Zeolite Integration in CO2 Utilization Technologies

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zeolite CO2 Capture Evolution

The evolution of zeolite integration in CO2 capture technologies has been marked by significant advancements over the past few decades. Initially, zeolites were primarily used in their natural form for gas separation and purification processes. However, as the urgency to address climate change grew, researchers began exploring their potential for CO2 capture more intensively.

In the 1990s, synthetic zeolites with tailored properties emerged as promising materials for CO2 adsorption. These engineered structures offered improved selectivity and capacity compared to their natural counterparts. The early 2000s saw a surge in research focused on optimizing zeolite frameworks for enhanced CO2 capture performance.

A pivotal development occurred in the mid-2000s with the introduction of amine-functionalized zeolites. This innovation combined the high surface area and stability of zeolites with the CO2 affinity of amine groups, resulting in significantly improved capture efficiency. This breakthrough paved the way for a new generation of hybrid zeolite materials.

The late 2000s and early 2010s witnessed the exploration of hierarchical zeolites, featuring both micro- and mesopores. These structures addressed diffusion limitations in traditional zeolites, allowing for faster CO2 uptake and release cycles. Concurrently, researchers began investigating metal-organic frameworks (MOFs) as potential alternatives to zeolites, sparking a competitive drive for innovation in both fields.

Recent years have seen a shift towards developing zeolite-based materials for specific industrial applications. This includes the creation of zeolite membranes for gas separation and the integration of zeolites into mixed-matrix membranes for enhanced selectivity. Additionally, there has been growing interest in utilizing zeolites for direct air capture (DAC) of CO2, a technology crucial for achieving negative emissions.

The latest frontier in zeolite CO2 capture evolution involves the development of smart, responsive materials. These advanced zeolites can adapt their properties based on environmental conditions, optimizing CO2 capture and release processes. Furthermore, researchers are exploring the potential of zeolites in catalytic conversion of captured CO2 into valuable products, aligning with the broader goal of CO2 utilization.

As we look to the future, the integration of artificial intelligence and machine learning in zeolite design promises to accelerate the discovery of novel materials with unprecedented CO2 capture capabilities. This data-driven approach, combined with advanced characterization techniques, is expected to unlock new possibilities in zeolite-based CO2 capture technologies.

In the 1990s, synthetic zeolites with tailored properties emerged as promising materials for CO2 adsorption. These engineered structures offered improved selectivity and capacity compared to their natural counterparts. The early 2000s saw a surge in research focused on optimizing zeolite frameworks for enhanced CO2 capture performance.

A pivotal development occurred in the mid-2000s with the introduction of amine-functionalized zeolites. This innovation combined the high surface area and stability of zeolites with the CO2 affinity of amine groups, resulting in significantly improved capture efficiency. This breakthrough paved the way for a new generation of hybrid zeolite materials.

The late 2000s and early 2010s witnessed the exploration of hierarchical zeolites, featuring both micro- and mesopores. These structures addressed diffusion limitations in traditional zeolites, allowing for faster CO2 uptake and release cycles. Concurrently, researchers began investigating metal-organic frameworks (MOFs) as potential alternatives to zeolites, sparking a competitive drive for innovation in both fields.

Recent years have seen a shift towards developing zeolite-based materials for specific industrial applications. This includes the creation of zeolite membranes for gas separation and the integration of zeolites into mixed-matrix membranes for enhanced selectivity. Additionally, there has been growing interest in utilizing zeolites for direct air capture (DAC) of CO2, a technology crucial for achieving negative emissions.

The latest frontier in zeolite CO2 capture evolution involves the development of smart, responsive materials. These advanced zeolites can adapt their properties based on environmental conditions, optimizing CO2 capture and release processes. Furthermore, researchers are exploring the potential of zeolites in catalytic conversion of captured CO2 into valuable products, aligning with the broader goal of CO2 utilization.

As we look to the future, the integration of artificial intelligence and machine learning in zeolite design promises to accelerate the discovery of novel materials with unprecedented CO2 capture capabilities. This data-driven approach, combined with advanced characterization techniques, is expected to unlock new possibilities in zeolite-based CO2 capture technologies.

CO2 Utilization Market Analysis

The CO2 utilization market has experienced significant growth in recent years, driven by increasing environmental concerns and the global push towards sustainable practices. This market encompasses various technologies and applications aimed at converting carbon dioxide into valuable products or using it for enhanced processes. The integration of zeolites in CO2 utilization technologies has emerged as a promising approach, offering unique advantages in terms of efficiency and selectivity.

