Role of robotics in EREV assembly line production

AUG 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Robotics in EREV Assembly: Background and Objectives

The integration of robotics in Extended Range Electric Vehicle (EREV) assembly line production represents a significant technological advancement in the automotive industry. This convergence of robotics and electric vehicle manufacturing has evolved over the past decade, driven by the increasing demand for more efficient, precise, and cost-effective production processes.

The evolution of robotics in automotive manufacturing can be traced back to the 1960s when the first industrial robots were introduced in assembly lines. However, the application of robotics in EREV production is a more recent development, coinciding with the rise of electric and hybrid vehicles in the global market. The transition from traditional internal combustion engine vehicles to EREVs has necessitated a reimagining of the assembly process, creating new opportunities for robotic integration.

The primary objective of incorporating robotics in EREV assembly is to enhance production efficiency, improve quality control, and reduce manufacturing costs. Robots are particularly well-suited for tasks that require high precision, repetitive motions, and handling of heavy components – all of which are crucial in EREV assembly. For instance, the placement and connection of battery modules, the installation of electric motors, and the assembly of complex drivetrain components can all benefit from robotic assistance.

Another key goal is to improve workplace safety by delegating potentially hazardous tasks to robots, thereby reducing the risk of injury to human workers. This is especially relevant in EREV production, where high-voltage components and heavy battery packs are involved. Robotics can also contribute to consistency in production quality, minimizing variations that can occur with manual assembly.

The technological trend in this field is moving towards more advanced, flexible, and collaborative robotic systems. Modern robots in EREV assembly lines are equipped with sophisticated sensors, machine vision capabilities, and artificial intelligence, allowing them to adapt to different vehicle models and production requirements. This flexibility is crucial in the rapidly evolving electric vehicle market, where manufacturers need to quickly adjust their production lines to meet changing consumer demands and technological advancements.

Looking forward, the role of robotics in EREV assembly is expected to expand further. Emerging technologies such as autonomous mobile robots (AMRs) for material handling, collaborative robots (cobots) working alongside human operators, and AI-driven quality inspection systems are set to revolutionize the production process. These advancements aim to create smarter, more efficient assembly lines capable of producing increasingly complex EREV models while maintaining high quality standards and cost-effectiveness.

The evolution of robotics in automotive manufacturing can be traced back to the 1960s when the first industrial robots were introduced in assembly lines. However, the application of robotics in EREV production is a more recent development, coinciding with the rise of electric and hybrid vehicles in the global market. The transition from traditional internal combustion engine vehicles to EREVs has necessitated a reimagining of the assembly process, creating new opportunities for robotic integration.

The primary objective of incorporating robotics in EREV assembly is to enhance production efficiency, improve quality control, and reduce manufacturing costs. Robots are particularly well-suited for tasks that require high precision, repetitive motions, and handling of heavy components – all of which are crucial in EREV assembly. For instance, the placement and connection of battery modules, the installation of electric motors, and the assembly of complex drivetrain components can all benefit from robotic assistance.

Another key goal is to improve workplace safety by delegating potentially hazardous tasks to robots, thereby reducing the risk of injury to human workers. This is especially relevant in EREV production, where high-voltage components and heavy battery packs are involved. Robotics can also contribute to consistency in production quality, minimizing variations that can occur with manual assembly.

The technological trend in this field is moving towards more advanced, flexible, and collaborative robotic systems. Modern robots in EREV assembly lines are equipped with sophisticated sensors, machine vision capabilities, and artificial intelligence, allowing them to adapt to different vehicle models and production requirements. This flexibility is crucial in the rapidly evolving electric vehicle market, where manufacturers need to quickly adjust their production lines to meet changing consumer demands and technological advancements.

Looking forward, the role of robotics in EREV assembly is expected to expand further. Emerging technologies such as autonomous mobile robots (AMRs) for material handling, collaborative robots (cobots) working alongside human operators, and AI-driven quality inspection systems are set to revolutionize the production process. These advancements aim to create smarter, more efficient assembly lines capable of producing increasingly complex EREV models while maintaining high quality standards and cost-effectiveness.

