The impact of silicon photonics on supply chain logistics.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Photonics Evolution

Silicon photonics has undergone a remarkable evolution since its inception in the late 1980s. Initially conceived as a means to integrate optical components with electronic circuits, the technology has progressed through several key stages, each marked by significant advancements and breakthroughs.

The early 1990s saw the development of basic silicon waveguides, which laid the foundation for light manipulation on silicon chips. This period was characterized by efforts to overcome the inherent limitations of silicon as an optical material, particularly its indirect bandgap, which made light emission challenging.

By the early 2000s, researchers had made substantial progress in creating essential photonic components, including modulators and detectors. The demonstration of the first silicon Raman laser in 2004 marked a pivotal moment, showcasing the potential for light amplification and generation in silicon.

The late 2000s and early 2010s witnessed a surge in integration capabilities. Researchers successfully combined multiple photonic functions on a single chip, paving the way for more complex photonic integrated circuits (PICs). This era also saw the emergence of silicon photonics in data center applications, with companies like Intel and IBM investing heavily in the technology.

From 2015 onwards, silicon photonics entered a phase of commercial maturity. The technology began to find applications beyond data centers, expanding into areas such as telecommunications, sensing, and even quantum computing. Advancements in manufacturing processes, particularly the adaptation of CMOS fabrication techniques, enabled the production of silicon photonic devices at scale.

Recent years have seen a focus on enhancing the performance and efficiency of silicon photonic devices. Innovations in materials science, such as the integration of III-V semiconductors with silicon, have addressed some of the longstanding challenges in light emission and amplification. Additionally, the development of novel architectures, like photonic neural networks, has opened up new possibilities for AI and machine learning applications.

Looking towards the future, silicon photonics is poised to play a crucial role in next-generation computing and communication systems. The technology's potential to enable faster, more energy-efficient data processing and transmission aligns well with the growing demands of cloud computing, 5G networks, and the Internet of Things. As silicon photonics continues to evolve, it is expected to have far-reaching impacts on various industries, including supply chain logistics, by enabling more efficient data handling and real-time decision-making capabilities.

The early 1990s saw the development of basic silicon waveguides, which laid the foundation for light manipulation on silicon chips. This period was characterized by efforts to overcome the inherent limitations of silicon as an optical material, particularly its indirect bandgap, which made light emission challenging.

By the early 2000s, researchers had made substantial progress in creating essential photonic components, including modulators and detectors. The demonstration of the first silicon Raman laser in 2004 marked a pivotal moment, showcasing the potential for light amplification and generation in silicon.

The late 2000s and early 2010s witnessed a surge in integration capabilities. Researchers successfully combined multiple photonic functions on a single chip, paving the way for more complex photonic integrated circuits (PICs). This era also saw the emergence of silicon photonics in data center applications, with companies like Intel and IBM investing heavily in the technology.

From 2015 onwards, silicon photonics entered a phase of commercial maturity. The technology began to find applications beyond data centers, expanding into areas such as telecommunications, sensing, and even quantum computing. Advancements in manufacturing processes, particularly the adaptation of CMOS fabrication techniques, enabled the production of silicon photonic devices at scale.

Recent years have seen a focus on enhancing the performance and efficiency of silicon photonic devices. Innovations in materials science, such as the integration of III-V semiconductors with silicon, have addressed some of the longstanding challenges in light emission and amplification. Additionally, the development of novel architectures, like photonic neural networks, has opened up new possibilities for AI and machine learning applications.

Looking towards the future, silicon photonics is poised to play a crucial role in next-generation computing and communication systems. The technology's potential to enable faster, more energy-efficient data processing and transmission aligns well with the growing demands of cloud computing, 5G networks, and the Internet of Things. As silicon photonics continues to evolve, it is expected to have far-reaching impacts on various industries, including supply chain logistics, by enabling more efficient data handling and real-time decision-making capabilities.

Supply Chain Logistics Demand

The demand for efficient supply chain logistics has been steadily increasing in recent years, driven by the growth of e-commerce, globalization, and the need for faster, more reliable delivery systems. Silicon photonics technology has emerged as a potential game-changer in this field, offering significant improvements in data transmission speed, energy efficiency, and overall system performance.

In the context of supply chain logistics, the market demand for silicon photonics solutions is primarily focused on enhancing communication networks, data centers, and sensor systems. These technologies are crucial for managing complex supply chains, tracking inventory, and optimizing logistics operations. The global supply chain management market is expected to grow substantially, with a significant portion of this growth attributed to technological advancements like silicon photonics.

