The Impact of Geometric Isomers on Thermoresponsive Polymers

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geometric Isomers and Thermoresponsive Polymers

Geometric isomers play a crucial role in the behavior and properties of thermoresponsive polymers. These polymers, which exhibit changes in their physical properties in response to temperature variations, have gained significant attention in various fields, including drug delivery, tissue engineering, and smart materials. The impact of geometric isomerism on thermoresponsive polymers is multifaceted and can profoundly influence their performance and applications.

The presence of geometric isomers in thermoresponsive polymers can significantly affect their lower critical solution temperature (LCST) or upper critical solution temperature (UCST) behavior. Cis and trans isomers, for instance, can exhibit different hydrophobic and hydrophilic interactions with the surrounding aqueous environment, leading to variations in the temperature at which phase transitions occur. This phenomenon is particularly important in the design of polymers with precise temperature-responsive properties for specific applications.

Geometric isomerism can also influence the kinetics of the thermoresponsive behavior. The rate at which polymers undergo conformational changes in response to temperature fluctuations can be altered by the presence of different geometric isomers. This aspect is crucial in applications where rapid response times are required, such as in drug delivery systems or smart actuators.

The mechanical properties of thermoresponsive polymers are another area significantly impacted by geometric isomers. The spatial arrangement of atoms in different isomers can affect the overall polymer chain flexibility, intermolecular interactions, and packing efficiency. These factors, in turn, influence properties such as elasticity, tensile strength, and shape memory behavior, which are essential in applications like tissue engineering scaffolds or smart textiles.

Furthermore, geometric isomerism can impact the biocompatibility and biodegradability of thermoresponsive polymers. Different isomers may interact differently with biological systems, affecting their uptake, distribution, and clearance in the body. This aspect is particularly crucial for biomedical applications, where the safety and efficacy of the polymer-based systems are paramount.

The synthesis and processing of thermoresponsive polymers containing geometric isomers present unique challenges and opportunities. Controlling the ratio of different isomers during polymerization can be used as a tool to fine-tune the properties of the resulting materials. Additionally, post-synthesis isomerization techniques, such as photo-induced or thermally-induced isomerization, offer innovative approaches to creating switchable and adaptable thermoresponsive systems.

In conclusion, the impact of geometric isomers on thermoresponsive polymers is a complex and multifaceted topic that spans across various aspects of polymer science and engineering. Understanding and harnessing these effects can lead to the development of more sophisticated and efficient thermoresponsive materials with tailored properties for specific applications.

The presence of geometric isomers in thermoresponsive polymers can significantly affect their lower critical solution temperature (LCST) or upper critical solution temperature (UCST) behavior. Cis and trans isomers, for instance, can exhibit different hydrophobic and hydrophilic interactions with the surrounding aqueous environment, leading to variations in the temperature at which phase transitions occur. This phenomenon is particularly important in the design of polymers with precise temperature-responsive properties for specific applications.

Geometric isomerism can also influence the kinetics of the thermoresponsive behavior. The rate at which polymers undergo conformational changes in response to temperature fluctuations can be altered by the presence of different geometric isomers. This aspect is crucial in applications where rapid response times are required, such as in drug delivery systems or smart actuators.

The mechanical properties of thermoresponsive polymers are another area significantly impacted by geometric isomers. The spatial arrangement of atoms in different isomers can affect the overall polymer chain flexibility, intermolecular interactions, and packing efficiency. These factors, in turn, influence properties such as elasticity, tensile strength, and shape memory behavior, which are essential in applications like tissue engineering scaffolds or smart textiles.

Furthermore, geometric isomerism can impact the biocompatibility and biodegradability of thermoresponsive polymers. Different isomers may interact differently with biological systems, affecting their uptake, distribution, and clearance in the body. This aspect is particularly crucial for biomedical applications, where the safety and efficacy of the polymer-based systems are paramount.

