery systems represents a critical factor in addressing sustainability challenges in zinc coating waste management. Initial investment costs for comprehensive zinc recovery systems typically range from $500,000 to $3 million, depending on facility size, processing capacity, and technological sophistication. These systems include filtration equipment, chemical treatment units, and metal recovery infrastructure that require significant capital expenditure.

Operating costs present another important consideration, with energy consumption, chemical reagents, maintenance, and skilled labor contributing to ongoing expenses. However, these costs must be evaluated against the substantial revenue potential from recovered zinc, which currently trades at approximately $2,700-3,000 per metric ton on global markets. For facilities generating significant zinc-containing waste, recovery rates of 85-95% can translate to considerable material value recapture.

Return on investment (ROI) calculations typically indicate payback periods of 2-5 years for medium to large-scale operations, with smaller facilities experiencing longer timeframes. This economic equation improves significantly when factoring in avoided waste disposal costs, which have risen steadily due to stricter environmental regulations and limited landfill capacity.

Scale economies play a decisive role in feasibility assessments. Facilities processing less than 100 tons of zinc waste annually may struggle to justify dedicated recovery systems, while those handling larger volumes benefit from improved cost-efficiency ratios. This has prompted the emergence of centralized recovery facilities serving multiple smaller operations within industrial clusters.

Government incentives further enhance economic feasibility through tax credits, subsidies, and grants targeting circular economy initiatives. The European Union's Circular Economy Action Plan and similar programs in North America and Asia provide financial mechanisms that can reduce initial investment burdens by 15-30%, significantly improving project viability.

Market volatility represents a risk factor, as fluctuating zinc prices impact revenue projections. However, long-term price trends remain positive due to zinc's essential role in galvanization, die-casting, and emerging applications in renewable energy storage. Additionally, as virgin zinc extraction faces increasing environmental scrutiny and resource depletion concerns, recovered zinc commands growing market preference and potential premium pricing.

Operating costs present another important consideration, with energy consumption, chemical reagents, maintenance, and skilled labor contributing to ongoing expenses. However, these costs must be evaluated against the substantial revenue potential from recovered zinc, which currently trades at approximately $2,700-3,000 per metric ton on global markets. For facilities generating significant zinc-containing waste, recovery rates of 85-95% can translate to considerable material value recapture.

Return on investment (ROI) calculations typically indicate payback periods of 2-5 years for medium to large-scale operations, with smaller facilities experiencing longer timeframes. This economic equation improves significantly when factoring in avoided waste disposal costs, which have risen steadily due to stricter environmental regulations and limited landfill capacity.

Scale economies play a decisive role in feasibility assessments. Facilities processing less than 100 tons of zinc waste annually may struggle to justify dedicated recovery systems, while those handling larger volumes benefit from improved cost-efficiency ratios. This has prompted the emergence of centralized recovery facilities serving multiple smaller operations within industrial clusters.

Government incentives further enhance economic feasibility through tax credits, subsidies, and grants targeting circular economy initiatives. The European Union's Circular Economy Action Plan and similar programs in North America and Asia provide financial mechanisms that can reduce initial investment burdens by 15-30%, significantly improving project viability.

Market volatility represents a risk factor, as fluctuating zinc prices impact revenue projections. However, long-term price trends remain positive due to zinc's essential role in galvanization, die-casting, and emerging applications in renewable energy storage. Additionally, as virgin zinc extraction faces increasing environmental scrutiny and resource depletion concerns, recovered zinc commands growing market preference and potential premium pricing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!