The Next Wave in Responsive Cellophane Technologies

JUL 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Tech Evolution

Cellophane technology has undergone significant evolution since its inception in the early 20th century. Initially developed as a moisture-proof packaging material, cellophane has transformed into a versatile and responsive material with applications across various industries.

The early stages of cellophane development focused primarily on improving its barrier properties and manufacturing processes. In the 1920s and 1930s, advancements in chemical treatments enhanced cellophane's moisture resistance and clarity, making it an ideal packaging material for food and consumer goods.

The 1950s and 1960s saw the introduction of heat-sealable cellophane, which revolutionized packaging efficiency and opened up new possibilities for product preservation. This period also marked the beginning of cellophane's use in non-packaging applications, such as in the textile and electronics industries.

The late 20th century brought about a shift towards more environmentally friendly cellophane production methods. Manufacturers began exploring alternatives to the traditional viscose process, seeking to reduce the environmental impact of cellophane production while maintaining its desirable properties.

The turn of the 21st century heralded a new era for cellophane technology, with a focus on developing responsive and smart functionalities. Researchers began incorporating nanomaterials and responsive polymers into cellophane structures, creating materials that could react to environmental stimuli such as temperature, humidity, and light.

Recent advancements have led to the development of cellophane with self-healing properties, enhanced biodegradability, and improved mechanical strength. These innovations have expanded cellophane's potential applications in fields such as biomedical engineering, flexible electronics, and advanced packaging solutions.

The latest wave of cellophane technology focuses on creating truly responsive and interactive materials. This includes the development of cellophane that can change color or transparency in response to specific stimuli, as well as materials that can actively monitor and respond to their environment.

Looking ahead, the future of cellophane technology is likely to involve further integration with smart systems and the Internet of Things (IoT). Researchers are exploring ways to incorporate sensors and actuators directly into cellophane structures, creating intelligent packaging and materials that can communicate with users and adapt to changing conditions in real-time.

As sustainability concerns continue to drive innovation, we can expect to see increased efforts to develop fully biodegradable and compostable cellophane variants that maintain the material's responsive properties. This evolution will likely involve the use of bio-based feedstocks and green chemistry principles to create environmentally friendly yet highly functional cellophane products.

The early stages of cellophane development focused primarily on improving its barrier properties and manufacturing processes. In the 1920s and 1930s, advancements in chemical treatments enhanced cellophane's moisture resistance and clarity, making it an ideal packaging material for food and consumer goods.

The 1950s and 1960s saw the introduction of heat-sealable cellophane, which revolutionized packaging efficiency and opened up new possibilities for product preservation. This period also marked the beginning of cellophane's use in non-packaging applications, such as in the textile and electronics industries.

The late 20th century brought about a shift towards more environmentally friendly cellophane production methods. Manufacturers began exploring alternatives to the traditional viscose process, seeking to reduce the environmental impact of cellophane production while maintaining its desirable properties.

The turn of the 21st century heralded a new era for cellophane technology, with a focus on developing responsive and smart functionalities. Researchers began incorporating nanomaterials and responsive polymers into cellophane structures, creating materials that could react to environmental stimuli such as temperature, humidity, and light.

Recent advancements have led to the development of cellophane with self-healing properties, enhanced biodegradability, and improved mechanical strength. These innovations have expanded cellophane's potential applications in fields such as biomedical engineering, flexible electronics, and advanced packaging solutions.

The latest wave of cellophane technology focuses on creating truly responsive and interactive materials. This includes the development of cellophane that can change color or transparency in response to specific stimuli, as well as materials that can actively monitor and respond to their environment.

Looking ahead, the future of cellophane technology is likely to involve further integration with smart systems and the Internet of Things (IoT). Researchers are exploring ways to incorporate sensors and actuators directly into cellophane structures, creating intelligent packaging and materials that can communicate with users and adapt to changing conditions in real-time.