One of the key drivers of demand is the need for real-time data processing and analysis in supply chain operations. Silicon photonics enables faster data transmission and processing, allowing for more accurate tracking of goods, improved inventory management, and better decision-making in logistics operations. This is particularly important in industries with time-sensitive supply chains, such as pharmaceuticals, fresh produce, and just-in-time manufacturing.

Another factor contributing to the demand for silicon photonics in supply chain logistics is the increasing adoption of Internet of Things (IoT) devices and sensors. These devices generate vast amounts of data that need to be transmitted and processed quickly and efficiently. Silicon photonics technology can provide the necessary bandwidth and low-latency communication required to handle this data influx, making it an attractive solution for companies looking to implement IoT-based supply chain management systems.

The demand for more energy-efficient logistics operations is also driving interest in silicon photonics. As companies strive to reduce their carbon footprint and operational costs, the energy-saving potential of silicon photonics becomes increasingly appealing. The technology's ability to transmit data with lower power consumption compared to traditional electronic systems makes it an attractive option for large-scale logistics operations and data centers supporting supply chain management.

Furthermore, the growing trend towards automation and robotics in warehouses and distribution centers is creating additional demand for high-speed, reliable communication systems. Silicon photonics can support the data-intensive requirements of these automated systems, enabling smoother operations and improved efficiency in logistics hubs.

As supply chains become more global and complex, there is an increasing need for advanced tracking and monitoring systems. Silicon photonics-based sensors and communication systems can provide more accurate and real-time information about the location, condition, and status of goods throughout the supply chain. This capability is particularly valuable for industries dealing with sensitive or perishable goods, where maintaining optimal conditions during transport is critical.

In the context of supply chain logistics, the market demand for silicon photonics solutions is primarily focused on enhancing communication networks, data centers, and sensor systems. These technologies are crucial for managing complex supply chains, tracking inventory, and optimizing logistics operations. The global supply chain management market is expected to grow substantially, with a significant portion of this growth attributed to technological advancements like silicon photonics.

One of the key drivers of demand is the need for real-time data processing and analysis in supply chain operations. Silicon photonics enables faster data transmission and processing, allowing for more accurate tracking of goods, improved inventory management, and better decision-making in logistics operations. This is particularly important in industries with time-sensitive supply chains, such as pharmaceuticals, fresh produce, and just-in-time manufacturing.

Another factor contributing to the demand for silicon photonics in supply chain logistics is the increasing adoption of Internet of Things (IoT) devices and sensors. These devices generate vast amounts of data that need to be transmitted and processed quickly and efficiently. Silicon photonics technology can provide the necessary bandwidth and low-latency communication required to handle this data influx, making it an attractive solution for companies looking to implement IoT-based supply chain management systems.

The demand for more energy-efficient logistics operations is also driving interest in silicon photonics. As companies strive to reduce their carbon footprint and operational costs, the energy-saving potential of silicon photonics becomes increasingly appealing. The technology's ability to transmit data with lower power consumption compared to traditional electronic systems makes it an attractive option for large-scale logistics operations and data centers supporting supply chain management.

Furthermore, the growing trend towards automation and robotics in warehouses and distribution centers is creating additional demand for high-speed, reliable communication systems. Silicon photonics can support the data-intensive requirements of these automated systems, enabling smoother operations and improved efficiency in logistics hubs.

As supply chains become more global and complex, there is an increasing need for advanced tracking and monitoring systems. Silicon photonics-based sensors and communication systems can provide more accurate and real-time information about the location, condition, and status of goods throughout the supply chain. This capability is particularly valuable for industries dealing with sensitive or perishable goods, where maintaining optimal conditions during transport is critical.

Current Challenges in Integration

The integration of silicon photonics into supply chain logistics presents several significant challenges that need to be addressed for widespread adoption. One of the primary obstacles is the complexity of manufacturing processes required for silicon photonic devices. The fabrication of these components demands highly specialized equipment and clean room environments, which are not readily available in traditional electronics manufacturing facilities. This limitation creates a bottleneck in the supply chain, as only a few facilities worldwide can produce these advanced components at scale.

Another challenge lies in the thermal management of silicon photonic devices. These components are sensitive to temperature fluctuations, which can affect their performance and reliability. Integrating effective cooling systems into logistics hardware without significantly increasing size, weight, or power consumption remains a hurdle. This issue is particularly critical in data centers and telecommunications networks, where space and energy efficiency are paramount.

