Structures and Mechanisms: Sodium Percarbonate in Pathogen Removal

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Percarbonate Pathogen Removal Background

Sodium percarbonate, a compound consisting of sodium carbonate and hydrogen peroxide, has gained significant attention in recent years for its potential in pathogen removal. This adduct, with the chemical formula 2Na2CO3·3H2O2, releases hydrogen peroxide when dissolved in water, making it an effective oxidizing agent and disinfectant.

The use of sodium percarbonate for pathogen removal has its roots in the broader field of water treatment and disinfection. Historically, chlorine-based compounds have been the primary choice for water disinfection. However, concerns over the formation of harmful byproducts and the emergence of chlorine-resistant pathogens have led researchers to explore alternative methods.

Sodium percarbonate emerged as a promising candidate due to its ability to generate hydrogen peroxide, a powerful oxidizing agent known for its broad-spectrum antimicrobial properties. The compound's stability in dry form and its ease of handling make it particularly attractive for various applications, ranging from household cleaning to industrial water treatment.

The mechanism of pathogen removal by sodium percarbonate primarily relies on the oxidative stress induced by the released hydrogen peroxide. When dissolved in water, sodium percarbonate dissociates into sodium carbonate and hydrogen peroxide. The hydrogen peroxide then decomposes into water and oxygen, with the latter acting as a potent oxidizing agent.

This oxidative action targets various cellular components of pathogens, including proteins, lipids, and nucleic acids. The reactive oxygen species generated during this process can disrupt cell membranes, denature proteins, and damage genetic material, ultimately leading to the inactivation or death of microorganisms.

One of the key advantages of sodium percarbonate in pathogen removal is its environmentally friendly nature. Unlike chlorine-based disinfectants, the byproducts of sodium percarbonate decomposition are primarily oxygen and water, posing minimal environmental risk. This characteristic aligns well with the growing emphasis on sustainable and eco-friendly water treatment solutions.

The evolution of sodium percarbonate use in pathogen removal has been marked by continuous research and development efforts. Scientists have been exploring ways to enhance its efficacy, improve its stability, and expand its applications. These efforts have led to the development of various formulations and delivery systems, tailored to specific use cases and environmental conditions.

As the global demand for safe and clean water continues to rise, the role of sodium percarbonate in pathogen removal is expected to grow. Its versatility, effectiveness, and environmental compatibility position it as a valuable tool in addressing water-borne pathogens and contributing to improved public health outcomes.

The use of sodium percarbonate for pathogen removal has its roots in the broader field of water treatment and disinfection. Historically, chlorine-based compounds have been the primary choice for water disinfection. However, concerns over the formation of harmful byproducts and the emergence of chlorine-resistant pathogens have led researchers to explore alternative methods.

Sodium percarbonate emerged as a promising candidate due to its ability to generate hydrogen peroxide, a powerful oxidizing agent known for its broad-spectrum antimicrobial properties. The compound's stability in dry form and its ease of handling make it particularly attractive for various applications, ranging from household cleaning to industrial water treatment.

The mechanism of pathogen removal by sodium percarbonate primarily relies on the oxidative stress induced by the released hydrogen peroxide. When dissolved in water, sodium percarbonate dissociates into sodium carbonate and hydrogen peroxide. The hydrogen peroxide then decomposes into water and oxygen, with the latter acting as a potent oxidizing agent.

This oxidative action targets various cellular components of pathogens, including proteins, lipids, and nucleic acids. The reactive oxygen species generated during this process can disrupt cell membranes, denature proteins, and damage genetic material, ultimately leading to the inactivation or death of microorganisms.

One of the key advantages of sodium percarbonate in pathogen removal is its environmentally friendly nature. Unlike chlorine-based disinfectants, the byproducts of sodium percarbonate decomposition are primarily oxygen and water, posing minimal environmental risk. This characteristic aligns well with the growing emphasis on sustainable and eco-friendly water treatment solutions.