As sustainability concerns continue to drive innovation, we can expect to see increased efforts to develop fully biodegradable and compostable cellophane variants that maintain the material's responsive properties. This evolution will likely involve the use of bio-based feedstocks and green chemistry principles to create environmentally friendly yet highly functional cellophane products.

Market Demand Analysis

The responsive cellophane technology market is experiencing a significant surge in demand, driven by the increasing need for smart packaging solutions across various industries. This innovative technology, which allows cellophane to change its properties in response to external stimuli, has captured the attention of manufacturers, retailers, and consumers alike.

In the food and beverage sector, responsive cellophane is gaining traction due to its ability to enhance food safety and extend shelf life. The technology can indicate freshness levels, detect spoilage, and even release preservatives when needed. This functionality addresses growing consumer concerns about food quality and waste reduction, making it an attractive option for both producers and environmentally conscious consumers.

The pharmaceutical industry is another key driver of market demand for responsive cellophane technologies. With the ability to monitor drug efficacy, control release rates, and provide tamper-evident packaging, this technology offers significant benefits in ensuring medication safety and patient compliance. As healthcare becomes increasingly personalized, the demand for smart packaging solutions in pharmaceuticals is expected to grow substantially.

In the cosmetics and personal care sector, responsive cellophane is being explored for its potential to create interactive and personalized packaging experiences. The technology can change color or texture in response to touch or environmental conditions, offering unique marketing opportunities and enhancing product differentiation in a highly competitive market.

The electronics industry is also showing interest in responsive cellophane for protective packaging applications. The technology's ability to respond to temperature changes, humidity, or physical impact makes it an ideal solution for safeguarding sensitive electronic components during shipping and storage.

Market analysis indicates that the global smart packaging market, which includes responsive cellophane technologies, is projected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is fueled by increasing consumer demand for convenience, product safety, and sustainability.

However, the market faces challenges in terms of cost and scalability. While the technology shows promise, the current production costs are higher than traditional packaging materials, which may limit widespread adoption in price-sensitive markets. Additionally, there are concerns about the environmental impact of these advanced materials, prompting research into biodegradable and recyclable responsive cellophane options.

Despite these challenges, the potential applications and benefits of responsive cellophane technologies continue to drive market interest and investment. As manufacturing processes improve and costs decrease, it is anticipated that the technology will see broader adoption across multiple industries, opening up new opportunities for innovation in packaging and product design.

In the food and beverage sector, responsive cellophane is gaining traction due to its ability to enhance food safety and extend shelf life. The technology can indicate freshness levels, detect spoilage, and even release preservatives when needed. This functionality addresses growing consumer concerns about food quality and waste reduction, making it an attractive option for both producers and environmentally conscious consumers.

The pharmaceutical industry is another key driver of market demand for responsive cellophane technologies. With the ability to monitor drug efficacy, control release rates, and provide tamper-evident packaging, this technology offers significant benefits in ensuring medication safety and patient compliance. As healthcare becomes increasingly personalized, the demand for smart packaging solutions in pharmaceuticals is expected to grow substantially.

In the cosmetics and personal care sector, responsive cellophane is being explored for its potential to create interactive and personalized packaging experiences. The technology can change color or texture in response to touch or environmental conditions, offering unique marketing opportunities and enhancing product differentiation in a highly competitive market.

The electronics industry is also showing interest in responsive cellophane for protective packaging applications. The technology's ability to respond to temperature changes, humidity, or physical impact makes it an ideal solution for safeguarding sensitive electronic components during shipping and storage.

Market analysis indicates that the global smart packaging market, which includes responsive cellophane technologies, is projected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is fueled by increasing consumer demand for convenience, product safety, and sustainability.

However, the market faces challenges in terms of cost and scalability. While the technology shows promise, the current production costs are higher than traditional packaging materials, which may limit widespread adoption in price-sensitive markets. Additionally, there are concerns about the environmental impact of these advanced materials, prompting research into biodegradable and recyclable responsive cellophane options.

