The Role of Geometric Isomers in Polymer Synthesis Strategies

AUG 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geometric Isomers in Polymer Synthesis: Background and Objectives

Geometric isomers have played a pivotal role in the evolution of polymer synthesis strategies, significantly influencing the properties and applications of resulting materials. The concept of geometric isomerism in polymer science dates back to the mid-20th century, when researchers began to recognize the impact of molecular arrangement on macroscopic properties. This realization sparked a new era of polymer design, where control over isomeric structures became a key focus in achieving desired material characteristics.

The development of polymer synthesis techniques has been closely intertwined with the understanding and manipulation of geometric isomers. Early synthetic methods often resulted in random distributions of isomers, leading to inconsistent material properties. As the field progressed, chemists and materials scientists sought ways to control isomeric composition, recognizing its potential to fine-tune polymer performance.

The importance of geometric isomers in polymer synthesis lies in their ability to affect chain conformation, packing, and intermolecular interactions. These factors directly influence crucial polymer properties such as crystallinity, melting point, glass transition temperature, and mechanical strength. For instance, the presence of cis or trans isomers in polydienes can dramatically alter elasticity and toughness, while the ratio of head-to-head versus head-to-tail configurations in vinyl polymers can impact solubility and thermal stability.

Recent advancements in synthetic methodologies have enabled unprecedented control over isomeric structures in polymers. Techniques such as stereospecific polymerization, living polymerization, and post-polymerization modification have opened new avenues for tailoring isomeric compositions. These developments have not only enhanced our ability to create materials with precise properties but have also expanded the range of achievable polymer architectures.

The objectives of current research in this field are multifaceted. Firstly, there is a drive to develop more efficient and selective methods for controlling isomeric structures during polymerization. This includes the design of novel catalysts and the optimization of reaction conditions to favor specific isomeric configurations. Secondly, researchers aim to elucidate the relationship between isomeric composition and macroscopic properties more comprehensively, enabling more accurate prediction and control of material behavior.

Furthermore, there is growing interest in leveraging geometric isomerism for the creation of smart and responsive polymers. By incorporating isomers that can undergo reversible transformations in response to external stimuli, scientists are exploring new frontiers in adaptive materials and drug delivery systems. The potential applications of such materials span diverse fields, including biomedical engineering, electronics, and environmental science.

As we look to the future, the role of geometric isomers in polymer synthesis strategies is expected to become increasingly sophisticated. The integration of computational modeling, high-throughput experimentation, and advanced characterization techniques promises to accelerate the discovery and optimization of isomer-controlled polymers. This synergy of approaches will likely lead to the development of materials with unprecedented combinations of properties, opening new possibilities in both fundamental polymer science and practical applications.

The development of polymer synthesis techniques has been closely intertwined with the understanding and manipulation of geometric isomers. Early synthetic methods often resulted in random distributions of isomers, leading to inconsistent material properties. As the field progressed, chemists and materials scientists sought ways to control isomeric composition, recognizing its potential to fine-tune polymer performance.

The importance of geometric isomers in polymer synthesis lies in their ability to affect chain conformation, packing, and intermolecular interactions. These factors directly influence crucial polymer properties such as crystallinity, melting point, glass transition temperature, and mechanical strength. For instance, the presence of cis or trans isomers in polydienes can dramatically alter elasticity and toughness, while the ratio of head-to-head versus head-to-tail configurations in vinyl polymers can impact solubility and thermal stability.

Recent advancements in synthetic methodologies have enabled unprecedented control over isomeric structures in polymers. Techniques such as stereospecific polymerization, living polymerization, and post-polymerization modification have opened new avenues for tailoring isomeric compositions. These developments have not only enhanced our ability to create materials with precise properties but have also expanded the range of achievable polymer architectures.

