Sodium Percarbonate's Impact on Contract Cleaners' Efficiency

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Percarbonate Overview and Objectives

Sodium percarbonate, a white crystalline compound with the chemical formula 2Na2CO3·3H2O2, has emerged as a significant player in the cleaning industry. This adduct of sodium carbonate and hydrogen peroxide has gained prominence due to its versatile cleaning properties and environmentally friendly nature. As a powerful oxidizing agent, sodium percarbonate releases oxygen when dissolved in water, making it an effective bleaching and cleaning agent.

The evolution of sodium percarbonate in the cleaning industry can be traced back to the early 20th century, with its commercial production beginning in the 1960s. Since then, it has steadily gained traction, particularly in the last two decades, as environmental concerns and the demand for eco-friendly cleaning solutions have increased. The compound's ability to break down into harmless byproducts of water, oxygen, and sodium carbonate has positioned it as a sustainable alternative to traditional chlorine-based bleaches.

In the context of contract cleaners' efficiency, sodium percarbonate presents a compelling solution to several challenges faced by the industry. Its multi-functional nature allows for a reduction in the number of cleaning products required, potentially streamlining operations and reducing costs. The compound's effectiveness in both hot and cold water applications provides flexibility in cleaning processes, which is particularly beneficial for contract cleaners who often work in diverse environments with varying requirements.

The primary objective of exploring sodium percarbonate's impact on contract cleaners' efficiency is to assess its potential for improving productivity, cost-effectiveness, and environmental sustainability in professional cleaning operations. This involves evaluating its performance across various cleaning tasks, its compatibility with existing cleaning equipment and methodologies, and its overall impact on the workflow of contract cleaning services.

Furthermore, this technical exploration aims to identify the optimal conditions and applications for sodium percarbonate use in contract cleaning, considering factors such as concentration levels, water temperature, and surface compatibility. By understanding these parameters, we can develop guidelines for maximizing the compound's efficiency in real-world cleaning scenarios, potentially leading to standardized best practices in the industry.

Another crucial aspect of this investigation is to compare sodium percarbonate-based cleaning solutions with traditional cleaning agents in terms of efficacy, cost, and environmental impact. This comparative analysis will provide valuable insights into the potential for sodium percarbonate to revolutionize the contract cleaning industry, offering a balance between powerful cleaning performance and ecological responsibility.

The evolution of sodium percarbonate in the cleaning industry can be traced back to the early 20th century, with its commercial production beginning in the 1960s. Since then, it has steadily gained traction, particularly in the last two decades, as environmental concerns and the demand for eco-friendly cleaning solutions have increased. The compound's ability to break down into harmless byproducts of water, oxygen, and sodium carbonate has positioned it as a sustainable alternative to traditional chlorine-based bleaches.

In the context of contract cleaners' efficiency, sodium percarbonate presents a compelling solution to several challenges faced by the industry. Its multi-functional nature allows for a reduction in the number of cleaning products required, potentially streamlining operations and reducing costs. The compound's effectiveness in both hot and cold water applications provides flexibility in cleaning processes, which is particularly beneficial for contract cleaners who often work in diverse environments with varying requirements.

The primary objective of exploring sodium percarbonate's impact on contract cleaners' efficiency is to assess its potential for improving productivity, cost-effectiveness, and environmental sustainability in professional cleaning operations. This involves evaluating its performance across various cleaning tasks, its compatibility with existing cleaning equipment and methodologies, and its overall impact on the workflow of contract cleaning services.

Furthermore, this technical exploration aims to identify the optimal conditions and applications for sodium percarbonate use in contract cleaning, considering factors such as concentration levels, water temperature, and surface compatibility. By understanding these parameters, we can develop guidelines for maximizing the compound's efficiency in real-world cleaning scenarios, potentially leading to standardized best practices in the industry.

