Shaft Furnace Design and Hydrogen Injection Strategies in Hydrogen DRI

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen DRI Technology Evolution and Objectives

Direct Reduction of Iron (DRI) technology has evolved significantly since its inception in the 1950s, with traditional methods relying heavily on natural gas as the primary reducing agent. The evolution towards hydrogen-based DRI represents a paradigm shift in ironmaking, driven by the urgent need to decarbonize the steel industry, which accounts for approximately 7-9% of global CO2 emissions. This transition aligns with global climate goals and positions the steel industry to contribute meaningfully to carbon neutrality targets.

The technological evolution of hydrogen DRI can be traced through several distinct phases. Initially, conventional gas-based DRI processes dominated, utilizing syngas derived from natural gas reformation. The MIDREX and HYL/Energiron processes emerged as industry standards, with shaft furnace designs optimized for natural gas operation. The intermediate phase saw the gradual introduction of hydrogen blending, where existing DRI plants began incorporating limited hydrogen percentages into their reducing gas mixtures.

Currently, we are witnessing the emergence of hybrid systems capable of operating with variable hydrogen content, allowing for flexible transition pathways. These systems represent a critical stepping stone toward the ultimate objective: 100% hydrogen-based direct reduction processes that eliminate carbon-based reducing agents entirely.

The primary technical objective of hydrogen DRI development is to achieve carbon-neutral ironmaking while maintaining or improving process efficiency and product quality. This involves redesigning shaft furnaces to accommodate hydrogen's distinct thermodynamic and kinetic properties compared to carbon monoxide. Specific objectives include optimizing hydrogen injection strategies to ensure uniform gas distribution throughout the furnace, managing the endothermic nature of hydrogen reduction reactions, and controlling the metallization rate to prevent material degradation.

Additional objectives focus on addressing hydrogen's higher diffusivity and reactivity, which necessitate modifications to traditional shaft furnace designs. These include revised burden distribution systems, modified shaft geometries, and enhanced temperature control mechanisms. Process control systems must also evolve to manage the faster reduction kinetics and different heat transfer characteristics associated with hydrogen-based reduction.

Long-term technological goals include developing integrated hydrogen production, storage, and utilization systems specifically tailored for DRI applications. This encompasses renewable hydrogen generation, efficient storage solutions, and intelligent furnace management systems that can adapt to fluctuating hydrogen availability from renewable sources, ultimately enabling the steel industry to operate within a circular hydrogen economy framework.

The technological evolution of hydrogen DRI can be traced through several distinct phases. Initially, conventional gas-based DRI processes dominated, utilizing syngas derived from natural gas reformation. The MIDREX and HYL/Energiron processes emerged as industry standards, with shaft furnace designs optimized for natural gas operation. The intermediate phase saw the gradual introduction of hydrogen blending, where existing DRI plants began incorporating limited hydrogen percentages into their reducing gas mixtures.

Currently, we are witnessing the emergence of hybrid systems capable of operating with variable hydrogen content, allowing for flexible transition pathways. These systems represent a critical stepping stone toward the ultimate objective: 100% hydrogen-based direct reduction processes that eliminate carbon-based reducing agents entirely.

The primary technical objective of hydrogen DRI development is to achieve carbon-neutral ironmaking while maintaining or improving process efficiency and product quality. This involves redesigning shaft furnaces to accommodate hydrogen's distinct thermodynamic and kinetic properties compared to carbon monoxide. Specific objectives include optimizing hydrogen injection strategies to ensure uniform gas distribution throughout the furnace, managing the endothermic nature of hydrogen reduction reactions, and controlling the metallization rate to prevent material degradation.

Additional objectives focus on addressing hydrogen's higher diffusivity and reactivity, which necessitate modifications to traditional shaft furnace designs. These include revised burden distribution systems, modified shaft geometries, and enhanced temperature control mechanisms. Process control systems must also evolve to manage the faster reduction kinetics and different heat transfer characteristics associated with hydrogen-based reduction.

Long-term technological goals include developing integrated hydrogen production, storage, and utilization systems specifically tailored for DRI applications. This encompasses renewable hydrogen generation, efficient storage solutions, and intelligent furnace management systems that can adapt to fluctuating hydrogen availability from renewable sources, ultimately enabling the steel industry to operate within a circular hydrogen economy framework.