The objectives of current research in this field are multifaceted. Firstly, there is a drive to develop more efficient and selective methods for controlling isomeric structures during polymerization. This includes the design of novel catalysts and the optimization of reaction conditions to favor specific isomeric configurations. Secondly, researchers aim to elucidate the relationship between isomeric composition and macroscopic properties more comprehensively, enabling more accurate prediction and control of material behavior.

Furthermore, there is growing interest in leveraging geometric isomerism for the creation of smart and responsive polymers. By incorporating isomers that can undergo reversible transformations in response to external stimuli, scientists are exploring new frontiers in adaptive materials and drug delivery systems. The potential applications of such materials span diverse fields, including biomedical engineering, electronics, and environmental science.

As we look to the future, the role of geometric isomers in polymer synthesis strategies is expected to become increasingly sophisticated. The integration of computational modeling, high-throughput experimentation, and advanced characterization techniques promises to accelerate the discovery and optimization of isomer-controlled polymers. This synergy of approaches will likely lead to the development of materials with unprecedented combinations of properties, opening new possibilities in both fundamental polymer science and practical applications.

Market Demand for Isomer-Controlled Polymers

The market demand for isomer-controlled polymers has been steadily growing in recent years, driven by the increasing need for high-performance materials in various industries. This demand is particularly evident in sectors such as electronics, healthcare, and advanced manufacturing, where precise control over material properties is crucial.

In the electronics industry, isomer-controlled polymers are gaining traction due to their unique optical and electrical properties. These materials are being utilized in the development of organic light-emitting diodes (OLEDs), photovoltaic cells, and flexible electronics. The ability to fine-tune the polymer structure through isomer control allows for enhanced device performance and efficiency.

The healthcare sector is another significant driver of demand for isomer-controlled polymers. These materials are finding applications in drug delivery systems, tissue engineering, and medical devices. The controlled release of pharmaceuticals and the creation of biocompatible scaffolds for tissue regeneration are areas where the precise manipulation of polymer structures through isomer control is proving invaluable.

Advanced manufacturing, particularly in the aerospace and automotive industries, is also contributing to the growing market for isomer-controlled polymers. These materials offer improved mechanical properties, thermal stability, and chemical resistance, making them ideal for use in lightweight composites and high-performance coatings.

The global market for specialty polymers, which includes isomer-controlled variants, is projected to experience substantial growth. This expansion is fueled by the increasing adoption of these materials in emerging technologies and the ongoing shift towards more sustainable and efficient manufacturing processes.

Environmental concerns and regulatory pressures are further shaping the market demand for isomer-controlled polymers. As industries seek to reduce their carbon footprint and improve the recyclability of their products, there is a growing interest in polymers that can be precisely engineered to meet these requirements while maintaining high performance standards.

The Asia-Pacific region is expected to be a key growth area for isomer-controlled polymers, driven by rapid industrialization and increasing investments in research and development. North America and Europe continue to be significant markets, with a focus on high-value applications in sectors such as healthcare and advanced materials.

As the technology for synthesizing and characterizing isomer-controlled polymers advances, it is anticipated that new applications will emerge, further expanding the market. The ability to create materials with tailored properties at the molecular level is opening up possibilities in fields such as nanotechnology, smart materials, and responsive polymers.

In the electronics industry, isomer-controlled polymers are gaining traction due to their unique optical and electrical properties. These materials are being utilized in the development of organic light-emitting diodes (OLEDs), photovoltaic cells, and flexible electronics. The ability to fine-tune the polymer structure through isomer control allows for enhanced device performance and efficiency.

The healthcare sector is another significant driver of demand for isomer-controlled polymers. These materials are finding applications in drug delivery systems, tissue engineering, and medical devices. The controlled release of pharmaceuticals and the creation of biocompatible scaffolds for tissue regeneration are areas where the precise manipulation of polymer structures through isomer control is proving invaluable.

Advanced manufacturing, particularly in the aerospace and automotive industries, is also contributing to the growing market for isomer-controlled polymers. These materials offer improved mechanical properties, thermal stability, and chemical resistance, making them ideal for use in lightweight composites and high-performance coatings.

