Thermal Stability of Resistive RAM by Material Analysis

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RRAM Thermal Stability Background and Objectives

Resistive Random Access Memory (RRAM) has emerged as a promising candidate for next-generation non-volatile memory technologies due to its simple structure, high density, low power consumption, and compatibility with CMOS processes. The evolution of RRAM technology can be traced back to the early 2000s when researchers began exploring metal-oxide-based resistive switching phenomena. Since then, significant advancements have been made in understanding the underlying mechanisms and improving device performance.

The thermal stability of RRAM devices represents a critical challenge that must be addressed for widespread commercial adoption. As electronic devices continue to miniaturize and integrate more components, heat generation and dissipation become increasingly problematic. RRAM devices operating in high-temperature environments or subjected to thermal cycling during normal operation may experience degradation in retention time, endurance, and overall reliability.

Material analysis plays a pivotal role in enhancing the thermal stability of RRAM. The selection of appropriate materials for the switching layer, electrodes, and barrier layers significantly impacts device performance under thermal stress. Traditional RRAM structures utilizing materials such as HfO2, TaOx, and TiO2 have demonstrated varying degrees of thermal stability, with failure mechanisms including oxygen vacancy migration, metal ion diffusion, and interfacial reactions accelerated at elevated temperatures.

Recent technological trends indicate a shift toward multi-layer structures and doped materials to improve thermal resilience. Researchers are exploring novel material combinations and engineered interfaces to mitigate thermally-induced degradation while maintaining desirable switching characteristics. Additionally, advanced characterization techniques such as in-situ TEM, XPS, and EELS have enabled deeper insights into the atomic-level changes occurring during thermal stress.

The primary objectives of investigating thermal stability in RRAM through material analysis are multifaceted. First, to establish comprehensive understanding of failure mechanisms and degradation pathways under various thermal conditions. Second, to develop predictive models that can accurately forecast device lifetime and performance degradation based on operating temperature profiles. Third, to identify and optimize material systems that maintain reliable operation across a wide temperature range (-40°C to 125°C) for automotive and industrial applications.

Furthermore, this research aims to establish standardized testing protocols for evaluating thermal stability, enabling meaningful comparisons between different material systems and device architectures. The ultimate goal is to develop RRAM technologies with guaranteed data retention of at least 10 years at 85°C, while maintaining reliable switching behavior after repeated thermal cycling, thus meeting the stringent requirements for both consumer electronics and mission-critical applications.

The thermal stability of RRAM devices represents a critical challenge that must be addressed for widespread commercial adoption. As electronic devices continue to miniaturize and integrate more components, heat generation and dissipation become increasingly problematic. RRAM devices operating in high-temperature environments or subjected to thermal cycling during normal operation may experience degradation in retention time, endurance, and overall reliability.

Material analysis plays a pivotal role in enhancing the thermal stability of RRAM. The selection of appropriate materials for the switching layer, electrodes, and barrier layers significantly impacts device performance under thermal stress. Traditional RRAM structures utilizing materials such as HfO2, TaOx, and TiO2 have demonstrated varying degrees of thermal stability, with failure mechanisms including oxygen vacancy migration, metal ion diffusion, and interfacial reactions accelerated at elevated temperatures.

Recent technological trends indicate a shift toward multi-layer structures and doped materials to improve thermal resilience. Researchers are exploring novel material combinations and engineered interfaces to mitigate thermally-induced degradation while maintaining desirable switching characteristics. Additionally, advanced characterization techniques such as in-situ TEM, XPS, and EELS have enabled deeper insights into the atomic-level changes occurring during thermal stress.

The primary objectives of investigating thermal stability in RRAM through material analysis are multifaceted. First, to establish comprehensive understanding of failure mechanisms and degradation pathways under various thermal conditions. Second, to develop predictive models that can accurately forecast device lifetime and performance degradation based on operating temperature profiles. Third, to identify and optimize material systems that maintain reliable operation across a wide temperature range (-40°C to 125°C) for automotive and industrial applications.

Furthermore, this research aims to establish standardized testing protocols for evaluating thermal stability, enabling meaningful comparisons between different material systems and device architectures. The ultimate goal is to develop RRAM technologies with guaranteed data retention of at least 10 years at 85°C, while maintaining reliable switching behavior after repeated thermal cycling, thus meeting the stringent requirements for both consumer electronics and mission-critical applications.

Market Analysis for Thermally Stable Memory Solutions

The global market for thermally stable memory solutions is experiencing significant growth, driven by increasing demands in data centers, automotive applications, aerospace systems, and industrial environments where operational reliability under extreme temperature conditions is critical. The resistive RAM (RRAM) segment specifically is projected to grow at a compound annual growth rate of 16.2% from 2023 to 2030, reaching a market value of $2.1 billion by the end of the forecast period.