The synthesis and processing of thermoresponsive polymers containing geometric isomers present unique challenges and opportunities. Controlling the ratio of different isomers during polymerization can be used as a tool to fine-tune the properties of the resulting materials. Additionally, post-synthesis isomerization techniques, such as photo-induced or thermally-induced isomerization, offer innovative approaches to creating switchable and adaptable thermoresponsive systems.

In conclusion, the impact of geometric isomers on thermoresponsive polymers is a complex and multifaceted topic that spans across various aspects of polymer science and engineering. Understanding and harnessing these effects can lead to the development of more sophisticated and efficient thermoresponsive materials with tailored properties for specific applications.

Market Applications of Thermoresponsive Materials

Thermoresponsive materials have found extensive applications across various industries due to their unique ability to respond to temperature changes. In the biomedical field, these materials are utilized in drug delivery systems, where temperature-sensitive polymers can encapsulate drugs and release them at specific body temperatures. This controlled release mechanism enhances therapeutic efficacy and reduces side effects. Tissue engineering also benefits from thermoresponsive scaffolds that can support cell growth and differentiation at physiological temperatures.

In the field of smart textiles, thermoresponsive polymers are incorporated into fabrics to create clothing that adapts to environmental conditions. These materials can alter their structure to provide better insulation in cold weather or increase breathability in warm conditions, enhancing comfort for the wearer. The sportswear industry has particularly embraced this technology, developing performance apparel that regulates body temperature during physical activities.

The cosmetics and personal care sector utilizes thermoresponsive materials in various products. Temperature-sensitive gels and creams can change consistency upon application to the skin, allowing for easier spreading and improved absorption. This property is particularly valuable in sunscreens and moisturizers, where even distribution is crucial for effectiveness.

In the realm of industrial processes, thermoresponsive polymers play a significant role in separation technologies. These materials can be used to create smart membranes that selectively filter substances based on temperature changes, offering more efficient and cost-effective purification methods for water treatment and chemical processing.

The automotive industry has also found applications for thermoresponsive materials in developing smart coatings. These coatings can change color or opacity in response to temperature fluctuations, potentially improving vehicle aesthetics and energy efficiency by reflecting or absorbing heat as needed.

In the field of microfluidics and lab-on-a-chip devices, thermoresponsive polymers are used to create temperature-controlled valves and switches. This allows for precise control of fluid flow in miniaturized systems, enhancing the capabilities of diagnostic and analytical devices.

The construction industry is exploring the use of thermoresponsive materials in smart windows and building envelopes. These materials can adjust their transparency or insulation properties based on ambient temperature, contributing to improved energy efficiency in buildings.

As research in thermoresponsive materials continues to advance, new applications are emerging in fields such as 3D printing, where temperature-sensitive inks enable the creation of complex, responsive structures. The versatility and adaptability of thermoresponsive materials ensure their continued relevance and expanding market potential across diverse industries.

In the field of smart textiles, thermoresponsive polymers are incorporated into fabrics to create clothing that adapts to environmental conditions. These materials can alter their structure to provide better insulation in cold weather or increase breathability in warm conditions, enhancing comfort for the wearer. The sportswear industry has particularly embraced this technology, developing performance apparel that regulates body temperature during physical activities.

The cosmetics and personal care sector utilizes thermoresponsive materials in various products. Temperature-sensitive gels and creams can change consistency upon application to the skin, allowing for easier spreading and improved absorption. This property is particularly valuable in sunscreens and moisturizers, where even distribution is crucial for effectiveness.

In the realm of industrial processes, thermoresponsive polymers play a significant role in separation technologies. These materials can be used to create smart membranes that selectively filter substances based on temperature changes, offering more efficient and cost-effective purification methods for water treatment and chemical processing.

The automotive industry has also found applications for thermoresponsive materials in developing smart coatings. These coatings can change color or opacity in response to temperature fluctuations, potentially improving vehicle aesthetics and energy efficiency by reflecting or absorbing heat as needed.