Market Demand Analysis for Green Steel Production

The global steel industry is experiencing a significant shift towards greener production methods, driven by increasing environmental regulations and corporate sustainability commitments. The market for green steel, particularly that produced using hydrogen-based direct reduced iron (DRI) processes, is projected to grow substantially over the next decade. Current estimates indicate that green steel production could capture up to 30% of the global steel market by 2050, representing a market value exceeding $400 billion.

Regulatory pressures are a primary driver of this market growth. The European Union's Carbon Border Adjustment Mechanism (CBAM) and similar policies in other regions are creating financial incentives for steel producers to reduce carbon emissions. Steel production currently accounts for approximately 7-9% of global CO2 emissions, making it a critical target for decarbonization efforts.

Consumer demand is also reshaping the market landscape. Major end-users of steel, including automotive manufacturers, construction companies, and consumer goods producers, are increasingly setting targets for embodied carbon reduction in their supply chains. Companies like Volvo, Mercedes-Benz, and BMW have already announced commitments to use low-carbon or carbon-neutral steel in their vehicles, creating a premium market segment for green steel products.

The economic viability of hydrogen DRI technology is improving rapidly. While traditional blast furnace production currently maintains a cost advantage, this gap is narrowing as hydrogen production costs decrease and carbon pricing mechanisms become more widespread. Industry analysts predict cost parity between traditional and hydrogen-based steel production could be achieved in certain markets by 2030, particularly in regions with abundant renewable energy resources.

Regional market dynamics show significant variation. Europe leads in terms of policy support and corporate commitments, with several commercial-scale hydrogen DRI projects already under development. The Asia-Pacific region, particularly China and Japan, represents the largest potential market by volume but faces challenges in transitioning existing infrastructure. North America shows growing interest, driven by both policy incentives and corporate sustainability goals.

Investment in hydrogen DRI technology has accelerated dramatically, with announced projects representing over $50 billion in capital expenditure globally. This investment surge indicates strong market confidence in the technology's commercial potential and suggests that production capacity will expand significantly in the coming years.

The market for shaft furnace design and hydrogen injection technologies specifically is expected to grow at a compound annual rate exceeding 15% through 2030, as steel producers seek to optimize hydrogen utilization and maximize the efficiency of DRI production processes.

Regulatory pressures are a primary driver of this market growth. The European Union's Carbon Border Adjustment Mechanism (CBAM) and similar policies in other regions are creating financial incentives for steel producers to reduce carbon emissions. Steel production currently accounts for approximately 7-9% of global CO2 emissions, making it a critical target for decarbonization efforts.

Consumer demand is also reshaping the market landscape. Major end-users of steel, including automotive manufacturers, construction companies, and consumer goods producers, are increasingly setting targets for embodied carbon reduction in their supply chains. Companies like Volvo, Mercedes-Benz, and BMW have already announced commitments to use low-carbon or carbon-neutral steel in their vehicles, creating a premium market segment for green steel products.

The economic viability of hydrogen DRI technology is improving rapidly. While traditional blast furnace production currently maintains a cost advantage, this gap is narrowing as hydrogen production costs decrease and carbon pricing mechanisms become more widespread. Industry analysts predict cost parity between traditional and hydrogen-based steel production could be achieved in certain markets by 2030, particularly in regions with abundant renewable energy resources.

Regional market dynamics show significant variation. Europe leads in terms of policy support and corporate commitments, with several commercial-scale hydrogen DRI projects already under development. The Asia-Pacific region, particularly China and Japan, represents the largest potential market by volume but faces challenges in transitioning existing infrastructure. North America shows growing interest, driven by both policy incentives and corporate sustainability goals.

Investment in hydrogen DRI technology has accelerated dramatically, with announced projects representing over $50 billion in capital expenditure globally. This investment surge indicates strong market confidence in the technology's commercial potential and suggests that production capacity will expand significantly in the coming years.

The market for shaft furnace design and hydrogen injection technologies specifically is expected to grow at a compound annual rate exceeding 15% through 2030, as steel producers seek to optimize hydrogen utilization and maximize the efficiency of DRI production processes.

Current State and Challenges in Shaft Furnace Technology

Shaft furnace technology for Direct Reduced Iron (DRI) production has evolved significantly over the past decades, with current designs predominantly optimized for natural gas as the primary reducing agent. Leading commercial technologies include Midrex and HYL/Energiron processes, which together account for approximately 90% of the global DRI production. These technologies have achieved high levels of operational efficiency with carbon-based reducing agents but face substantial challenges when transitioning to hydrogen-based reduction.