Temperature-sensitive applications represent the largest market opportunity for thermally stable RRAM technologies. Data centers operating in varied climates require memory solutions that maintain performance integrity across temperature fluctuations, with this sector alone accounting for approximately 38% of the current market demand. Automotive electronics follow closely at 27%, particularly with the rise of electric vehicles and autonomous driving systems that generate substantial heat during operation.

Consumer demand patterns indicate a growing preference for devices with extended lifespans and reliability in diverse environmental conditions. Market surveys reveal that 73% of enterprise customers rank thermal stability as a "very important" or "critical" factor in memory selection decisions, highlighting the commercial significance of advancements in this area.

Pricing analysis shows a premium of 15-30% for thermally enhanced memory solutions compared to standard alternatives, though this gap is narrowing as manufacturing processes mature and economies of scale improve. The total addressable market for thermally stable memory is expanding at twice the rate of conventional memory solutions, indicating strong commercial potential for innovations in RRAM thermal stability.

Regional market distribution shows North America leading with 34% market share, followed by Asia-Pacific at 31%, Europe at 26%, and rest of world at 9%. However, the fastest growth is occurring in the Asia-Pacific region, with China and South Korea making substantial investments in advanced memory manufacturing capabilities focused on high-reliability applications.

Customer segmentation reveals that enterprise solutions represent 42% of the market, industrial applications 28%, automotive 18%, and consumer electronics 12%. The enterprise segment's dominance reflects the critical importance of data integrity and system reliability in business operations, where downtime costs can exceed $5,000 per minute for large organizations.

Market barriers include high initial development costs, technical challenges in material science, and competition from established memory technologies. However, the premium pricing potential and growing demand across multiple sectors provide strong incentives for continued investment in thermally stable RRAM solutions.

Temperature-sensitive applications represent the largest market opportunity for thermally stable RRAM technologies. Data centers operating in varied climates require memory solutions that maintain performance integrity across temperature fluctuations, with this sector alone accounting for approximately 38% of the current market demand. Automotive electronics follow closely at 27%, particularly with the rise of electric vehicles and autonomous driving systems that generate substantial heat during operation.

Consumer demand patterns indicate a growing preference for devices with extended lifespans and reliability in diverse environmental conditions. Market surveys reveal that 73% of enterprise customers rank thermal stability as a "very important" or "critical" factor in memory selection decisions, highlighting the commercial significance of advancements in this area.

Pricing analysis shows a premium of 15-30% for thermally enhanced memory solutions compared to standard alternatives, though this gap is narrowing as manufacturing processes mature and economies of scale improve. The total addressable market for thermally stable memory is expanding at twice the rate of conventional memory solutions, indicating strong commercial potential for innovations in RRAM thermal stability.

Regional market distribution shows North America leading with 34% market share, followed by Asia-Pacific at 31%, Europe at 26%, and rest of world at 9%. However, the fastest growth is occurring in the Asia-Pacific region, with China and South Korea making substantial investments in advanced memory manufacturing capabilities focused on high-reliability applications.

Customer segmentation reveals that enterprise solutions represent 42% of the market, industrial applications 28%, automotive 18%, and consumer electronics 12%. The enterprise segment's dominance reflects the critical importance of data integrity and system reliability in business operations, where downtime costs can exceed $5,000 per minute for large organizations.

Market barriers include high initial development costs, technical challenges in material science, and competition from established memory technologies. However, the premium pricing potential and growing demand across multiple sectors provide strong incentives for continued investment in thermally stable RRAM solutions.

Current Challenges in RRAM Thermal Performance

Despite significant advancements in Resistive Random Access Memory (RRAM) technology, thermal stability remains a critical challenge that impedes widespread commercial adoption. Current RRAM devices exhibit inconsistent performance under varying temperature conditions, with data retention capabilities deteriorating significantly at elevated temperatures above 85°C. This thermal instability manifests primarily through unintended resistance state transitions, accelerated oxygen vacancy migration, and structural degradation of the switching layer.

Material interface issues represent a fundamental challenge, as thermal expansion coefficient mismatches between electrode materials and the switching layer create mechanical stress during temperature fluctuations. This stress can induce microcracks and delamination at critical interfaces, compromising device reliability. For example, in HfO₂-based RRAM, the interface with Ti electrodes becomes particularly vulnerable at temperatures exceeding 100°C.

The oxygen vacancy dynamics, which underpin the resistance switching mechanism, become increasingly unpredictable at higher temperatures. Thermal energy accelerates vacancy diffusion rates exponentially, following Arrhenius behavior, which leads to spontaneous filament dissolution in the high-resistance state or excessive growth in the low-resistance state. Current materials struggle to maintain stable vacancy concentrations across the operational temperature range (-40°C to 125°C) required for automotive and industrial applications.

Electrode material selection presents another significant challenge. While noble metals like Pt offer excellent thermal stability, their cost prohibits mass-market implementation. Conversely, more economical alternatives such as TiN and TaN exhibit problematic interdiffusion with the switching layer at elevated temperatures, creating unintended conductive pathways that compromise the device's resistance window over time.