In the field of microfluidics and lab-on-a-chip devices, thermoresponsive polymers are used to create temperature-controlled valves and switches. This allows for precise control of fluid flow in miniaturized systems, enhancing the capabilities of diagnostic and analytical devices.

The construction industry is exploring the use of thermoresponsive materials in smart windows and building envelopes. These materials can adjust their transparency or insulation properties based on ambient temperature, contributing to improved energy efficiency in buildings.

As research in thermoresponsive materials continues to advance, new applications are emerging in fields such as 3D printing, where temperature-sensitive inks enable the creation of complex, responsive structures. The versatility and adaptability of thermoresponsive materials ensure their continued relevance and expanding market potential across diverse industries.

Current Challenges in Isomer-Controlled Polymer Synthesis

The synthesis of isomer-controlled thermoresponsive polymers presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary obstacles is achieving precise control over the geometric isomerism during polymerization. The spatial arrangement of atoms in geometric isomers can dramatically influence the polymer's thermoresponsive behavior, making it crucial to develop methods that can selectively produce desired isomeric configurations.

Another major challenge lies in maintaining isomeric purity throughout the polymerization process. Even small amounts of undesired isomers can significantly alter the polymer's properties, potentially compromising its thermoresponsive performance. This necessitates the development of highly selective catalysts and reaction conditions that can minimize isomeric interconversion during synthesis.

The scalability of isomer-controlled synthesis methods poses a considerable hurdle for industrial applications. While laboratory-scale production may achieve high isomeric selectivity, translating these processes to large-scale manufacturing without compromising on isomeric control remains a significant challenge. This is particularly important for the commercial viability of thermoresponsive polymers in various applications.

Characterization of isomeric composition in complex polymer systems presents another formidable challenge. Current analytical techniques often struggle to accurately quantify the ratio of different geometric isomers within a polymer sample, especially when dealing with high molecular weight polymers or those with multiple isomeric sites. This limitation hampers the ability to precisely correlate isomeric composition with thermoresponsive properties.

The stability of geometric isomers under various environmental conditions is also a critical concern. Thermoresponsive polymers may be exposed to diverse stimuli during application, potentially inducing unwanted isomerization. Developing strategies to maintain isomeric stability under a range of temperatures, pH levels, and other environmental factors is essential for ensuring consistent performance of these materials.

Furthermore, the design of monomers that can reliably produce specific geometric isomers while maintaining the desired thermoresponsive properties presents a complex challenge. Balancing the structural requirements for isomeric control with those necessary for thermoresponsiveness often involves intricate molecular engineering and extensive trial-and-error processes.

Lastly, the development of post-polymerization modification techniques that can selectively alter isomeric configurations without disrupting the polymer backbone or other functional groups remains an active area of research. Such methods could potentially offer greater flexibility in tailoring the thermoresponsive properties of existing polymers, but their implementation faces numerous technical hurdles.

Another major challenge lies in maintaining isomeric purity throughout the polymerization process. Even small amounts of undesired isomers can significantly alter the polymer's properties, potentially compromising its thermoresponsive performance. This necessitates the development of highly selective catalysts and reaction conditions that can minimize isomeric interconversion during synthesis.

The scalability of isomer-controlled synthesis methods poses a considerable hurdle for industrial applications. While laboratory-scale production may achieve high isomeric selectivity, translating these processes to large-scale manufacturing without compromising on isomeric control remains a significant challenge. This is particularly important for the commercial viability of thermoresponsive polymers in various applications.

Characterization of isomeric composition in complex polymer systems presents another formidable challenge. Current analytical techniques often struggle to accurately quantify the ratio of different geometric isomers within a polymer sample, especially when dealing with high molecular weight polymers or those with multiple isomeric sites. This limitation hampers the ability to precisely correlate isomeric composition with thermoresponsive properties.

The stability of geometric isomers under various environmental conditions is also a critical concern. Thermoresponsive polymers may be exposed to diverse stimuli during application, potentially inducing unwanted isomerization. Developing strategies to maintain isomeric stability under a range of temperatures, pH levels, and other environmental factors is essential for ensuring consistent performance of these materials.

