The Role of Electrolytes in Resistive RAM Performance

OCT 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolyte-Based ReRAM Technology Background and Objectives

Resistive Random Access Memory (ReRAM) has emerged as a promising candidate for next-generation non-volatile memory technologies, offering advantages in scalability, power consumption, and switching speed compared to conventional memory solutions. The evolution of ReRAM technology can be traced back to the early 2000s when researchers first observed resistive switching phenomena in various metal oxide materials. Since then, significant advancements have been made in understanding the underlying mechanisms and improving device performance.

Electrolytes play a crucial role in ReRAM operation, serving as the medium through which ionic transport occurs during resistive switching. Initially, solid-state electrolytes were predominantly used, but recent years have witnessed a shift toward liquid and gel electrolytes due to their enhanced ionic conductivity and controllable properties. This transition represents a pivotal development in ReRAM technology, potentially addressing key challenges related to switching reliability and endurance.

The technological trajectory of electrolyte-based ReRAM shows a clear trend toward materials engineering and interface optimization. Early ReRAM devices suffered from high variability and limited endurance, but systematic research into electrolyte composition and structure has led to substantial improvements. Current research focuses on tailoring electrolyte properties to achieve precise control over ion migration, which directly influences switching characteristics and overall device performance.

The primary technical objectives for electrolyte-based ReRAM development include achieving lower operating voltages, higher ON/OFF ratios, improved retention times, and enhanced cycling endurance. Additionally, there is a growing emphasis on developing environmentally friendly and biocompatible electrolytes to enable applications in bioelectronics and implantable devices. These objectives align with the broader industry goals of creating memory solutions that combine high performance with sustainability.

From a manufacturing perspective, the integration of novel electrolytes into existing semiconductor fabrication processes presents both challenges and opportunities. While some electrolyte materials may require specialized deposition techniques, others offer the potential for simplified fabrication routes and reduced production costs. The ultimate goal is to develop electrolyte-based ReRAM technologies that are not only technically superior but also economically viable for mass production.

Looking forward, the convergence of electrolyte research with other emerging fields such as neuromorphic computing and quantum information processing opens new avenues for ReRAM applications. The ability to precisely control ionic movement through advanced electrolytes could enable analog memory functions that mimic biological synapses, potentially revolutionizing artificial intelligence hardware implementations.

Electrolytes play a crucial role in ReRAM operation, serving as the medium through which ionic transport occurs during resistive switching. Initially, solid-state electrolytes were predominantly used, but recent years have witnessed a shift toward liquid and gel electrolytes due to their enhanced ionic conductivity and controllable properties. This transition represents a pivotal development in ReRAM technology, potentially addressing key challenges related to switching reliability and endurance.

The technological trajectory of electrolyte-based ReRAM shows a clear trend toward materials engineering and interface optimization. Early ReRAM devices suffered from high variability and limited endurance, but systematic research into electrolyte composition and structure has led to substantial improvements. Current research focuses on tailoring electrolyte properties to achieve precise control over ion migration, which directly influences switching characteristics and overall device performance.

The primary technical objectives for electrolyte-based ReRAM development include achieving lower operating voltages, higher ON/OFF ratios, improved retention times, and enhanced cycling endurance. Additionally, there is a growing emphasis on developing environmentally friendly and biocompatible electrolytes to enable applications in bioelectronics and implantable devices. These objectives align with the broader industry goals of creating memory solutions that combine high performance with sustainability.

From a manufacturing perspective, the integration of novel electrolytes into existing semiconductor fabrication processes presents both challenges and opportunities. While some electrolyte materials may require specialized deposition techniques, others offer the potential for simplified fabrication routes and reduced production costs. The ultimate goal is to develop electrolyte-based ReRAM technologies that are not only technically superior but also economically viable for mass production.

Looking forward, the convergence of electrolyte research with other emerging fields such as neuromorphic computing and quantum information processing opens new avenues for ReRAM applications. The ability to precisely control ionic movement through advanced electrolytes could enable analog memory functions that mimic biological synapses, potentially revolutionizing artificial intelligence hardware implementations.