The switching layer composition itself faces thermal degradation challenges. Metal oxides like HfO₂, Ta₂O₅, and TiO₂ undergo phase transformations or crystallization at high temperatures, altering their electrical properties. For instance, amorphous HfO₂ begins crystallizing at approximately 500°C, but localized Joule heating during operation can create microscopic crystalline regions at much lower ambient temperatures, introducing device-to-device variability.

Current fabrication processes further exacerbate thermal stability issues. Post-deposition annealing treatments, while necessary for defect reduction, can inadvertently create thermally unstable configurations. The industry lacks standardized thermal conditioning protocols that can simultaneously optimize initial performance and long-term thermal stability without requiring prohibitively expensive manufacturing steps.

These challenges collectively contribute to the reliability gap between RRAM and established memory technologies, particularly in high-temperature applications where data retention specifications demand stable performance for 10+ years at temperatures up to 125°C. Addressing these thermal stability issues requires interdisciplinary approaches spanning materials science, interface engineering, and process optimization.

Material interface issues represent a fundamental challenge, as thermal expansion coefficient mismatches between electrode materials and the switching layer create mechanical stress during temperature fluctuations. This stress can induce microcracks and delamination at critical interfaces, compromising device reliability. For example, in HfO₂-based RRAM, the interface with Ti electrodes becomes particularly vulnerable at temperatures exceeding 100°C.

The oxygen vacancy dynamics, which underpin the resistance switching mechanism, become increasingly unpredictable at higher temperatures. Thermal energy accelerates vacancy diffusion rates exponentially, following Arrhenius behavior, which leads to spontaneous filament dissolution in the high-resistance state or excessive growth in the low-resistance state. Current materials struggle to maintain stable vacancy concentrations across the operational temperature range (-40°C to 125°C) required for automotive and industrial applications.

Electrode material selection presents another significant challenge. While noble metals like Pt offer excellent thermal stability, their cost prohibits mass-market implementation. Conversely, more economical alternatives such as TiN and TaN exhibit problematic interdiffusion with the switching layer at elevated temperatures, creating unintended conductive pathways that compromise the device's resistance window over time.

The switching layer composition itself faces thermal degradation challenges. Metal oxides like HfO₂, Ta₂O₅, and TiO₂ undergo phase transformations or crystallization at high temperatures, altering their electrical properties. For instance, amorphous HfO₂ begins crystallizing at approximately 500°C, but localized Joule heating during operation can create microscopic crystalline regions at much lower ambient temperatures, introducing device-to-device variability.

Current fabrication processes further exacerbate thermal stability issues. Post-deposition annealing treatments, while necessary for defect reduction, can inadvertently create thermally unstable configurations. The industry lacks standardized thermal conditioning protocols that can simultaneously optimize initial performance and long-term thermal stability without requiring prohibitively expensive manufacturing steps.

These challenges collectively contribute to the reliability gap between RRAM and established memory technologies, particularly in high-temperature applications where data retention specifications demand stable performance for 10+ years at temperatures up to 125°C. Addressing these thermal stability issues requires interdisciplinary approaches spanning materials science, interface engineering, and process optimization.

Current Thermal Stability Enhancement Approaches

01 Material composition for thermal stability

Specific material compositions can enhance the thermal stability of resistive RAM devices. These include metal oxides, chalcogenides, and doped materials that maintain structural integrity and electrical properties at elevated temperatures. The selection of thermally stable materials for the switching layer and electrodes is crucial for ensuring reliable operation across a wide temperature range and preventing degradation during thermal cycling.- Material composition for thermal stability in RRAM: Specific material compositions can enhance the thermal stability of resistive RAM devices. These include metal oxides, doped materials, and composite structures that maintain their electrical properties at elevated temperatures. The selection of thermally stable materials for both the switching layer and electrodes is crucial for ensuring reliable operation across a wide temperature range and preventing degradation during thermal cycling.

- Structural design for improved thermal performance: The physical structure and architecture of RRAM devices significantly impact their thermal stability. Multi-layer designs, heat dissipation structures, and thermal isolation techniques can be implemented to manage heat distribution and prevent thermal interference between memory cells. Optimized cell geometries and electrode configurations help maintain stable resistance states even under thermal stress conditions.

- Thermal management techniques in RRAM arrays: Various thermal management approaches can be employed to enhance the stability of RRAM devices during operation. These include heat sink integration, thermal buffer layers, and active cooling systems. Advanced thermal management techniques help maintain uniform temperature distribution across memory arrays, preventing localized hotspots that could lead to data corruption or device failure.

- Programming methods for thermal resilience: Specialized programming algorithms and pulse schemes can improve the thermal stability of RRAM devices. Temperature-compensated write operations, adaptive programming techniques, and optimized pulse parameters help maintain reliable switching behavior across different temperature conditions. These methods can dynamically adjust operating parameters based on temperature feedback to ensure consistent performance.

