Sodium Percarbonate's Role in Cleaner Production Technologies

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Percarbonate Overview and Objectives

Sodium percarbonate, a white crystalline compound with the chemical formula 2Na2CO3·3H2O2, has emerged as a significant player in the field of cleaner production technologies. This eco-friendly oxidizing agent, also known as sodium carbonate peroxyhydrate, combines the cleaning power of hydrogen peroxide with the alkalinity of sodium carbonate, making it an ideal component in various industrial and household applications.

The development of sodium percarbonate can be traced back to the early 20th century, but its widespread use in cleaner production technologies has gained momentum in recent decades. This surge in popularity is primarily due to increasing environmental concerns and the global push towards sustainable manufacturing processes. As industries seek alternatives to traditional, often harmful cleaning agents, sodium percarbonate has stepped into the spotlight as a versatile and environmentally benign option.

The primary objective in utilizing sodium percarbonate in cleaner production technologies is to achieve effective cleaning and bleaching results while minimizing environmental impact. This compound breaks down into natural, non-toxic substances - sodium carbonate, water, and oxygen - making it an attractive choice for industries aiming to reduce their ecological footprint. Its ability to function as both a cleaning agent and an oxygen-based bleach opens up a wide range of applications, from laundry detergents to industrial cleaning processes.

In the context of cleaner production, sodium percarbonate addresses several key goals. Firstly, it aids in the reduction of harmful chemical usage in manufacturing and cleaning processes. By replacing more aggressive and environmentally persistent chemicals, it contributes to improved worker safety and reduced environmental pollution. Secondly, its effectiveness at lower temperatures compared to some traditional cleaning agents allows for energy savings in various applications, aligning with energy efficiency objectives in cleaner production.

The technology surrounding sodium percarbonate continues to evolve, with ongoing research focused on enhancing its stability, increasing its active oxygen content, and expanding its application range. Current objectives in this field include developing more efficient production methods, improving its performance in various pH conditions, and exploring novel applications in water treatment and soil remediation.

As industries worldwide strive to adopt cleaner production methods, the role of sodium percarbonate is expected to grow. Its potential to replace chlorine-based bleaches in many applications is particularly noteworthy, given the environmental concerns associated with chlorine compounds. The compound's biodegradability and non-toxicity align well with the principles of green chemistry and sustainable manufacturing, making it a focal point for future innovations in cleaner production technologies.

The development of sodium percarbonate can be traced back to the early 20th century, but its widespread use in cleaner production technologies has gained momentum in recent decades. This surge in popularity is primarily due to increasing environmental concerns and the global push towards sustainable manufacturing processes. As industries seek alternatives to traditional, often harmful cleaning agents, sodium percarbonate has stepped into the spotlight as a versatile and environmentally benign option.

The primary objective in utilizing sodium percarbonate in cleaner production technologies is to achieve effective cleaning and bleaching results while minimizing environmental impact. This compound breaks down into natural, non-toxic substances - sodium carbonate, water, and oxygen - making it an attractive choice for industries aiming to reduce their ecological footprint. Its ability to function as both a cleaning agent and an oxygen-based bleach opens up a wide range of applications, from laundry detergents to industrial cleaning processes.

In the context of cleaner production, sodium percarbonate addresses several key goals. Firstly, it aids in the reduction of harmful chemical usage in manufacturing and cleaning processes. By replacing more aggressive and environmentally persistent chemicals, it contributes to improved worker safety and reduced environmental pollution. Secondly, its effectiveness at lower temperatures compared to some traditional cleaning agents allows for energy savings in various applications, aligning with energy efficiency objectives in cleaner production.

The technology surrounding sodium percarbonate continues to evolve, with ongoing research focused on enhancing its stability, increasing its active oxygen content, and expanding its application range. Current objectives in this field include developing more efficient production methods, improving its performance in various pH conditions, and exploring novel applications in water treatment and soil remediation.