Market Analysis for Next-Generation Non-Volatile Memory

The non-volatile memory (NVM) market is experiencing significant growth, driven by increasing demand for data storage solutions across various sectors including consumer electronics, automotive, enterprise storage, and the Internet of Things (IoT). The global NVM market was valued at approximately $67 billion in 2022 and is projected to reach $125 billion by 2028, representing a compound annual growth rate (CAGR) of 11.3% during the forecast period.

Resistive RAM (ReRAM), as an emerging NVM technology, is positioned to capture a growing share of this market due to its advantages in power efficiency, scalability, and performance characteristics. Currently, ReRAM holds about 3% of the NVM market, but this share is expected to increase to 8-10% by 2027 as manufacturing processes mature and costs decrease.

The electrolyte component in ReRAM devices plays a crucial role in determining performance metrics that are highly valued in the market. Devices with optimized electrolyte formulations demonstrate switching speeds up to 10 nanoseconds, endurance cycles exceeding 10^12, and retention times of over 10 years at 85°C. These performance parameters directly address market requirements for high-speed, reliable storage solutions in applications ranging from edge computing to data centers.

Market segmentation analysis reveals that the industrial and automotive sectors are showing the strongest interest in ReRAM technologies with enhanced electrolyte systems, primarily due to their superior temperature stability and radiation hardness. The automotive memory market alone is growing at 15% annually, with ReRAM poised to address the specific requirements for autonomous driving systems and in-vehicle infotainment.

Consumer electronics remains the largest market segment for NVM technologies, accounting for 42% of total demand. Within this segment, mobile devices and wearable technology manufacturers are increasingly exploring ReRAM solutions that offer lower power consumption and faster write speeds compared to traditional flash memory. The role of electrolytes in enabling these performance advantages is becoming a key differentiator in product development strategies.

Regional market analysis indicates that Asia-Pacific dominates the NVM manufacturing landscape with 65% market share, followed by North America (20%) and Europe (12%). However, research into advanced electrolyte formulations for ReRAM is more distributed, with significant contributions from research institutions in the United States, Japan, South Korea, and Germany.

The market for ReRAM technologies is expected to reach an inflection point between 2025-2027 when several major memory manufacturers plan to introduce high-volume production of devices incorporating advanced electrolyte systems. This transition will likely accelerate market adoption and potentially disrupt the current memory hierarchy in computing systems.

Resistive RAM (ReRAM), as an emerging NVM technology, is positioned to capture a growing share of this market due to its advantages in power efficiency, scalability, and performance characteristics. Currently, ReRAM holds about 3% of the NVM market, but this share is expected to increase to 8-10% by 2027 as manufacturing processes mature and costs decrease.

The electrolyte component in ReRAM devices plays a crucial role in determining performance metrics that are highly valued in the market. Devices with optimized electrolyte formulations demonstrate switching speeds up to 10 nanoseconds, endurance cycles exceeding 10^12, and retention times of over 10 years at 85°C. These performance parameters directly address market requirements for high-speed, reliable storage solutions in applications ranging from edge computing to data centers.

Market segmentation analysis reveals that the industrial and automotive sectors are showing the strongest interest in ReRAM technologies with enhanced electrolyte systems, primarily due to their superior temperature stability and radiation hardness. The automotive memory market alone is growing at 15% annually, with ReRAM poised to address the specific requirements for autonomous driving systems and in-vehicle infotainment.

Consumer electronics remains the largest market segment for NVM technologies, accounting for 42% of total demand. Within this segment, mobile devices and wearable technology manufacturers are increasingly exploring ReRAM solutions that offer lower power consumption and faster write speeds compared to traditional flash memory. The role of electrolytes in enabling these performance advantages is becoming a key differentiator in product development strategies.