The packaging of silicon photonic devices also poses integration challenges. Unlike traditional electronic components, photonic devices require precise alignment of optical interfaces, which can be disrupted during transportation or installation. Developing robust packaging solutions that can withstand the rigors of supply chain logistics while maintaining optical alignment is an ongoing area of research and development.

Interoperability between silicon photonic devices and existing electronic systems presents another integration challenge. Many current logistics systems rely on electronic interfaces, and bridging the gap between optical and electronic domains requires additional components and expertise. This transition often results in increased complexity and potential points of failure within the supply chain infrastructure.

Furthermore, the testing and quality control of integrated silicon photonic systems in a logistics environment pose unique challenges. Traditional electronic testing methods are not always applicable to photonic components, necessitating the development of new testing protocols and equipment. This requirement can lead to increased costs and longer lead times in the supply chain.

Lastly, the integration of silicon photonics into supply chain logistics faces challenges related to standardization. The lack of widely accepted industry standards for silicon photonic components and interfaces can hinder interoperability and slow down adoption. Establishing common standards and protocols is crucial for ensuring seamless integration across different manufacturers and systems within the supply chain ecosystem.

Another challenge lies in the thermal management of silicon photonic devices. These components are sensitive to temperature fluctuations, which can affect their performance and reliability. Integrating effective cooling systems into logistics hardware without significantly increasing size, weight, or power consumption remains a hurdle. This issue is particularly critical in data centers and telecommunications networks, where space and energy efficiency are paramount.

The packaging of silicon photonic devices also poses integration challenges. Unlike traditional electronic components, photonic devices require precise alignment of optical interfaces, which can be disrupted during transportation or installation. Developing robust packaging solutions that can withstand the rigors of supply chain logistics while maintaining optical alignment is an ongoing area of research and development.

Interoperability between silicon photonic devices and existing electronic systems presents another integration challenge. Many current logistics systems rely on electronic interfaces, and bridging the gap between optical and electronic domains requires additional components and expertise. This transition often results in increased complexity and potential points of failure within the supply chain infrastructure.

Furthermore, the testing and quality control of integrated silicon photonic systems in a logistics environment pose unique challenges. Traditional electronic testing methods are not always applicable to photonic components, necessitating the development of new testing protocols and equipment. This requirement can lead to increased costs and longer lead times in the supply chain.

Lastly, the integration of silicon photonics into supply chain logistics faces challenges related to standardization. The lack of widely accepted industry standards for silicon photonic components and interfaces can hinder interoperability and slow down adoption. Establishing common standards and protocols is crucial for ensuring seamless integration across different manufacturers and systems within the supply chain ecosystem.

Existing Implementation Strategies

01 Integrated photonic devices

Silicon photonics technology enables the integration of various optical components on a single chip. This includes waveguides, modulators, detectors, and other photonic elements, allowing for compact and efficient optical systems. The integration of these components facilitates high-speed data transmission and processing in a small form factor.- Integrated photonic devices: Silicon photonics technology enables the integration of various optical components on a single chip. This includes waveguides, modulators, detectors, and other photonic elements, allowing for compact and efficient optical systems. The integration of these components facilitates high-speed data transmission and processing in a small form factor.

- Optical communication systems: Silicon photonics is extensively used in optical communication systems to enhance data transmission capabilities. This technology enables the development of high-bandwidth, low-latency communication links for applications such as data centers, telecommunications, and long-distance fiber optic networks. It allows for efficient modulation, multiplexing, and detection of optical signals.

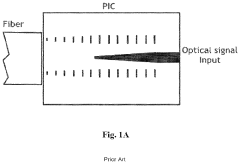

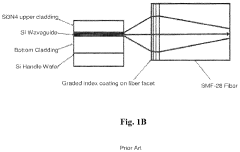

- Photonic integrated circuits (PICs): Silicon photonics facilitates the creation of photonic integrated circuits, which combine multiple optical functions on a single chip. These PICs can include lasers, modulators, multiplexers, and photodetectors, enabling complex optical processing and routing capabilities. The integration of electronic and photonic components on the same substrate enhances overall system performance and reduces power consumption.

- Silicon-based light sources: Developing efficient light sources in silicon is a key area of research in silicon photonics. This includes the integration of III-V materials with silicon to create on-chip lasers, as well as the exploration of novel light-emitting structures using silicon itself. These advancements aim to overcome the indirect bandgap limitation of silicon and enable fully integrated photonic systems.