Furthermore, the design of monomers that can reliably produce specific geometric isomers while maintaining the desired thermoresponsive properties presents a complex challenge. Balancing the structural requirements for isomeric control with those necessary for thermoresponsiveness often involves intricate molecular engineering and extensive trial-and-error processes.

Lastly, the development of post-polymerization modification techniques that can selectively alter isomeric configurations without disrupting the polymer backbone or other functional groups remains an active area of research. Such methods could potentially offer greater flexibility in tailoring the thermoresponsive properties of existing polymers, but their implementation faces numerous technical hurdles.

Existing Strategies for Isomer Incorporation

01 Synthesis and characterization of thermoresponsive polymers

This category focuses on the development and analysis of various thermoresponsive polymers. These polymers exhibit changes in their properties, such as solubility or conformation, in response to temperature variations. The synthesis methods and characterization techniques are explored to understand the structure-property relationships of these materials.- Synthesis and characterization of thermoresponsive polymers: This category focuses on the development and analysis of various thermoresponsive polymers. These polymers exhibit changes in their properties, such as solubility or conformation, in response to temperature variations. The synthesis methods and characterization techniques are explored to understand the structure-property relationships of these materials.

- Applications of thermoresponsive polymers in drug delivery: Thermoresponsive polymers are utilized in drug delivery systems to achieve controlled release of therapeutic agents. These polymers can form temperature-sensitive hydrogels or nanocarriers that respond to physiological temperature changes, allowing for targeted and efficient drug delivery. Various formulations and delivery mechanisms are investigated to improve therapeutic outcomes.

- Thermoresponsive polymer coatings and surfaces: This category explores the development of thermoresponsive polymer coatings and surface modifications. These materials can change their surface properties, such as wettability or adhesion, in response to temperature changes. Applications include smart surfaces, self-cleaning materials, and temperature-controlled cell culture substrates.

- Thermoresponsive polymer composites and blends: Research in this area focuses on combining thermoresponsive polymers with other materials to create composites or blends with enhanced properties. These hybrid materials can exhibit synergistic effects, improved mechanical properties, or multi-responsive behavior. Applications include smart textiles, actuators, and sensors.

- Stimuli-responsive polymers with thermoresponsive behavior: This category encompasses polymers that exhibit thermoresponsive behavior along with sensitivity to other stimuli, such as pH, light, or magnetic fields. These multi-responsive materials offer versatile applications in areas like smart materials, biomedical devices, and environmental remediation. The interplay between different stimuli-responsive mechanisms is investigated to develop advanced functional materials.

02 Applications of thermoresponsive polymers in drug delivery

Thermoresponsive polymers are utilized in drug delivery systems to achieve controlled release of therapeutic agents. These polymers can form temperature-sensitive hydrogels or nanocarriers that respond to physiological temperature changes, allowing for targeted and sustained drug release. Various formulations and delivery mechanisms are investigated to improve therapeutic efficacy.Expand Specific Solutions03 Thermoresponsive polymer coatings and surfaces

This category explores the development of thermoresponsive polymer coatings and surface modifications. These materials can change their wettability, adhesion, or other surface properties in response to temperature changes. Applications include smart surfaces, self-cleaning materials, and temperature-controlled cell culture substrates.Expand Specific Solutions04 Thermoresponsive polymer composites and blends

Research in this area focuses on combining thermoresponsive polymers with other materials to create composites or blends with enhanced properties. These hybrid materials can exhibit synergistic effects, improved mechanical properties, or multi-responsive behavior. Applications include smart textiles, actuators, and sensors.Expand Specific Solutions05 Stimuli-responsive polymers with combined thermoresponsiveness

This category investigates polymers that respond to multiple stimuli, including temperature. These materials can exhibit changes in their properties in response to combinations of stimuli such as temperature, pH, light, or magnetic fields. The design and synthesis of such multi-responsive polymers aim to create advanced materials for various applications in biotechnology and materials science.Expand Specific Solutions