The evolution of sodium percarbonate use in pathogen removal has been marked by continuous research and development efforts. Scientists have been exploring ways to enhance its efficacy, improve its stability, and expand its applications. These efforts have led to the development of various formulations and delivery systems, tailored to specific use cases and environmental conditions.

As the global demand for safe and clean water continues to rise, the role of sodium percarbonate in pathogen removal is expected to grow. Its versatility, effectiveness, and environmental compatibility position it as a valuable tool in addressing water-borne pathogens and contributing to improved public health outcomes.

Market Analysis for Disinfection Solutions

The global disinfection solutions market has experienced significant growth in recent years, driven by increasing awareness of hygiene and sanitation, particularly in the wake of the COVID-19 pandemic. The market for sodium percarbonate-based disinfectants, as a subset of this broader market, has shown promising potential due to its effectiveness in pathogen removal and eco-friendly properties.

The disinfection solutions market is segmented by product type, application, and end-user industry. Sodium percarbonate falls under the category of oxidizing agents, which have gained traction due to their broad-spectrum antimicrobial activity. The healthcare sector remains a primary consumer of disinfection solutions, with hospitals, clinics, and long-term care facilities driving demand for effective pathogen removal products.

Consumer demand for household disinfectants has also surged, creating new opportunities for sodium percarbonate-based products in the retail market. The food and beverage industry represents another significant segment, where the need for safe and efficient disinfection solutions is paramount to ensure food safety and prevent contamination.

Geographically, North America and Europe lead the market for advanced disinfection solutions, including those based on sodium percarbonate. These regions have stringent regulations regarding hygiene standards and a high adoption rate of innovative cleaning technologies. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid urbanization, increasing healthcare expenditure, and growing awareness of sanitation practices.

The market for disinfection solutions is highly competitive, with key players continuously investing in research and development to improve product efficacy and safety profiles. Sodium percarbonate-based disinfectants are gaining market share due to their dual action as both a cleaning agent and an oxygen bleach, offering a compelling value proposition to consumers and industrial users alike.

Environmental concerns and the shift towards sustainable products have further bolstered the market potential for sodium percarbonate disinfectants. As consumers and businesses increasingly prioritize eco-friendly options, the demand for biodegradable and non-toxic disinfection solutions is expected to rise, positioning sodium percarbonate favorably in the market.

The market analysis indicates a growing trend towards multi-functional disinfection products that offer convenience and versatility. Sodium percarbonate's ability to act as both a disinfectant and a stain remover aligns well with this trend, potentially expanding its applications across various industries and consumer segments.

The disinfection solutions market is segmented by product type, application, and end-user industry. Sodium percarbonate falls under the category of oxidizing agents, which have gained traction due to their broad-spectrum antimicrobial activity. The healthcare sector remains a primary consumer of disinfection solutions, with hospitals, clinics, and long-term care facilities driving demand for effective pathogen removal products.

Consumer demand for household disinfectants has also surged, creating new opportunities for sodium percarbonate-based products in the retail market. The food and beverage industry represents another significant segment, where the need for safe and efficient disinfection solutions is paramount to ensure food safety and prevent contamination.

Geographically, North America and Europe lead the market for advanced disinfection solutions, including those based on sodium percarbonate. These regions have stringent regulations regarding hygiene standards and a high adoption rate of innovative cleaning technologies. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid urbanization, increasing healthcare expenditure, and growing awareness of sanitation practices.

The market for disinfection solutions is highly competitive, with key players continuously investing in research and development to improve product efficacy and safety profiles. Sodium percarbonate-based disinfectants are gaining market share due to their dual action as both a cleaning agent and an oxygen bleach, offering a compelling value proposition to consumers and industrial users alike.

Environmental concerns and the shift towards sustainable products have further bolstered the market potential for sodium percarbonate disinfectants. As consumers and businesses increasingly prioritize eco-friendly options, the demand for biodegradable and non-toxic disinfection solutions is expected to rise, positioning sodium percarbonate favorably in the market.