Market Demand for Automated EREV Production

The market demand for automated Extended Range Electric Vehicle (EREV) production is experiencing significant growth, driven by the increasing adoption of electric vehicles and the need for more efficient manufacturing processes. As governments worldwide implement stricter emissions regulations and consumers become more environmentally conscious, the demand for EREVs has surged. This shift in consumer preferences has created a pressing need for automotive manufacturers to scale up their production capabilities while maintaining high quality standards and cost-effectiveness.

Automation in EREV assembly lines has become a critical factor in meeting this growing demand. Traditional manual assembly processes are often unable to keep pace with the required production volumes, leading to bottlenecks and increased costs. Robotics and automated systems offer a solution to these challenges by enhancing production speed, precision, and consistency. The integration of robotics in EREV assembly lines allows manufacturers to achieve higher throughput rates, reduce labor costs, and minimize human error.

The market for automated EREV production systems is expected to expand rapidly in the coming years. This growth is fueled by the automotive industry's push towards electrification and the need to remain competitive in a rapidly evolving market. Major automotive manufacturers are investing heavily in retooling their production facilities to accommodate EREV assembly, creating a substantial demand for advanced robotics and automation solutions.

Furthermore, the complexity of EREV powertrains and battery systems requires highly precise assembly processes that are well-suited to robotic systems. Tasks such as battery cell placement, motor assembly, and intricate wiring installations benefit greatly from the repeatability and accuracy of automated systems. This precision not only improves product quality but also enhances safety standards, which are paramount in electric vehicle production.

The market demand extends beyond just the automotive manufacturers themselves. Tier 1 and Tier 2 suppliers in the automotive industry are also seeking to upgrade their production capabilities to meet the requirements of EREV components. This creates a ripple effect throughout the supply chain, further driving the demand for automated production solutions.

Additionally, the need for flexible manufacturing systems that can adapt to different EREV models and configurations is becoming increasingly important. As automakers strive to offer a wider range of electric vehicle options, the ability to quickly reconfigure production lines is crucial. This flexibility is a key selling point for advanced robotic systems in EREV assembly lines, as they can be reprogrammed and adjusted more easily than traditional fixed automation systems.

In conclusion, the market demand for automated EREV production is robust and multifaceted. It is driven by the need for increased production capacity, improved quality control, enhanced flexibility, and the ability to meet stringent safety and regulatory requirements. As the EREV market continues to expand, the demand for sophisticated robotic solutions in assembly line production is expected to grow in tandem, presenting significant opportunities for both robotics manufacturers and automotive companies alike.

Automation in EREV assembly lines has become a critical factor in meeting this growing demand. Traditional manual assembly processes are often unable to keep pace with the required production volumes, leading to bottlenecks and increased costs. Robotics and automated systems offer a solution to these challenges by enhancing production speed, precision, and consistency. The integration of robotics in EREV assembly lines allows manufacturers to achieve higher throughput rates, reduce labor costs, and minimize human error.

The market for automated EREV production systems is expected to expand rapidly in the coming years. This growth is fueled by the automotive industry's push towards electrification and the need to remain competitive in a rapidly evolving market. Major automotive manufacturers are investing heavily in retooling their production facilities to accommodate EREV assembly, creating a substantial demand for advanced robotics and automation solutions.

Furthermore, the complexity of EREV powertrains and battery systems requires highly precise assembly processes that are well-suited to robotic systems. Tasks such as battery cell placement, motor assembly, and intricate wiring installations benefit greatly from the repeatability and accuracy of automated systems. This precision not only improves product quality but also enhances safety standards, which are paramount in electric vehicle production.

The market demand extends beyond just the automotive manufacturers themselves. Tier 1 and Tier 2 suppliers in the automotive industry are also seeking to upgrade their production capabilities to meet the requirements of EREV components. This creates a ripple effect throughout the supply chain, further driving the demand for automated production solutions.