The global market for specialty polymers, which includes isomer-controlled variants, is projected to experience substantial growth. This expansion is fueled by the increasing adoption of these materials in emerging technologies and the ongoing shift towards more sustainable and efficient manufacturing processes.

Environmental concerns and regulatory pressures are further shaping the market demand for isomer-controlled polymers. As industries seek to reduce their carbon footprint and improve the recyclability of their products, there is a growing interest in polymers that can be precisely engineered to meet these requirements while maintaining high performance standards.

The Asia-Pacific region is expected to be a key growth area for isomer-controlled polymers, driven by rapid industrialization and increasing investments in research and development. North America and Europe continue to be significant markets, with a focus on high-value applications in sectors such as healthcare and advanced materials.

As the technology for synthesizing and characterizing isomer-controlled polymers advances, it is anticipated that new applications will emerge, further expanding the market. The ability to create materials with tailored properties at the molecular level is opening up possibilities in fields such as nanotechnology, smart materials, and responsive polymers.

Current Challenges in Geometric Isomer Control

The control of geometric isomers in polymer synthesis presents several significant challenges that researchers and industry professionals are actively working to overcome. One of the primary difficulties lies in the precise manipulation of molecular structures during polymerization processes. Achieving high selectivity for specific geometric isomers often requires carefully tailored reaction conditions and catalysts, which can be complex to develop and implement on a large scale.

Temperature control during synthesis is a critical factor that poses challenges in geometric isomer control. Many polymerization reactions are sensitive to temperature fluctuations, which can lead to undesired isomerization or loss of stereochemical integrity. Maintaining consistent and optimal temperatures throughout the reaction vessel, especially in industrial-scale production, remains a technical hurdle.

Another significant challenge is the development of highly selective catalysts that can promote the formation of desired geometric isomers while suppressing unwanted configurations. The design of such catalysts often involves intricate molecular engineering and can be both time-consuming and costly. Furthermore, even when effective catalysts are developed, their performance may be sensitive to impurities or variations in reaction conditions, making consistent results difficult to achieve.

The characterization and quantification of geometric isomers in polymer products also present ongoing challenges. While techniques such as NMR spectroscopy and X-ray crystallography can provide valuable insights, they may not always offer the resolution or throughput required for rapid, large-scale analysis. This limitation can hinder quality control processes and the development of structure-property relationships crucial for optimizing polymer performance.

Scalability remains a persistent issue in the control of geometric isomers. Methods that work well in laboratory settings may not translate effectively to industrial production scales due to factors such as heat and mass transfer limitations, mixing inefficiencies, and economic constraints. Bridging this gap between lab-scale success and commercial viability is an ongoing challenge for polymer scientists and engineers.

Environmental and regulatory considerations add another layer of complexity to geometric isomer control. As sustainability becomes increasingly important, there is growing pressure to develop greener synthesis methods that minimize the use of harmful solvents and reduce energy consumption. Balancing these environmental concerns with the need for precise isomer control often requires innovative approaches and may necessitate trade-offs in process efficiency or product purity.

Lastly, the dynamic nature of some polymer systems poses challenges in maintaining geometric isomer configurations over time. Post-polymerization isomerization can occur due to various factors such as light exposure, thermal stress, or mechanical forces during processing and use. Developing strategies to stabilize desired isomeric structures throughout the polymer lifecycle is an area of ongoing research and development in the field.

Temperature control during synthesis is a critical factor that poses challenges in geometric isomer control. Many polymerization reactions are sensitive to temperature fluctuations, which can lead to undesired isomerization or loss of stereochemical integrity. Maintaining consistent and optimal temperatures throughout the reaction vessel, especially in industrial-scale production, remains a technical hurdle.

Another significant challenge is the development of highly selective catalysts that can promote the formation of desired geometric isomers while suppressing unwanted configurations. The design of such catalysts often involves intricate molecular engineering and can be both time-consuming and costly. Furthermore, even when effective catalysts are developed, their performance may be sensitive to impurities or variations in reaction conditions, making consistent results difficult to achieve.