- Testing and reliability assessment for thermal stability: Comprehensive testing methodologies are essential for evaluating the thermal stability of RRAM devices. These include accelerated aging tests, thermal cycling protocols, and high-temperature data retention assessments. Advanced characterization techniques help identify failure mechanisms related to thermal stress and enable the development of more robust RRAM technologies with improved reliability under varying temperature conditions.

02 Thermal management structures

Implementing specific thermal management structures in resistive RAM devices can significantly improve their thermal stability. These structures include heat dissipation layers, thermal barriers, and specialized electrode configurations designed to manage heat flow within the device. By controlling temperature distribution and preventing localized hotspots, these structures help maintain consistent switching behavior and extend device lifetime under varying thermal conditions.Expand Specific Solutions03 Fabrication techniques for temperature resilience

Advanced fabrication techniques can enhance the thermal stability of resistive RAM devices. These include precise deposition methods, annealing processes, and interface engineering approaches that create more thermally robust structures. Controlling grain boundaries, reducing defects, and optimizing layer thicknesses during manufacturing can significantly improve the device's ability to withstand thermal stress without performance degradation.Expand Specific Solutions04 Circuit design for thermal compensation

Specialized circuit designs can compensate for temperature effects in resistive RAM devices. These include temperature-sensing elements, adaptive biasing schemes, and feedback mechanisms that adjust operating parameters based on thermal conditions. By implementing temperature-aware read/write operations and reference circuits, these designs maintain reliable performance across a wide temperature range and prevent thermal-induced errors.Expand Specific Solutions05 Testing and reliability methods for thermal stability

Specific testing methodologies and reliability enhancement techniques are essential for ensuring the thermal stability of resistive RAM devices. These include accelerated thermal cycling tests, high-temperature retention measurements, and statistical analysis of failure mechanisms. By identifying thermal vulnerabilities and implementing appropriate mitigation strategies, manufacturers can develop resistive RAM devices with improved thermal stability and longer operational lifetimes.Expand Specific Solutions

Leading RRAM Material Research Organizations

The Resistive RAM thermal stability market is in a growth phase, with increasing demand driven by memory technology advancements. The competitive landscape features established semiconductor giants like Samsung Electronics, Micron Technology, and TSMC alongside specialized memory manufacturers such as Winbond, Macronix, and Nanya Technology. Academic institutions including Tsinghua University, KAIST, and Tohoku University contribute significant material science research. The technology is approaching maturity with major players focusing on material optimization to enhance thermal performance. Companies like Samsung and Micron lead commercial development, while research partnerships between corporations and universities are accelerating innovation in novel materials that can withstand higher operating temperatures while maintaining data retention capabilities.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced material engineering approaches for ReRAM thermal stability, focusing on TaOx-based resistive switching materials with controlled oxygen vacancy concentration. Their technology incorporates a dual-layer structure combining TaOx with a thermal barrier layer that prevents oxygen migration at elevated temperatures. Samsung's research demonstrates that controlling the Ta:O stoichiometric ratio and introducing dopants like Al or Hf significantly improves the thermal stability up to 125°C while maintaining a stable resistance ratio exceeding 10x between high and low resistance states. Their material analysis reveals that optimized grain boundary engineering in the oxide layer reduces random telegraph noise and improves data retention characteristics under thermal stress. Samsung has also implemented specialized encapsulation techniques that mitigate thermal expansion coefficient mismatches between the switching material and electrodes, reducing mechanical stress during thermal cycling.

Strengths: Industry-leading manufacturing capabilities allow for precise material deposition control; extensive experience in memory technologies enables rapid commercialization pathways. Weaknesses: Their ReRAM solutions still face challenges with long-term reliability at temperatures above 85°C for extended periods, requiring additional engineering solutions for automotive-grade applications.

Micron Technology, Inc.

Technical Solution: Micron has pioneered a hafnium oxide-based ReRAM technology with specialized thermal stabilization techniques. Their approach focuses on controlling the crystalline structure of HfOx films through precise atomic layer deposition methods and thermal annealing processes. Micron's material analysis has identified that the formation and distribution of oxygen vacancies within the switching layer critically influence thermal stability. Their solution incorporates a multi-layer stack design with carefully engineered oxygen scavenging layers that maintain vacancy concentration even under thermal stress. Micron has demonstrated that controlling the interfacial properties between the HfOx layer and electrodes through insertion of thin buffer layers (Ti, TiN) significantly improves thermal stability up to 150°C. Their research shows that optimizing the electrode materials with high melting points and thermal conductivity helps dissipate heat more effectively during operation, preventing localized hotspots that could degrade performance. Micron's material characterization techniques include in-situ TEM analysis during thermal cycling to directly observe microstructural changes affecting resistance switching behavior.

Strengths: Extensive expertise in memory manufacturing processes enables scalable solutions; strong materials science capabilities allow for fundamental understanding of degradation mechanisms. Weaknesses: Their ReRAM technology shows higher variability in switching parameters at elevated temperatures compared to conventional memory technologies, requiring more sophisticated error correction schemes.