The market analysis indicates a growing trend towards multi-functional disinfection products that offer convenience and versatility. Sodium percarbonate's ability to act as both a disinfectant and a stain remover aligns well with this trend, potentially expanding its applications across various industries and consumer segments.

Current Challenges in Pathogen Removal Technologies

Pathogen removal technologies have made significant strides in recent years, yet several challenges persist in achieving optimal efficacy and efficiency. One of the primary obstacles is the diverse nature of pathogens, ranging from bacteria and viruses to fungi and parasites. Each type of pathogen requires specific removal strategies, making it difficult to develop a universal solution.

The increasing resistance of pathogens to traditional disinfection methods poses another significant challenge. Many microorganisms have evolved mechanisms to withstand common disinfectants, necessitating the development of more potent and innovative removal techniques. This resistance not only reduces the effectiveness of current technologies but also raises concerns about the potential emergence of super-resistant pathogens.

Environmental concerns and regulatory restrictions present additional hurdles in pathogen removal. Many effective disinfectants have been found to produce harmful by-products or pose risks to aquatic ecosystems when released into water bodies. This has led to stricter regulations on the use of certain chemicals, limiting the options available for pathogen removal in various applications.

The need for rapid and cost-effective pathogen removal methods is another pressing challenge. In many scenarios, such as water treatment plants or healthcare facilities, quick turnaround times are crucial. However, many current technologies require extended contact times or complex processes, which can be impractical in real-world applications.

Scalability and adaptability of pathogen removal technologies also present significant challenges. Solutions that work well in laboratory settings or small-scale applications often face difficulties when scaled up for industrial or municipal use. Factors such as varying water quality, temperature fluctuations, and the presence of organic matter can significantly impact the effectiveness of removal methods.

The detection and quantification of pathogens remain challenging aspects of removal technologies. Many current methods rely on time-consuming culture-based techniques or expensive molecular testing. The development of rapid, accurate, and cost-effective detection methods is crucial for implementing effective removal strategies and monitoring their success.

In the context of sodium percarbonate as a pathogen removal agent, specific challenges include optimizing its stability in aqueous solutions, enhancing its effectiveness against a broad spectrum of pathogens, and minimizing potential environmental impacts. While sodium percarbonate offers promising oxidative properties, its relatively short half-life in water and potential for generating harmful by-products require further research and development to overcome these limitations.

The increasing resistance of pathogens to traditional disinfection methods poses another significant challenge. Many microorganisms have evolved mechanisms to withstand common disinfectants, necessitating the development of more potent and innovative removal techniques. This resistance not only reduces the effectiveness of current technologies but also raises concerns about the potential emergence of super-resistant pathogens.

Environmental concerns and regulatory restrictions present additional hurdles in pathogen removal. Many effective disinfectants have been found to produce harmful by-products or pose risks to aquatic ecosystems when released into water bodies. This has led to stricter regulations on the use of certain chemicals, limiting the options available for pathogen removal in various applications.

The need for rapid and cost-effective pathogen removal methods is another pressing challenge. In many scenarios, such as water treatment plants or healthcare facilities, quick turnaround times are crucial. However, many current technologies require extended contact times or complex processes, which can be impractical in real-world applications.

Scalability and adaptability of pathogen removal technologies also present significant challenges. Solutions that work well in laboratory settings or small-scale applications often face difficulties when scaled up for industrial or municipal use. Factors such as varying water quality, temperature fluctuations, and the presence of organic matter can significantly impact the effectiveness of removal methods.

The detection and quantification of pathogens remain challenging aspects of removal technologies. Many current methods rely on time-consuming culture-based techniques or expensive molecular testing. The development of rapid, accurate, and cost-effective detection methods is crucial for implementing effective removal strategies and monitoring their success.