The characterization and quantification of geometric isomers in polymer products also present ongoing challenges. While techniques such as NMR spectroscopy and X-ray crystallography can provide valuable insights, they may not always offer the resolution or throughput required for rapid, large-scale analysis. This limitation can hinder quality control processes and the development of structure-property relationships crucial for optimizing polymer performance.

Scalability remains a persistent issue in the control of geometric isomers. Methods that work well in laboratory settings may not translate effectively to industrial production scales due to factors such as heat and mass transfer limitations, mixing inefficiencies, and economic constraints. Bridging this gap between lab-scale success and commercial viability is an ongoing challenge for polymer scientists and engineers.

Environmental and regulatory considerations add another layer of complexity to geometric isomer control. As sustainability becomes increasingly important, there is growing pressure to develop greener synthesis methods that minimize the use of harmful solvents and reduce energy consumption. Balancing these environmental concerns with the need for precise isomer control often requires innovative approaches and may necessitate trade-offs in process efficiency or product purity.

Lastly, the dynamic nature of some polymer systems poses challenges in maintaining geometric isomer configurations over time. Post-polymerization isomerization can occur due to various factors such as light exposure, thermal stress, or mechanical forces during processing and use. Developing strategies to stabilize desired isomeric structures throughout the polymer lifecycle is an area of ongoing research and development in the field.

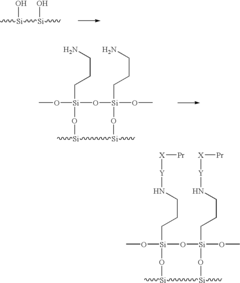

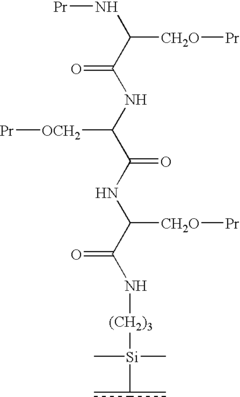

Existing Strategies for Geometric Isomer Manipulation

01 Synthesis and separation of geometric isomers

Methods for synthesizing and separating geometric isomers, including techniques for isolating specific isomers from mixtures. This involves various chemical processes and separation techniques to obtain pure geometric isomers for further use or study.- Synthesis and separation of geometric isomers: Methods for synthesizing and separating geometric isomers, including techniques for controlling the formation of specific isomers during chemical reactions and purification processes to isolate desired isomers from mixtures.

- Characterization and analysis of geometric isomers: Techniques for identifying and analyzing geometric isomers, including spectroscopic methods, chromatography, and computational modeling to determine molecular structures and properties of different isomeric forms.

- Applications of geometric isomers in pharmaceuticals: Utilization of geometric isomers in drug development and formulation, focusing on the different biological activities and therapeutic effects of various isomeric forms of pharmaceutical compounds.

- Geometric isomers in materials science and engineering: Exploration of geometric isomers in the development of new materials with specific properties, including applications in polymer science, nanotechnology, and optoelectronic devices.

- Computational methods for studying geometric isomers: Development and application of computational algorithms and software tools for modeling, predicting, and visualizing geometric isomers and their properties, including quantum chemical calculations and molecular dynamics simulations.

02 Geometric isomers in pharmaceutical compounds

The importance of geometric isomers in pharmaceutical compounds, including their effects on drug efficacy and safety. This involves studying the different biological activities of geometric isomers and developing methods to produce specific isomers for pharmaceutical applications.Expand Specific Solutions03 Analytical methods for identifying geometric isomers

Development of analytical techniques for identifying and characterizing geometric isomers. This includes spectroscopic methods, chromatography, and other advanced analytical tools to distinguish between different geometric isomers in complex mixtures.Expand Specific Solutions04 Computational modeling of geometric isomers