Additionally, the need for flexible manufacturing systems that can adapt to different EREV models and configurations is becoming increasingly important. As automakers strive to offer a wider range of electric vehicle options, the ability to quickly reconfigure production lines is crucial. This flexibility is a key selling point for advanced robotic systems in EREV assembly lines, as they can be reprogrammed and adjusted more easily than traditional fixed automation systems.

In conclusion, the market demand for automated EREV production is robust and multifaceted. It is driven by the need for increased production capacity, improved quality control, enhanced flexibility, and the ability to meet stringent safety and regulatory requirements. As the EREV market continues to expand, the demand for sophisticated robotic solutions in assembly line production is expected to grow in tandem, presenting significant opportunities for both robotics manufacturers and automotive companies alike.

Current State and Challenges in EREV Assembly Robotics

The current state of robotics in Extended Range Electric Vehicle (EREV) assembly line production is characterized by significant advancements and ongoing challenges. Robotic systems have become increasingly prevalent in EREV manufacturing, offering enhanced precision, efficiency, and consistency in assembly processes. These systems are particularly valuable in tasks requiring repetitive motions, heavy lifting, and intricate component placement.

One of the primary advantages of robotics in EREV assembly is the ability to maintain high levels of quality control. Automated systems can perform tasks with a degree of accuracy that surpasses human capabilities, reducing errors and ensuring consistent product quality. This is especially crucial in the assembly of complex EREV components, such as battery packs and electric drivetrains, where precision is paramount.

However, the integration of robotics in EREV assembly lines also presents several challenges. One significant hurdle is the need for flexibility in production processes. EREVs often require customization and frequent model updates, which can be challenging for traditional robotic systems designed for high-volume, standardized production. Adapting robotic systems to accommodate these variations without sacrificing efficiency remains an ongoing challenge for manufacturers.

Another critical challenge lies in the complexity of EREV components. The assembly of battery systems, power electronics, and electric motors requires specialized handling and intricate procedures. While robots excel in repetitive tasks, they may struggle with the nuanced assembly steps required for these complex components. This necessitates the development of more advanced, adaptive robotic systems capable of handling diverse and intricate assembly processes.

The human-robot collaboration aspect also presents both opportunities and challenges. While collaborative robots (cobots) have shown promise in enhancing worker safety and productivity, integrating them seamlessly into existing assembly line workflows requires careful planning and implementation. Ensuring effective communication and coordination between human workers and robotic systems remains a key area of focus for EREV manufacturers.

Furthermore, the rapid pace of technological advancements in both EREVs and robotics creates a constant need for updating and upgrading assembly line systems. Manufacturers must balance the benefits of implementing cutting-edge robotic technologies with the costs and potential disruptions associated with frequent system overhauls.

Lastly, the shortage of skilled personnel capable of programming, operating, and maintaining advanced robotic systems in EREV assembly lines poses a significant challenge. As the complexity of both EREVs and robotic systems increases, there is a growing demand for workers with specialized skills in robotics, automation, and electric vehicle technology. Addressing this skills gap is crucial for the continued advancement of robotics in EREV production.

One of the primary advantages of robotics in EREV assembly is the ability to maintain high levels of quality control. Automated systems can perform tasks with a degree of accuracy that surpasses human capabilities, reducing errors and ensuring consistent product quality. This is especially crucial in the assembly of complex EREV components, such as battery packs and electric drivetrains, where precision is paramount.

However, the integration of robotics in EREV assembly lines also presents several challenges. One significant hurdle is the need for flexibility in production processes. EREVs often require customization and frequent model updates, which can be challenging for traditional robotic systems designed for high-volume, standardized production. Adapting robotic systems to accommodate these variations without sacrificing efficiency remains an ongoing challenge for manufacturers.

Another critical challenge lies in the complexity of EREV components. The assembly of battery systems, power electronics, and electric motors requires specialized handling and intricate procedures. While robots excel in repetitive tasks, they may struggle with the nuanced assembly steps required for these complex components. This necessitates the development of more advanced, adaptive robotic systems capable of handling diverse and intricate assembly processes.

