Addressing challenges in mild hybrid system thermal management

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Thermal Management Background and Objectives

Mild hybrid systems have emerged as a crucial technology in the automotive industry's pursuit of improved fuel efficiency and reduced emissions. These systems, which combine a conventional internal combustion engine with a small electric motor, have gained significant traction in recent years due to their ability to provide enhanced performance and fuel economy without the complexity and cost associated with full hybrid or electric vehicles.

The evolution of mild hybrid technology can be traced back to the early 2000s, with initial implementations focusing on simple start-stop functionality. Over time, the technology has progressed to include more advanced features such as regenerative braking, electric torque assist, and electric boost during acceleration. This progression has been driven by increasingly stringent emissions regulations and consumer demand for more fuel-efficient vehicles.

As mild hybrid systems have become more sophisticated, thermal management has emerged as a critical challenge. The integration of electrical components with traditional internal combustion engines introduces new heat sources and thermal loads that must be carefully managed to ensure optimal performance, efficiency, and longevity of the system. Effective thermal management is essential for maintaining the temperature of various components within their optimal operating ranges, including the battery pack, electric motor, power electronics, and the internal combustion engine itself.

The primary objectives of addressing thermal management challenges in mild hybrid systems are multifaceted. Firstly, there is a need to optimize the overall system efficiency by minimizing energy losses due to heat generation and dissipation. This involves developing innovative cooling strategies that can effectively manage the thermal loads of both the electrical and mechanical components. Secondly, engineers aim to enhance the durability and reliability of mild hybrid systems by preventing thermal-related degradation and failures. This is particularly crucial for components such as batteries and power electronics, which are sensitive to temperature fluctuations.

Another key objective is to improve the overall performance of mild hybrid vehicles. Effective thermal management can contribute to better acceleration, smoother operation of the start-stop system, and more efficient regenerative braking. Additionally, there is a growing focus on reducing the complexity and cost of thermal management systems while maintaining their effectiveness. This includes exploring integrated cooling solutions that can serve multiple components and utilizing advanced materials with superior thermal properties.

As the automotive industry continues to push the boundaries of mild hybrid technology, addressing these thermal management challenges becomes increasingly critical. The successful development of efficient, reliable, and cost-effective thermal management solutions will play a pivotal role in the widespread adoption of mild hybrid systems and their contribution to meeting global emissions targets.

The evolution of mild hybrid technology can be traced back to the early 2000s, with initial implementations focusing on simple start-stop functionality. Over time, the technology has progressed to include more advanced features such as regenerative braking, electric torque assist, and electric boost during acceleration. This progression has been driven by increasingly stringent emissions regulations and consumer demand for more fuel-efficient vehicles.

As mild hybrid systems have become more sophisticated, thermal management has emerged as a critical challenge. The integration of electrical components with traditional internal combustion engines introduces new heat sources and thermal loads that must be carefully managed to ensure optimal performance, efficiency, and longevity of the system. Effective thermal management is essential for maintaining the temperature of various components within their optimal operating ranges, including the battery pack, electric motor, power electronics, and the internal combustion engine itself.

The primary objectives of addressing thermal management challenges in mild hybrid systems are multifaceted. Firstly, there is a need to optimize the overall system efficiency by minimizing energy losses due to heat generation and dissipation. This involves developing innovative cooling strategies that can effectively manage the thermal loads of both the electrical and mechanical components. Secondly, engineers aim to enhance the durability and reliability of mild hybrid systems by preventing thermal-related degradation and failures. This is particularly crucial for components such as batteries and power electronics, which are sensitive to temperature fluctuations.

Another key objective is to improve the overall performance of mild hybrid vehicles. Effective thermal management can contribute to better acceleration, smoother operation of the start-stop system, and more efficient regenerative braking. Additionally, there is a growing focus on reducing the complexity and cost of thermal management systems while maintaining their effectiveness. This includes exploring integrated cooling solutions that can serve multiple components and utilizing advanced materials with superior thermal properties.

As the automotive industry continues to push the boundaries of mild hybrid technology, addressing these thermal management challenges becomes increasingly critical. The successful development of efficient, reliable, and cost-effective thermal management solutions will play a pivotal role in the widespread adoption of mild hybrid systems and their contribution to meeting global emissions targets.