The current shaft furnace designs typically feature a cylindrical vertical reactor with internal diameters ranging from 5 to 7 meters and heights between 9 and 12 meters. The furnaces operate at temperatures between 800°C and 1050°C, with reduction gas flowing counter-currently to the descending iron ore. While these fundamental design principles remain relevant for hydrogen-based DRI, significant modifications are necessary to accommodate hydrogen's distinct thermodynamic and kinetic properties.

A critical challenge in current shaft furnace technology is the gas distribution system. Conventional designs optimize for natural gas-based reducing agents, which have different flow characteristics compared to hydrogen. Hydrogen's lower density and higher diffusivity require redesigned gas injection systems to ensure uniform distribution throughout the furnace bed, preventing channeling effects that can lead to uneven reduction and decreased metallization rates.

Temperature management presents another significant challenge. Hydrogen reduction reactions are highly endothermic, requiring more precise thermal management than natural gas-based processes. Current furnace designs lack the sophisticated temperature control systems needed to maintain optimal reduction conditions throughout the furnace when using hydrogen as the primary reductant.

Material handling systems in existing shaft furnaces also pose limitations. The different reduction kinetics of hydrogen necessitate adjustments to residence time and burden distribution. Current charging and discharging mechanisms may not provide the flexibility required for optimized hydrogen-based operations.

From a geographical perspective, shaft furnace technology development has been concentrated in industrialized regions, particularly in Europe, North America, and Japan. Recently, significant advancements have emerged from China and India as these countries expand their steel production capabilities. This geographical distribution creates disparities in technology access and implementation capabilities across different regions.

Instrumentation and control systems in current shaft furnaces typically lack the advanced monitoring capabilities required for hydrogen-based processes. The faster reaction kinetics of hydrogen reduction demand more responsive control systems and real-time monitoring of reduction progress throughout the furnace volume, capabilities not fully developed in existing technologies.

The current shaft furnace designs typically feature a cylindrical vertical reactor with internal diameters ranging from 5 to 7 meters and heights between 9 and 12 meters. The furnaces operate at temperatures between 800°C and 1050°C, with reduction gas flowing counter-currently to the descending iron ore. While these fundamental design principles remain relevant for hydrogen-based DRI, significant modifications are necessary to accommodate hydrogen's distinct thermodynamic and kinetic properties.

A critical challenge in current shaft furnace technology is the gas distribution system. Conventional designs optimize for natural gas-based reducing agents, which have different flow characteristics compared to hydrogen. Hydrogen's lower density and higher diffusivity require redesigned gas injection systems to ensure uniform distribution throughout the furnace bed, preventing channeling effects that can lead to uneven reduction and decreased metallization rates.

Temperature management presents another significant challenge. Hydrogen reduction reactions are highly endothermic, requiring more precise thermal management than natural gas-based processes. Current furnace designs lack the sophisticated temperature control systems needed to maintain optimal reduction conditions throughout the furnace when using hydrogen as the primary reductant.

Material handling systems in existing shaft furnaces also pose limitations. The different reduction kinetics of hydrogen necessitate adjustments to residence time and burden distribution. Current charging and discharging mechanisms may not provide the flexibility required for optimized hydrogen-based operations.

From a geographical perspective, shaft furnace technology development has been concentrated in industrialized regions, particularly in Europe, North America, and Japan. Recently, significant advancements have emerged from China and India as these countries expand their steel production capabilities. This geographical distribution creates disparities in technology access and implementation capabilities across different regions.

Instrumentation and control systems in current shaft furnaces typically lack the advanced monitoring capabilities required for hydrogen-based processes. The faster reaction kinetics of hydrogen reduction demand more responsive control systems and real-time monitoring of reduction progress throughout the furnace volume, capabilities not fully developed in existing technologies.

Current Hydrogen Injection Strategies for DRI Production

01 Shaft furnace design optimization for hydrogen injection

Optimizing shaft furnace design specifically for hydrogen injection involves structural modifications to accommodate the unique properties of hydrogen gas. These designs include specialized gas distribution systems, modified shaft geometry, and enhanced refractory linings that can withstand hydrogen's higher reactivity and different combustion characteristics. The optimized designs focus on improving gas flow patterns, temperature distribution, and reaction efficiency when using hydrogen as a reducing agent.- Shaft furnace structural design optimization: Optimizing the structural design of shaft furnaces involves considerations for improved thermal efficiency, gas flow dynamics, and material handling. Key design elements include the furnace geometry, refractory lining configuration, and charging mechanisms. Advanced designs incorporate features that enhance heat transfer, reduce energy consumption, and improve the uniformity of temperature distribution throughout the furnace. These structural optimizations contribute to increased productivity and reduced environmental impact.