The human-robot collaboration aspect also presents both opportunities and challenges. While collaborative robots (cobots) have shown promise in enhancing worker safety and productivity, integrating them seamlessly into existing assembly line workflows requires careful planning and implementation. Ensuring effective communication and coordination between human workers and robotic systems remains a key area of focus for EREV manufacturers.

Furthermore, the rapid pace of technological advancements in both EREVs and robotics creates a constant need for updating and upgrading assembly line systems. Manufacturers must balance the benefits of implementing cutting-edge robotic technologies with the costs and potential disruptions associated with frequent system overhauls.

Lastly, the shortage of skilled personnel capable of programming, operating, and maintaining advanced robotic systems in EREV assembly lines poses a significant challenge. As the complexity of both EREVs and robotic systems increases, there is a growing demand for workers with specialized skills in robotics, automation, and electric vehicle technology. Addressing this skills gap is crucial for the continued advancement of robotics in EREV production.

Existing Robotic Solutions for EREV Assembly Lines

01 Robotic manipulation and gripping systems

Advanced robotic systems for handling and manipulating objects, including innovative gripping mechanisms and control systems for precise object manipulation in various industrial and research applications.- Robotic manipulation and gripping systems: Advanced robotic systems for handling and manipulating objects, including innovative gripping mechanisms and control systems for precise object manipulation in various industrial and research applications.

- Vision systems and image processing for robotics: Integration of advanced vision systems and image processing techniques in robotics, enabling robots to perceive and interpret their environment for improved navigation, object recognition, and task execution.

- Autonomous navigation and path planning: Development of algorithms and systems for autonomous robot navigation and path planning, allowing robots to move efficiently and safely in complex environments while avoiding obstacles and optimizing routes.

- Human-robot interaction and collaborative robotics: Advancements in human-robot interaction technologies and collaborative robotics, focusing on safe and efficient cooperation between humans and robots in various settings, including industrial, healthcare, and service environments.

- Artificial intelligence and machine learning in robotics: Integration of AI and machine learning techniques in robotic systems, enabling robots to learn from experience, adapt to new situations, and make intelligent decisions in real-time for improved performance and autonomy.

02 Vision systems and image processing for robotics

Integration of advanced vision systems and image processing techniques in robotics, enabling robots to perceive and interpret their environment for improved navigation, object recognition, and task execution.Expand Specific Solutions03 Autonomous navigation and path planning

Development of algorithms and systems for autonomous robot navigation and path planning, allowing robots to move efficiently and safely in complex environments while avoiding obstacles and optimizing routes.Expand Specific Solutions04 Human-robot interaction and collaborative robotics

Advancements in human-robot interaction technologies and collaborative robotics, focusing on safe and efficient cooperation between humans and robots in various settings, including industrial, healthcare, and service environments.Expand Specific Solutions05 Robotic control systems and artificial intelligence

Integration of advanced control systems and artificial intelligence in robotics, enabling more sophisticated decision-making, learning capabilities, and adaptive behaviors in robotic systems across various applications.Expand Specific Solutions

Key Players in EREV Assembly Robotics

The robotics industry in EREV assembly line production is in a growth phase, with increasing market size and technological advancements. The competitive landscape is characterized by a mix of established automotive manufacturers, robotics specialists, and emerging players. Companies like ABB Group, FANUC Corp., and GM Global Technology Operations are leading in industrial robotics, while traditional automakers such as China FAW Co., Ltd. are integrating robotics into their production lines. The technology is maturing rapidly, with innovations in AI, machine learning, and sensor technologies driving improvements in efficiency and precision. However, there's still room for further development in areas like human-robot collaboration and flexibility in production processes.