Despite these challenges, the potential applications and benefits of responsive cellophane technologies continue to drive market interest and investment. As manufacturing processes improve and costs decrease, it is anticipated that the technology will see broader adoption across multiple industries, opening up new opportunities for innovation in packaging and product design.

Current Challenges

The field of responsive cellophane technologies is currently facing several significant challenges that hinder its widespread adoption and full potential realization. These obstacles span across technical, economic, and practical domains, requiring innovative solutions to propel the industry forward.

One of the primary technical challenges lies in achieving precise and reliable responsiveness to specific stimuli. While current cellophane materials can respond to certain environmental changes, such as temperature or humidity, the accuracy and consistency of these responses often fall short of industry requirements. Engineers are grappling with the complexities of fine-tuning the molecular structure of cellophane to enhance its sensitivity and reactivity to a broader range of stimuli, including light, pressure, and chemical agents.

Another critical hurdle is the scalability of production processes for responsive cellophane. Laboratory-scale successes have been achieved, but translating these into large-scale, cost-effective manufacturing methods remains a significant challenge. The intricate nature of incorporating responsive elements into the cellophane structure while maintaining its essential properties demands sophisticated production techniques that are not yet fully developed or economically viable for mass production.

Durability and longevity of responsive cellophane products also present ongoing challenges. The repeated activation and deactivation of responsive mechanisms can lead to material fatigue and degradation over time, potentially limiting the lifespan and reliability of products incorporating this technology. Researchers are actively seeking ways to enhance the resilience of responsive cellophane to ensure it can withstand numerous cycles of use without significant loss of functionality.

Environmental concerns pose another set of challenges for the industry. As sustainability becomes increasingly important, there is growing pressure to develop responsive cellophane technologies that are biodegradable or easily recyclable. Balancing the advanced functionalities of responsive materials with eco-friendly characteristics is proving to be a complex task, requiring innovative approaches in material science and green chemistry.

The integration of responsive cellophane with other materials and technologies presents yet another frontier of challenges. For many applications, responsive cellophane needs to work seamlessly with electronic components, sensors, or other smart materials. Achieving this integration while maintaining the desired responsive properties and overall product performance is a multifaceted challenge that demands interdisciplinary collaboration and novel engineering solutions.

Lastly, the regulatory landscape surrounding responsive cellophane technologies is still evolving, creating uncertainty for manufacturers and potential adopters. Establishing clear standards and safety protocols for these novel materials is crucial for their acceptance in various industries, particularly in sensitive sectors like food packaging and medical devices. The lack of comprehensive regulatory frameworks can impede investment and slow down the commercialization of promising responsive cellophane innovations.

One of the primary technical challenges lies in achieving precise and reliable responsiveness to specific stimuli. While current cellophane materials can respond to certain environmental changes, such as temperature or humidity, the accuracy and consistency of these responses often fall short of industry requirements. Engineers are grappling with the complexities of fine-tuning the molecular structure of cellophane to enhance its sensitivity and reactivity to a broader range of stimuli, including light, pressure, and chemical agents.

Another critical hurdle is the scalability of production processes for responsive cellophane. Laboratory-scale successes have been achieved, but translating these into large-scale, cost-effective manufacturing methods remains a significant challenge. The intricate nature of incorporating responsive elements into the cellophane structure while maintaining its essential properties demands sophisticated production techniques that are not yet fully developed or economically viable for mass production.

Durability and longevity of responsive cellophane products also present ongoing challenges. The repeated activation and deactivation of responsive mechanisms can lead to material fatigue and degradation over time, potentially limiting the lifespan and reliability of products incorporating this technology. Researchers are actively seeking ways to enhance the resilience of responsive cellophane to ensure it can withstand numerous cycles of use without significant loss of functionality.