Market Analysis for Mild Hybrid Vehicles

The mild hybrid vehicle market has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent emissions regulations worldwide. This segment bridges the gap between conventional internal combustion engine vehicles and full hybrid or electric vehicles, offering improved fuel efficiency and reduced emissions at a more accessible price point.

Market demand for mild hybrid vehicles has been particularly strong in Europe and Asia, with major automotive markets such as Germany, France, China, and Japan leading the adoption. In Europe, the market share of mild hybrid vehicles has been steadily increasing, with some estimates suggesting that they could account for up to 30% of new car sales in the region by 2025. The Asian market, especially China and India, is also showing rapid growth due to government incentives and growing consumer awareness of environmental issues.

The global mild hybrid vehicle market size was valued at approximately $20 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 10% from 2021 to 2026. This growth is attributed to factors such as increasing fuel efficiency requirements, lower cost compared to full hybrids, and the ability to retrofit existing vehicle platforms with mild hybrid technology.

Key market drivers include tightening emissions standards, such as the EU's target to reduce CO2 emissions from new cars by 37.5% by 2030 compared to 2021 levels. Additionally, the cost-effectiveness of mild hybrid systems compared to full hybrid or electric powertrains makes them an attractive option for both manufacturers and consumers. The technology allows automakers to meet emissions targets without significant changes to their existing production lines or vehicle architectures.

However, the market faces challenges, including competition from full hybrid and electric vehicles, which offer greater fuel efficiency and emission reductions. The ongoing global semiconductor shortage has also impacted production and sales of mild hybrid vehicles, as these systems rely heavily on electronic components.

In terms of vehicle segments, mild hybrid technology has been widely adopted in mid-size and luxury vehicles, with increasing penetration in compact and SUV segments. The commercial vehicle sector is also beginning to explore mild hybrid solutions, particularly for light-duty trucks and vans operating in urban environments.

Looking ahead, the mild hybrid vehicle market is expected to continue its growth trajectory, with technological advancements focusing on improving system efficiency, reducing costs, and addressing thermal management challenges. As the automotive industry transitions towards electrification, mild hybrid technology is likely to play a crucial role in the medium term, offering a balance between environmental performance and cost-effectiveness.

Market demand for mild hybrid vehicles has been particularly strong in Europe and Asia, with major automotive markets such as Germany, France, China, and Japan leading the adoption. In Europe, the market share of mild hybrid vehicles has been steadily increasing, with some estimates suggesting that they could account for up to 30% of new car sales in the region by 2025. The Asian market, especially China and India, is also showing rapid growth due to government incentives and growing consumer awareness of environmental issues.

The global mild hybrid vehicle market size was valued at approximately $20 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 10% from 2021 to 2026. This growth is attributed to factors such as increasing fuel efficiency requirements, lower cost compared to full hybrids, and the ability to retrofit existing vehicle platforms with mild hybrid technology.

Key market drivers include tightening emissions standards, such as the EU's target to reduce CO2 emissions from new cars by 37.5% by 2030 compared to 2021 levels. Additionally, the cost-effectiveness of mild hybrid systems compared to full hybrid or electric powertrains makes them an attractive option for both manufacturers and consumers. The technology allows automakers to meet emissions targets without significant changes to their existing production lines or vehicle architectures.

However, the market faces challenges, including competition from full hybrid and electric vehicles, which offer greater fuel efficiency and emission reductions. The ongoing global semiconductor shortage has also impacted production and sales of mild hybrid vehicles, as these systems rely heavily on electronic components.

In terms of vehicle segments, mild hybrid technology has been widely adopted in mid-size and luxury vehicles, with increasing penetration in compact and SUV segments. The commercial vehicle sector is also beginning to explore mild hybrid solutions, particularly for light-duty trucks and vans operating in urban environments.

Looking ahead, the mild hybrid vehicle market is expected to continue its growth trajectory, with technological advancements focusing on improving system efficiency, reducing costs, and addressing thermal management challenges. As the automotive industry transitions towards electrification, mild hybrid technology is likely to play a crucial role in the medium term, offering a balance between environmental performance and cost-effectiveness.