ABB Group

Technical Solution: ABB has developed a comprehensive robotics solution for EREV assembly lines, focusing on flexibility and scalability. Their YuMi collaborative robot is specifically designed for small parts assembly, making it ideal for battery pack and electrical component installation[1]. ABB's RobotStudio software allows for offline programming and simulation of the entire assembly line, optimizing processes before physical implementation[2]. The company has also introduced advanced vision systems and force control technology, enabling robots to handle delicate components with precision[3]. ABB's robots are integrated with IoT platforms, allowing for real-time monitoring and predictive maintenance, which is crucial for maintaining high uptime in EREV production[4].

Strengths: Highly flexible and scalable solutions, advanced software integration, and expertise in electrical systems. Weaknesses: May require significant customization for specific EREV models and potential high costs for full-scale implementation.

GM Global Technology Operations LLC

Technical Solution: GM has developed a proprietary robotic system for EREV assembly, leveraging its extensive experience in automotive manufacturing. Their approach focuses on modular assembly stations that can be quickly reconfigured for different EREV models[1]. GM's robots are equipped with advanced sensors and machine learning algorithms to adapt to variations in component supply and assembly sequences[2]. The company has implemented a digital twin system that allows for real-time monitoring and optimization of the entire assembly process[3]. GM's robotics solution also incorporates augmented reality (AR) technology to assist human operators in complex assembly tasks, enhancing overall productivity and reducing errors[4].

Strengths: Deep automotive industry expertise, highly adaptable systems, and integration of cutting-edge technologies. Weaknesses: Potentially less flexible for non-GM EREV manufacturers and may have higher implementation costs for smaller-scale operations.

Core Innovations in EREV Assembly Automation

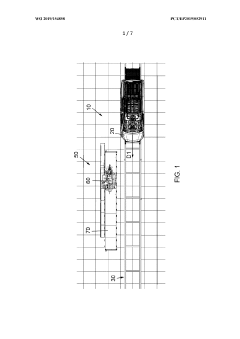

Robot parts assembly on a workpiece moving on an assembly line

PatentInactiveEP2271465A1

Innovation

- A system that combines a 2D vision system with force and position feedback to control an industrial robot's movement, using a single camera with simple calibration and force control to track and assemble parts on a randomly moving workpiece, ensuring accurate alignment and preventing damage through simultaneous signal processing from the vision and force sensors.

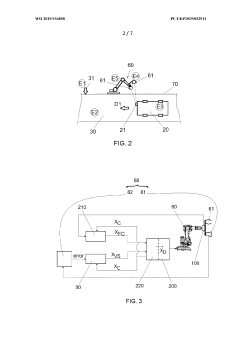

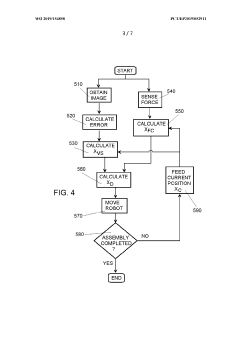

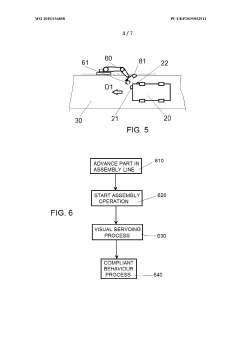

Assembling parts in an assembly line

PatentWO2019154858A1

Innovation

- A method utilizing a combination of real-time vision systems to monitor the position of Automated Guided Vehicles and target areas, enabling visual servoing and compliant behavior processes to synchronize the movement of industrial robots with the conveyor, allowing accurate and efficient assembly operations without stopping the conveyor and compensating for various sources of error.

Environmental Impact of Robotic EREV Assembly

The integration of robotics in Extended Range Electric Vehicle (EREV) assembly lines has significant environmental implications. Robotic systems in EREV production contribute to improved energy efficiency and reduced waste generation. Advanced robotic technologies enable precise control over manufacturing processes, minimizing material waste and optimizing resource utilization. This precision extends to the application of adhesives, sealants, and coatings, reducing overspray and excess material usage.