- Hydrogen injection systems and equipment: Specialized equipment and systems for hydrogen injection in shaft furnaces include advanced nozzle designs, pressure control mechanisms, and distribution systems. These systems are engineered to deliver precise amounts of hydrogen at optimal locations within the furnace. The injection equipment must withstand high temperatures while maintaining operational reliability. Modern systems incorporate sensors and monitoring devices to ensure consistent hydrogen flow rates and prevent potential hazards associated with hydrogen handling.

- Computational modeling and simulation for furnace design: Advanced computational modeling and simulation techniques are employed to optimize shaft furnace design and hydrogen injection strategies. These include computational fluid dynamics (CFD), finite element analysis, and thermodynamic modeling to predict gas flow patterns, heat transfer, and chemical reactions within the furnace. Simulation tools enable engineers to test various design configurations and injection parameters virtually before implementation, reducing development costs and improving performance outcomes. These models account for complex interactions between hydrogen, other gases, and solid materials in the furnace environment.

- Hydrogen injection strategies and process control: Strategic approaches to hydrogen injection in shaft furnaces involve optimizing injection timing, location, volume, and pressure to maximize reduction efficiency and minimize energy consumption. Process control systems monitor and adjust hydrogen injection parameters in real-time based on furnace conditions, material properties, and production requirements. Advanced control strategies incorporate predictive algorithms and feedback mechanisms to maintain optimal operating conditions throughout varying production cycles. These strategies aim to balance metallurgical outcomes with operational efficiency and environmental considerations.

- Environmental and efficiency improvements through hydrogen utilization: Hydrogen injection in shaft furnaces offers significant environmental benefits and efficiency improvements compared to traditional reduction methods. By partially or completely replacing carbon-based reducing agents with hydrogen, CO2 emissions can be substantially reduced. Hydrogen utilization strategies focus on optimizing the reduction process, improving energy efficiency, and enhancing product quality. Implementation approaches include gradual transition pathways from conventional to hydrogen-based processes, with considerations for hydrogen production, storage, and integration with existing furnace systems.

02 Hydrogen injection strategies and control systems

Advanced control systems for hydrogen injection in shaft furnaces involve precise regulation of gas flow rates, injection points, and timing. These systems utilize real-time monitoring of furnace conditions to optimize hydrogen utilization and process efficiency. Strategies include pulsed injection, variable flow rates based on burden conditions, and adaptive control algorithms that respond to changes in furnace parameters. These control systems help maintain stable operation while maximizing the benefits of hydrogen as a reducing agent.Expand Specific Solutions03 Hybrid injection systems combining hydrogen with conventional fuels

Hybrid injection systems allow shaft furnaces to operate with varying ratios of hydrogen and conventional fuels like natural gas or pulverized coal. These systems include specialized injectors, mixing chambers, and control mechanisms that can adjust the fuel composition based on process requirements. The hybrid approach enables gradual transition to hydrogen while maintaining operational stability and provides flexibility to optimize energy efficiency and emissions reduction based on economic and environmental factors.Expand Specific Solutions04 Computational modeling and simulation for hydrogen-based shaft furnaces

Advanced computational modeling techniques are used to simulate and optimize hydrogen injection in shaft furnaces. These include computational fluid dynamics (CFD), thermochemical models, and digital twins that predict gas flow patterns, heat transfer, and chemical reactions. Simulation tools help engineers design more efficient furnace configurations, optimize injection parameters, and predict operational challenges before implementation. These models account for hydrogen's unique properties and its interactions with furnace materials and burden.Expand Specific Solutions05 Safety and monitoring systems for hydrogen-injected shaft furnaces

Specialized safety systems for hydrogen-injected shaft furnaces address the unique hazards associated with hydrogen use. These include advanced leak detection systems, explosion prevention measures, and emergency shutdown protocols. Continuous monitoring of hydrogen concentration, pressure, and temperature throughout the furnace system helps prevent dangerous conditions. Additional features include flame arrestors, purging systems, and specialized materials resistant to hydrogen embrittlement to ensure safe and reliable operation.Expand Specific Solutions