Another crucial aspect of this investigation is to compare sodium percarbonate-based cleaning solutions with traditional cleaning agents in terms of efficacy, cost, and environmental impact. This comparative analysis will provide valuable insights into the potential for sodium percarbonate to revolutionize the contract cleaning industry, offering a balance between powerful cleaning performance and ecological responsibility.

Market Analysis for Cleaning Industry

The cleaning industry has experienced significant growth and transformation in recent years, driven by increasing demand for professional cleaning services across various sectors. The global commercial cleaning market was valued at $292.6 billion in 2019 and is projected to reach $468.2 billion by 2027, growing at a CAGR of 6.1% from 2020 to 2027. This growth is attributed to factors such as urbanization, rising hygiene awareness, and the expansion of commercial spaces.

The contract cleaning segment, which includes services provided to businesses, institutions, and government facilities, represents a substantial portion of the overall market. In the United States alone, the contract cleaning industry generates annual revenues exceeding $78 billion. The market is characterized by a high degree of fragmentation, with numerous small and medium-sized enterprises competing alongside larger national and international players.

Recent trends in the cleaning industry include the adoption of eco-friendly and sustainable cleaning solutions, driven by increasing environmental concerns and regulatory pressures. This shift has led to a growing demand for green cleaning products and practices, with many contract cleaners incorporating environmentally friendly options into their service offerings.

The COVID-19 pandemic has had a profound impact on the cleaning industry, significantly increasing the demand for professional cleaning and disinfection services. This has led to the emergence of new cleaning protocols and technologies, such as electrostatic spraying and UV-C disinfection, which have gained traction in various sectors, including healthcare, hospitality, and education.

In terms of market segmentation, the commercial cleaning industry serves a diverse range of sectors, including office buildings, healthcare facilities, educational institutions, retail spaces, and industrial sites. Each sector has unique cleaning requirements and challenges, driving the need for specialized services and products.

The introduction of innovative cleaning agents, such as sodium percarbonate, has the potential to significantly impact the efficiency and effectiveness of contract cleaners. These advanced cleaning solutions offer benefits such as improved stain removal, reduced environmental impact, and enhanced safety for cleaning staff and building occupants. As a result, there is growing interest in the adoption of such products among contract cleaning companies seeking to improve their service quality and operational efficiency.

The contract cleaning segment, which includes services provided to businesses, institutions, and government facilities, represents a substantial portion of the overall market. In the United States alone, the contract cleaning industry generates annual revenues exceeding $78 billion. The market is characterized by a high degree of fragmentation, with numerous small and medium-sized enterprises competing alongside larger national and international players.

Recent trends in the cleaning industry include the adoption of eco-friendly and sustainable cleaning solutions, driven by increasing environmental concerns and regulatory pressures. This shift has led to a growing demand for green cleaning products and practices, with many contract cleaners incorporating environmentally friendly options into their service offerings.

The COVID-19 pandemic has had a profound impact on the cleaning industry, significantly increasing the demand for professional cleaning and disinfection services. This has led to the emergence of new cleaning protocols and technologies, such as electrostatic spraying and UV-C disinfection, which have gained traction in various sectors, including healthcare, hospitality, and education.

In terms of market segmentation, the commercial cleaning industry serves a diverse range of sectors, including office buildings, healthcare facilities, educational institutions, retail spaces, and industrial sites. Each sector has unique cleaning requirements and challenges, driving the need for specialized services and products.

The introduction of innovative cleaning agents, such as sodium percarbonate, has the potential to significantly impact the efficiency and effectiveness of contract cleaners. These advanced cleaning solutions offer benefits such as improved stain removal, reduced environmental impact, and enhanced safety for cleaning staff and building occupants. As a result, there is growing interest in the adoption of such products among contract cleaning companies seeking to improve their service quality and operational efficiency.