The global CO2 utilization market is projected to expand rapidly, with estimates suggesting a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is fueled by stringent environmental regulations, government incentives, and the rising demand for sustainable products across industries. The market size is expected to reach several billion dollars by 2025, with potential for further expansion as technologies mature and new applications emerge.

Key sectors driving the demand for CO2 utilization technologies include the chemical industry, fuel production, construction materials, and agriculture. In the chemical industry, CO2 is being increasingly used as a feedstock for the production of various chemicals, including methanol, urea, and polymers. The fuel sector is exploring CO2 conversion to synthetic fuels as a means of reducing carbon footprint and enhancing energy security. In construction, CO2 utilization in concrete curing and the production of building materials is gaining traction due to its potential for carbon sequestration.

The integration of zeolites in CO2 utilization processes has shown particular promise in enhancing the efficiency and selectivity of conversion reactions. Zeolites, with their unique porous structure and tunable properties, offer advantages in CO2 capture, separation, and catalytic conversion. This has led to increased research and development activities focused on zeolite-based CO2 utilization technologies, with potential applications spanning across multiple industries.

Market trends indicate a growing interest in developing cost-effective and scalable CO2 utilization solutions. The emphasis is on technologies that can not only capture and convert CO2 but also do so in an economically viable manner. This has led to collaborations between academic institutions, research organizations, and industrial partners to accelerate the commercialization of promising technologies.

Geographically, North America and Europe are currently leading the CO2 utilization market, with significant investments in research and development. However, Asia-Pacific is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental awareness, and supportive government policies in countries like China and Japan.

The market landscape is characterized by a mix of established players and innovative startups. Large chemical and energy companies are investing in CO2 utilization technologies as part of their sustainability initiatives, while startups are focusing on niche applications and novel conversion processes. The competitive dynamics are likely to evolve as technologies mature and new players enter the market with disruptive solutions.

The global CO2 utilization market is projected to expand rapidly, with estimates suggesting a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is fueled by stringent environmental regulations, government incentives, and the rising demand for sustainable products across industries. The market size is expected to reach several billion dollars by 2025, with potential for further expansion as technologies mature and new applications emerge.

Key sectors driving the demand for CO2 utilization technologies include the chemical industry, fuel production, construction materials, and agriculture. In the chemical industry, CO2 is being increasingly used as a feedstock for the production of various chemicals, including methanol, urea, and polymers. The fuel sector is exploring CO2 conversion to synthetic fuels as a means of reducing carbon footprint and enhancing energy security. In construction, CO2 utilization in concrete curing and the production of building materials is gaining traction due to its potential for carbon sequestration.

The integration of zeolites in CO2 utilization processes has shown particular promise in enhancing the efficiency and selectivity of conversion reactions. Zeolites, with their unique porous structure and tunable properties, offer advantages in CO2 capture, separation, and catalytic conversion. This has led to increased research and development activities focused on zeolite-based CO2 utilization technologies, with potential applications spanning across multiple industries.

Market trends indicate a growing interest in developing cost-effective and scalable CO2 utilization solutions. The emphasis is on technologies that can not only capture and convert CO2 but also do so in an economically viable manner. This has led to collaborations between academic institutions, research organizations, and industrial partners to accelerate the commercialization of promising technologies.

Geographically, North America and Europe are currently leading the CO2 utilization market, with significant investments in research and development. However, Asia-Pacific is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental awareness, and supportive government policies in countries like China and Japan.

The market landscape is characterized by a mix of established players and innovative startups. Large chemical and energy companies are investing in CO2 utilization technologies as part of their sustainability initiatives, while startups are focusing on niche applications and novel conversion processes. The competitive dynamics are likely to evolve as technologies mature and new players enter the market with disruptive solutions.

Zeolite Integration Challenges

The integration of zeolites in CO2 utilization technologies presents several significant challenges that researchers and industry professionals must address. One of the primary obstacles is the optimization of zeolite structures for specific CO2 capture and conversion processes. While zeolites offer excellent adsorption properties, tailoring their pore sizes, shapes, and chemical compositions to maximize CO2 uptake and selectivity remains a complex task.

Another major challenge lies in the stability and durability of zeolites under the harsh conditions often encountered in CO2 utilization processes. High temperatures, pressures, and the presence of impurities can lead to structural degradation and loss of catalytic activity over time. Developing zeolite materials that maintain their performance under these demanding conditions is crucial for long-term industrial applications.