Key Industry Players in Hydrogen-based Steelmaking

The hydrogen-based Direct Reduced Iron (DRI) technology market is currently in a transitional growth phase, with increasing momentum toward decarbonization in steelmaking. The global market is projected to expand significantly as steel producers seek to reduce carbon emissions. Leading technology providers like Midrex Technologies and Paul Wurth have developed mature shaft furnace designs, while major steel producers such as ArcelorMittal and HBIS Group are actively implementing hydrogen injection strategies. Research institutions including the Institute of Process Engineering CAS and University of Science & Technology Beijing are advancing fundamental research. Industrial gas specialists Air Liquide, Air Products, and Linde are contributing critical hydrogen supply expertise. The competitive landscape features established players with proven technologies alongside emerging innovators developing next-generation solutions for hydrogen optimization in shaft furnace operations.

Midrex Technologies, Inc.

Technical Solution: Midrex has developed the MIDREX H2™ process specifically for hydrogen-based direct reduction of iron ore. Their shaft furnace design incorporates a specialized hydrogen injection system that allows for flexible operation with varying H2/natural gas ratios, from 100% natural gas to 100% hydrogen. The technology features a multi-point injection strategy with carefully engineered tuyeres that optimize gas distribution throughout the reduction zone. Midrex's approach includes precise temperature control mechanisms to manage the endothermic nature of hydrogen reduction, with advanced refractory materials designed to withstand hydrogen embrittlement. Their system incorporates sophisticated process control algorithms that continuously adjust gas flow rates, composition, and temperature based on real-time monitoring of reduction efficiency and product quality. The MIDREX H2™ process achieves metallization rates exceeding 94% while maintaining energy efficiency through advanced heat recovery systems that capture and reuse thermal energy from the process gas circuit.

Strengths: Industry-leading experience with over 90 MIDREX modules installed worldwide provides extensive operational data for hydrogen implementation. Their flexible design allows for gradual transition from natural gas to hydrogen, reducing investment risks. Weaknesses: Higher capital costs compared to conventional DRI plants, and requires significant modifications to existing plants for high hydrogen percentages.

Paul Wurth SA

Technical Solution: Paul Wurth has developed the PRODURES (PRocess for the Direct RedUction with Renewable Energy Sources) technology for hydrogen-based direct reduction. Their shaft furnace design features a specialized hydrogen injection system with multiple injection points arranged in a helical pattern to ensure uniform gas distribution and maximize contact between hydrogen and iron ore particles. The furnace incorporates a dual-zone design with separate control systems for the reduction and cooling zones, allowing for precise temperature management throughout the process. Paul Wurth's technology includes advanced computational fluid dynamics modeling to optimize gas flow patterns and minimize channeling effects. Their hydrogen injection strategy incorporates variable pressure control to maintain optimal reduction conditions despite the different physical properties of hydrogen compared to natural gas. The system also features specialized refractory materials and sealing solutions designed to prevent hydrogen leakage and manage the challenges of hydrogen embrittlement at high temperatures.

Strengths: Extensive experience in ironmaking technologies and furnace design provides strong foundation for hydrogen DRI implementation. Their advanced computational modeling capabilities enable highly optimized gas flow patterns. Weaknesses: Less operational experience with full-scale hydrogen DRI compared to some competitors, and their system requires sophisticated control systems that increase complexity and maintenance requirements.

Critical Patents in Shaft Furnace Design for H2 Utilization

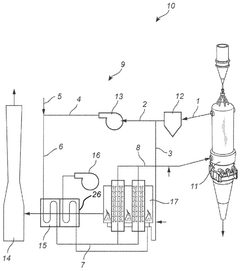

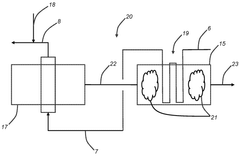

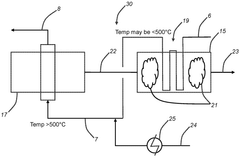

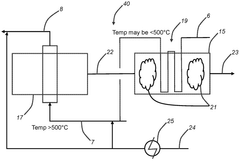

Methods and systems to produce high quality syngas for the production of direct reduced iron (DRI) while maintaining high energy efficiency

PatentWO2025106172A1

Innovation

- Introducing preheated hydrogen gas directly into the hot feed gas, which is preheated using heat recovery systems before being fed into the reformer, maintains high feed gas preheat temperatures above 500 °C, even when hydrogen supplies exceed 30% of the total process fuel, thereby optimizing reformer performance and energy efficiency.