- Photonic computing and sensing: Silicon photonics technology is being applied to develop novel computing architectures and sensing applications. This includes optical neural networks for AI acceleration, photonic quantum computing, and integrated photonic sensors for various applications such as biosensing and environmental monitoring. The use of light for computation and sensing offers potential advantages in speed, energy efficiency, and sensitivity.

02 Optical communication systems

Silicon photonics is extensively used in optical communication systems, particularly for high-bandwidth data transmission. These systems utilize silicon-based photonic components to transmit and receive optical signals, enabling faster and more efficient data transfer in telecommunications and data center applications.Expand Specific Solutions03 Photonic integrated circuits (PICs)

Photonic integrated circuits are a key application of silicon photonics, integrating multiple photonic functions on a single chip. These circuits can include lasers, modulators, multiplexers, and detectors, all working together to process and transmit optical signals. PICs offer advantages in terms of size, power consumption, and performance compared to traditional electronic circuits.Expand Specific Solutions04 Silicon-based optical interconnects

Silicon photonics enables the development of optical interconnects for chip-to-chip and intra-chip communication. These interconnects use light instead of electrical signals to transmit data, offering higher bandwidth and lower power consumption. This technology is particularly important for high-performance computing and data center applications.Expand Specific Solutions05 Integration with electronic circuits

Silicon photonics technology allows for the integration of photonic components with traditional electronic circuits. This integration enables the creation of hybrid electro-optical systems that combine the benefits of both photonics and electronics. Such integration is crucial for developing next-generation computing and communication systems that leverage the strengths of both technologies.Expand Specific Solutions

Key Industry Players

The silicon photonics market is rapidly evolving, with significant implications for supply chain logistics. Currently in its growth phase, the industry is experiencing increasing adoption across various sectors, particularly in data centers and telecommunications. Market size is expanding, driven by demand for high-speed data transmission and energy-efficient solutions. Technologically, silicon photonics is maturing, with key players like Intel, IBM, and Huawei making substantial advancements. Companies such as GlobalFoundries and TSMC are enhancing manufacturing capabilities, while research institutions like Zhejiang University and ETRI contribute to innovation. The competitive landscape is diverse, with established tech giants, specialized foundries like Advanced Micro Foundry, and emerging startups like Aeponyx vying for market share, indicating a dynamic and promising future for silicon photonics in supply chain optimization.

Intel Corp.

Technical Solution: Intel has developed advanced silicon photonics technology for high-speed data transmission in data centers and cloud computing environments. Their 100G and 400G optical transceivers integrate lasers, modulators, and detectors on a single chip, enabling faster and more energy-efficient data transfer[1]. Intel's silicon photonics solutions also address supply chain challenges by reducing the number of discrete components needed, simplifying manufacturing processes, and improving reliability. The company has demonstrated transmission speeds up to 224 Gbps per fiber, significantly enhancing bandwidth capabilities for large-scale data operations[2].

Strengths: Vertical integration of design and manufacturing; established presence in data center market. Weaknesses: Potential for higher initial costs; reliance on specialized fabrication facilities.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has invested heavily in silicon photonics technology, focusing on integrating optical components with traditional CMOS processes. Their approach aims to create high-performance, low-power chips for next-generation data centers and 5G networks. TSMC's silicon photonics platform offers multi-project wafer (MPW) services, allowing customers to prototype designs cost-effectively[3]. The company has achieved significant milestones in reducing optical loss and improving modulation efficiency, which are crucial for enhancing supply chain logistics through faster data processing and transmission[4].

Strengths: World-leading semiconductor manufacturing capabilities; extensive R&D resources. Weaknesses: Dependent on external design partners; potential for capacity constraints during high demand periods.

Breakthrough Silicon Photonics Technologies

Optical subassembly for non-reciprocal coupling of light and assembly process thereof

PatentActiveUS11966081B2

Innovation

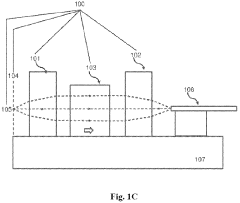

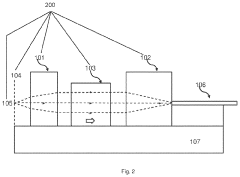

- An optical subassembly incorporating a focusing optical system with first and second focusing lenses, an optical isolator positioned between the foci, and a carrier to support the assembly, which aligns the input focus with the optical subassembly boundary, ensuring low transmission loss and unidirectional light transmission by magnifying the mode size of the SIP waveguide output to match the fiber, and integrating an optical isolator for preventing reverse light propagation.