Environmental concerns pose another set of challenges for the industry. As sustainability becomes increasingly important, there is growing pressure to develop responsive cellophane technologies that are biodegradable or easily recyclable. Balancing the advanced functionalities of responsive materials with eco-friendly characteristics is proving to be a complex task, requiring innovative approaches in material science and green chemistry.

The integration of responsive cellophane with other materials and technologies presents yet another frontier of challenges. For many applications, responsive cellophane needs to work seamlessly with electronic components, sensors, or other smart materials. Achieving this integration while maintaining the desired responsive properties and overall product performance is a multifaceted challenge that demands interdisciplinary collaboration and novel engineering solutions.

Lastly, the regulatory landscape surrounding responsive cellophane technologies is still evolving, creating uncertainty for manufacturers and potential adopters. Establishing clear standards and safety protocols for these novel materials is crucial for their acceptance in various industries, particularly in sensitive sectors like food packaging and medical devices. The lack of comprehensive regulatory frameworks can impede investment and slow down the commercialization of promising responsive cellophane innovations.

Existing Solutions

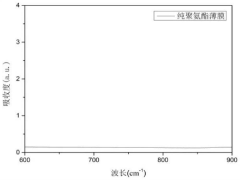

01 Responsive cellophane materials

Development of cellophane materials that exhibit responsive properties to external stimuli such as temperature, pH, or light. These materials can change their physical or chemical properties in response to environmental changes, making them suitable for various applications in packaging, sensors, and smart materials.- Responsive cellophane materials: Development of cellophane materials that exhibit responsive properties to various stimuli such as temperature, pH, or light. These materials can change their physical or chemical properties in response to environmental changes, making them suitable for smart packaging or sensor applications.

- Cellophane-based biosensors: Creation of biosensors using cellophane as a substrate or component. These sensors can detect and respond to biological molecules or environmental changes, potentially useful in medical diagnostics or environmental monitoring.

- Smart packaging with responsive cellophane: Development of intelligent packaging systems incorporating responsive cellophane. These packages can indicate freshness, detect spoilage, or respond to temperature changes, enhancing food safety and quality control in the supply chain.

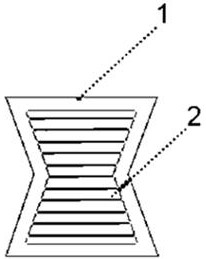

- Cellophane-based actuators and devices: Creation of actuators or mechanical devices using responsive cellophane. These devices can change shape, size, or properties in response to external stimuli, potentially useful in soft robotics or adaptive structures.

- Responsive cellophane coatings and films: Development of coatings or thin films made from or incorporating responsive cellophane. These coatings can change properties such as permeability, color, or adhesion in response to environmental factors, useful in various industries including electronics and packaging.

02 Cellophane-based biosensors

Creation of biosensors using cellophane as a substrate or component. These sensors can detect and respond to biological or chemical agents, potentially useful in medical diagnostics, environmental monitoring, and food safety applications.Expand Specific Solutions03 Smart packaging with responsive cellophane

Development of intelligent packaging systems incorporating responsive cellophane. These packages can indicate product freshness, detect contamination, or respond to environmental conditions, enhancing food safety and quality control in the packaging industry.Expand Specific Solutions04 Cellophane-based actuators and devices

Creation of actuators and devices using responsive cellophane materials. These can include microfluidic devices, soft robotics components, or adaptive structures that change shape or properties in response to specific stimuli.Expand Specific Solutions05 Modification techniques for enhancing cellophane responsiveness

Development of methods to modify cellophane to enhance its responsive properties. This can include chemical treatments, incorporation of nanoparticles, or surface modifications to improve sensitivity, selectivity, or response time to various stimuli.Expand Specific Solutions