Method for manufacturing direct reduced iron and DRI manufacturing equipment

PatentActiveZA202310332B

Innovation

- Utilization of hydrogen extracted from coke oven gas through a hydrogen separation unit for iron ore reduction in DRI shaft furnace, providing a sustainable hydrogen source.

- Strategic injection of the remaining coke oven gas into the transition section of the DRI shaft to precisely control carbon content (0.5-3 wt.%) in the final DRI product.

- Integration of hydrogen separation unit directly with the DRI shaft furnace system, creating a closed-loop process that maximizes resource utilization from coke oven gas.

Energy Efficiency and Carbon Reduction Potential

The implementation of hydrogen-based direct reduced iron (DRI) technology in shaft furnaces represents a significant opportunity for energy efficiency improvements and carbon emissions reduction in the steel industry. Traditional blast furnace ironmaking processes typically emit 1.8-2.0 tons of CO2 per ton of steel produced, while hydrogen DRI technology has the potential to reduce these emissions by 80-95% when powered by renewable energy sources.

Energy efficiency in hydrogen DRI shaft furnaces is primarily achieved through optimized furnace design and strategic hydrogen injection methods. Modern shaft furnace designs incorporating improved heat recovery systems can achieve thermal efficiency rates of 76-82%, compared to 65-70% in conventional natural gas-based DRI processes. This translates to energy savings of approximately 2.5-3.2 GJ per ton of DRI produced.

The carbon reduction potential is particularly promising when green hydrogen is utilized. Life cycle assessments indicate that hydrogen DRI can reduce the carbon footprint to 0.3-0.5 tons of CO2 per ton of steel, representing an 85% reduction compared to conventional blast furnace routes. Even when considering the transition period using blue hydrogen (produced from natural gas with carbon capture), emissions can be reduced by 60-70%.

Economic modeling suggests that the energy cost structure shifts significantly with hydrogen DRI implementation. While traditional ironmaking processes allocate 40-45% of energy costs to coal and coke, hydrogen-based processes redirect this investment toward electricity for hydrogen production. This shift creates opportunities for integration with variable renewable energy sources, potentially allowing steel plants to operate as flexible energy consumers in future smart grid systems.

The temperature profile management within shaft furnaces using hydrogen injection presents additional efficiency opportunities. Advanced computational fluid dynamics modeling indicates that strategic multi-point hydrogen injection can improve reduction efficiency by 15-20% compared to single-point injection systems, while simultaneously reducing the specific energy consumption by 0.8-1.2 GJ per ton of DRI.

Regional analysis demonstrates varying carbon reduction potentials based on electricity grid compositions. Regions with high renewable energy penetration could achieve near-zero emission steel production, while those still reliant on fossil fuel electricity generation would realize more modest benefits of 30-50% emissions reduction until their energy infrastructure transitions to cleaner sources.

Energy efficiency in hydrogen DRI shaft furnaces is primarily achieved through optimized furnace design and strategic hydrogen injection methods. Modern shaft furnace designs incorporating improved heat recovery systems can achieve thermal efficiency rates of 76-82%, compared to 65-70% in conventional natural gas-based DRI processes. This translates to energy savings of approximately 2.5-3.2 GJ per ton of DRI produced.

The carbon reduction potential is particularly promising when green hydrogen is utilized. Life cycle assessments indicate that hydrogen DRI can reduce the carbon footprint to 0.3-0.5 tons of CO2 per ton of steel, representing an 85% reduction compared to conventional blast furnace routes. Even when considering the transition period using blue hydrogen (produced from natural gas with carbon capture), emissions can be reduced by 60-70%.

Economic modeling suggests that the energy cost structure shifts significantly with hydrogen DRI implementation. While traditional ironmaking processes allocate 40-45% of energy costs to coal and coke, hydrogen-based processes redirect this investment toward electricity for hydrogen production. This shift creates opportunities for integration with variable renewable energy sources, potentially allowing steel plants to operate as flexible energy consumers in future smart grid systems.