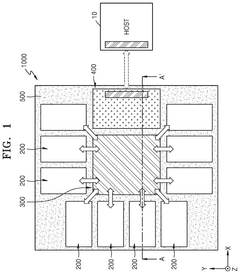

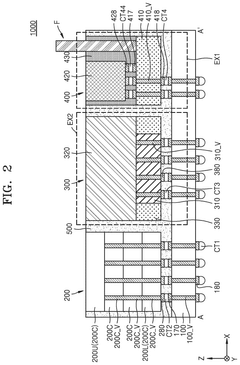

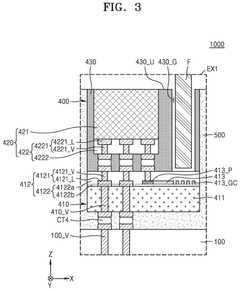

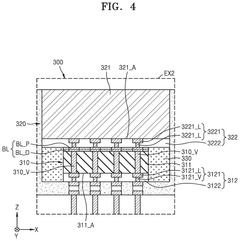

Semiconductor package and method of manufacturing the same

PatentPendingUS20250183243A1

Innovation

- A semiconductor package design that includes a package substrate with stack structures, a buffer chip for memory control, a memory controller chip for interconnection, and a photonics package with a PIC chip and an electronic integrated circuit (EIC) chip, surrounded by molding layers for thermal management.

Economic Impact Analysis

The integration of silicon photonics into supply chain logistics is poised to bring about significant economic impacts across various sectors. This technology's potential to revolutionize data transmission and processing capabilities will likely lead to substantial cost reductions in logistics operations. By enabling faster and more efficient data transfer, silicon photonics can optimize inventory management, reduce transportation costs, and minimize delays in supply chains.

The implementation of silicon photonics in logistics networks is expected to drive down operational expenses for businesses. As data centers and communication networks adopt this technology, the increased bandwidth and reduced power consumption will translate into lower infrastructure costs. This cost-saving potential could lead to more competitive pricing for logistics services, benefiting both providers and end-users.

Furthermore, the enhanced data processing capabilities offered by silicon photonics may catalyze the development of more sophisticated predictive analytics and artificial intelligence systems in supply chain management. These advancements could result in improved demand forecasting, route optimization, and real-time inventory tracking, all of which contribute to increased economic efficiency and reduced waste in logistics operations.

The economic impact of silicon photonics extends beyond direct cost savings. By enabling more responsive and agile supply chains, this technology can help businesses adapt more quickly to market changes and consumer demands. This increased flexibility could lead to improved customer satisfaction, potentially driving sales growth and market expansion for companies that effectively leverage silicon photonics in their logistics operations.

Additionally, the adoption of silicon photonics in supply chain logistics is likely to stimulate innovation and create new economic opportunities. As the technology matures, we can anticipate the emergence of new startups and services focused on developing and implementing silicon photonics solutions for logistics applications. This could lead to job creation in high-tech sectors and contribute to overall economic growth.

However, it is important to consider the potential economic disruptions that may occur as silicon photonics reshapes the logistics landscape. Some traditional logistics roles may become obsolete, necessitating workforce retraining and adaptation. The initial investment required to implement silicon photonics infrastructure may also present a barrier for smaller logistics providers, potentially leading to market consolidation or the need for government support to ensure widespread adoption and maintain competitive markets.

The implementation of silicon photonics in logistics networks is expected to drive down operational expenses for businesses. As data centers and communication networks adopt this technology, the increased bandwidth and reduced power consumption will translate into lower infrastructure costs. This cost-saving potential could lead to more competitive pricing for logistics services, benefiting both providers and end-users.

Furthermore, the enhanced data processing capabilities offered by silicon photonics may catalyze the development of more sophisticated predictive analytics and artificial intelligence systems in supply chain management. These advancements could result in improved demand forecasting, route optimization, and real-time inventory tracking, all of which contribute to increased economic efficiency and reduced waste in logistics operations.

The economic impact of silicon photonics extends beyond direct cost savings. By enabling more responsive and agile supply chains, this technology can help businesses adapt more quickly to market changes and consumer demands. This increased flexibility could lead to improved customer satisfaction, potentially driving sales growth and market expansion for companies that effectively leverage silicon photonics in their logistics operations.