In the context of sodium percarbonate as a pathogen removal agent, specific challenges include optimizing its stability in aqueous solutions, enhancing its effectiveness against a broad spectrum of pathogens, and minimizing potential environmental impacts. While sodium percarbonate offers promising oxidative properties, its relatively short half-life in water and potential for generating harmful by-products require further research and development to overcome these limitations.

Existing Sodium Percarbonate Applications

01 Sodium percarbonate as a disinfectant

Sodium percarbonate is used as an effective disinfectant for pathogen removal. When dissolved in water, it releases hydrogen peroxide, which has strong oxidizing properties that can kill various microorganisms, including bacteria, viruses, and fungi. This makes it suitable for water treatment and surface disinfection applications.- Antimicrobial properties of sodium percarbonate: Sodium percarbonate exhibits strong antimicrobial properties, making it effective for pathogen removal. When dissolved in water, it releases hydrogen peroxide, which acts as a powerful oxidizing agent capable of destroying various microorganisms, including bacteria, viruses, and fungi. This property makes sodium percarbonate suitable for use in disinfection and sterilization applications.

- Formulation of sodium percarbonate-based cleaning compositions: Sodium percarbonate can be formulated into cleaning compositions for enhanced pathogen removal. These formulations may include additional components such as surfactants, enzymes, or other oxidizing agents to improve cleaning efficacy and broaden the spectrum of pathogens targeted. The compositions can be designed for various applications, including household cleaning, industrial sanitation, and water treatment.

- Controlled release of active oxygen for sustained pathogen removal: Techniques have been developed to control the release of active oxygen from sodium percarbonate, allowing for sustained pathogen removal over time. This can be achieved through various methods, such as coating the sodium percarbonate particles or incorporating them into specific matrices. Controlled release ensures a prolonged disinfection effect and can be particularly useful in water treatment systems or long-lasting cleaning products.

- Synergistic combinations with other disinfectants: Sodium percarbonate can be combined with other disinfectants to create synergistic effects for enhanced pathogen removal. These combinations may include other oxidizing agents, quaternary ammonium compounds, or natural antimicrobial substances. The synergistic approach can lead to improved efficacy against a broader range of pathogens and potentially reduce the required concentrations of individual components.

- Application-specific formulations for targeted pathogen removal: Sodium percarbonate-based formulations can be tailored for specific applications to target particular pathogens or environments. This may involve adjusting pH levels, incorporating specific additives, or optimizing particle size and dissolution rates. Such customized formulations can be developed for diverse uses, including medical device sterilization, food processing sanitation, and water purification in challenging environments.

02 Formulation with other active ingredients

Sodium percarbonate is often combined with other active ingredients to enhance its pathogen removal efficacy. These formulations may include surfactants, pH adjusters, stabilizers, or other oxidizing agents. The combination of sodium percarbonate with complementary ingredients can provide a broader spectrum of antimicrobial activity and improved performance in various applications.Expand Specific Solutions03 Application in water treatment systems

Sodium percarbonate is utilized in water treatment systems for pathogen removal. It can be incorporated into filtration systems, water purification tablets, or added directly to water sources. The controlled release of hydrogen peroxide from sodium percarbonate helps in disinfecting water and removing harmful microorganisms, making it suitable for both small-scale and large-scale water treatment applications.Expand Specific Solutions04 Use in cleaning and disinfecting products

Sodium percarbonate is a key ingredient in various cleaning and disinfecting products. It is used in laundry detergents, household cleaners, and surface disinfectants. The oxygen-based bleaching action of sodium percarbonate not only removes stains but also helps in eliminating pathogens from surfaces and fabrics, providing both cleaning and disinfecting properties in a single product.Expand Specific Solutions05 Controlled release and stability enhancement

Techniques have been developed to improve the stability and controlled release of sodium percarbonate for more effective pathogen removal. These may include coating the sodium percarbonate particles, incorporating stabilizers, or using specific packaging methods. Such enhancements help in maintaining the active oxygen content and ensuring a sustained release of the disinfecting agent over time, leading to improved efficacy in pathogen removal applications.Expand Specific Solutions