Current Challenges in Professional Cleaning

The professional cleaning industry faces several significant challenges in today's rapidly evolving market. One of the primary concerns is the increasing demand for environmentally friendly cleaning solutions. As sustainability becomes a key focus for businesses and consumers alike, contract cleaners are under pressure to adopt eco-friendly practices and products. This shift requires a delicate balance between maintaining cleaning efficacy and reducing environmental impact.

Another major challenge is the rising cost of labor and materials. With minimum wage increases and stricter labor regulations in many regions, contract cleaning companies are experiencing tighter profit margins. This financial pressure is compounded by the need to invest in new technologies and training to stay competitive, creating a significant strain on resources.

The COVID-19 pandemic has also introduced new complexities to the professional cleaning landscape. Enhanced cleaning protocols and increased frequency of disinfection have become standard expectations, requiring additional time, resources, and specialized knowledge. This has led to a need for more advanced cleaning technologies and products capable of effectively eliminating pathogens while being safe for frequent use.

Workforce management presents another ongoing challenge. The cleaning industry often experiences high turnover rates, making it difficult to maintain a skilled and reliable workforce. This instability can lead to inconsistent service quality and increased training costs. Additionally, there is a growing need for workers with technical skills to operate increasingly sophisticated cleaning equipment and manage digital cleaning management systems.

Technology adoption is both a challenge and an opportunity in the professional cleaning sector. While new technologies offer the potential for improved efficiency and effectiveness, they also require significant investment and can be met with resistance from traditional cleaning staff. Integrating smart cleaning solutions, IoT devices, and data analytics into cleaning operations demands a shift in mindset and skillset across the organization.

Regulatory compliance is becoming increasingly complex, with stricter health and safety standards, chemical usage regulations, and waste management requirements. Contract cleaners must navigate this regulatory landscape while ensuring their practices remain cost-effective and efficient. This often necessitates ongoing education and adaptation of cleaning methodologies.

Lastly, customer expectations continue to evolve, with a growing emphasis on transparency, customization, and measurable results. Clients now demand detailed reporting on cleaning activities, real-time communication, and tailored service packages. Meeting these expectations while maintaining operational efficiency poses a significant challenge for many cleaning service providers.

Another major challenge is the rising cost of labor and materials. With minimum wage increases and stricter labor regulations in many regions, contract cleaning companies are experiencing tighter profit margins. This financial pressure is compounded by the need to invest in new technologies and training to stay competitive, creating a significant strain on resources.

The COVID-19 pandemic has also introduced new complexities to the professional cleaning landscape. Enhanced cleaning protocols and increased frequency of disinfection have become standard expectations, requiring additional time, resources, and specialized knowledge. This has led to a need for more advanced cleaning technologies and products capable of effectively eliminating pathogens while being safe for frequent use.

Workforce management presents another ongoing challenge. The cleaning industry often experiences high turnover rates, making it difficult to maintain a skilled and reliable workforce. This instability can lead to inconsistent service quality and increased training costs. Additionally, there is a growing need for workers with technical skills to operate increasingly sophisticated cleaning equipment and manage digital cleaning management systems.

Technology adoption is both a challenge and an opportunity in the professional cleaning sector. While new technologies offer the potential for improved efficiency and effectiveness, they also require significant investment and can be met with resistance from traditional cleaning staff. Integrating smart cleaning solutions, IoT devices, and data analytics into cleaning operations demands a shift in mindset and skillset across the organization.

Regulatory compliance is becoming increasingly complex, with stricter health and safety standards, chemical usage regulations, and waste management requirements. Contract cleaners must navigate this regulatory landscape while ensuring their practices remain cost-effective and efficient. This often necessitates ongoing education and adaptation of cleaning methodologies.

Lastly, customer expectations continue to evolve, with a growing emphasis on transparency, customization, and measurable results. Clients now demand detailed reporting on cleaning activities, real-time communication, and tailored service packages. Meeting these expectations while maintaining operational efficiency poses a significant challenge for many cleaning service providers.