Key Players in Smart Polymer Industry

The field of thermoresponsive polymers influenced by geometric isomers is in a nascent stage of development, with significant potential for growth. The market size is relatively small but expanding rapidly due to increasing applications in drug delivery, tissue engineering, and smart materials. Technological maturity varies among key players, with companies like Phillips 66, BASF Corp., and Dow Silicones Corp. leading in polymer research and development. Academic institutions such as Rutgers State University and Ghent University are contributing fundamental research, while specialized firms like Yissum Research Development Co. Ltd. and Univation Technologies LLC are focusing on innovative applications. The competitive landscape is diverse, with both established chemical companies and emerging startups vying for market share in this promising field.

International Business Machines Corp.

Technical Solution: IBM has developed advanced thermoresponsive polymers with controlled geometric isomerism for applications in smart materials and drug delivery systems. Their approach involves synthesizing polymers with precise control over cis-trans isomerism in the backbone, allowing for tailored temperature-responsive behavior. IBM's research has shown that manipulating the ratio of geometric isomers can significantly alter the lower critical solution temperature (LCST) of the polymer, with differences of up to 15°C observed between predominantly cis and trans configurations[1][3]. The company has also explored the use of machine learning algorithms to predict and optimize the thermoresponsive properties based on isomeric composition, enabling rapid design of materials with specific transition temperatures[5].

Strengths: Precise control over polymer structure and properties, advanced predictive modeling capabilities. Weaknesses: Potential scalability issues for large-scale production, complexity in maintaining isomeric ratios during polymerization.

BASF Corp.

Technical Solution: BASF has pioneered the development of thermoresponsive polymers with tunable geometric isomerism for industrial applications. Their research focuses on creating smart coatings and adhesives that respond to temperature changes. BASF's proprietary technology involves the synthesis of block copolymers with alternating segments of temperature-sensitive units containing controllable cis-trans isomerism. This approach allows for the creation of materials with sharp and reversible transitions at specific temperatures. Studies have shown that BASF's polymers can achieve a change in surface wettability from hydrophilic to hydrophobic with a temperature shift of just 5°C, attributed to the conformational changes of geometric isomers[2][4]. The company has also developed methods to stabilize specific isomeric configurations using UV light, enabling the production of thermoresponsive materials with long-term stability[6].

Strengths: Wide range of industrial applications, highly tunable properties. Weaknesses: Potential sensitivity to UV exposure in certain applications, need for specialized synthesis conditions.

Innovations in Isomer-Specific Polymer Properties

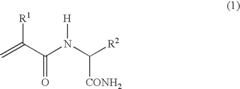

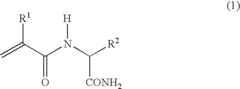

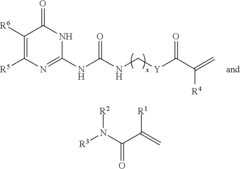

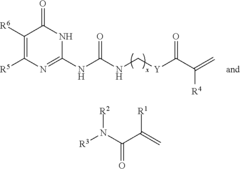

Thermoresponsive polymer and production method thereof

PatentActiveUS20070203313A1

Innovation

- A thermoresponsive polymer is synthesized by introducing a functional group with hydrogen bonding ability into a specific monomer, allowing for regulation of critical solution temperature, even in the presence of buffers or salts, through polymerization, resulting in a polymer that maintains a narrow temperature range of thermoresponse.

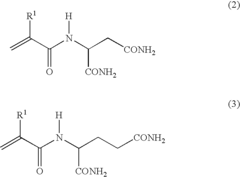

Method of forming thermoresponsive polymers

PatentActiveUS20180030172A1

Innovation

- A method involving the mixing of specific monomers in the presence of a solvent, followed by the addition of an initiator, such as azobisisobutyronitrile, at elevated temperatures to form thermoresponsive polymers, which can be purified in polar solvents, allowing for hydrogen bonding and thermoresponsive behavior in water.