As industries worldwide strive to adopt cleaner production methods, the role of sodium percarbonate is expected to grow. Its potential to replace chlorine-based bleaches in many applications is particularly noteworthy, given the environmental concerns associated with chlorine compounds. The compound's biodegradability and non-toxicity align well with the principles of green chemistry and sustainable manufacturing, making it a focal point for future innovations in cleaner production technologies.

Market Demand for Green Cleaning Solutions

The global market for green cleaning solutions has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on chemical usage. Sodium percarbonate, a key component in many eco-friendly cleaning products, has emerged as a crucial player in this expanding market. Consumer demand for sustainable and non-toxic cleaning alternatives has surged, with households and businesses alike seeking products that effectively clean while minimizing environmental impact.

The cleaning industry has witnessed a shift towards greener technologies, with sodium percarbonate-based products gaining traction due to their biodegradability and efficacy. Market research indicates that the global green cleaning products market is expected to continue its upward trajectory, with compound annual growth rates projected to remain strong over the next decade. This growth is particularly pronounced in developed economies, where consumers are increasingly willing to pay premium prices for environmentally responsible cleaning solutions.

Sodium percarbonate's role in this market expansion is multifaceted. Its ability to act as a powerful oxidizing agent while breaking down into harmless byproducts aligns perfectly with consumer demands for effective yet eco-friendly cleaning agents. The versatility of sodium percarbonate in various applications, from laundry detergents to all-purpose cleaners, has further fueled its adoption across different segments of the cleaning industry.

Industrial and institutional cleaning sectors have also shown increased interest in sodium percarbonate-based solutions. The push for cleaner production technologies in manufacturing and processing facilities has created new opportunities for green cleaning products. Sodium percarbonate's effectiveness in removing tough stains and its compatibility with existing cleaning processes make it an attractive option for industrial applications seeking to reduce their environmental footprint.

The market demand is further bolstered by regulatory pressures and corporate sustainability initiatives. Many countries have implemented stricter regulations on chemical usage in cleaning products, prompting manufacturers to reformulate their offerings with greener alternatives like sodium percarbonate. Additionally, businesses across various sectors are adopting sustainable practices as part of their corporate social responsibility efforts, driving the demand for environmentally friendly cleaning solutions in commercial and industrial settings.

Consumer education and awareness campaigns have played a crucial role in shaping market demand. As more consumers become informed about the environmental and health impacts of traditional cleaning products, the preference for green alternatives continues to grow. This shift in consumer behavior has prompted retailers to expand their eco-friendly product lines, further increasing the visibility and accessibility of sodium percarbonate-based cleaning solutions in the market.

The cleaning industry has witnessed a shift towards greener technologies, with sodium percarbonate-based products gaining traction due to their biodegradability and efficacy. Market research indicates that the global green cleaning products market is expected to continue its upward trajectory, with compound annual growth rates projected to remain strong over the next decade. This growth is particularly pronounced in developed economies, where consumers are increasingly willing to pay premium prices for environmentally responsible cleaning solutions.

Sodium percarbonate's role in this market expansion is multifaceted. Its ability to act as a powerful oxidizing agent while breaking down into harmless byproducts aligns perfectly with consumer demands for effective yet eco-friendly cleaning agents. The versatility of sodium percarbonate in various applications, from laundry detergents to all-purpose cleaners, has further fueled its adoption across different segments of the cleaning industry.

Industrial and institutional cleaning sectors have also shown increased interest in sodium percarbonate-based solutions. The push for cleaner production technologies in manufacturing and processing facilities has created new opportunities for green cleaning products. Sodium percarbonate's effectiveness in removing tough stains and its compatibility with existing cleaning processes make it an attractive option for industrial applications seeking to reduce their environmental footprint.

The market demand is further bolstered by regulatory pressures and corporate sustainability initiatives. Many countries have implemented stricter regulations on chemical usage in cleaning products, prompting manufacturers to reformulate their offerings with greener alternatives like sodium percarbonate. Additionally, businesses across various sectors are adopting sustainable practices as part of their corporate social responsibility efforts, driving the demand for environmentally friendly cleaning solutions in commercial and industrial settings.