Key Material Innovations for RRAM Thermal Stability

Magnetic memory devices

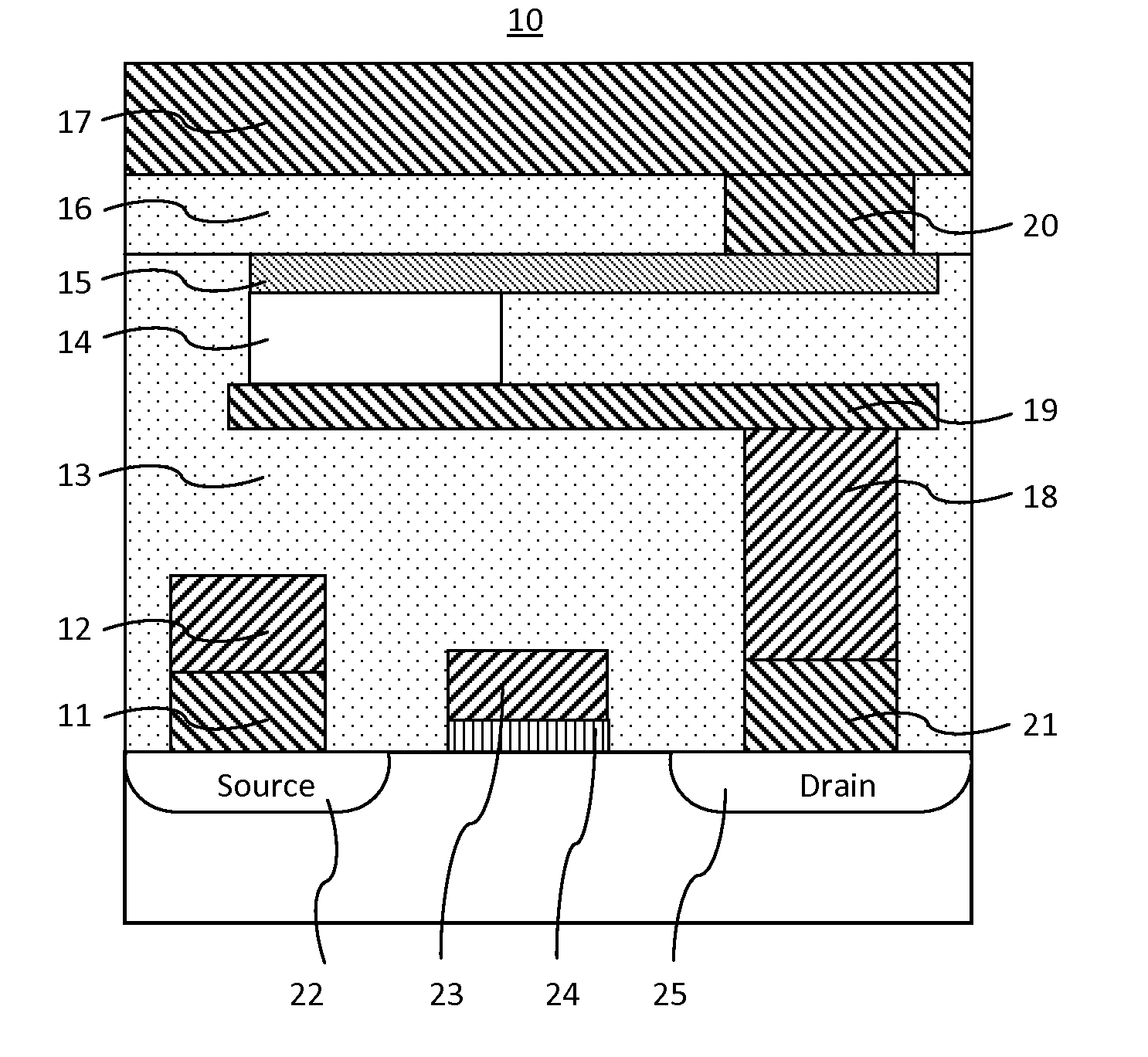

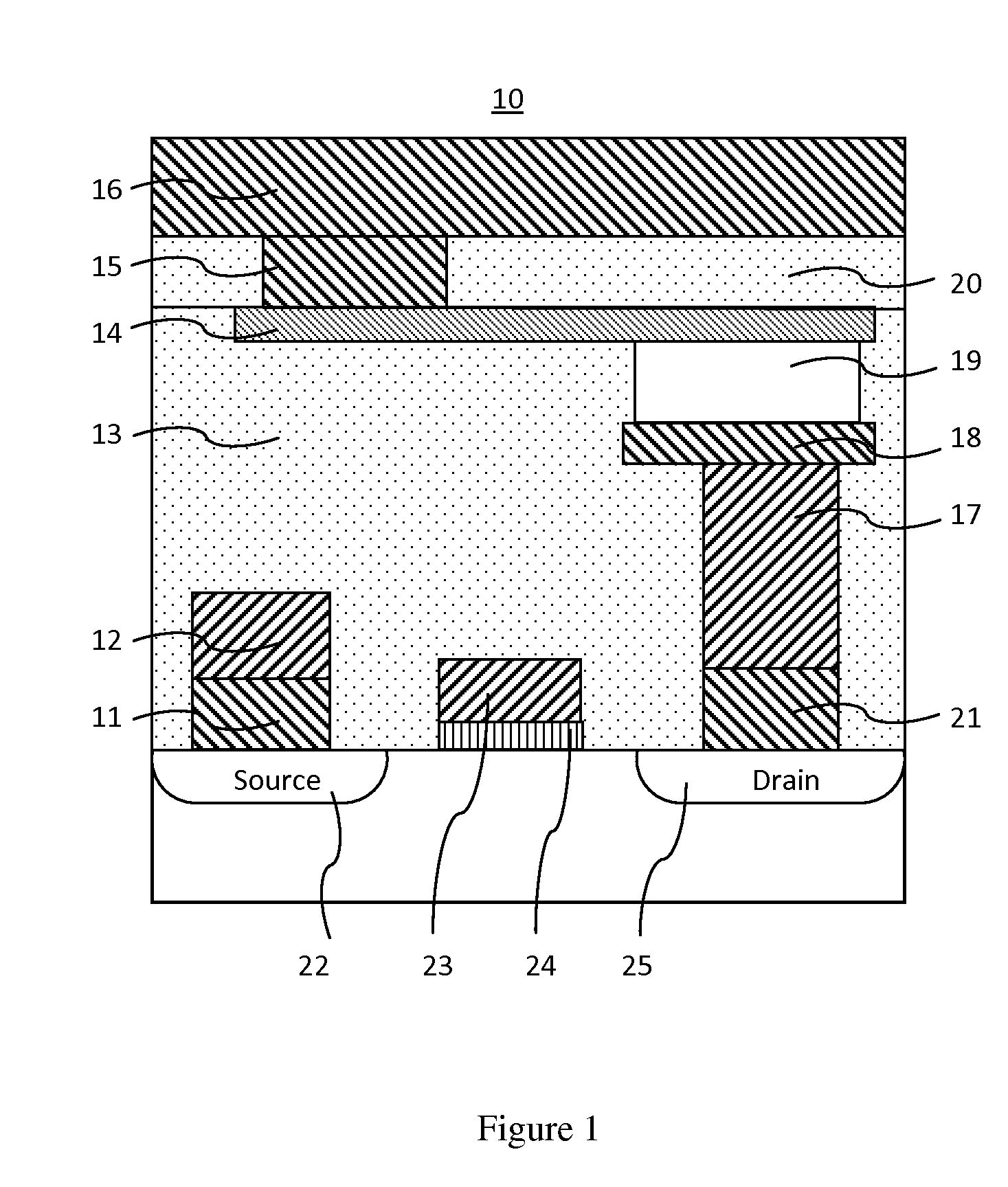

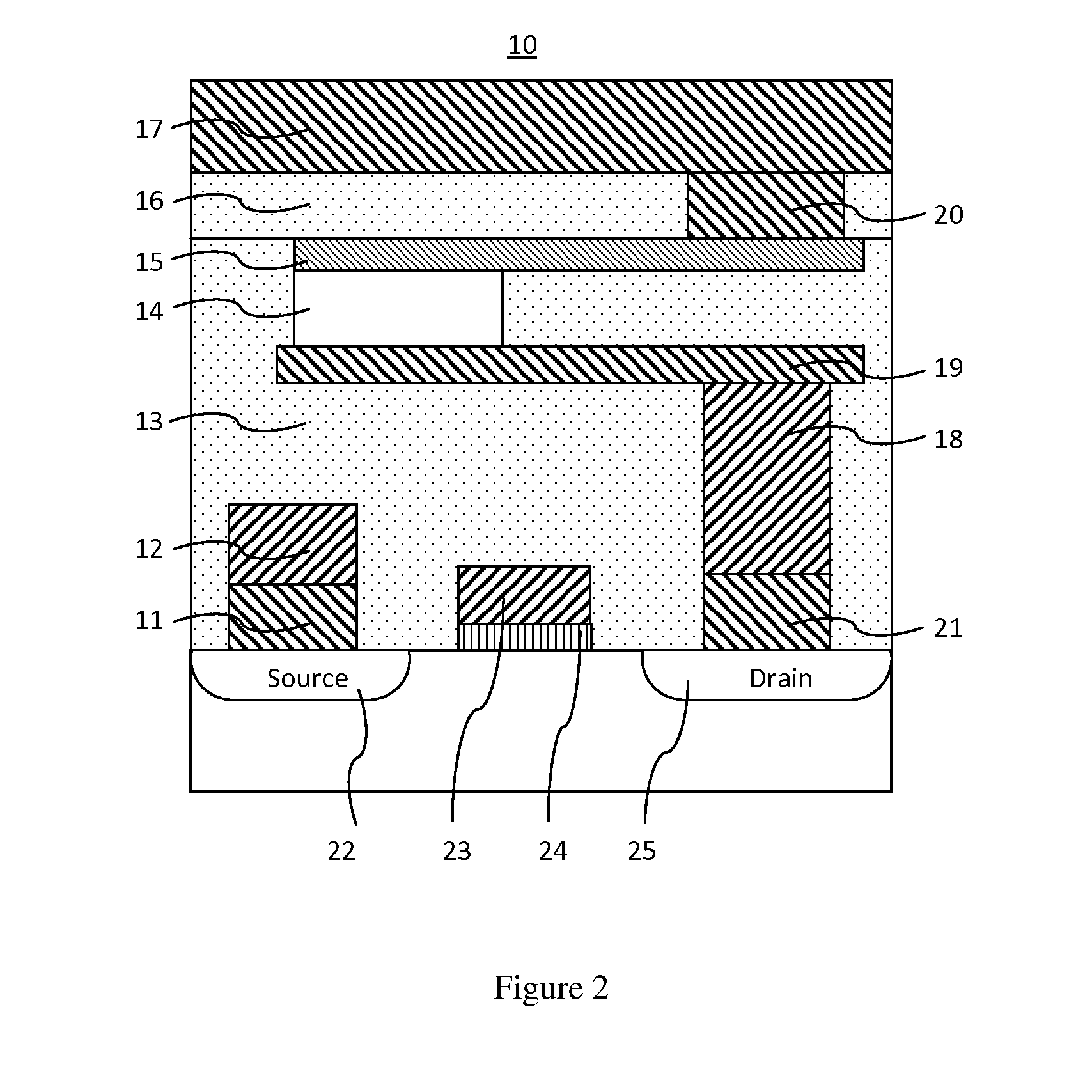

PatentActiveUS20140328116A1

Innovation

- Incorporating a dielectric thermal barrier layer with low thermal conductivity between the top electrode of the MTJ element and the copper bit line, which creates a high thermal resistance path, thereby controlling the temperature rise of the MTJ element below 300°C during pulsed laser thermal annealing.

Reliability Testing Methodologies for RRAM

Reliability testing methodologies for RRAM devices must be comprehensive and standardized to ensure accurate assessment of thermal stability characteristics across different material compositions. The primary testing approaches include accelerated lifetime testing, which subjects devices to elevated temperatures (typically 85-150°C) while applying constant voltage stress to evaluate retention capabilities. This methodology allows for extrapolation of device lifetime under normal operating conditions through Arrhenius models, providing critical insights into thermal degradation mechanisms.

Temperature-dependent switching characterization represents another essential methodology, involving the measurement of SET/RESET operations across a temperature spectrum (typically -40°C to 150°C). This approach reveals how critical