Regional market analysis indicates that Asia-Pacific dominates the NVM manufacturing landscape with 65% market share, followed by North America (20%) and Europe (12%). However, research into advanced electrolyte formulations for ReRAM is more distributed, with significant contributions from research institutions in the United States, Japan, South Korea, and Germany.

The market for ReRAM technologies is expected to reach an inflection point between 2025-2027 when several major memory manufacturers plan to introduce high-volume production of devices incorporating advanced electrolyte systems. This transition will likely accelerate market adoption and potentially disrupt the current memory hierarchy in computing systems.

Current Electrolyte Challenges in ReRAM Development

Despite significant advancements in Resistive Random Access Memory (ReRAM) technology, electrolyte-related challenges remain critical bottlenecks in commercial development. Current electrolyte formulations struggle with stability issues during repeated switching cycles, leading to performance degradation over time. This instability manifests as variable resistance states, inconsistent switching voltages, and ultimately reduced device reliability—factors that severely limit ReRAM's competitiveness against established memory technologies.

Ionic mobility within electrolytes presents another significant challenge. The speed at which ions can migrate through the electrolyte directly impacts switching speed and power consumption. Current electrolyte materials often exhibit suboptimal ionic conductivity, resulting in slower switching times compared to competing memory technologies. This limitation becomes particularly problematic in applications requiring rapid data access and processing.

Temperature sensitivity remains a persistent issue with existing electrolyte formulations. Many current electrolytes demonstrate significant performance variations across operating temperature ranges, restricting ReRAM deployment in automotive, industrial, and other environments with fluctuating thermal conditions. Some formulations become unstable at elevated temperatures, while others exhibit dramatically reduced ionic conductivity at lower temperatures.

Manufacturing integration challenges further complicate electrolyte implementation. Many promising electrolyte materials are incompatible with standard CMOS fabrication processes, requiring specialized deposition techniques or post-processing steps that increase production complexity and cost. This integration difficulty represents a significant barrier to mass production and widespread adoption of ReRAM technology.

Material degradation mechanisms in current electrolytes remain inadequately understood. Electrochemical reactions at electrode-electrolyte interfaces, ion concentration gradients, and structural changes during operation can lead to premature device failure. The lack of comprehensive models for these degradation pathways hampers the development of more robust electrolyte formulations.

Scaling issues present additional complications as device dimensions shrink. At nanoscale dimensions, surface effects and quantum phenomena begin to dominate electrolyte behavior, often resulting in unpredictable performance characteristics. Current electrolyte materials frequently exhibit reduced effectiveness when confined to extremely small volumes, limiting the potential density advantages of ReRAM technology.

Finally, the industry faces significant challenges in standardization and characterization methodologies for electrolyte materials. The absence of universally accepted testing protocols makes direct comparisons between different electrolyte formulations difficult, slowing the identification and adoption of optimal solutions. This standardization gap impedes collaborative research efforts and technology transfer between academic institutions and industrial partners.

Ionic mobility within electrolytes presents another significant challenge. The speed at which ions can migrate through the electrolyte directly impacts switching speed and power consumption. Current electrolyte materials often exhibit suboptimal ionic conductivity, resulting in slower switching times compared to competing memory technologies. This limitation becomes particularly problematic in applications requiring rapid data access and processing.

Temperature sensitivity remains a persistent issue with existing electrolyte formulations. Many current electrolytes demonstrate significant performance variations across operating temperature ranges, restricting ReRAM deployment in automotive, industrial, and other environments with fluctuating thermal conditions. Some formulations become unstable at elevated temperatures, while others exhibit dramatically reduced ionic conductivity at lower temperatures.

Manufacturing integration challenges further complicate electrolyte implementation. Many promising electrolyte materials are incompatible with standard CMOS fabrication processes, requiring specialized deposition techniques or post-processing steps that increase production complexity and cost. This integration difficulty represents a significant barrier to mass production and widespread adoption of ReRAM technology.