Sodium Percarbonate Applications

01 Stabilization of sodium percarbonate

Various methods are employed to stabilize sodium percarbonate, enhancing its efficiency and shelf life. These include coating the particles with inorganic or organic compounds, adding stabilizing agents, and controlling moisture content. Stabilization techniques improve the performance of sodium percarbonate in cleaning and bleaching applications.- Stabilization of sodium percarbonate: Various methods are employed to stabilize sodium percarbonate, enhancing its efficiency and shelf life. These include coating the particles with inorganic or organic materials, adding stabilizing agents, and controlling moisture content. Stabilization techniques improve the performance of sodium percarbonate in cleaning and bleaching applications.

- Sodium percarbonate production methods: Different production methods are used to manufacture sodium percarbonate with improved efficiency. These include spray drying, fluidized bed processes, and crystallization techniques. The choice of production method can affect the particle size, stability, and overall performance of the sodium percarbonate.

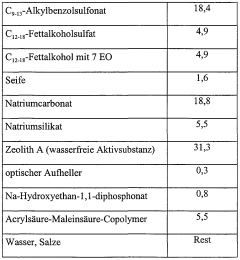

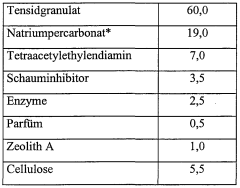

- Formulation with other active ingredients: Sodium percarbonate is often formulated with other active ingredients to enhance its efficiency in cleaning and bleaching applications. These formulations may include surfactants, enzymes, chelating agents, and other oxidizing agents. The combination of ingredients can lead to synergistic effects, improving overall performance.

- Particle size and morphology control: Controlling the particle size and morphology of sodium percarbonate can significantly impact its efficiency. Smaller particles or specific shapes may improve dissolution rates and stability. Various techniques are employed to achieve desired particle characteristics, including granulation and milling processes.

- Application-specific optimization: Sodium percarbonate efficiency can be optimized for specific applications, such as laundry detergents, dishwashing formulations, or industrial cleaning processes. This involves tailoring the product's properties, such as dissolution rate, stability, and active oxygen content, to meet the requirements of each application.

02 Particle size and morphology control

The efficiency of sodium percarbonate is influenced by its particle size and morphology. Controlling these parameters during production can lead to improved dissolution rates, stability, and overall performance. Techniques such as spray drying, granulation, and particle shaping are used to optimize the physical characteristics of sodium percarbonate.Expand Specific Solutions03 Incorporation in cleaning formulations

Sodium percarbonate is widely used in cleaning and laundry formulations. Its efficiency can be enhanced by combining it with other active ingredients, surfactants, and enzymes. Formulation techniques focus on improving the release of active oxygen and maintaining stability in the presence of other components.Expand Specific Solutions04 Production process optimization

Improving the efficiency of sodium percarbonate production processes can lead to higher quality and more cost-effective products. This includes optimizing reaction conditions, improving raw material purity, and developing novel production methods. Continuous production processes and energy-efficient techniques are also explored to enhance overall efficiency.Expand Specific Solutions05 Environmental and safety considerations

Enhancing the environmental profile and safety of sodium percarbonate use is crucial for its efficiency in various applications. This includes developing more eco-friendly production methods, improving biodegradability, and reducing potential risks associated with its use. Research also focuses on minimizing the environmental impact of sodium percarbonate in wastewater and aquatic ecosystems.Expand Specific Solutions

Key Players in Cleaning Chemical Industry

The sodium percarbonate market for contract cleaners is in a growth phase, driven by increasing demand for eco-friendly cleaning solutions. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, sodium percarbonate is well-established, but innovations in formulation and application continue. Key players like Solvay SA, Evonik Operations GmbH, and Henkel AG & Co. KGaA are at the forefront of development, while companies such as Zhejiang Jinke Daily Chemical Co. Ltd. and Shandong Tianli Energy Co., Ltd. are emerging as significant contributors. The competitive landscape is characterized by a mix of established chemical giants and specialized manufacturers, with ongoing research focused on enhancing efficiency and environmental compatibility for contract cleaning applications.