The scalability of zeolite-based CO2 utilization technologies also presents significant hurdles. While zeolites show promising results in laboratory settings, translating these successes to large-scale industrial processes requires overcoming engineering challenges related to heat and mass transfer, as well as ensuring consistent performance across larger volumes of material.

Cost-effectiveness is another critical factor that impacts the widespread adoption of zeolite-integrated CO2 utilization technologies. The synthesis of specialized zeolites can be expensive, and the overall economic viability of these processes must be carefully evaluated against existing carbon capture and utilization methods.

Furthermore, the regeneration of zeolites after CO2 capture cycles poses a significant challenge. Developing efficient and energy-effective methods for desorbing captured CO2 and restoring the zeolite's adsorption capacity without compromising its structure is essential for practical applications.

The integration of zeolites into existing industrial processes and equipment also presents technical challenges. Retrofitting current systems or designing new ones that can effectively incorporate zeolite-based technologies requires careful engineering and may necessitate significant capital investments.

Lastly, the environmental impact of zeolite production and disposal must be considered. Ensuring that the entire lifecycle of zeolite-based CO2 utilization technologies results in a net positive environmental effect is crucial for their long-term sustainability and acceptance.

Addressing these challenges requires interdisciplinary collaboration between materials scientists, chemical engineers, and process designers. Continued research and development efforts are needed to overcome these obstacles and fully realize the potential of zeolites in CO2 utilization technologies.

Another major challenge lies in the stability and durability of zeolites under the harsh conditions often encountered in CO2 utilization processes. High temperatures, pressures, and the presence of impurities can lead to structural degradation and loss of catalytic activity over time. Developing zeolite materials that maintain their performance under these demanding conditions is crucial for long-term industrial applications.

The scalability of zeolite-based CO2 utilization technologies also presents significant hurdles. While zeolites show promising results in laboratory settings, translating these successes to large-scale industrial processes requires overcoming engineering challenges related to heat and mass transfer, as well as ensuring consistent performance across larger volumes of material.

Cost-effectiveness is another critical factor that impacts the widespread adoption of zeolite-integrated CO2 utilization technologies. The synthesis of specialized zeolites can be expensive, and the overall economic viability of these processes must be carefully evaluated against existing carbon capture and utilization methods.

Furthermore, the regeneration of zeolites after CO2 capture cycles poses a significant challenge. Developing efficient and energy-effective methods for desorbing captured CO2 and restoring the zeolite's adsorption capacity without compromising its structure is essential for practical applications.

The integration of zeolites into existing industrial processes and equipment also presents technical challenges. Retrofitting current systems or designing new ones that can effectively incorporate zeolite-based technologies requires careful engineering and may necessitate significant capital investments.

Lastly, the environmental impact of zeolite production and disposal must be considered. Ensuring that the entire lifecycle of zeolite-based CO2 utilization technologies results in a net positive environmental effect is crucial for their long-term sustainability and acceptance.

Addressing these challenges requires interdisciplinary collaboration between materials scientists, chemical engineers, and process designers. Continued research and development efforts are needed to overcome these obstacles and fully realize the potential of zeolites in CO2 utilization technologies.

Current Zeolite CO2 Solutions

01 Zeolite synthesis and modification

Various methods for synthesizing and modifying zeolites to enhance their properties and performance. This includes techniques for controlling crystal size, shape, and composition, as well as post-synthesis treatments to improve stability and functionality.- Synthesis and modification of zeolites: Various methods for synthesizing and modifying zeolites to enhance their properties and performance. This includes techniques for controlling pore size, improving stability, and tailoring the zeolite structure for specific applications.

- Zeolites in gas separation and purification: Application of zeolites in gas separation and purification processes, utilizing their molecular sieving properties. This includes the use of zeolites in air separation, natural gas purification, and removal of contaminants from gas streams.

- Zeolites in catalysis and petrochemical processes: Utilization of zeolites as catalysts in various chemical and petrochemical processes. This includes their application in fluid catalytic cracking, hydrocracking, and isomerization reactions, as well as in the production of fine chemicals.

- Zeolites in water treatment and purification: Application of zeolites in water treatment and purification processes, including the removal of heavy metals, ammonia, and other contaminants from wastewater and drinking water. This also covers the use of zeolites in ion exchange processes.