Material degradation mechanisms in current electrolytes remain inadequately understood. Electrochemical reactions at electrode-electrolyte interfaces, ion concentration gradients, and structural changes during operation can lead to premature device failure. The lack of comprehensive models for these degradation pathways hampers the development of more robust electrolyte formulations.

Scaling issues present additional complications as device dimensions shrink. At nanoscale dimensions, surface effects and quantum phenomena begin to dominate electrolyte behavior, often resulting in unpredictable performance characteristics. Current electrolyte materials frequently exhibit reduced effectiveness when confined to extremely small volumes, limiting the potential density advantages of ReRAM technology.

Finally, the industry faces significant challenges in standardization and characterization methodologies for electrolyte materials. The absence of universally accepted testing protocols makes direct comparisons between different electrolyte formulations difficult, slowing the identification and adoption of optimal solutions. This standardization gap impedes collaborative research efforts and technology transfer between academic institutions and industrial partners.

Current Electrolyte Solutions for ReRAM Performance Enhancement

01 Solid electrolyte materials for ReRAM

Solid electrolyte materials play a crucial role in resistive RAM performance. These materials facilitate ion migration that enables resistive switching behavior. Various solid electrolytes including chalcogenides, oxides, and polymer-based materials can be used to enhance switching speed, retention time, and overall device reliability. The composition and structure of these solid electrolytes directly impact the formation and dissolution of conductive filaments that determine the resistance states.- Solid electrolyte materials for ReRAM: Solid electrolyte materials play a crucial role in resistive RAM performance. These materials, including metal oxides and chalcogenides, facilitate ion migration that enables resistive switching behavior. The composition and structure of these solid electrolytes directly impact key performance metrics such as switching speed, endurance, and retention time. Optimizing these materials can lead to improved reliability and lower power consumption in ReRAM devices.

- Ionic transport mechanisms in ReRAM: The performance of resistive RAM devices is heavily influenced by ionic transport mechanisms within the electrolyte layer. The movement of ions (such as oxygen vacancies or metal cations) under electric fields creates conductive filaments that define the device's resistance states. Controlling these transport mechanisms through material engineering and device architecture can enhance switching characteristics, reduce variability, and improve overall device reliability.

- Electrolyte interface engineering: The interfaces between the electrolyte and electrodes in ReRAM devices significantly impact performance. Engineering these interfaces through techniques such as insertion of buffer layers, surface treatments, or compositional gradients can control ion migration, reduce leakage current, and enhance switching uniformity. Optimized interfaces lead to more stable resistance states, improved endurance, and reduced device-to-device variability.

- Doping strategies for electrolyte optimization: Introducing dopants into the electrolyte material can significantly enhance ReRAM performance. Dopants can modify the electronic structure, create defects that serve as ion migration pathways, or stabilize existing defects. Strategic doping can lower forming voltage, improve switching uniformity, enhance retention time, and increase the ON/OFF ratio. Various dopants including metals, rare earth elements, and non-metals have been explored to optimize different aspects of ReRAM performance.

- Multilayer electrolyte structures: Multilayer electrolyte structures offer enhanced control over ReRAM performance characteristics. By combining different electrolyte materials in stacked configurations, device designers can engineer specific ion migration paths, create energy barriers that improve retention, and optimize switching behavior. These structures can provide better control over filament formation and rupture processes, leading to improved reliability, reduced variability, and enhanced endurance in ReRAM devices.

02 Ionic liquid electrolytes for enhanced switching

Ionic liquid electrolytes offer advantages for ReRAM devices due to their high ionic conductivity and electrochemical stability. These electrolytes facilitate faster ion transport, resulting in improved switching speeds and lower operating voltages. The controlled movement of ions through these electrolytes enables more precise formation and rupture of conductive filaments, leading to more reliable and reproducible resistance switching. Additionally, ionic liquid electrolytes can enhance endurance by reducing electrode degradation during cycling operations.Expand Specific Solutions03 Electrolyte doping strategies