Solvay SA

Technical Solution: Solvay SA has developed advanced sodium percarbonate (SPC) formulations specifically tailored for contract cleaners. Their SPC products feature enhanced stability and controlled release properties, allowing for prolonged cleaning action. Solvay's innovative encapsulation technology protects SPC particles, ensuring they remain active even in the presence of metal ions and organic soils[1]. This results in improved cleaning efficiency, as the oxygen bleach is released gradually, maintaining its effectiveness throughout the cleaning process. Solvay's SPC formulations also incorporate surfactant systems that enhance the overall cleaning performance, allowing for better penetration of soils and improved stain removal capabilities[2].

Strengths: Superior stability and controlled release properties, enhanced cleaning efficiency, and compatibility with various cleaning formulations. Weaknesses: Potentially higher cost compared to standard SPC products, may require specialized handling and storage.

Evonik Operations GmbH

Technical Solution: Evonik has developed a range of sodium percarbonate products under their PERCARB® brand, specifically designed to enhance the efficiency of contract cleaners. Their technology focuses on particle size optimization and surface treatment to improve dissolution rates and stability. Evonik's PERCARB® SPC products feature a unique coating that protects the active oxygen content from premature decomposition, ensuring consistent performance even in challenging cleaning environments[3]. The company has also introduced a fast-dissolving variant that rapidly releases active oxygen, making it ideal for quick cleaning tasks. Additionally, Evonik's SPC formulations are designed to work synergistically with their BREAK-THRU® surfactants, enhancing overall cleaning power and efficiency[4].

Strengths: Optimized particle size for improved dissolution, enhanced stability through protective coating, and synergistic formulations with proprietary surfactants. Weaknesses: May be more expensive than conventional SPC products, potential limitations in extreme temperature or humidity conditions.

Innovative Formulations with Sodium Percarbonate

Washing and cleaning agent shaped bodies comprising sodium percarbonate

PatentWO2000017307A1

Innovation

- The development of detergent tablets with sodium percarbonate, where at least 60% by weight of the sodium percarbonate particles have a particle size below 0.8 mm, and the proportion with sizes above 800 μm is less than 40% by weight, ensuring a finely divided and homogeneous particle size distribution, which enhances disintegration properties and bleaching performance.

Use of polyasparaginic acid in cleaning formula with abrasive effect

PatentInactiveEP0987316A1

Innovation

- Combining sodium bicarbonate with polyaspartic acids or their salts as dispersants in cleaning agents to enhance dirt solubilization and dispersion, reducing sedimentation and allowing for direct, environmentally friendly disposal of wastewater.

Environmental Impact Assessment

The environmental impact of sodium percarbonate on contract cleaners' efficiency is a crucial aspect to consider in the broader context of sustainable cleaning practices. Sodium percarbonate, a compound of sodium carbonate and hydrogen peroxide, has gained popularity as an eco-friendly alternative to traditional cleaning agents. Its decomposition into oxygen, water, and sodium carbonate presents a significantly reduced environmental footprint compared to conventional chlorine-based cleaners.

When assessing the environmental impact, it is essential to consider the entire lifecycle of sodium percarbonate, from production to disposal. The manufacturing process of sodium percarbonate is relatively energy-efficient, requiring less energy input compared to the production of chlorine-based bleaches. This reduced energy consumption translates to lower greenhouse gas emissions associated with its production.

In terms of water pollution, sodium percarbonate offers distinct advantages. Unlike chlorine-based cleaners, it does not produce harmful chlorinated organic compounds when released into water systems. The oxygen released during its decomposition can actually have a beneficial effect on aquatic ecosystems by increasing dissolved oxygen levels. However, it is important to note that excessive use of any cleaning agent, including sodium percarbonate, can lead to nutrient enrichment in water bodies, potentially causing algal blooms.