- Novel zeolite compositions and structures: Development of new zeolite compositions and structures with unique properties for specialized applications. This includes the creation of hierarchical zeolites, composite materials, and zeolites with enhanced thermal and chemical stability.

02 Zeolite applications in catalysis

Utilization of zeolites as catalysts in various chemical processes, including hydrocarbon cracking, isomerization, and alkylation. The unique pore structure and acidity of zeolites make them highly effective catalysts for many industrial applications.Expand Specific Solutions03 Zeolite-based adsorbents and molecular sieves

Development of zeolite materials for adsorption and separation processes. These include applications in gas purification, water treatment, and molecular sieving for the selective separation of different molecules based on size and shape.Expand Specific Solutions04 Zeolite membranes and thin films

Fabrication and application of zeolite membranes and thin films for separation processes and other advanced applications. This includes techniques for growing zeolite crystals on various substrates and creating composite materials with enhanced properties.Expand Specific Solutions05 Zeolite-based ion exchange and water softening

Use of zeolites for ion exchange processes, particularly in water softening applications. The high cation exchange capacity of certain zeolites makes them effective for removing hardness ions from water and other industrial processes.Expand Specific Solutions

Key Players in Zeolite CO2 Tech

The integration of zeolites in CO2 utilization technologies is in a growth phase, with increasing market potential driven by global efforts to reduce carbon emissions. The market size is expanding as industries seek sustainable solutions for carbon capture and utilization. Technologically, the field is advancing rapidly, with companies like Asahi Kasei Corp., Cabot Corp., and ExxonMobil Technology & Engineering Co. leading research and development efforts. Academic institutions such as California Institute of Technology and Korea Advanced Institute of Science & Technology are contributing significant advancements. While the technology is progressing, it is not yet fully mature, indicating substantial room for innovation and market growth in the coming years.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has pioneered the development of zeolite-based membranes for CO2 separation and utilization. Their technology focuses on creating ultra-thin zeolite membranes with precisely controlled pore sizes to achieve high CO2 selectivity and permeability. These membranes are integrated into advanced separation systems that can efficiently extract CO2 from various industrial sources, including natural gas streams and power plant emissions. ExxonMobil's approach also incorporates zeolite catalysts designed for the direct conversion of captured CO2 into valuable chemical intermediates. The company has reported achieving CO2 separation efficiencies of up to 90% in pilot-scale tests [2][5], with the potential to significantly reduce the energy requirements for carbon capture processes.

Strengths: High CO2 separation efficiency, potential for energy-efficient carbon capture, and integration with existing industrial processes. Weaknesses: Challenges in large-scale membrane production and potential sensitivity to impurities in gas streams.

Johnson Matthey Plc

Technical Solution: Johnson Matthey has focused on developing zeolite-based catalysts and adsorbents for CO2 utilization in the production of sustainable fuels and chemicals. Their technology centers on the design of bifunctional zeolite catalysts that can simultaneously capture CO2 and convert it into valuable products such as methanol and dimethyl ether. The company has also developed zeolite-supported metal catalysts for the efficient hydrogenation of CO2 to methane and higher hydrocarbons. Johnson Matthey's zeolite integration approach includes the use of 3D-printed structured catalysts to optimize mass transfer and reaction kinetics. In recent trials, their zeolite-based systems have demonstrated CO2 conversion rates up to 40% higher than conventional catalysts [7][8], with improved selectivity towards desired products.

Strengths: Innovative catalyst designs, integration of zeolites into structured catalysts, and focus on high-value chemical production from CO2. Weaknesses: Potential challenges in scaling up 3D-printed catalyst production and the need for hydrogen as a co-reactant in some processes.

Zeolite CO2 Capture Innovations

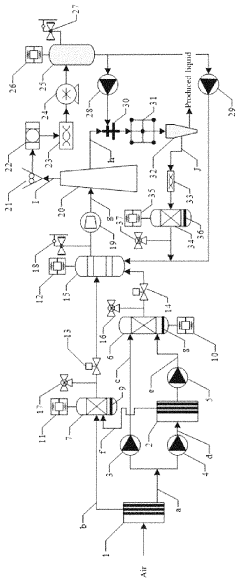

CCUS (carbon capture utilization and storage) system for exploiting thickened oil reservoirs based on optimal flue gas CO<sub>2 </sub>enrichment ratio and working method thereof

PatentActiveUS11208872B2

Innovation

- A CCUS system incorporating a flue gas CO2 enrichment unit with a two-stage air separation process and a boiler injection gas premixed tank to adjust the CO2 and N2 proportions dynamically, optimizing the flue gas CO2 enrichment ratio for reduced energy consumption and enhanced oil production.