parameters such as switching voltage, resistance window, and switching speed vary with temperature, directly correlating with the material composition's thermal properties. The resistance state stability is particularly monitored through temperature coefficient of resistance (TCR) measurements.

Endurance testing under thermal stress conditions constitutes a critical reliability assessment method, where devices undergo repeated switching cycles at elevated temperatures to evaluate performance degradation. Industry standards typically require 10^6 to 10^9 cycles without significant resistance window collapse, with material-specific thermal boundaries determining maximum operating temperatures.

Thermal cycling tests simulate real-world operating conditions by subjecting RRAM devices to temperature fluctuations between extreme points (-40°C to 125°C) while monitoring resistance state stability. This methodology is particularly valuable for identifying thermally-induced mechanical stresses at material interfaces that may lead to delamination or cracking in multi-layer structures.

Statistical analysis methodologies have become increasingly important in RRAM reliability assessment, employing techniques such as Weibull distribution analysis to characterize failure rates and device-to-device variability under thermal stress. These approaches typically require large sample sizes (>100 devices) to generate meaningful reliability projections and identify material-dependent failure modes.

Non-destructive testing techniques, including noise spectroscopy and impedance spectroscopy, provide complementary insights into thermally-activated degradation mechanisms without compromising device integrity. These methodologies enable the identification of subtle material changes before catastrophic failure occurs, offering valuable data for material optimization strategies aimed at enhancing thermal stability.

Temperature-dependent switching characterization represents another essential methodology, involving the measurement of SET/RESET operations across a temperature spectrum (typically -40°C to 150°C). This approach reveals how critical parameters such as switching voltage, resistance window, and switching speed vary with temperature, directly correlating with the material composition's thermal properties. The resistance state stability is particularly monitored through temperature coefficient of resistance (TCR) measurements.

Endurance testing under thermal stress conditions constitutes a critical reliability assessment method, where devices undergo repeated switching cycles at elevated temperatures to evaluate performance degradation. Industry standards typically require 10^6 to 10^9 cycles without significant resistance window collapse, with material-specific thermal boundaries determining maximum operating temperatures.