Use of computational methods to model and predict the properties of geometric isomers. This involves molecular modeling, quantum chemical calculations, and other computational techniques to study the structure, stability, and reactivity of geometric isomers.Expand Specific Solutions05 Applications of geometric isomers in materials science

Exploration of geometric isomers in materials science, including their use in developing new materials with specific properties. This involves studying how the arrangement of atoms in geometric isomers affects material properties and developing applications in fields such as optics, electronics, and nanotechnology.Expand Specific Solutions

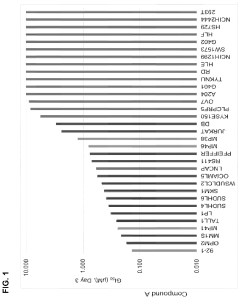

Key Players in Polymer Synthesis Industry

The field of geometric isomers in polymer synthesis strategies is in a mature stage of development, with a substantial market size driven by diverse industrial applications. The technology has reached a high level of maturity, as evidenced by the involvement of major players like Schlumberger Technology BV, The Chemours Co., and Mitsui Chemicals, Inc. These companies have established strong research and development capabilities in this area. The competitive landscape is characterized by a mix of large multinational corporations and specialized chemical companies, each contributing to advancements in polymer synthesis techniques. As the demand for high-performance polymers continues to grow across various sectors, including automotive, electronics, and healthcare, the market for innovative geometric isomer-based synthesis strategies is expected to expand further.

The Chemours Co.

Technical Solution: The Chemours Company has developed advanced polymer synthesis strategies utilizing geometric isomers to enhance material properties. Their approach involves controlling the spatial arrangement of atoms in polymer chains, particularly focusing on cis-trans isomerism in fluoropolymers. By manipulating the ratio of cis and trans isomers, they have achieved improvements in thermal stability, chemical resistance, and mechanical strength of their products[1]. The company employs catalytic systems that selectively produce desired isomeric configurations, allowing for precise control over polymer architecture[3]. This technology has been particularly successful in the development of high-performance fluoroelastomers and perfluoropolyethers (PFPEs) used in demanding industrial applications[5].

Strengths: Precise control over polymer properties, enhanced material performance, and applicability in extreme environments. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

Univation Technologies LLC

Technical Solution: Univation Technologies has pioneered the use of geometric isomers in polyolefin synthesis, particularly in the production of polyethylene. Their UNIPOL™ PE Process technology incorporates metallocene catalysts that can control the stereochemistry of polymer chains, including the manipulation of geometric isomers[2]. This approach allows for the creation of polyethylene with tailored molecular structures, resulting in improved physical properties such as increased tensile strength and enhanced processability[4]. The company has developed methods to fine-tune the distribution of different isomeric forms within the polymer, leading to materials with optimized performance characteristics for specific applications, from packaging to industrial products[6].

Strengths: Versatile technology applicable to a wide range of polyolefin products, improved material properties, and scalable production processes. Weaknesses: Potential limitations in achieving certain extreme property combinations, and higher catalyst costs compared to traditional Ziegler-Natta systems.

Innovative Approaches in Isomer-Selective Catalysis

Combinatorial strategies for polymer synthesis

PatentInactiveUS6864101B1

Innovation

- A method involving the formation of channels or grooves on a substrate with microvalves to deliver and react monomers in parallel, allowing for high-density synthesis of diverse polymer sequences without relying solely on light activation, using mechanical systems to control reagent flow and coupling at multiple sites simultaneously.

Compounds and uses thereof

PatentPendingUS20230145003A1

Innovation

- Development of specific compounds that modulate the BAF complex by inhibiting BRG1 and/or BRM activity, which can be used alone or in combination with other pharmaceutically active agents to treat disorders like cancer.

Environmental Impact of Isomer-Controlled Polymers

The environmental impact of isomer-controlled polymers is a critical consideration in the development and application of advanced materials. These polymers, synthesized with precise control over geometric isomers, offer unique properties that can significantly influence their interaction with the environment throughout their lifecycle.