Key Industry Players

The responsive cellophane technology market is in its early growth stage, characterized by rapid innovation and increasing competition. The market size is expanding as applications in flexible electronics and smart packaging gain traction. Technologically, the field is evolving quickly but still maturing, with companies like Qingdao Zhihui New Material Technology, Weihai Hualing Opto-Electronics, and Shenzhen Guohua Optoelectronics leading research and development efforts. Academic institutions such as Soochow University and Fudan University are also contributing significantly to advancing the technology. As the industry progresses, collaborations between research institutions and commercial entities are likely to accelerate technological breakthroughs and market adoption.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz is developing responsive cellophane technologies for automotive applications. Their approach focuses on creating flexible, transparent displays for windshields and interior surfaces. The company has developed a multi-layer cellophane-like material that can switch between transparent and display modes instantly[7]. This allows for heads-up displays that can appear and disappear as needed. Mercedes-Benz has also incorporated haptic feedback into their flexible displays, enabling touch controls without physical buttons[8]. The system uses AI to anticipate driver needs and adjust display content accordingly[9].

Strengths: Integration with advanced vehicle systems, focus on safety and user experience. Weaknesses: Limited to automotive applications, potentially high costs for luxury market.

Ford Motor Co.

Technical Solution: Ford is exploring responsive cellophane technologies for both interior and exterior vehicle applications. Their approach includes developing flexible, color-changing surfaces that can alter the vehicle's appearance on demand[10]. This technology uses electrochromic materials embedded in cellophane-like layers, allowing for instant color changes and pattern displays. Ford has also developed transparent solar panels using similar flexible materials, integrating energy generation into windows and body panels[11]. For interiors, Ford is working on shapeshifting surfaces that can transform from flat displays to tactile controls as needed[12].

Strengths: Innovative applications beyond traditional displays, potential for mass-market implementation. Weaknesses: Regulatory challenges for exterior use, durability concerns in harsh automotive environments.

Core Innovations

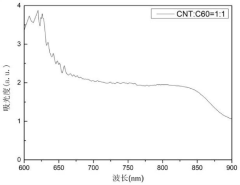

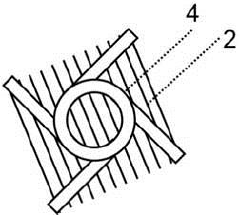

Fullerene/carbon nanotube/thermoplastic resin composite film as well as preparation method and application thereof

PatentActiveCN112126217A

Innovation

- Oxidation-modified fullerene and oxidation-modified carbon nanotubes are assembled to form a three-dimensional bridge structure, combined with thermoplastic resin to form a composite film, and van der Waals force assembly and solution blending methods are used to prepare fullerene/carbon nanoparticles with photostimulation response. Tube/thermoplastic resin composite film.

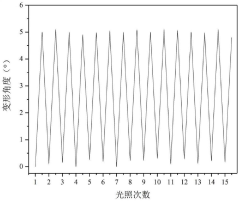

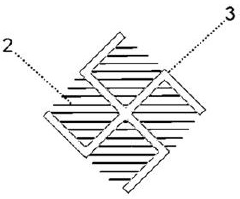

Negative Poisson's ratio structural body and manufacturing method thereof

PatentActiveCN116102873A

Innovation

- The combined structure of a negative Poisson's ratio framework and responsive gel is used, including a variety of cell units and ionic liquid gels or phase-change oil hydrogels. Through the coordination of photoinitiators and polymers, the materials are adaptable and simple. preparation process.

Environmental Impact

The environmental impact of responsive cellophane technologies is a critical consideration in their development and implementation. As these materials become more prevalent in various industries, their potential effects on ecosystems and natural resources must be carefully evaluated.

Responsive cellophane, being a biodegradable material, offers significant advantages over traditional plastics in terms of environmental sustainability. Its ability to decompose naturally reduces the long-term accumulation of waste in landfills and oceans. However, the production process of responsive cellophane still requires energy and resources, which can contribute to carbon emissions and resource depletion if not managed responsibly.