Robotic assembly lines for EREVs also facilitate the implementation of lean manufacturing principles, leading to streamlined production processes and reduced energy consumption. Automated systems can operate with minimal lighting and climate control requirements, further decreasing the overall energy footprint of manufacturing facilities. Additionally, robots can handle hazardous materials more safely, reducing the risk of spills and environmental contamination.

The use of robotics in EREV assembly promotes the adoption of advanced recycling and remanufacturing processes. Robots can efficiently disassemble end-of-life vehicles, separating components for recycling or refurbishment with greater accuracy than manual processes. This capability enhances the circular economy potential of EREV production, reducing the demand for raw materials and minimizing waste sent to landfills.

However, the environmental impact of robotic EREV assembly extends beyond the production floor. The manufacturing of robots themselves requires energy and resources, and their eventual disposal presents environmental challenges. To mitigate these effects, manufacturers are increasingly focusing on developing robots with longer operational lifespans and incorporating recyclable materials in their construction.

The shift towards robotic assembly in EREV production also influences supply chain dynamics. Automated systems enable more localized production, potentially reducing transportation-related emissions. Furthermore, the precision and consistency offered by robotic assembly contribute to the production of higher-quality EREVs with improved energy efficiency and longevity, indirectly benefiting the environment through reduced lifecycle emissions.

As EREV technology continues to evolve, the role of robotics in assembly is expected to expand, bringing further environmental benefits. Future developments may include the integration of artificial intelligence to optimize energy use in real-time and the implementation of collaborative robots that can work alongside human operators, combining the efficiency of automation with the flexibility of human decision-making to further enhance sustainable manufacturing practices.

Robotic assembly lines for EREVs also facilitate the implementation of lean manufacturing principles, leading to streamlined production processes and reduced energy consumption. Automated systems can operate with minimal lighting and climate control requirements, further decreasing the overall energy footprint of manufacturing facilities. Additionally, robots can handle hazardous materials more safely, reducing the risk of spills and environmental contamination.

The use of robotics in EREV assembly promotes the adoption of advanced recycling and remanufacturing processes. Robots can efficiently disassemble end-of-life vehicles, separating components for recycling or refurbishment with greater accuracy than manual processes. This capability enhances the circular economy potential of EREV production, reducing the demand for raw materials and minimizing waste sent to landfills.

However, the environmental impact of robotic EREV assembly extends beyond the production floor. The manufacturing of robots themselves requires energy and resources, and their eventual disposal presents environmental challenges. To mitigate these effects, manufacturers are increasingly focusing on developing robots with longer operational lifespans and incorporating recyclable materials in their construction.

The shift towards robotic assembly in EREV production also influences supply chain dynamics. Automated systems enable more localized production, potentially reducing transportation-related emissions. Furthermore, the precision and consistency offered by robotic assembly contribute to the production of higher-quality EREVs with improved energy efficiency and longevity, indirectly benefiting the environment through reduced lifecycle emissions.

As EREV technology continues to evolve, the role of robotics in assembly is expected to expand, bringing further environmental benefits. Future developments may include the integration of artificial intelligence to optimize energy use in real-time and the implementation of collaborative robots that can work alongside human operators, combining the efficiency of automation with the flexibility of human decision-making to further enhance sustainable manufacturing practices.

Safety Standards for Robotics in EREV Manufacturing

Safety standards for robotics in EREV (Extended Range Electric Vehicle) manufacturing are crucial to ensure the well-being of workers and the quality of production. These standards encompass a wide range of considerations, from the design and installation of robotic systems to their operation and maintenance.

One of the primary safety standards focuses on the physical separation of humans and robots. This is typically achieved through the implementation of safety fences, light curtains, and other barrier systems. These measures prevent accidental contact between workers and moving robotic parts during normal operation. Additionally, safety-rated monitored stops and speed reduction mechanisms are required to allow human intervention when necessary, such as during maintenance or troubleshooting.