Current Challenges in Mild Hybrid Thermal Management

Mild hybrid systems, while offering significant improvements in fuel efficiency and emissions reduction, face several thermal management challenges that need to be addressed for optimal performance and longevity. One of the primary issues is the increased heat generation from the electric motor and power electronics, which adds to the overall thermal load of the vehicle. This additional heat must be effectively managed to prevent overheating and ensure the system's reliability.

The integration of the electric components with the internal combustion engine (ICE) creates a complex thermal environment. The electric motor, typically positioned between the engine and transmission, is subject to heat from both the ICE and its own operation. This placement complicates the cooling strategy, as traditional engine cooling systems may not be sufficient to handle the combined thermal load.

Battery thermal management is another critical challenge in mild hybrid systems. The lithium-ion batteries used in these vehicles are sensitive to temperature fluctuations, with performance and lifespan significantly affected by both high and low temperatures. Maintaining the battery pack within an optimal temperature range is crucial for ensuring consistent performance and preventing premature degradation.

The stop-start functionality of mild hybrid systems introduces additional thermal management complexities. Frequent engine shutoffs and restarts can lead to temperature fluctuations in the engine and cooling system, potentially affecting the overall thermal balance of the vehicle. This cyclic operation requires a more sophisticated thermal management approach to maintain stable temperatures across all components.

Power electronics, including inverters and DC-DC converters, also contribute to the thermal management challenge. These components generate substantial heat during operation and require efficient cooling to maintain their performance and reliability. The compact nature of mild hybrid systems often limits the space available for traditional cooling solutions, necessitating innovative approaches to thermal management.

Another significant challenge is the need for a more intelligent and adaptive thermal management system. The varying operating conditions of mild hybrid vehicles, from urban stop-and-go traffic to highway cruising, demand a dynamic approach to thermal management. This requires advanced control algorithms and sensors to optimize the distribution of thermal energy across different vehicle systems.

Lastly, the pursuit of improved fuel efficiency in mild hybrid systems can sometimes conflict with effective thermal management. For instance, strategies to reduce parasitic losses from the cooling system may inadvertently compromise the system's ability to manage heat effectively under all operating conditions. Striking the right balance between efficiency and thermal performance remains an ongoing challenge for engineers and designers in the automotive industry.

The integration of the electric components with the internal combustion engine (ICE) creates a complex thermal environment. The electric motor, typically positioned between the engine and transmission, is subject to heat from both the ICE and its own operation. This placement complicates the cooling strategy, as traditional engine cooling systems may not be sufficient to handle the combined thermal load.

Battery thermal management is another critical challenge in mild hybrid systems. The lithium-ion batteries used in these vehicles are sensitive to temperature fluctuations, with performance and lifespan significantly affected by both high and low temperatures. Maintaining the battery pack within an optimal temperature range is crucial for ensuring consistent performance and preventing premature degradation.

The stop-start functionality of mild hybrid systems introduces additional thermal management complexities. Frequent engine shutoffs and restarts can lead to temperature fluctuations in the engine and cooling system, potentially affecting the overall thermal balance of the vehicle. This cyclic operation requires a more sophisticated thermal management approach to maintain stable temperatures across all components.

Power electronics, including inverters and DC-DC converters, also contribute to the thermal management challenge. These components generate substantial heat during operation and require efficient cooling to maintain their performance and reliability. The compact nature of mild hybrid systems often limits the space available for traditional cooling solutions, necessitating innovative approaches to thermal management.

Another significant challenge is the need for a more intelligent and adaptive thermal management system. The varying operating conditions of mild hybrid vehicles, from urban stop-and-go traffic to highway cruising, demand a dynamic approach to thermal management. This requires advanced control algorithms and sensors to optimize the distribution of thermal energy across different vehicle systems.

Lastly, the pursuit of improved fuel efficiency in mild hybrid systems can sometimes conflict with effective thermal management. For instance, strategies to reduce parasitic losses from the cooling system may inadvertently compromise the system's ability to manage heat effectively under all operating conditions. Striking the right balance between efficiency and thermal performance remains an ongoing challenge for engineers and designers in the automotive industry.