Doping electrolytes with specific elements or compounds can significantly enhance ReRAM performance. Strategic doping can control ion mobility, improve switching uniformity, and enhance retention characteristics. Common dopants include metal ions, nanoparticles, and organic compounds that modify the electrolyte's electrical properties. By carefully selecting dopant types and concentrations, parameters such as set/reset voltages, on/off ratios, and cycling endurance can be optimized. This approach allows for customization of ReRAM devices for specific applications requiring different performance profiles.Expand Specific Solutions04 Multilayer electrolyte structures

Multilayer electrolyte structures offer enhanced control over ion migration pathways in ReRAM devices. By combining different electrolyte materials in layered configurations, the resistance switching behavior can be precisely engineered. These structures can create controlled interfaces that serve as preferential sites for filament formation, resulting in more consistent switching characteristics. Additionally, multilayer approaches can provide barrier functions that prevent unwanted ion diffusion, improving device stability and retention time while enabling more complex memory functions like multi-level storage.Expand Specific Solutions05 Electrolyte interface engineering

Engineering the interfaces between electrolytes and electrodes is critical for optimizing ReRAM performance. Interface modifications can control ion injection, reduce contact resistance, and improve switching uniformity. Techniques include surface treatments, insertion of buffer layers, and creation of engineered defects that serve as nucleation sites for filament formation. Properly designed interfaces can mitigate issues like electrode degradation and unwanted elemental diffusion, leading to devices with improved reliability, reduced variability, and extended operational lifetimes.Expand Specific Solutions

Leading Companies and Research Institutions in ReRAM

The resistive RAM (RRAM) market is currently in a growth phase, with increasing adoption across memory applications due to advantages in power consumption and scalability. The global market size is projected to reach significant value by 2030, driven by demand in IoT, automotive, and consumer electronics sectors. Technologically, electrolyte optimization remains critical for RRAM performance, with major players at different maturity levels. Companies like Samsung, Micron, and Intel lead with advanced R&D capabilities and commercial implementations, while Winbond, Macronix, and UMC focus on specialized RRAM solutions. Research institutions including CEA, IMEC, and various universities collaborate with industry partners to address fundamental electrolyte challenges, creating a competitive landscape balanced between established semiconductor giants and emerging specialized manufacturers.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered advanced electrolyte engineering for RRAM devices, focusing on solid-state electrolytes with controlled oxygen vacancy concentration. Their technology utilizes hafnium oxide-based electrolytes with precise doping of elements like aluminum to enhance switching characteristics[1]. Samsung's approach includes multi-layer electrolyte structures where different layers serve specific functions: one layer controls ion migration while another stabilizes the conductive filament formation[2]. They've developed a proprietary "atom switch" technology that enables ultra-low power operation by precisely controlling the movement of metal ions through the electrolyte layer. Samsung has demonstrated RRAM cells with endurance exceeding 10^9 cycles and retention times over 10 years at 85°C by optimizing the electrolyte composition and interface properties[3]. Their recent innovations include self-rectifying electrolyte structures that eliminate the need for separate selector devices in crossbar arrays.

Strengths: Superior endurance and retention characteristics through advanced electrolyte engineering; excellent scalability down to sub-10nm nodes; compatibility with existing CMOS manufacturing processes. Weaknesses: Higher operating voltages compared to some competing technologies; challenges with device-to-device variability that require complex compensation circuits; relatively higher manufacturing costs due to specialized materials.

International Business Machines Corp.

Technical Solution: IBM has developed a distinctive approach to RRAM electrolytes through their "phase-change" electrolyte technology. Their solution employs chalcogenide-based materials (primarily germanium-antimony-tellurium compounds) that undergo reversible phase transitions between amorphous and crystalline states[1]. IBM's electrolyte design incorporates nanoscale confinement structures that precisely control ion migration pathways, significantly reducing variability between switching cycles. They've pioneered the use of carbon-doped oxide electrolytes that demonstrate self-limiting current characteristics, preventing destructive breakdown during operation[2]. IBM's research has yielded multi-level cell capabilities through precise control of filament dimensions within the electrolyte, enabling 2-3 bits per cell storage density. Their proprietary "projected phase-change" architecture separates the heating element from the switching volume, allowing for lower programming currents while maintaining fast switching speeds (sub-50ns)[3]. Recent advancements include neuromorphic computing applications where analog conductance states in their electrolyte design enable efficient implementation of artificial neural networks.