Consumer education and awareness campaigns have played a crucial role in shaping market demand. As more consumers become informed about the environmental and health impacts of traditional cleaning products, the preference for green alternatives continues to grow. This shift in consumer behavior has prompted retailers to expand their eco-friendly product lines, further increasing the visibility and accessibility of sodium percarbonate-based cleaning solutions in the market.

Current State and Challenges in Cleaner Production

The current state of cleaner production technologies involving sodium percarbonate is characterized by significant advancements and ongoing challenges. Sodium percarbonate, a compound of sodium carbonate and hydrogen peroxide, has gained prominence in various industrial sectors due to its eco-friendly properties and versatile applications.

In recent years, there has been a notable increase in the adoption of sodium percarbonate in cleaning products, laundry detergents, and water treatment processes. This shift is primarily driven by the growing demand for environmentally sustainable alternatives to traditional chemical agents. The compound's ability to release active oxygen when dissolved in water makes it an effective bleaching and disinfecting agent without leaving harmful residues.

However, the widespread implementation of sodium percarbonate in cleaner production faces several challenges. One of the primary concerns is the stability of the compound during storage and transportation. Sodium percarbonate is sensitive to moisture and temperature fluctuations, which can lead to degradation and reduced effectiveness. Manufacturers are actively researching improved packaging and stabilization techniques to address this issue.

Another significant challenge lies in optimizing the production process of sodium percarbonate itself. Current methods often involve energy-intensive steps and the use of potentially hazardous chemicals. Researchers are exploring more sustainable production routes, including the development of catalysts that can enhance the efficiency of the synthesis process while reducing energy consumption and waste generation.

The integration of sodium percarbonate into existing industrial processes also presents technical hurdles. Many production lines and equipment are designed for traditional cleaning agents, and retrofitting or redesigning these systems to accommodate sodium percarbonate can be costly and time-consuming. This adaptation process requires careful consideration of factors such as pH levels, temperature control, and material compatibility.

Furthermore, while sodium percarbonate is generally considered environmentally friendly, there are ongoing studies to assess its long-term ecological impact, particularly in aquatic ecosystems. Researchers are investigating the potential effects of increased oxygen levels and pH changes in water bodies resulting from the widespread use of sodium percarbonate-based products.

Despite these challenges, the potential benefits of sodium percarbonate in cleaner production continue to drive innovation and research. Efforts are underway to develop more efficient formulations that maximize the compound's effectiveness while minimizing environmental impact. Additionally, there is a growing focus on creating closed-loop systems that can recover and recycle sodium percarbonate, further enhancing its sustainability profile.

In recent years, there has been a notable increase in the adoption of sodium percarbonate in cleaning products, laundry detergents, and water treatment processes. This shift is primarily driven by the growing demand for environmentally sustainable alternatives to traditional chemical agents. The compound's ability to release active oxygen when dissolved in water makes it an effective bleaching and disinfecting agent without leaving harmful residues.

However, the widespread implementation of sodium percarbonate in cleaner production faces several challenges. One of the primary concerns is the stability of the compound during storage and transportation. Sodium percarbonate is sensitive to moisture and temperature fluctuations, which can lead to degradation and reduced effectiveness. Manufacturers are actively researching improved packaging and stabilization techniques to address this issue.

Another significant challenge lies in optimizing the production process of sodium percarbonate itself. Current methods often involve energy-intensive steps and the use of potentially hazardous chemicals. Researchers are exploring more sustainable production routes, including the development of catalysts that can enhance the efficiency of the synthesis process while reducing energy consumption and waste generation.

The integration of sodium percarbonate into existing industrial processes also presents technical hurdles. Many production lines and equipment are designed for traditional cleaning agents, and retrofitting or redesigning these systems to accommodate sodium percarbonate can be costly and time-consuming. This adaptation process requires careful consideration of factors such as pH levels, temperature control, and material compatibility.