The impact on soil quality is another critical consideration. Sodium percarbonate's decomposition products are generally benign to soil microorganisms and plant life. The sodium carbonate residue can have a slight alkalizing effect on soil, which may be beneficial in certain acidic soil conditions but could potentially alter soil pH if used excessively over time.

Air quality is minimally affected by the use of sodium percarbonate. Unlike many traditional cleaning agents, it does not release volatile organic compounds (VOCs) or other harmful fumes during use. This characteristic not only reduces indoor air pollution but also contributes to a healthier working environment for cleaning staff.

From a waste management perspective, sodium percarbonate presents fewer challenges than many conventional cleaning agents. Its biodegradable nature means that it does not persist in the environment, reducing the long-term impact on ecosystems. The packaging of sodium percarbonate products, however, remains an area for potential improvement in terms of environmental sustainability.

In conclusion, while sodium percarbonate offers significant environmental benefits compared to many traditional cleaning agents, its impact is not entirely neutral. Proper use, dosage control, and responsible disposal practices are crucial to maximizing its environmental benefits while minimizing potential negative impacts. Contract cleaners adopting sodium percarbonate can significantly reduce their environmental footprint, aligning with growing demands for sustainable cleaning solutions in various industries.

When assessing the environmental impact, it is essential to consider the entire lifecycle of sodium percarbonate, from production to disposal. The manufacturing process of sodium percarbonate is relatively energy-efficient, requiring less energy input compared to the production of chlorine-based bleaches. This reduced energy consumption translates to lower greenhouse gas emissions associated with its production.

In terms of water pollution, sodium percarbonate offers distinct advantages. Unlike chlorine-based cleaners, it does not produce harmful chlorinated organic compounds when released into water systems. The oxygen released during its decomposition can actually have a beneficial effect on aquatic ecosystems by increasing dissolved oxygen levels. However, it is important to note that excessive use of any cleaning agent, including sodium percarbonate, can lead to nutrient enrichment in water bodies, potentially causing algal blooms.

The impact on soil quality is another critical consideration. Sodium percarbonate's decomposition products are generally benign to soil microorganisms and plant life. The sodium carbonate residue can have a slight alkalizing effect on soil, which may be beneficial in certain acidic soil conditions but could potentially alter soil pH if used excessively over time.

Air quality is minimally affected by the use of sodium percarbonate. Unlike many traditional cleaning agents, it does not release volatile organic compounds (VOCs) or other harmful fumes during use. This characteristic not only reduces indoor air pollution but also contributes to a healthier working environment for cleaning staff.

From a waste management perspective, sodium percarbonate presents fewer challenges than many conventional cleaning agents. Its biodegradable nature means that it does not persist in the environment, reducing the long-term impact on ecosystems. The packaging of sodium percarbonate products, however, remains an area for potential improvement in terms of environmental sustainability.

In conclusion, while sodium percarbonate offers significant environmental benefits compared to many traditional cleaning agents, its impact is not entirely neutral. Proper use, dosage control, and responsible disposal practices are crucial to maximizing its environmental benefits while minimizing potential negative impacts. Contract cleaners adopting sodium percarbonate can significantly reduce their environmental footprint, aligning with growing demands for sustainable cleaning solutions in various industries.

Cost-Benefit Analysis for Contract Cleaners

The implementation of sodium percarbonate in cleaning processes can significantly impact the operational efficiency and cost-effectiveness of contract cleaning services. This cost-benefit analysis aims to provide a comprehensive evaluation of the financial implications associated with adopting sodium percarbonate-based cleaning solutions.

Initial investment costs for transitioning to sodium percarbonate-based products may include the purchase of new cleaning equipment, staff training, and potentially higher upfront costs for the cleaning agents themselves. However, these initial expenses should be weighed against the long-term benefits and potential savings.