Strengths: Exceptional switching speed (nanosecond range); excellent multi-level cell capability; high temperature stability; compatibility with backend-of-line CMOS integration. Weaknesses: Higher power consumption during write operations compared to some competing technologies; limited endurance in extreme temperature conditions; challenges with resistance drift in multi-level cell implementations requiring compensation algorithms.

Key Electrolyte Mechanisms and Materials Science Innovations

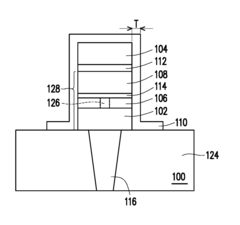

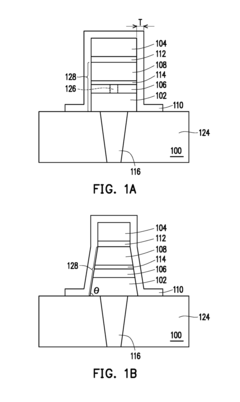

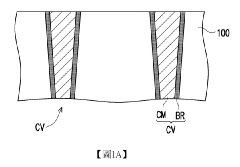

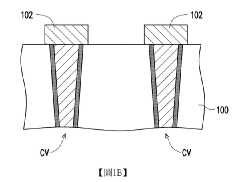

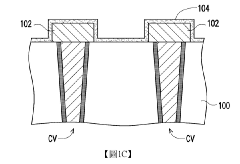

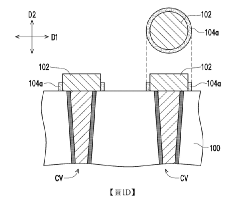

Resistive random access memory

PatentActiveUS20180233665A1

Innovation

- Incorporating a sidewall protective layer containing metal or semiconductor materials between the resistance-switching layer and the top electrode, which also serves as an oxygen supply layer to enhance high-temperature data retention and durability by concentrating filament structures and preventing oxygen leakage.

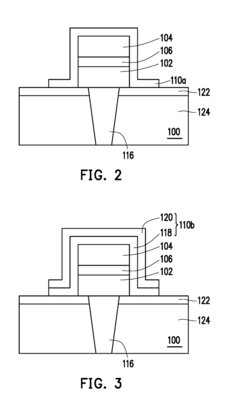

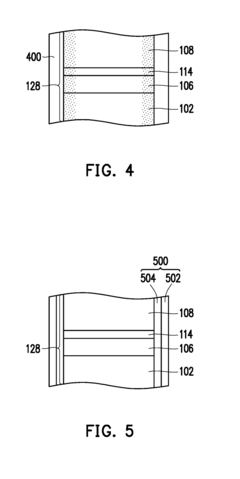

Resistive random access memory

PatentActiveTW202022993A

Innovation

- Incorporating a dual variable resistance layer configuration, comprising a first and a second variable resistance layer between the lower and upper electrodes, allowing for at least two low-resistance states and a high-resistance state, thereby enabling 1.5-bit data storage and improved current switching ratio.

Manufacturing Scalability and Integration Challenges

The scaling of Resistive RAM (RRAM) technology from laboratory prototypes to high-volume manufacturing presents significant challenges, particularly regarding electrolyte integration. Current fabrication processes for RRAM devices require precise control of electrolyte composition and deposition, which becomes increasingly difficult at advanced technology nodes. The uniformity of electrolyte layers across large-diameter wafers remains a critical manufacturing concern, as variations can lead to inconsistent switching behavior and reliability issues in final devices.