The use of responsive cellophane in packaging applications presents an opportunity to reduce overall material consumption. As these materials can adapt to changing environmental conditions, they potentially extend the shelf life of products and minimize food waste. This reduction in waste can lead to decreased methane emissions from landfills and a lower overall carbon footprint associated with food production and distribution.

Water usage is another important factor to consider in the environmental impact assessment of responsive cellophane technologies. The production of cellophane typically requires less water compared to traditional plastic manufacturing processes. However, as the technology advances and production scales up, it is crucial to implement water-efficient practices and closed-loop systems to minimize the strain on local water resources.

The sourcing of raw materials for responsive cellophane production also plays a significant role in its environmental impact. Cellulose, the primary component of cellophane, is derived from renewable sources such as wood pulp or cotton linters. Sustainable forestry practices and responsible agricultural methods are essential to ensure that the increased demand for these raw materials does not lead to deforestation or soil degradation.

End-of-life considerations for responsive cellophane products are generally more favorable compared to conventional plastics. While the material is biodegradable, it is important to develop and promote proper disposal and recycling infrastructure to maximize its environmental benefits. Education and awareness campaigns can help consumers understand the correct ways to dispose of responsive cellophane products, ensuring they do not contribute to environmental pollution.

As the technology evolves, there is potential for responsive cellophane to incorporate additional eco-friendly features. For instance, research into embedding natural antimicrobial agents or incorporating sensors for real-time monitoring of product freshness could further reduce waste and improve resource efficiency throughout the supply chain.

In conclusion, while responsive cellophane technologies offer promising environmental benefits, a comprehensive life cycle assessment is necessary to fully understand and mitigate any potential negative impacts. Continued research and development should focus on optimizing production processes, enhancing biodegradability, and exploring innovative applications that leverage the unique properties of these materials to address pressing environmental challenges.

Responsive cellophane, being a biodegradable material, offers significant advantages over traditional plastics in terms of environmental sustainability. Its ability to decompose naturally reduces the long-term accumulation of waste in landfills and oceans. However, the production process of responsive cellophane still requires energy and resources, which can contribute to carbon emissions and resource depletion if not managed responsibly.

The use of responsive cellophane in packaging applications presents an opportunity to reduce overall material consumption. As these materials can adapt to changing environmental conditions, they potentially extend the shelf life of products and minimize food waste. This reduction in waste can lead to decreased methane emissions from landfills and a lower overall carbon footprint associated with food production and distribution.

Water usage is another important factor to consider in the environmental impact assessment of responsive cellophane technologies. The production of cellophane typically requires less water compared to traditional plastic manufacturing processes. However, as the technology advances and production scales up, it is crucial to implement water-efficient practices and closed-loop systems to minimize the strain on local water resources.

The sourcing of raw materials for responsive cellophane production also plays a significant role in its environmental impact. Cellulose, the primary component of cellophane, is derived from renewable sources such as wood pulp or cotton linters. Sustainable forestry practices and responsible agricultural methods are essential to ensure that the increased demand for these raw materials does not lead to deforestation or soil degradation.

End-of-life considerations for responsive cellophane products are generally more favorable compared to conventional plastics. While the material is biodegradable, it is important to develop and promote proper disposal and recycling infrastructure to maximize its environmental benefits. Education and awareness campaigns can help consumers understand the correct ways to dispose of responsive cellophane products, ensuring they do not contribute to environmental pollution.

As the technology evolves, there is potential for responsive cellophane to incorporate additional eco-friendly features. For instance, research into embedding natural antimicrobial agents or incorporating sensors for real-time monitoring of product freshness could further reduce waste and improve resource efficiency throughout the supply chain.

In conclusion, while responsive cellophane technologies offer promising environmental benefits, a comprehensive life cycle assessment is necessary to fully understand and mitigate any potential negative impacts. Continued research and development should focus on optimizing production processes, enhancing biodegradability, and exploring innovative applications that leverage the unique properties of these materials to address pressing environmental challenges.