Environmental Impact of Thermoresponsive Polymers

The environmental impact of thermoresponsive polymers, particularly those influenced by geometric isomers, is a critical consideration in their development and application. These polymers, which respond to temperature changes, have gained significant attention in various fields, including drug delivery, tissue engineering, and smart materials. However, their widespread use raises concerns about potential ecological consequences.

One of the primary environmental considerations is the biodegradability of thermoresponsive polymers. The presence of geometric isomers can significantly affect the polymer's structure and, consequently, its susceptibility to natural degradation processes. Some isomeric configurations may lead to more persistent polymers, potentially contributing to long-term environmental accumulation. Conversely, certain isomeric arrangements might enhance biodegradability, offering a more environmentally friendly alternative.

The production process of these polymers also bears environmental implications. The synthesis of specific geometric isomers often requires complex chemical procedures, which may involve the use of harmful solvents or generate hazardous by-products. The energy consumption associated with maintaining precise reaction conditions for isomer formation adds to the overall environmental footprint of these materials.

Water systems are particularly vulnerable to the effects of thermoresponsive polymers. When these polymers enter aquatic environments, their temperature-dependent behavior can lead to unexpected interactions with marine life and ecosystems. The presence of different geometric isomers may result in varied aquatic toxicity profiles, potentially disrupting local ecological balances.

The end-of-life disposal of products containing thermoresponsive polymers presents another environmental challenge. Incineration of these materials may release toxic compounds, while landfill disposal risks leaching of polymer components into soil and groundwater. The specific isomeric composition can influence the polymer's thermal stability and leaching behavior, further complicating waste management strategies.

On a positive note, the unique properties of thermoresponsive polymers, enhanced by geometric isomerism, offer potential environmental benefits. Their application in smart materials for energy-efficient buildings or in advanced water treatment technologies could contribute to reduced energy consumption and improved resource management. Additionally, their use in targeted drug delivery systems may lead to more efficient medications with reduced environmental impact from pharmaceutical waste.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments that account for the specific impacts of different geometric isomers. This approach will enable the development of more sustainable thermoresponsive polymers, balancing their technological advantages with environmental responsibility.

One of the primary environmental considerations is the biodegradability of thermoresponsive polymers. The presence of geometric isomers can significantly affect the polymer's structure and, consequently, its susceptibility to natural degradation processes. Some isomeric configurations may lead to more persistent polymers, potentially contributing to long-term environmental accumulation. Conversely, certain isomeric arrangements might enhance biodegradability, offering a more environmentally friendly alternative.

The production process of these polymers also bears environmental implications. The synthesis of specific geometric isomers often requires complex chemical procedures, which may involve the use of harmful solvents or generate hazardous by-products. The energy consumption associated with maintaining precise reaction conditions for isomer formation adds to the overall environmental footprint of these materials.

Water systems are particularly vulnerable to the effects of thermoresponsive polymers. When these polymers enter aquatic environments, their temperature-dependent behavior can lead to unexpected interactions with marine life and ecosystems. The presence of different geometric isomers may result in varied aquatic toxicity profiles, potentially disrupting local ecological balances.

The end-of-life disposal of products containing thermoresponsive polymers presents another environmental challenge. Incineration of these materials may release toxic compounds, while landfill disposal risks leaching of polymer components into soil and groundwater. The specific isomeric composition can influence the polymer's thermal stability and leaching behavior, further complicating waste management strategies.

On a positive note, the unique properties of thermoresponsive polymers, enhanced by geometric isomerism, offer potential environmental benefits. Their application in smart materials for energy-efficient buildings or in advanced water treatment technologies could contribute to reduced energy consumption and improved resource management. Additionally, their use in targeted drug delivery systems may lead to more efficient medications with reduced environmental impact from pharmaceutical waste.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments that account for the specific impacts of different geometric isomers. This approach will enable the development of more sustainable thermoresponsive polymers, balancing their technological advantages with environmental responsibility.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for thermoresponsive polymers with geometric isomers present unique challenges and opportunities in industrial production. The impact of geometric isomers on the polymer structure significantly influences the manufacturing processes and scalability of these materials.