Additionally, the adoption of silicon photonics in supply chain logistics is likely to stimulate innovation and create new economic opportunities. As the technology matures, we can anticipate the emergence of new startups and services focused on developing and implementing silicon photonics solutions for logistics applications. This could lead to job creation in high-tech sectors and contribute to overall economic growth.

However, it is important to consider the potential economic disruptions that may occur as silicon photonics reshapes the logistics landscape. Some traditional logistics roles may become obsolete, necessitating workforce retraining and adaptation. The initial investment required to implement silicon photonics infrastructure may also present a barrier for smaller logistics providers, potentially leading to market consolidation or the need for government support to ensure widespread adoption and maintain competitive markets.

Sustainability Considerations

Silicon photonics technology has the potential to significantly enhance the sustainability of supply chain logistics. By leveraging light-based communication and data processing, this technology can reduce energy consumption and carbon emissions across various aspects of the supply chain.

One of the primary sustainability benefits of silicon photonics in logistics is its ability to improve energy efficiency in data centers and communication networks. These facilities are critical components of modern supply chains, handling vast amounts of information for inventory management, order processing, and tracking. Silicon photonic devices consume less power compared to traditional electronic components, leading to reduced energy requirements and lower heat generation in data centers. This not only decreases the overall carbon footprint but also minimizes the need for cooling systems, further enhancing energy savings.

In transportation and warehousing, silicon photonics can enable more efficient inventory management and tracking systems. High-speed, low-latency optical communication networks powered by silicon photonics allow for real-time monitoring and optimization of inventory levels, reducing waste and unnecessary transportation. This technology can also support the development of smart warehouses with automated systems that minimize energy consumption and optimize space utilization.

The integration of silicon photonics in sensor networks throughout the supply chain can lead to more sustainable practices. These sensors can monitor environmental conditions, product quality, and equipment performance with greater accuracy and energy efficiency. This enhanced monitoring capability allows for proactive maintenance, reducing downtime and extending the lifespan of logistics infrastructure and equipment.

Furthermore, silicon photonics can contribute to the development of more sustainable packaging solutions. By enabling advanced quality control systems and real-time monitoring during the manufacturing process, it can help reduce material waste and improve the efficiency of packaging production. This technology can also support the implementation of smart packaging with embedded sensors, allowing for better tracking of product conditions and reducing spoilage in perishable goods transportation.

As supply chains become increasingly digitalized, the role of silicon photonics in supporting sustainable practices will likely expand. Its potential to enable more efficient data processing and communication can lead to optimized routing, reduced transportation emissions, and improved overall supply chain visibility. These advancements can contribute to more sustainable decision-making processes and resource allocation throughout the logistics network.

One of the primary sustainability benefits of silicon photonics in logistics is its ability to improve energy efficiency in data centers and communication networks. These facilities are critical components of modern supply chains, handling vast amounts of information for inventory management, order processing, and tracking. Silicon photonic devices consume less power compared to traditional electronic components, leading to reduced energy requirements and lower heat generation in data centers. This not only decreases the overall carbon footprint but also minimizes the need for cooling systems, further enhancing energy savings.

In transportation and warehousing, silicon photonics can enable more efficient inventory management and tracking systems. High-speed, low-latency optical communication networks powered by silicon photonics allow for real-time monitoring and optimization of inventory levels, reducing waste and unnecessary transportation. This technology can also support the development of smart warehouses with automated systems that minimize energy consumption and optimize space utilization.

The integration of silicon photonics in sensor networks throughout the supply chain can lead to more sustainable practices. These sensors can monitor environmental conditions, product quality, and equipment performance with greater accuracy and energy efficiency. This enhanced monitoring capability allows for proactive maintenance, reducing downtime and extending the lifespan of logistics infrastructure and equipment.

Furthermore, silicon photonics can contribute to the development of more sustainable packaging solutions. By enabling advanced quality control systems and real-time monitoring during the manufacturing process, it can help reduce material waste and improve the efficiency of packaging production. This technology can also support the implementation of smart packaging with embedded sensors, allowing for better tracking of product conditions and reducing spoilage in perishable goods transportation.

As supply chains become increasingly digitalized, the role of silicon photonics in supporting sustainable practices will likely expand. Its potential to enable more efficient data processing and communication can lead to optimized routing, reduced transportation emissions, and improved overall supply chain visibility. These advancements can contribute to more sustainable decision-making processes and resource allocation throughout the logistics network.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!