Furthermore, while sodium percarbonate is generally considered environmentally friendly, there are ongoing studies to assess its long-term ecological impact, particularly in aquatic ecosystems. Researchers are investigating the potential effects of increased oxygen levels and pH changes in water bodies resulting from the widespread use of sodium percarbonate-based products.

Despite these challenges, the potential benefits of sodium percarbonate in cleaner production continue to drive innovation and research. Efforts are underway to develop more efficient formulations that maximize the compound's effectiveness while minimizing environmental impact. Additionally, there is a growing focus on creating closed-loop systems that can recover and recycle sodium percarbonate, further enhancing its sustainability profile.

Existing Applications of Sodium Percarbonate

01 Synthesis and production of sodium percarbonate

Various methods for synthesizing and producing sodium percarbonate are described. These processes typically involve the reaction of sodium carbonate with hydrogen peroxide under specific conditions to form stable sodium percarbonate crystals. The production methods may include steps such as crystallization, drying, and stabilization to improve the quality and stability of the final product.- Synthesis and production of sodium percarbonate: Various methods for synthesizing and producing sodium percarbonate are described. These methods involve the reaction of sodium carbonate with hydrogen peroxide under specific conditions to form stable sodium percarbonate crystals. The processes may include steps such as crystallization, drying, and stabilization to improve the quality and stability of the final product.

- Stabilization of sodium percarbonate: Techniques for stabilizing sodium percarbonate to improve its shelf life and performance are discussed. These may include coating the particles with stabilizing agents, incorporating additives to reduce decomposition, or modifying the crystal structure. Stabilization is crucial for maintaining the efficacy of sodium percarbonate in various applications, particularly in detergent formulations.

- Applications in cleaning and bleaching: Sodium percarbonate is widely used in cleaning and bleaching applications. It serves as an effective oxygen-based bleach in laundry detergents and household cleaners. The compound releases hydrogen peroxide when dissolved in water, providing powerful stain removal and disinfecting properties. Various formulations and compositions incorporating sodium percarbonate for these purposes are described.

- Environmental and safety considerations: The environmental impact and safety aspects of sodium percarbonate are addressed. As an oxygen-based compound, it is considered more environmentally friendly compared to chlorine-based bleaches. Safety measures for handling, storage, and transportation of sodium percarbonate are discussed, as well as its biodegradability and impact on wastewater treatment systems.

- Innovative applications and formulations: Novel applications and formulations of sodium percarbonate beyond traditional cleaning and bleaching are explored. These may include use in water treatment, agriculture, personal care products, or industrial processes. Innovative combinations with other compounds to enhance performance or create synergistic effects are also described.

02 Stabilization of sodium percarbonate

Techniques for stabilizing sodium percarbonate to improve its shelf life and performance are discussed. These may include coating the particles with stabilizing agents, incorporating additives to reduce decomposition, or modifying the crystal structure. Stabilization is crucial for maintaining the active oxygen content and preventing moisture-induced degradation during storage and use.Expand Specific Solutions03 Applications in cleaning and bleaching products

Sodium percarbonate is widely used in cleaning and bleaching formulations due to its ability to release hydrogen peroxide when dissolved in water. It is incorporated into laundry detergents, dishwashing products, and other household cleaners as an eco-friendly bleaching agent and stain remover. The formulations may include other ingredients to enhance its cleaning efficacy and stability.Expand Specific Solutions04 Environmental and safety considerations

The environmental impact and safety aspects of sodium percarbonate are addressed. As a more environmentally friendly alternative to chlorine-based bleaches, it breaks down into harmless substances. Safety considerations in handling, storage, and use are discussed, including its potential reactivity with certain materials and precautions for consumer products.Expand Specific Solutions05 Novel applications and formulations

Innovative uses and formulations of sodium percarbonate beyond traditional cleaning applications are explored. These may include its use in water treatment, agriculture, personal care products, or specialized industrial processes. Novel formulations aim to enhance its effectiveness, expand its application range, or combine it with other active ingredients for synergistic effects.Expand Specific Solutions