Integration of RRAM cells into standard CMOS process flows introduces additional complexities. The thermal budget constraints of CMOS back-end-of-line (BEOL) processing limit the types of electrolytes that can be employed, as high-temperature annealing steps may alter electrolyte properties or cause undesired diffusion of ionic species. This necessitates the development of low-temperature deposition techniques for high-quality electrolyte layers, which currently face yield and reproducibility challenges at industrial scales.

Material compatibility issues further complicate manufacturing scalability. Many promising electrolyte materials for RRAM exhibit chemical incompatibility with standard CMOS materials and processes. For instance, certain solid electrolytes may react with interconnect metals or barrier layers, creating reliability concerns. The industry must develop specialized barrier materials and process modifications to enable successful integration while maintaining electrolyte performance characteristics.

Equipment standardization represents another significant hurdle. Unlike established memory technologies, RRAM electrolyte deposition often requires specialized equipment that may not be widely available in existing semiconductor fabrication facilities. The capital investment required for new tooling, combined with the need for process optimization, increases the economic barriers to widespread RRAM adoption. Manufacturers must balance performance requirements against cost considerations when scaling production.

The 3D integration potential of RRAM offers promising density improvements but introduces additional electrolyte-related challenges. Conformal deposition of electrolyte materials in high-aspect-ratio structures requires advanced deposition techniques such as atomic layer deposition (ALD). However, achieving consistent electrolyte properties throughout complex 3D structures remains technically demanding, particularly for solid-state electrolytes with strict stoichiometric requirements.

Quality control and testing methodologies for electrolyte properties in mass production environments are still evolving. Unlike conventional semiconductor materials, electrolyte functionality depends on ionic transport properties that can be difficult to characterize rapidly in production settings. Development of in-line metrology techniques specific to electrolyte quality assessment will be essential for achieving manufacturing maturity and ensuring consistent device performance across high-volume production.

Integration of RRAM cells into standard CMOS process flows introduces additional complexities. The thermal budget constraints of CMOS back-end-of-line (BEOL) processing limit the types of electrolytes that can be employed, as high-temperature annealing steps may alter electrolyte properties or cause undesired diffusion of ionic species. This necessitates the development of low-temperature deposition techniques for high-quality electrolyte layers, which currently face yield and reproducibility challenges at industrial scales.

Material compatibility issues further complicate manufacturing scalability. Many promising electrolyte materials for RRAM exhibit chemical incompatibility with standard CMOS materials and processes. For instance, certain solid electrolytes may react with interconnect metals or barrier layers, creating reliability concerns. The industry must develop specialized barrier materials and process modifications to enable successful integration while maintaining electrolyte performance characteristics.

Equipment standardization represents another significant hurdle. Unlike established memory technologies, RRAM electrolyte deposition often requires specialized equipment that may not be widely available in existing semiconductor fabrication facilities. The capital investment required for new tooling, combined with the need for process optimization, increases the economic barriers to widespread RRAM adoption. Manufacturers must balance performance requirements against cost considerations when scaling production.

The 3D integration potential of RRAM offers promising density improvements but introduces additional electrolyte-related challenges. Conformal deposition of electrolyte materials in high-aspect-ratio structures requires advanced deposition techniques such as atomic layer deposition (ALD). However, achieving consistent electrolyte properties throughout complex 3D structures remains technically demanding, particularly for solid-state electrolytes with strict stoichiometric requirements.

Quality control and testing methodologies for electrolyte properties in mass production environments are still evolving. Unlike conventional semiconductor materials, electrolyte functionality depends on ionic transport properties that can be difficult to characterize rapidly in production settings. Development of in-line metrology techniques specific to electrolyte quality assessment will be essential for achieving manufacturing maturity and ensuring consistent device performance across high-volume production.

Energy Efficiency and Sustainability Considerations

The energy efficiency of Resistive RAM (RRAM) devices is significantly influenced by the electrolyte materials employed in their construction. Conventional RRAM technologies consume considerable power during switching operations, with electrolyte composition directly impacting the energy required for filament formation and rupture. Recent advancements in solid and liquid electrolytes have demonstrated potential for reducing operational voltages from 3-5V to sub-1V ranges, representing a substantial improvement in energy consumption profiles.