Regulatory Landscape

The regulatory landscape for responsive cellophane technologies is rapidly evolving to keep pace with technological advancements. Governments and international bodies are increasingly recognizing the potential impact of these materials on various industries and are developing frameworks to ensure their safe and responsible use.

In the United States, the Food and Drug Administration (FDA) has taken a proactive approach to regulating responsive cellophane technologies, particularly in food packaging and medical device applications. The agency has established guidelines for manufacturers to demonstrate the safety and efficacy of these materials, focusing on their ability to respond to environmental stimuli without compromising product integrity or consumer safety.

The European Union, through the European Chemicals Agency (ECHA), has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to responsive cellophane technologies. Manufacturers must provide detailed information on the chemical composition and potential risks associated with these materials, ensuring transparency and safety throughout the supply chain.

In Asia, countries like Japan and South Korea have introduced specific regulations for smart packaging materials, including responsive cellophane. These regulations emphasize the importance of biodegradability and environmental impact, aligning with global sustainability goals.

Environmental concerns have led to the development of standards for biodegradable and compostable responsive cellophane. Organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have established criteria for assessing the environmental impact of these materials throughout their lifecycle.

Intellectual property protection is another crucial aspect of the regulatory landscape. Patent offices worldwide are adapting their processes to address the unique challenges posed by responsive cellophane technologies, particularly in distinguishing between material composition and responsive properties.

As the technology advances, regulatory bodies are also grappling with the potential dual-use nature of responsive cellophane. Concerns about security and potential misuse have led to discussions about export controls and monitoring mechanisms for certain advanced formulations.

The global nature of supply chains for responsive cellophane technologies has necessitated international cooperation in regulatory efforts. Organizations like the World Trade Organization (WTO) are working to harmonize standards and reduce trade barriers while maintaining necessary safety and quality controls.

Looking ahead, the regulatory landscape is likely to continue evolving, with a focus on balancing innovation with safety, environmental protection, and ethical considerations. Stakeholders in the responsive cellophane industry must remain vigilant and adaptable to navigate this complex and dynamic regulatory environment.

In the United States, the Food and Drug Administration (FDA) has taken a proactive approach to regulating responsive cellophane technologies, particularly in food packaging and medical device applications. The agency has established guidelines for manufacturers to demonstrate the safety and efficacy of these materials, focusing on their ability to respond to environmental stimuli without compromising product integrity or consumer safety.

The European Union, through the European Chemicals Agency (ECHA), has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to responsive cellophane technologies. Manufacturers must provide detailed information on the chemical composition and potential risks associated with these materials, ensuring transparency and safety throughout the supply chain.

In Asia, countries like Japan and South Korea have introduced specific regulations for smart packaging materials, including responsive cellophane. These regulations emphasize the importance of biodegradability and environmental impact, aligning with global sustainability goals.

Environmental concerns have led to the development of standards for biodegradable and compostable responsive cellophane. Organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have established criteria for assessing the environmental impact of these materials throughout their lifecycle.

Intellectual property protection is another crucial aspect of the regulatory landscape. Patent offices worldwide are adapting their processes to address the unique challenges posed by responsive cellophane technologies, particularly in distinguishing between material composition and responsive properties.

As the technology advances, regulatory bodies are also grappling with the potential dual-use nature of responsive cellophane. Concerns about security and potential misuse have led to discussions about export controls and monitoring mechanisms for certain advanced formulations.

The global nature of supply chains for responsive cellophane technologies has necessitated international cooperation in regulatory efforts. Organizations like the World Trade Organization (WTO) are working to harmonize standards and reduce trade barriers while maintaining necessary safety and quality controls.

Looking ahead, the regulatory landscape is likely to continue evolving, with a focus on balancing innovation with safety, environmental protection, and ethical considerations. Stakeholders in the responsive cellophane industry must remain vigilant and adaptable to navigate this complex and dynamic regulatory environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!