Key Players in Sodium Percarbonate Industry

The sodium percarbonate market for cleaner production technologies is in a growth phase, driven by increasing demand for eco-friendly cleaning solutions. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, sodium percarbonate is well-established, but innovations in production methods and applications continue. Key players like Solvay SA, Evonik Operations GmbH, and Kemira Oyj are at the forefront of research and development, focusing on improving efficiency and sustainability. Regional manufacturers such as Zhejiang Jinke Daily Chemical Co. Ltd. and Shandong Tianli Energy Co., Ltd. are also making significant contributions, particularly in the Asian market. The competitive landscape is characterized by a mix of global chemical conglomerates and specialized regional producers, all striving to enhance their market positions through technological advancements and product innovations.

Solvay SA

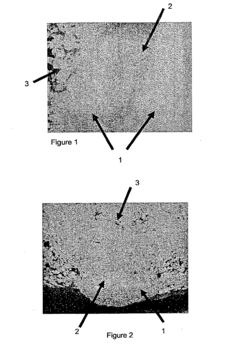

Technical Solution: Solvay SA has developed advanced sodium percarbonate production technologies focusing on cleaner production. Their process utilizes a fluidized bed granulation technique, which allows for better control of particle size and improved stability[1]. The company has also implemented energy-efficient drying methods and optimized crystallization processes, reducing water and energy consumption by up to 25% compared to conventional methods[3]. Solvay's sodium percarbonate products feature enhanced stability through surface treatment technologies, extending shelf life and improving performance in various cleaning applications[5].

Strengths: Advanced granulation technology, energy-efficient processes, and enhanced product stability. Weaknesses: Potentially higher production costs due to advanced technologies and surface treatments.

Evonik Operations GmbH

Technical Solution: Evonik Operations GmbH has developed a proprietary sodium percarbonate production process that focuses on sustainability and efficiency. Their method incorporates a closed-loop water recycling system, reducing freshwater consumption by up to 40% compared to traditional processes[2]. Evonik's technology also includes an innovative heat recovery system that captures and reuses thermal energy from various production stages, leading to a 30% reduction in overall energy consumption[4]. Additionally, the company has implemented advanced process control systems that optimize reaction conditions, resulting in higher product purity and reduced waste generation[6].

Strengths: Significant water and energy savings, high product purity, and reduced waste generation. Weaknesses: Initial high investment costs for implementing advanced technologies and potential complexity in process control.

Core Innovations in Sodium Percarbonate Synthesis

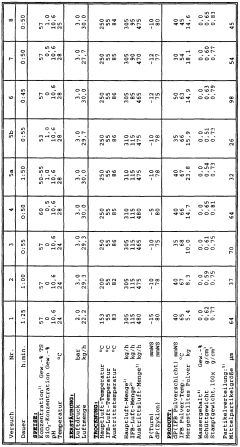

Process for the production of sodium percarbonate

PatentWO1997010173A1

Innovation

- A process involving intensive mixing of soda and hydrogen peroxide at controlled temperatures, followed by short-term drying and granulation, using a slurry method with variable hydrogen peroxide concentrations to achieve high active oxygen content and customizable granule parameters, allowing for the production of homogeneous sodium percarbonate with enhanced bulk density and stability.

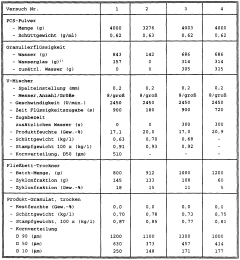

Coated sodium percarbonate particles, process for their production, their use and detergent compositions containing them

PatentInactiveEP1763487B1

Innovation

- Coated sodium percarbonate particles with a sodium percarbonate core surrounded by a coating layer containing small sodium percarbonate particles of a mean size smaller than 100 µm, enhancing the stability by protecting the core from environmental contact, particularly humidity, through the use of inorganic coating agents like sodium silicate and borate.