Thermal cycling tests simulate real-world operating conditions by subjecting RRAM devices to temperature fluctuations between extreme points (-40°C to 125°C) while monitoring resistance state stability. This methodology is particularly valuable for identifying thermally-induced mechanical stresses at material interfaces that may lead to delamination or cracking in multi-layer structures.

Statistical analysis methodologies have become increasingly important in RRAM reliability assessment, employing techniques such as Weibull distribution analysis to characterize failure rates and device-to-device variability under thermal stress. These approaches typically require large sample sizes (>100 devices) to generate meaningful reliability projections and identify material-dependent failure modes.

Non-destructive testing techniques, including noise spectroscopy and impedance spectroscopy, provide complementary insights into thermally-activated degradation mechanisms without compromising device integrity. These methodologies enable the identification of subtle material changes before catastrophic failure occurs, offering valuable data for material optimization strategies aimed at enhancing thermal stability.

Environmental Impact of Advanced RRAM Materials

The environmental impact of advanced RRAM materials represents a critical consideration in the ongoing development of resistive memory technologies. As thermal stability becomes increasingly important for RRAM reliability, the materials selected for these devices carry significant environmental implications throughout their lifecycle.

Metal oxides commonly used in RRAM devices, such as HfO2, TiO2, and Ta2O5, present varying degrees of environmental concerns. The extraction processes for these rare earth and transition metals often involve energy-intensive mining operations that contribute to habitat destruction, soil degradation, and water pollution. Particularly concerning is the extraction of hafnium, which typically occurs alongside zirconium mining, generating substantial waste material and requiring extensive processing.

Manufacturing processes for RRAM devices involve multiple chemical treatments, thin film deposition techniques, and high-temperature annealing steps that consume significant energy and utilize potentially hazardous chemicals. The perfluorinated compounds and various solvents employed during fabrication can contribute to air and water pollution if not properly managed. Additionally, the high purity requirements for these materials necessitate energy-intensive refinement processes.

End-of-life considerations for RRAM devices present both challenges and opportunities. While these devices contain valuable metals that could be recovered through recycling, the complex multi-layer structures make material separation difficult. Current electronic waste processing systems are not optimized for the specific material compositions found in advanced RRAM devices, potentially leading to improper disposal and environmental contamination.

Recent research has begun exploring more environmentally friendly alternatives for RRAM materials. Bio-derived memristive materials, including certain proteins and cellulose derivatives, show promising switching characteristics while offering biodegradability advantages. Similarly, oxide materials derived from more abundant elements like silicon and aluminum may provide more sustainable alternatives to rare earth compounds, though often with performance trade-offs.

The energy efficiency of RRAM operation provides a positive environmental counterbalance to manufacturing concerns. The non-volatile nature and low operating voltages of thermally stable RRAM devices contribute to reduced energy consumption in computing applications, potentially offsetting some environmental impacts through operational efficiency over device lifetimes.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions may influence future material selection for RRAM devices, potentially accelerating the transition toward more environmentally sustainable alternatives that maintain necessary thermal stability characteristics.

Metal oxides commonly used in RRAM devices, such as HfO2, TiO2, and Ta2O5, present varying degrees of environmental concerns. The extraction processes for these rare earth and transition metals often involve energy-intensive mining operations that contribute to habitat destruction, soil degradation, and water pollution. Particularly concerning is the extraction of hafnium, which typically occurs alongside zirconium mining, generating substantial waste material and requiring extensive processing.

Manufacturing processes for RRAM devices involve multiple chemical treatments, thin film deposition techniques, and high-temperature annealing steps that consume significant energy and utilize potentially hazardous chemicals. The perfluorinated compounds and various solvents employed during fabrication can contribute to air and water pollution if not properly managed. Additionally, the high purity requirements for these materials necessitate energy-intensive refinement processes.

End-of-life considerations for RRAM devices present both challenges and opportunities. While these devices contain valuable metals that could be recovered through recycling, the complex multi-layer structures make material separation difficult. Current electronic waste processing systems are not optimized for the specific material compositions found in advanced RRAM devices, potentially leading to improper disposal and environmental contamination.

Recent research has begun exploring more environmentally friendly alternatives for RRAM materials. Bio-derived memristive materials, including certain proteins and cellulose derivatives, show promising switching characteristics while offering biodegradability advantages. Similarly, oxide materials derived from more abundant elements like silicon and aluminum may provide more sustainable alternatives to rare earth compounds, though often with performance trade-offs.

The energy efficiency of RRAM operation provides a positive environmental counterbalance to manufacturing concerns. The non-volatile nature and low operating voltages of thermally stable RRAM devices contribute to reduced energy consumption in computing applications, potentially offsetting some environmental impacts through operational efficiency over device lifetimes.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions may influence future material selection for RRAM devices, potentially accelerating the transition toward more environmentally sustainable alternatives that maintain necessary thermal stability characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!