Key Players in Disinfectant Industry

The market for sodium percarbonate in pathogen removal is in a growth phase, driven by increasing demand for eco-friendly disinfectants and water treatment solutions. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, sodium percarbonate is well-established, but ongoing research focuses on enhancing its efficacy and application methods. Key players like Solvay SA, Ecolab USA, Inc., and Kemira Oyj are at the forefront of innovation, developing advanced formulations and application techniques. Emerging companies such as Puyang Hongye Environment Protection New Materials Co., Ltd. and Zhejiang Jinke Daily Chemical Co. Ltd. are also contributing to market competitiveness, particularly in the Asian region.

Solvay SA

Technical Solution: Solvay SA has developed advanced sodium percarbonate formulations for pathogen removal. Their technology involves stabilized sodium percarbonate particles with enhanced solubility and controlled release properties[1]. The company has engineered a coating process that protects the sodium percarbonate from moisture, increasing its shelf life and effectiveness[2]. Solvay's formulations are designed to generate a sustained release of hydrogen peroxide upon dissolution, providing prolonged antimicrobial activity[3]. The company has also focused on improving the compatibility of sodium percarbonate with other cleaning agents, allowing for more versatile applications in disinfection and sanitization processes[4].

Strengths: Improved stability and shelf life of sodium percarbonate, controlled release technology for sustained antimicrobial action, versatile formulations for various applications. Weaknesses: Potentially higher production costs due to advanced formulation processes, may require specific storage conditions to maintain efficacy.

Ecolab USA, Inc.

Technical Solution: Ecolab has developed a proprietary sodium percarbonate-based disinfection system for pathogen removal in various industries. Their technology incorporates a synergistic blend of sodium percarbonate with other oxidizing agents and surfactants to enhance its antimicrobial efficacy[1]. Ecolab's formulation is designed to create a powerful oxidative environment upon activation, effectively targeting a broad spectrum of pathogens, including bacteria, viruses, and fungi[2]. The company has also implemented a smart dosing system that optimizes the concentration of sodium percarbonate based on water quality and contamination levels, ensuring consistent pathogen removal while minimizing chemical usage[3]. Additionally, Ecolab has developed eco-friendly rinse aids that neutralize residual oxidants, making their system suitable for food-contact surfaces[4].

Strengths: Enhanced antimicrobial efficacy through synergistic formulations, smart dosing technology for optimal chemical usage, broad-spectrum pathogen removal. Weaknesses: May require specialized equipment for optimal performance, potentially higher initial implementation costs compared to conventional disinfection methods.

Core Mechanisms of Sodium Percarbonate

Process to control and kill pathogenic small life forms, particularly insects and worms

PatentInactiveEP0945063A1

Innovation

- A method using an aqueous percarboxylic acid solution with 1 to 6 carbon atoms applied to surfaces and water bodies to control and kill pathogenic insects and worms, particularly effective against mosquito larvae and schistosome larvae, utilizing peracetic acid and optionally surfactants, with concentrations between 1 to 5000 ppm.

Coated sodium percarbonate particles

PatentWO2014198804A1

Innovation

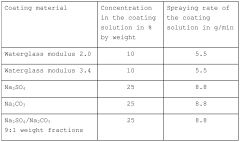

- The development of coated sodium percarbonate particles with a three-layered coating structure, where the inner layer consists predominantly of sodium sulphate, the middle layer of alkali metal silicate, and the outer layer of sodium sulphate and/or sodium carbonate, providing enhanced stability and preventing moisture-induced decomposition.

Environmental Impact Assessment

The use of sodium percarbonate in pathogen removal has significant environmental implications that warrant careful consideration. This compound, when dissolved in water, releases hydrogen peroxide and sodium carbonate, both of which have potential impacts on aquatic ecosystems.