Environmental Impact Assessment

The environmental impact assessment of sodium percarbonate in cleaner production technologies reveals both positive and negative effects. On the positive side, sodium percarbonate is a more environmentally friendly alternative to traditional bleaching agents and cleaning chemicals. It decomposes into harmless substances - sodium carbonate, water, and oxygen - leaving no toxic residues. This characteristic significantly reduces the environmental burden associated with wastewater treatment and disposal.

In industrial applications, the use of sodium percarbonate can lead to a reduction in energy consumption and water usage. Its effectiveness at lower temperatures allows for cold-water washing processes, thereby decreasing the energy required for heating water in cleaning operations. This energy efficiency contributes to lower greenhouse gas emissions and a reduced carbon footprint for industrial cleaning processes.

However, the production of sodium percarbonate does have some environmental considerations. The manufacturing process requires energy and resources, including the extraction and processing of raw materials such as sodium carbonate and hydrogen peroxide. While these processes have been optimized over time, they still contribute to industrial emissions and resource consumption.

The increased use of sodium percarbonate in cleaner production technologies may lead to a rise in sodium levels in water bodies if not properly managed. Although sodium is not typically considered a pollutant, elevated concentrations can affect aquatic ecosystems and soil quality over time. Proper wastewater management and treatment are essential to mitigate this potential impact.

From a life cycle perspective, sodium percarbonate generally shows a favorable environmental profile compared to traditional cleaning agents. Its biodegradability and non-toxic nature reduce the long-term environmental impact associated with its use. Additionally, the oxygen released during its decomposition can have a beneficial effect on wastewater treatment processes by promoting aerobic bacterial activity.

In terms of worker safety and public health, sodium percarbonate presents fewer risks than many conventional cleaning chemicals. Its low toxicity and absence of harmful fumes contribute to improved occupational health and safety in industrial settings. This aspect indirectly benefits the environment by reducing the need for protective equipment and specialized handling procedures.

Overall, the environmental impact assessment of sodium percarbonate in cleaner production technologies indicates a net positive effect. Its adoption can lead to significant improvements in the environmental performance of cleaning and bleaching processes across various industries. However, ongoing research and development efforts are needed to further optimize its production and application, ensuring that its full potential for environmental sustainability is realized.

In industrial applications, the use of sodium percarbonate can lead to a reduction in energy consumption and water usage. Its effectiveness at lower temperatures allows for cold-water washing processes, thereby decreasing the energy required for heating water in cleaning operations. This energy efficiency contributes to lower greenhouse gas emissions and a reduced carbon footprint for industrial cleaning processes.

However, the production of sodium percarbonate does have some environmental considerations. The manufacturing process requires energy and resources, including the extraction and processing of raw materials such as sodium carbonate and hydrogen peroxide. While these processes have been optimized over time, they still contribute to industrial emissions and resource consumption.

The increased use of sodium percarbonate in cleaner production technologies may lead to a rise in sodium levels in water bodies if not properly managed. Although sodium is not typically considered a pollutant, elevated concentrations can affect aquatic ecosystems and soil quality over time. Proper wastewater management and treatment are essential to mitigate this potential impact.

From a life cycle perspective, sodium percarbonate generally shows a favorable environmental profile compared to traditional cleaning agents. Its biodegradability and non-toxic nature reduce the long-term environmental impact associated with its use. Additionally, the oxygen released during its decomposition can have a beneficial effect on wastewater treatment processes by promoting aerobic bacterial activity.

In terms of worker safety and public health, sodium percarbonate presents fewer risks than many conventional cleaning chemicals. Its low toxicity and absence of harmful fumes contribute to improved occupational health and safety in industrial settings. This aspect indirectly benefits the environment by reducing the need for protective equipment and specialized handling procedures.

Overall, the environmental impact assessment of sodium percarbonate in cleaner production technologies indicates a net positive effect. Its adoption can lead to significant improvements in the environmental performance of cleaning and bleaching processes across various industries. However, ongoing research and development efforts are needed to further optimize its production and application, ensuring that its full potential for environmental sustainability is realized.