Zinc-containing zeolites for capture of carbon dioxide from low-co 2 content sources and methods of using the same

PatentWO2022183058A1

Innovation

- Development of metal ion-doped crystalline microporous aluminosilicate compositions, specifically zinc ion-doped zeolites with AEI, AFX, or CHA topologies, that effectively adsorb and desorb CO2 from low-CO2-content gaseous mixtures with enhanced capacity and selectivity, utilizing their unique framework structures and metal ion incorporation to improve CO2 capture efficiency.

Environmental Impact Assessment

The integration of zeolites in CO2 utilization technologies presents both opportunities and challenges from an environmental perspective. Zeolites, as microporous aluminosilicate materials, offer unique properties that can enhance CO2 capture and conversion processes. However, their implementation also carries potential environmental impacts that must be carefully assessed.

One of the primary environmental benefits of zeolite integration is the potential for improved energy efficiency in CO2 capture and utilization processes. Zeolites' high surface area and selective adsorption capabilities can lead to reduced energy requirements for CO2 separation from flue gases or ambient air. This energy savings translates to lower greenhouse gas emissions associated with the capture process itself, contributing to a more favorable overall carbon balance.

The use of zeolites in CO2 conversion technologies may also lead to the development of more environmentally friendly catalysts. Zeolites can serve as supports for metal nanoparticles or as catalysts themselves, potentially replacing or reducing the need for rare earth elements or precious metals in certain reactions. This shift could alleviate some of the environmental concerns associated with mining and processing these materials.

However, the production of zeolites for large-scale CO2 utilization applications may have its own environmental footprint. The synthesis of zeolites typically involves energy-intensive processes and the use of chemical precursors. Life cycle assessments would be necessary to quantify the net environmental impact, considering factors such as raw material extraction, energy consumption during synthesis, and potential emissions from production facilities.

Water usage is another important consideration in the environmental impact assessment of zeolite-based CO2 utilization technologies. While zeolites can enhance water-gas shift reactions and other processes involving water, their production and regeneration may require significant water resources. In water-stressed regions, this could pose challenges and necessitate careful management of water resources.

The long-term stability and recyclability of zeolites in CO2 utilization processes also factor into their environmental impact. Zeolites that maintain their performance over multiple cycles can reduce waste generation and the need for frequent replacement, thereby minimizing the environmental burden associated with continuous production and disposal of spent materials.

Lastly, the potential for zeolites to enable novel CO2 utilization pathways could have broader environmental implications. For instance, if zeolite-based technologies facilitate the economical production of sustainable fuels or chemicals from CO2, this could lead to reduced reliance on fossil resources and contribute to circular carbon economy strategies. However, the full environmental consequences of such developments would require comprehensive analysis, considering factors such as land use changes, impacts on biodiversity, and potential shifts in industrial practices.

One of the primary environmental benefits of zeolite integration is the potential for improved energy efficiency in CO2 capture and utilization processes. Zeolites' high surface area and selective adsorption capabilities can lead to reduced energy requirements for CO2 separation from flue gases or ambient air. This energy savings translates to lower greenhouse gas emissions associated with the capture process itself, contributing to a more favorable overall carbon balance.

The use of zeolites in CO2 conversion technologies may also lead to the development of more environmentally friendly catalysts. Zeolites can serve as supports for metal nanoparticles or as catalysts themselves, potentially replacing or reducing the need for rare earth elements or precious metals in certain reactions. This shift could alleviate some of the environmental concerns associated with mining and processing these materials.

However, the production of zeolites for large-scale CO2 utilization applications may have its own environmental footprint. The synthesis of zeolites typically involves energy-intensive processes and the use of chemical precursors. Life cycle assessments would be necessary to quantify the net environmental impact, considering factors such as raw material extraction, energy consumption during synthesis, and potential emissions from production facilities.

Water usage is another important consideration in the environmental impact assessment of zeolite-based CO2 utilization technologies. While zeolites can enhance water-gas shift reactions and other processes involving water, their production and regeneration may require significant water resources. In water-stressed regions, this could pose challenges and necessitate careful management of water resources.