The primary environmental benefit of using sodium percarbonate for pathogen removal is its effectiveness in reducing harmful microorganisms without introducing persistent toxic chemicals into the environment. Unlike some traditional disinfectants, the byproducts of sodium percarbonate decomposition are generally benign. Hydrogen peroxide breaks down into water and oxygen, while sodium carbonate is a naturally occurring substance in many water bodies.

However, the introduction of large quantities of sodium percarbonate into aquatic environments can lead to temporary changes in water chemistry. The release of hydrogen peroxide may cause short-term increases in dissolved oxygen levels, which can be beneficial for some aquatic organisms but potentially stressful for others adapted to lower oxygen conditions. The addition of sodium carbonate can temporarily raise the pH of water, potentially affecting sensitive aquatic species and altering ecosystem dynamics.

The impact on microbial communities is another important consideration. While sodium percarbonate effectively removes pathogens, it may also affect beneficial microorganisms that play crucial roles in nutrient cycling and ecosystem health. This disruption of microbial balance could have cascading effects throughout the food web.

Soil ecosystems may also be affected if sodium percarbonate-treated water is used for irrigation or enters the soil through runoff. Changes in soil pH and microbial composition could impact plant growth and soil fertility. However, these effects are generally short-lived due to the rapid breakdown of the compound.

Long-term environmental monitoring is essential to fully understand the ecological impacts of sodium percarbonate use in pathogen removal. Studies should focus on assessing changes in water quality parameters, microbial community composition, and potential effects on aquatic and terrestrial flora and fauna. Additionally, research into optimal application rates and methods could help minimize any negative environmental impacts while maximizing pathogen removal efficiency.

In conclusion, while sodium percarbonate offers a relatively environmentally friendly approach to pathogen removal, its use must be carefully managed to mitigate potential ecological disruptions. Balancing the benefits of improved water safety with the need to preserve ecosystem integrity is crucial for sustainable implementation of this technology.

The primary environmental benefit of using sodium percarbonate for pathogen removal is its effectiveness in reducing harmful microorganisms without introducing persistent toxic chemicals into the environment. Unlike some traditional disinfectants, the byproducts of sodium percarbonate decomposition are generally benign. Hydrogen peroxide breaks down into water and oxygen, while sodium carbonate is a naturally occurring substance in many water bodies.

However, the introduction of large quantities of sodium percarbonate into aquatic environments can lead to temporary changes in water chemistry. The release of hydrogen peroxide may cause short-term increases in dissolved oxygen levels, which can be beneficial for some aquatic organisms but potentially stressful for others adapted to lower oxygen conditions. The addition of sodium carbonate can temporarily raise the pH of water, potentially affecting sensitive aquatic species and altering ecosystem dynamics.

The impact on microbial communities is another important consideration. While sodium percarbonate effectively removes pathogens, it may also affect beneficial microorganisms that play crucial roles in nutrient cycling and ecosystem health. This disruption of microbial balance could have cascading effects throughout the food web.

Soil ecosystems may also be affected if sodium percarbonate-treated water is used for irrigation or enters the soil through runoff. Changes in soil pH and microbial composition could impact plant growth and soil fertility. However, these effects are generally short-lived due to the rapid breakdown of the compound.

Long-term environmental monitoring is essential to fully understand the ecological impacts of sodium percarbonate use in pathogen removal. Studies should focus on assessing changes in water quality parameters, microbial community composition, and potential effects on aquatic and terrestrial flora and fauna. Additionally, research into optimal application rates and methods could help minimize any negative environmental impacts while maximizing pathogen removal efficiency.

In conclusion, while sodium percarbonate offers a relatively environmentally friendly approach to pathogen removal, its use must be carefully managed to mitigate potential ecological disruptions. Balancing the benefits of improved water safety with the need to preserve ecosystem integrity is crucial for sustainable implementation of this technology.