Environmental sustainability considerations are increasingly critical in RRAM development, particularly regarding the materials utilized in electrolyte formulations. Traditional electrolytes often contain rare earth elements or environmentally problematic compounds that present challenges in sourcing and end-of-life management. Research trends indicate a shift toward more abundant and environmentally benign materials, with particular focus on bio-compatible and biodegradable electrolyte components that maintain performance while reducing ecological footprint.

The manufacturing processes for electrolyte-based RRAM devices also present significant sustainability implications. Current fabrication techniques frequently require high-temperature processing and energy-intensive deposition methods. Emerging room-temperature electrolyte synthesis approaches and solution-based processing techniques offer promising pathways to reduce the embodied energy in RRAM manufacturing, potentially decreasing carbon footprint by 30-45% compared to conventional semiconductor fabrication processes.

Lifecycle assessment studies of RRAM technologies reveal that electrolyte selection significantly impacts device longevity and recyclability. Devices utilizing stable, non-reactive electrolytes demonstrate extended operational lifespans, reducing replacement frequency and associated resource consumption. Furthermore, the development of electrolytes designed for easy separation during recycling processes represents an emerging research direction with substantial sustainability benefits.

Energy harvesting integration with RRAM systems presents another frontier in sustainability advancement. Novel electrolyte formulations compatible with piezoelectric or thermoelectric materials enable self-powered operation in specific applications, potentially eliminating external power requirements for low-duty-cycle operations. These developments align with broader trends toward ultra-low-power computing architectures where RRAM serves as both memory and computational elements.

The regulatory landscape surrounding electronic materials is evolving rapidly, with increasing restrictions on hazardous substances influencing electrolyte development trajectories. Forward-looking RRAM research increasingly prioritizes compliance with regulations such as RoHS and REACH, driving innovation in green electrolyte chemistry that maintains or enhances performance metrics while eliminating restricted substances.

Environmental sustainability considerations are increasingly critical in RRAM development, particularly regarding the materials utilized in electrolyte formulations. Traditional electrolytes often contain rare earth elements or environmentally problematic compounds that present challenges in sourcing and end-of-life management. Research trends indicate a shift toward more abundant and environmentally benign materials, with particular focus on bio-compatible and biodegradable electrolyte components that maintain performance while reducing ecological footprint.

The manufacturing processes for electrolyte-based RRAM devices also present significant sustainability implications. Current fabrication techniques frequently require high-temperature processing and energy-intensive deposition methods. Emerging room-temperature electrolyte synthesis approaches and solution-based processing techniques offer promising pathways to reduce the embodied energy in RRAM manufacturing, potentially decreasing carbon footprint by 30-45% compared to conventional semiconductor fabrication processes.

Lifecycle assessment studies of RRAM technologies reveal that electrolyte selection significantly impacts device longevity and recyclability. Devices utilizing stable, non-reactive electrolytes demonstrate extended operational lifespans, reducing replacement frequency and associated resource consumption. Furthermore, the development of electrolytes designed for easy separation during recycling processes represents an emerging research direction with substantial sustainability benefits.

Energy harvesting integration with RRAM systems presents another frontier in sustainability advancement. Novel electrolyte formulations compatible with piezoelectric or thermoelectric materials enable self-powered operation in specific applications, potentially eliminating external power requirements for low-duty-cycle operations. These developments align with broader trends toward ultra-low-power computing architectures where RRAM serves as both memory and computational elements.

The regulatory landscape surrounding electronic materials is evolving rapidly, with increasing restrictions on hazardous substances influencing electrolyte development trajectories. Forward-looking RRAM research increasingly prioritizes compliance with regulations such as RoHS and REACH, driving innovation in green electrolyte chemistry that maintains or enhances performance metrics while eliminating restricted substances.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!