The temperature profile management within shaft furnaces using hydrogen injection presents additional efficiency opportunities. Advanced computational fluid dynamics modeling indicates that strategic multi-point hydrogen injection can improve reduction efficiency by 15-20% compared to single-point injection systems, while simultaneously reducing the specific energy consumption by 0.8-1.2 GJ per ton of DRI.

Regional analysis demonstrates varying carbon reduction potentials based on electricity grid compositions. Regions with high renewable energy penetration could achieve near-zero emission steel production, while those still reliant on fossil fuel electricity generation would realize more modest benefits of 30-50% emissions reduction until their energy infrastructure transitions to cleaner sources.

Techno-Economic Assessment of H2-DRI Implementation

The techno-economic assessment of hydrogen-based direct reduced iron (H2-DRI) implementation requires comprehensive analysis of both capital expenditures and operational costs against potential benefits. Initial investment for retrofitting existing shaft furnaces or constructing new hydrogen-compatible facilities represents a significant financial commitment, typically ranging from $200-600 million depending on capacity and technology selection.

Operating costs present a complex economic equation where hydrogen production or procurement constitutes the dominant expense. Current hydrogen costs range from $1.5-6/kg depending on production method and regional energy prices, with green hydrogen generally commanding premium prices. This translates to approximately $50-200 per ton of DRI produced, significantly higher than natural gas-based reduction.

Energy efficiency considerations reveal that H2-DRI processes typically require 3.0-3.5 GJ/ton of iron, which compares favorably with conventional blast furnace routes (4.5-5.5 GJ/ton) when considering total system efficiency. However, the higher cost per energy unit for hydrogen currently offsets these efficiency gains.

Carbon pricing mechanisms substantially impact the economic viability of H2-DRI implementation. In regions with carbon prices exceeding €50-70/tCO2, hydrogen pathways begin to demonstrate competitive advantages against conventional routes. Projections indicate that with carbon prices reaching €100/tCO2 by 2030 in some markets, the economic case for H2-DRI strengthens considerably.

Production scale economics reveal that larger facilities (>1 million tons/year) achieve significantly better unit economics through improved thermal efficiency and better capital utilization. Smaller demonstration plants (<200,000 tons/year) currently show prohibitive unit costs without substantial subsidies or premium green steel markets.

Market premium analysis indicates that "green steel" currently commands a 10-25% price premium in select markets, though this premium remains inconsistent across regions and product categories. This premium partially offsets the higher production costs but may not fully compensate for the cost differential in most current scenarios.

Long-term economic modeling suggests that H2-DRI implementation becomes economically viable without subsidies when hydrogen prices fall below $2/kg and carbon prices exceed €80/tCO2. These conditions are projected to emerge in leading markets between 2028-2035, depending on policy support and technological advancement rates.

Operating costs present a complex economic equation where hydrogen production or procurement constitutes the dominant expense. Current hydrogen costs range from $1.5-6/kg depending on production method and regional energy prices, with green hydrogen generally commanding premium prices. This translates to approximately $50-200 per ton of DRI produced, significantly higher than natural gas-based reduction.

Energy efficiency considerations reveal that H2-DRI processes typically require 3.0-3.5 GJ/ton of iron, which compares favorably with conventional blast furnace routes (4.5-5.5 GJ/ton) when considering total system efficiency. However, the higher cost per energy unit for hydrogen currently offsets these efficiency gains.

Carbon pricing mechanisms substantially impact the economic viability of H2-DRI implementation. In regions with carbon prices exceeding €50-70/tCO2, hydrogen pathways begin to demonstrate competitive advantages against conventional routes. Projections indicate that with carbon prices reaching €100/tCO2 by 2030 in some markets, the economic case for H2-DRI strengthens considerably.

Production scale economics reveal that larger facilities (>1 million tons/year) achieve significantly better unit economics through improved thermal efficiency and better capital utilization. Smaller demonstration plants (<200,000 tons/year) currently show prohibitive unit costs without substantial subsidies or premium green steel markets.

Market premium analysis indicates that "green steel" currently commands a 10-25% price premium in select markets, though this premium remains inconsistent across regions and product categories. This premium partially offsets the higher production costs but may not fully compensate for the cost differential in most current scenarios.

Long-term economic modeling suggests that H2-DRI implementation becomes economically viable without subsidies when hydrogen prices fall below $2/kg and carbon prices exceed €80/tCO2. These conditions are projected to emerge in leading markets between 2028-2035, depending on policy support and technological advancement rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!