One of the primary environmental benefits of isomer-controlled polymers is their potential for enhanced biodegradability. By manipulating the geometric configuration of polymer chains, scientists can create materials that are more susceptible to natural breakdown processes. This characteristic is particularly valuable in addressing the global issue of plastic pollution, as it can lead to the development of environmentally friendly alternatives to conventional, persistent plastics.

The production process of isomer-controlled polymers also presents opportunities for reduced environmental impact. Precise control over isomeric composition often allows for more efficient synthesis methods, potentially reducing energy consumption and waste generation during manufacturing. Additionally, the ability to fine-tune polymer properties through isomer control may lead to the creation of materials with improved durability and longevity, thereby reducing the need for frequent replacement and minimizing overall resource consumption.

However, the environmental implications of these advanced polymers are not without challenges. The specialized synthesis techniques required for isomer control may involve the use of complex catalysts or reaction conditions, which could potentially introduce new environmental concerns if not properly managed. Furthermore, the fate of these polymers in various environmental compartments, such as soil and water systems, requires thorough investigation to ensure that their breakdown products do not pose unforeseen ecological risks.

The recyclability of isomer-controlled polymers is another crucial aspect of their environmental profile. While their unique structures may offer advantages in terms of material properties, they may also present challenges in conventional recycling processes. Research into specialized recycling methods for these advanced polymers is essential to maximize their environmental benefits and minimize end-of-life impacts.

In the context of climate change mitigation, isomer-controlled polymers show promise in several applications. For instance, their use in lightweight materials for transportation can contribute to improved fuel efficiency and reduced greenhouse gas emissions. Similarly, their potential in advanced insulation materials could enhance energy efficiency in buildings, further supporting climate change mitigation efforts.

As the field of isomer-controlled polymer synthesis continues to evolve, ongoing environmental assessment and life cycle analysis are crucial. These studies will help identify potential risks and benefits associated with different isomeric configurations and guide the development of environmentally optimal polymer designs. By carefully considering the environmental implications at every stage of development and application, researchers and industry professionals can harness the full potential of isomer-controlled polymers while minimizing their ecological footprint.

One of the primary environmental benefits of isomer-controlled polymers is their potential for enhanced biodegradability. By manipulating the geometric configuration of polymer chains, scientists can create materials that are more susceptible to natural breakdown processes. This characteristic is particularly valuable in addressing the global issue of plastic pollution, as it can lead to the development of environmentally friendly alternatives to conventional, persistent plastics.

The production process of isomer-controlled polymers also presents opportunities for reduced environmental impact. Precise control over isomeric composition often allows for more efficient synthesis methods, potentially reducing energy consumption and waste generation during manufacturing. Additionally, the ability to fine-tune polymer properties through isomer control may lead to the creation of materials with improved durability and longevity, thereby reducing the need for frequent replacement and minimizing overall resource consumption.

However, the environmental implications of these advanced polymers are not without challenges. The specialized synthesis techniques required for isomer control may involve the use of complex catalysts or reaction conditions, which could potentially introduce new environmental concerns if not properly managed. Furthermore, the fate of these polymers in various environmental compartments, such as soil and water systems, requires thorough investigation to ensure that their breakdown products do not pose unforeseen ecological risks.

The recyclability of isomer-controlled polymers is another crucial aspect of their environmental profile. While their unique structures may offer advantages in terms of material properties, they may also present challenges in conventional recycling processes. Research into specialized recycling methods for these advanced polymers is essential to maximize their environmental benefits and minimize end-of-life impacts.

In the context of climate change mitigation, isomer-controlled polymers show promise in several applications. For instance, their use in lightweight materials for transportation can contribute to improved fuel efficiency and reduced greenhouse gas emissions. Similarly, their potential in advanced insulation materials could enhance energy efficiency in buildings, further supporting climate change mitigation efforts.