The long-term stability and recyclability of zeolites in CO2 utilization processes also factor into their environmental impact. Zeolites that maintain their performance over multiple cycles can reduce waste generation and the need for frequent replacement, thereby minimizing the environmental burden associated with continuous production and disposal of spent materials.

Lastly, the potential for zeolites to enable novel CO2 utilization pathways could have broader environmental implications. For instance, if zeolite-based technologies facilitate the economical production of sustainable fuels or chemicals from CO2, this could lead to reduced reliance on fossil resources and contribute to circular carbon economy strategies. However, the full environmental consequences of such developments would require comprehensive analysis, considering factors such as land use changes, impacts on biodiversity, and potential shifts in industrial practices.

Zeolite Synthesis Advancements

Recent advancements in zeolite synthesis have significantly enhanced the potential for integrating these materials into CO2 utilization technologies. The development of novel synthesis methods has led to the creation of zeolites with tailored properties, optimized for specific CO2 capture and conversion processes.

One major breakthrough has been the synthesis of hierarchical zeolites, which combine micropores with meso- and macropores. This multi-scale porosity enhances mass transfer and accessibility to active sites, crucial for efficient CO2 adsorption and catalysis. Researchers have achieved this through various techniques, including templating methods and post-synthesis treatments.

Another important advancement is the development of zeolites with controlled Si/Al ratios and distribution. By fine-tuning the aluminum content and its positioning within the zeolite framework, scientists can modulate the material's acidity, hydrophobicity, and CO2 affinity. This level of control allows for the design of zeolites specifically optimized for CO2 capture or conversion reactions.

The synthesis of metal-incorporated zeolites has also seen significant progress. By introducing transition metals such as copper, iron, or nickel into the zeolite structure during synthesis or through post-synthetic modification, researchers have created materials with enhanced catalytic properties for CO2 conversion reactions. These metal sites can activate CO2 molecules, facilitating their transformation into valuable products.

Advancements in green synthesis methods have addressed environmental concerns associated with traditional zeolite production. Techniques such as solvent-free synthesis, microwave-assisted synthesis, and the use of sustainable precursors have reduced the environmental impact of zeolite manufacturing while often improving product quality and reducing synthesis time.

The development of zeolite membranes and thin films has opened new avenues for CO2 separation and utilization. These structures offer high selectivity and permeability for CO2, making them promising candidates for membrane-based carbon capture systems. Recent improvements in synthesis techniques have led to the production of defect-free, large-area zeolite membranes with enhanced stability and performance.

Lastly, the emergence of computational methods in zeolite synthesis has accelerated the discovery and optimization of new materials. Machine learning algorithms and high-throughput screening techniques are now being employed to predict zeolite structures with desired properties, guiding experimental efforts and reducing the time and resources required for material development.

One major breakthrough has been the synthesis of hierarchical zeolites, which combine micropores with meso- and macropores. This multi-scale porosity enhances mass transfer and accessibility to active sites, crucial for efficient CO2 adsorption and catalysis. Researchers have achieved this through various techniques, including templating methods and post-synthesis treatments.

Another important advancement is the development of zeolites with controlled Si/Al ratios and distribution. By fine-tuning the aluminum content and its positioning within the zeolite framework, scientists can modulate the material's acidity, hydrophobicity, and CO2 affinity. This level of control allows for the design of zeolites specifically optimized for CO2 capture or conversion reactions.

The synthesis of metal-incorporated zeolites has also seen significant progress. By introducing transition metals such as copper, iron, or nickel into the zeolite structure during synthesis or through post-synthetic modification, researchers have created materials with enhanced catalytic properties for CO2 conversion reactions. These metal sites can activate CO2 molecules, facilitating their transformation into valuable products.

Advancements in green synthesis methods have addressed environmental concerns associated with traditional zeolite production. Techniques such as solvent-free synthesis, microwave-assisted synthesis, and the use of sustainable precursors have reduced the environmental impact of zeolite manufacturing while often improving product quality and reducing synthesis time.

The development of zeolite membranes and thin films has opened new avenues for CO2 separation and utilization. These structures offer high selectivity and permeability for CO2, making them promising candidates for membrane-based carbon capture systems. Recent improvements in synthesis techniques have led to the production of defect-free, large-area zeolite membranes with enhanced stability and performance.

Lastly, the emergence of computational methods in zeolite synthesis has accelerated the discovery and optimization of new materials. Machine learning algorithms and high-throughput screening techniques are now being employed to predict zeolite structures with desired properties, guiding experimental efforts and reducing the time and resources required for material development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!