Another critical aspect of safety standards is the integration of advanced sensing and control systems. Modern robotic systems in EREV manufacturing are equipped with sophisticated vision systems, proximity sensors, and force-torque sensors. These technologies enable robots to detect the presence of humans or unexpected objects in their work envelope and respond accordingly, either by stopping or adjusting their movements to avoid collisions.

Risk assessment and hazard identification are fundamental components of safety standards in robotic EREV manufacturing. Manufacturers are required to conduct thorough risk analyses for each robotic application, identifying potential hazards and implementing appropriate mitigation strategies. This process involves evaluating factors such as robot speed, payload capacity, end-effector design, and the nature of tasks being performed.

Emergency stop systems are another crucial element of safety standards. These systems must be easily accessible, clearly marked, and capable of immediately halting all robotic operations in the event of an emergency. Furthermore, safety standards mandate regular testing and maintenance of these emergency systems to ensure their reliability.

Training and certification requirements for operators and maintenance personnel form an integral part of safety standards. Workers involved in programming, operating, or maintaining robotic systems in EREV manufacturing must undergo comprehensive training programs. These programs cover not only the technical aspects of robot operation but also safety protocols, emergency procedures, and risk awareness.

Cybersecurity is an increasingly important consideration in safety standards for robotic systems in EREV manufacturing. As these systems become more interconnected and reliant on digital technologies, protecting them from potential cyber threats is crucial. Standards now include requirements for secure communication protocols, access controls, and regular security audits to prevent unauthorized access or manipulation of robotic systems.

Human-robot collaboration (HRC) is an emerging area that is shaping new safety standards in EREV manufacturing. As collaborative robots become more prevalent, standards are evolving to address the unique challenges of environments where humans and robots work in close proximity. These standards focus on advanced safety features such as power and force limiting, speed monitoring, and adaptive safety zones that allow for safe and efficient human-robot interaction.

One of the primary safety standards focuses on the physical separation of humans and robots. This is typically achieved through the implementation of safety fences, light curtains, and other barrier systems. These measures prevent accidental contact between workers and moving robotic parts during normal operation. Additionally, safety-rated monitored stops and speed reduction mechanisms are required to allow human intervention when necessary, such as during maintenance or troubleshooting.

Another critical aspect of safety standards is the integration of advanced sensing and control systems. Modern robotic systems in EREV manufacturing are equipped with sophisticated vision systems, proximity sensors, and force-torque sensors. These technologies enable robots to detect the presence of humans or unexpected objects in their work envelope and respond accordingly, either by stopping or adjusting their movements to avoid collisions.

Risk assessment and hazard identification are fundamental components of safety standards in robotic EREV manufacturing. Manufacturers are required to conduct thorough risk analyses for each robotic application, identifying potential hazards and implementing appropriate mitigation strategies. This process involves evaluating factors such as robot speed, payload capacity, end-effector design, and the nature of tasks being performed.

Emergency stop systems are another crucial element of safety standards. These systems must be easily accessible, clearly marked, and capable of immediately halting all robotic operations in the event of an emergency. Furthermore, safety standards mandate regular testing and maintenance of these emergency systems to ensure their reliability.

Training and certification requirements for operators and maintenance personnel form an integral part of safety standards. Workers involved in programming, operating, or maintaining robotic systems in EREV manufacturing must undergo comprehensive training programs. These programs cover not only the technical aspects of robot operation but also safety protocols, emergency procedures, and risk awareness.

Cybersecurity is an increasingly important consideration in safety standards for robotic systems in EREV manufacturing. As these systems become more interconnected and reliant on digital technologies, protecting them from potential cyber threats is crucial. Standards now include requirements for secure communication protocols, access controls, and regular security audits to prevent unauthorized access or manipulation of robotic systems.

Human-robot collaboration (HRC) is an emerging area that is shaping new safety standards in EREV manufacturing. As collaborative robots become more prevalent, standards are evolving to address the unique challenges of environments where humans and robots work in close proximity. These standards focus on advanced safety features such as power and force limiting, speed monitoring, and adaptive safety zones that allow for safe and efficient human-robot interaction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!