As the field of isomer-controlled polymer synthesis continues to evolve, ongoing environmental assessment and life cycle analysis are crucial. These studies will help identify potential risks and benefits associated with different isomeric configurations and guide the development of environmentally optimal polymer designs. By carefully considering the environmental implications at every stage of development and application, researchers and industry professionals can harness the full potential of isomer-controlled polymers while minimizing their ecological footprint.

Regulatory Framework for Novel Polymer Materials

The regulatory framework for novel polymer materials is evolving rapidly to keep pace with advancements in polymer synthesis strategies, particularly those involving geometric isomers. Regulatory bodies worldwide are recognizing the need for updated guidelines to address the unique properties and potential risks associated with these innovative materials. The European Chemicals Agency (ECHA) has taken a leading role in developing comprehensive regulations for novel polymers, including those synthesized using geometric isomers.

Under the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation, polymers containing geometric isomers are subject to rigorous safety assessments. Manufacturers must provide detailed information on the chemical structure, physical properties, and potential environmental and health impacts of these materials. The regulatory process emphasizes the importance of understanding how different geometric configurations can influence the overall behavior and safety profile of the polymer.

In the United States, the Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA) to regulate novel polymer materials. The EPA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including polymers with geometric isomers. These notices must include comprehensive data on the polymer's composition, intended uses, and potential exposure scenarios. The agency has also established specific exemptions for certain low-risk polymers, streamlining the regulatory process for materials that meet predefined safety criteria.

Japan's regulatory approach, governed by the Chemical Substances Control Law (CSCL), has recently been updated to address the challenges posed by novel polymer materials. The revised framework includes provisions for polymers containing geometric isomers, requiring manufacturers to provide detailed information on the isomeric composition and its impact on the material's properties and potential risks.

International collaboration is becoming increasingly important in developing harmonized regulatory approaches for novel polymer materials. The Organization for Economic Co-operation and Development (OECD) has established working groups focused on creating standardized testing methods and risk assessment protocols for polymers, including those with geometric isomers. These efforts aim to facilitate global trade while ensuring consistent safety standards across different jurisdictions.

As the field of polymer synthesis continues to advance, regulatory frameworks are likely to undergo further refinement. Emerging areas of focus include the development of specific guidelines for biodegradable polymers, nano-scale polymer materials, and polymers designed for biomedical applications. Regulators are also exploring the use of computational modeling and artificial intelligence to enhance risk assessment processes for complex polymer systems involving geometric isomers.

Under the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation, polymers containing geometric isomers are subject to rigorous safety assessments. Manufacturers must provide detailed information on the chemical structure, physical properties, and potential environmental and health impacts of these materials. The regulatory process emphasizes the importance of understanding how different geometric configurations can influence the overall behavior and safety profile of the polymer.

In the United States, the Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA) to regulate novel polymer materials. The EPA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including polymers with geometric isomers. These notices must include comprehensive data on the polymer's composition, intended uses, and potential exposure scenarios. The agency has also established specific exemptions for certain low-risk polymers, streamlining the regulatory process for materials that meet predefined safety criteria.

Japan's regulatory approach, governed by the Chemical Substances Control Law (CSCL), has recently been updated to address the challenges posed by novel polymer materials. The revised framework includes provisions for polymers containing geometric isomers, requiring manufacturers to provide detailed information on the isomeric composition and its impact on the material's properties and potential risks.

International collaboration is becoming increasingly important in developing harmonized regulatory approaches for novel polymer materials. The Organization for Economic Co-operation and Development (OECD) has established working groups focused on creating standardized testing methods and risk assessment protocols for polymers, including those with geometric isomers. These efforts aim to facilitate global trade while ensuring consistent safety standards across different jurisdictions.

As the field of polymer synthesis continues to advance, regulatory frameworks are likely to undergo further refinement. Emerging areas of focus include the development of specific guidelines for biodegradable polymers, nano-scale polymer materials, and polymers designed for biomedical applications. Regulators are also exploring the use of computational modeling and artificial intelligence to enhance risk assessment processes for complex polymer systems involving geometric isomers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!