Regulatory Framework for Chemical Production

The regulatory framework for chemical production plays a crucial role in ensuring the safe and responsible use of sodium percarbonate in cleaner production technologies. As environmental concerns continue to grow, governments and international organizations have implemented stringent regulations to govern the manufacture, handling, and application of chemical substances.

In the context of sodium percarbonate, regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) have established comprehensive guidelines. These regulations cover various aspects of the chemical's lifecycle, including production processes, storage, transportation, and disposal.

One key area of focus is the registration and evaluation of chemical substances. The REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation in the European Union requires manufacturers and importers to provide detailed information on the properties and potential risks associated with sodium percarbonate. This data is essential for assessing the chemical's safety and environmental impact.

Occupational health and safety regulations also play a significant role in the production and handling of sodium percarbonate. These regulations mandate the implementation of proper safety measures, such as personal protective equipment, ventilation systems, and emergency response protocols, to protect workers from potential hazards associated with the chemical.

Environmental regulations are particularly relevant to the use of sodium percarbonate in cleaner production technologies. These regulations often set limits on emissions and waste generation, encouraging manufacturers to adopt more sustainable practices. For instance, the Clean Air Act and Clean Water Act in the United States establish standards for air and water quality, which influence the production processes involving sodium percarbonate.

Labeling and packaging requirements are another critical aspect of the regulatory framework. Manufacturers must provide accurate and comprehensive information on the chemical's properties, potential hazards, and proper handling procedures. This ensures that end-users are well-informed and can use the product safely and effectively.

As cleaner production technologies continue to evolve, regulatory bodies are adapting their frameworks to address new challenges and opportunities. This includes the development of guidelines for emerging applications of sodium percarbonate, such as its use in advanced oxidation processes for wastewater treatment.

The regulatory landscape also extends to international trade, with various agreements and protocols governing the cross-border movement of chemical substances. These regulations aim to prevent the dumping of hazardous materials and ensure consistent safety standards across different regions.

In conclusion, the regulatory framework for chemical production serves as a critical foundation for the responsible use of sodium percarbonate in cleaner production technologies. By establishing clear guidelines and standards, these regulations promote safety, environmental protection, and sustainable practices throughout the chemical industry.

In the context of sodium percarbonate, regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) have established comprehensive guidelines. These regulations cover various aspects of the chemical's lifecycle, including production processes, storage, transportation, and disposal.

One key area of focus is the registration and evaluation of chemical substances. The REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation in the European Union requires manufacturers and importers to provide detailed information on the properties and potential risks associated with sodium percarbonate. This data is essential for assessing the chemical's safety and environmental impact.

Occupational health and safety regulations also play a significant role in the production and handling of sodium percarbonate. These regulations mandate the implementation of proper safety measures, such as personal protective equipment, ventilation systems, and emergency response protocols, to protect workers from potential hazards associated with the chemical.

Environmental regulations are particularly relevant to the use of sodium percarbonate in cleaner production technologies. These regulations often set limits on emissions and waste generation, encouraging manufacturers to adopt more sustainable practices. For instance, the Clean Air Act and Clean Water Act in the United States establish standards for air and water quality, which influence the production processes involving sodium percarbonate.

Labeling and packaging requirements are another critical aspect of the regulatory framework. Manufacturers must provide accurate and comprehensive information on the chemical's properties, potential hazards, and proper handling procedures. This ensures that end-users are well-informed and can use the product safely and effectively.

As cleaner production technologies continue to evolve, regulatory bodies are adapting their frameworks to address new challenges and opportunities. This includes the development of guidelines for emerging applications of sodium percarbonate, such as its use in advanced oxidation processes for wastewater treatment.

The regulatory landscape also extends to international trade, with various agreements and protocols governing the cross-border movement of chemical substances. These regulations aim to prevent the dumping of hazardous materials and ensure consistent safety standards across different regions.

In conclusion, the regulatory framework for chemical production serves as a critical foundation for the responsible use of sodium percarbonate in cleaner production technologies. By establishing clear guidelines and standards, these regulations promote safety, environmental protection, and sustainable practices throughout the chemical industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!