Regulatory Framework for Disinfectants

The regulatory framework for disinfectants, including sodium percarbonate, is a complex and evolving landscape that varies across different regions and jurisdictions. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating disinfectants under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). The EPA requires manufacturers to register their products and provide extensive data on efficacy, safety, and environmental impact before approval.

The European Union operates under the Biocidal Products Regulation (BPR), which aims to harmonize the market for biocidal products while ensuring a high level of protection for humans and the environment. Under this framework, sodium percarbonate falls under Product Type 2 (disinfectants and algaecides not intended for direct application to humans or animals).

In Japan, the Ministry of Health, Labour and Welfare regulates disinfectants under the Pharmaceutical Affairs Law. Products containing sodium percarbonate must meet specific criteria for efficacy and safety before being approved for use as disinfectants.

Globally, the World Health Organization (WHO) provides guidelines for the use of disinfectants in various settings, including healthcare facilities and water treatment. These guidelines often influence national policies and regulations.

Many countries have established specific concentration limits and usage guidelines for sodium percarbonate in disinfectant applications. For instance, in the United States, the FDA has approved sodium percarbonate for use as an indirect food additive, subject to certain conditions.

Regulatory bodies often require manufacturers to conduct standardized efficacy tests against specific pathogens to validate claims of disinfectant properties. These tests typically follow protocols such as those outlined by the AOAC International or the European Committee for Standardization (CEN).

Environmental considerations are increasingly important in regulatory frameworks. Manufacturers must provide data on biodegradability, ecotoxicity, and potential impacts on aquatic ecosystems. This is particularly relevant for sodium percarbonate, given its potential use in water treatment applications.

Labeling requirements for disinfectants containing sodium percarbonate are typically stringent, with regulations mandating clear instructions for use, safety precautions, and disposal methods. Many jurisdictions also require hazard symbols and specific warning statements on product packaging.

As the global focus on public health and environmental safety intensifies, regulatory frameworks for disinfectants are likely to become more stringent. This may lead to increased scrutiny of sodium percarbonate and similar compounds, potentially driving innovation in formulation and application methods to meet evolving regulatory standards.

The European Union operates under the Biocidal Products Regulation (BPR), which aims to harmonize the market for biocidal products while ensuring a high level of protection for humans and the environment. Under this framework, sodium percarbonate falls under Product Type 2 (disinfectants and algaecides not intended for direct application to humans or animals).

In Japan, the Ministry of Health, Labour and Welfare regulates disinfectants under the Pharmaceutical Affairs Law. Products containing sodium percarbonate must meet specific criteria for efficacy and safety before being approved for use as disinfectants.

Globally, the World Health Organization (WHO) provides guidelines for the use of disinfectants in various settings, including healthcare facilities and water treatment. These guidelines often influence national policies and regulations.

Many countries have established specific concentration limits and usage guidelines for sodium percarbonate in disinfectant applications. For instance, in the United States, the FDA has approved sodium percarbonate for use as an indirect food additive, subject to certain conditions.

Regulatory bodies often require manufacturers to conduct standardized efficacy tests against specific pathogens to validate claims of disinfectant properties. These tests typically follow protocols such as those outlined by the AOAC International or the European Committee for Standardization (CEN).

Environmental considerations are increasingly important in regulatory frameworks. Manufacturers must provide data on biodegradability, ecotoxicity, and potential impacts on aquatic ecosystems. This is particularly relevant for sodium percarbonate, given its potential use in water treatment applications.

Labeling requirements for disinfectants containing sodium percarbonate are typically stringent, with regulations mandating clear instructions for use, safety precautions, and disposal methods. Many jurisdictions also require hazard symbols and specific warning statements on product packaging.

As the global focus on public health and environmental safety intensifies, regulatory frameworks for disinfectants are likely to become more stringent. This may lead to increased scrutiny of sodium percarbonate and similar compounds, potentially driving innovation in formulation and application methods to meet evolving regulatory standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!