One of the primary advantages of sodium percarbonate is its versatility as a cleaning agent. It can effectively replace multiple specialized cleaning products, potentially reducing inventory costs and simplifying procurement processes. This consolidation of cleaning supplies can lead to reduced storage requirements and improved inventory management efficiency.

Labor costs, which often constitute a significant portion of contract cleaners' expenses, may be positively impacted by the use of sodium percarbonate. Its powerful cleaning properties can reduce the time required for certain cleaning tasks, potentially increasing the number of cleaning jobs that can be completed within a given timeframe. This improved efficiency could translate to either reduced labor hours or increased service capacity without additional staffing.

The environmental and health benefits of sodium percarbonate should also be factored into the cost-benefit analysis. As a more eco-friendly alternative to harsh chemical cleaners, it may reduce potential health risks for cleaning staff and building occupants. This could lead to decreased sick leave, lower insurance premiums, and improved employee retention rates, all of which have positive financial implications for contract cleaning businesses.

Energy costs associated with cleaning processes may also be reduced. Sodium percarbonate is effective in cold water, potentially decreasing hot water usage and the associated energy costs. Additionally, its oxygen-releasing properties can enhance the effectiveness of other cleaning agents, potentially reducing the overall quantity of cleaning products required.

When considering long-term costs, the durability of surfaces cleaned with sodium percarbonate should be taken into account. Its gentler nature compared to some harsh chemical cleaners may extend the lifespan of cleaned surfaces, potentially reducing replacement and maintenance costs for clients. This could be a significant selling point for contract cleaners, potentially leading to increased client satisfaction and retention.

In conclusion, while there may be initial costs associated with adopting sodium percarbonate-based cleaning solutions, the potential for long-term savings and operational efficiencies appears substantial. Contract cleaners should conduct a thorough analysis of their specific operational context to determine the exact cost-benefit ratio for their business.

Initial investment costs for transitioning to sodium percarbonate-based products may include the purchase of new cleaning equipment, staff training, and potentially higher upfront costs for the cleaning agents themselves. However, these initial expenses should be weighed against the long-term benefits and potential savings.

One of the primary advantages of sodium percarbonate is its versatility as a cleaning agent. It can effectively replace multiple specialized cleaning products, potentially reducing inventory costs and simplifying procurement processes. This consolidation of cleaning supplies can lead to reduced storage requirements and improved inventory management efficiency.

Labor costs, which often constitute a significant portion of contract cleaners' expenses, may be positively impacted by the use of sodium percarbonate. Its powerful cleaning properties can reduce the time required for certain cleaning tasks, potentially increasing the number of cleaning jobs that can be completed within a given timeframe. This improved efficiency could translate to either reduced labor hours or increased service capacity without additional staffing.

The environmental and health benefits of sodium percarbonate should also be factored into the cost-benefit analysis. As a more eco-friendly alternative to harsh chemical cleaners, it may reduce potential health risks for cleaning staff and building occupants. This could lead to decreased sick leave, lower insurance premiums, and improved employee retention rates, all of which have positive financial implications for contract cleaning businesses.

Energy costs associated with cleaning processes may also be reduced. Sodium percarbonate is effective in cold water, potentially decreasing hot water usage and the associated energy costs. Additionally, its oxygen-releasing properties can enhance the effectiveness of other cleaning agents, potentially reducing the overall quantity of cleaning products required.

When considering long-term costs, the durability of surfaces cleaned with sodium percarbonate should be taken into account. Its gentler nature compared to some harsh chemical cleaners may extend the lifespan of cleaned surfaces, potentially reducing replacement and maintenance costs for clients. This could be a significant selling point for contract cleaners, potentially leading to increased client satisfaction and retention.

In conclusion, while there may be initial costs associated with adopting sodium percarbonate-based cleaning solutions, the potential for long-term savings and operational efficiencies appears substantial. Contract cleaners should conduct a thorough analysis of their specific operational context to determine the exact cost-benefit ratio for their business.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!