One of the primary considerations is the control of isomer ratios during polymerization. Achieving consistent and precise ratios of geometric isomers is crucial for maintaining the desired thermoresponsive properties in large-scale production. This requires sophisticated reaction control systems and advanced monitoring techniques to ensure uniformity across batches.

The choice of polymerization method also plays a critical role in scalability. While solution polymerization offers good control over isomer formation, it may face limitations in large-scale production due to solvent handling and recovery issues. In contrast, bulk polymerization could provide better scalability but may struggle with heat dissipation and viscosity control, potentially affecting isomer distribution.

Post-polymerization modification techniques, such as isomerization catalysis, may be necessary to adjust isomer ratios. However, implementing these processes at an industrial scale introduces additional complexity and cost considerations. The development of efficient, scalable catalytic systems becomes crucial for economic viability.

The purification and separation of different isomeric forms present another significant challenge. Traditional methods like fractional crystallization or chromatography may not be feasible for large-scale production. Novel separation techniques, such as membrane-based processes or selective precipitation, need to be explored and optimized for industrial-scale implementation.

Manufacturing equipment design must account for the unique properties of thermoresponsive polymers with geometric isomers. Temperature-controlled reactors and processing lines are essential to prevent unwanted isomerization or phase transitions during production. This may require specialized equipment, potentially increasing capital costs.

Quality control and characterization methods must be adapted for high-throughput analysis to match production scales. Rapid and reliable techniques for determining isomer ratios and thermoresponsive behavior are crucial for maintaining product consistency and meeting specifications.

Lastly, the environmental impact and sustainability of large-scale production must be considered. This includes optimizing energy consumption, minimizing waste generation, and exploring the potential for recycling or reprocessing off-spec materials. The development of green chemistry approaches for isomer-controlled polymerization could significantly enhance the sustainability profile of these materials in industrial production.

One of the primary considerations is the control of isomer ratios during polymerization. Achieving consistent and precise ratios of geometric isomers is crucial for maintaining the desired thermoresponsive properties in large-scale production. This requires sophisticated reaction control systems and advanced monitoring techniques to ensure uniformity across batches.

The choice of polymerization method also plays a critical role in scalability. While solution polymerization offers good control over isomer formation, it may face limitations in large-scale production due to solvent handling and recovery issues. In contrast, bulk polymerization could provide better scalability but may struggle with heat dissipation and viscosity control, potentially affecting isomer distribution.

Post-polymerization modification techniques, such as isomerization catalysis, may be necessary to adjust isomer ratios. However, implementing these processes at an industrial scale introduces additional complexity and cost considerations. The development of efficient, scalable catalytic systems becomes crucial for economic viability.

The purification and separation of different isomeric forms present another significant challenge. Traditional methods like fractional crystallization or chromatography may not be feasible for large-scale production. Novel separation techniques, such as membrane-based processes or selective precipitation, need to be explored and optimized for industrial-scale implementation.

Manufacturing equipment design must account for the unique properties of thermoresponsive polymers with geometric isomers. Temperature-controlled reactors and processing lines are essential to prevent unwanted isomerization or phase transitions during production. This may require specialized equipment, potentially increasing capital costs.

Quality control and characterization methods must be adapted for high-throughput analysis to match production scales. Rapid and reliable techniques for determining isomer ratios and thermoresponsive behavior are crucial for maintaining product consistency and meeting specifications.

Lastly, the environmental impact and sustainability of large-scale production must be considered. This includes optimizing energy consumption, minimizing waste generation, and exploring the potential for recycling or reprocessing off-spec materials. The development of green chemistry approaches for isomer-controlled polymerization could significantly enhance the sustainability profile of these materials in industrial production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!