Existing Thermal Management Solutions for Mild Hybrids

01 Thermal management system integration

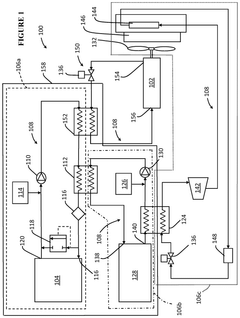

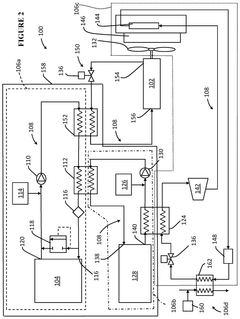

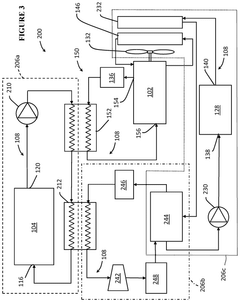

Mild hybrid systems incorporate integrated thermal management solutions to optimize the performance and efficiency of various components. These systems often combine cooling for the engine, electric motor, battery, and power electronics, ensuring optimal operating temperatures across the powertrain.- Thermal management systems for mild hybrid vehicles: Advanced thermal management systems are designed for mild hybrid vehicles to optimize the performance and efficiency of both the internal combustion engine and the electric components. These systems often include intelligent cooling circuits, heat exchangers, and temperature sensors to maintain optimal operating temperatures for various components, including the battery, electric motor, and power electronics.

- Battery thermal management in mild hybrid systems: Effective battery thermal management is crucial in mild hybrid systems to ensure optimal performance, longevity, and safety of the battery pack. This may involve active cooling or heating systems, insulation, and temperature monitoring to maintain the battery within its ideal operating temperature range under various driving conditions and ambient temperatures.

- Integrated cooling systems for engine and electric components: Mild hybrid systems often employ integrated cooling systems that manage the thermal needs of both the internal combustion engine and the electric components. These systems may use shared coolant circuits, intelligent flow control valves, and heat recovery mechanisms to efficiently distribute and utilize thermal energy across the vehicle's powertrain.

- Heat recovery and energy efficiency in mild hybrid thermal management: Advanced thermal management systems in mild hybrid vehicles focus on heat recovery and energy efficiency. This may include using waste heat from the engine to warm up the battery or cabin, implementing thermal storage solutions, and optimizing the use of electric heating elements to reduce the load on the internal combustion engine during cold starts.

- Control strategies for mild hybrid thermal management: Sophisticated control strategies are employed in mild hybrid thermal management systems to balance the thermal needs of various components while maximizing overall system efficiency. These strategies may involve predictive algorithms, real-time temperature monitoring, and adaptive control based on driving conditions, battery state of charge, and ambient temperature.

02 Battery thermal management

Effective thermal management of the battery is crucial in mild hybrid systems. This involves controlling the battery temperature within an optimal range to enhance performance, longevity, and safety. Solutions may include liquid cooling systems, air cooling, or phase change materials.Expand Specific Solutions03 Waste heat recovery and utilization

Mild hybrid systems often incorporate waste heat recovery mechanisms to improve overall system efficiency. This may involve capturing heat from the engine or exhaust system and using it for cabin heating, battery warming, or converting it to electrical energy through thermoelectric generators.Expand Specific Solutions04 Intelligent cooling control strategies

Advanced control strategies are employed to manage the thermal aspects of mild hybrid systems. These may include predictive algorithms, real-time temperature monitoring, and adaptive cooling strategies to optimize energy usage and system performance under various driving conditions.Expand Specific Solutions05 Integrated HVAC and powertrain cooling

Mild hybrid systems often feature integrated cooling solutions that combine the vehicle's HVAC system with powertrain cooling. This approach can improve overall system efficiency, reduce component count, and optimize thermal management across various subsystems.Expand Specific Solutions

Key Players in Mild Hybrid Thermal Technology

The mild hybrid system thermal management sector is in a growth phase, with increasing market size driven by the automotive industry's shift towards electrification. The technology is maturing rapidly, with major players like Valeo Thermal Systems, Geely, and FAW investing heavily in research and development. Companies such as BYD, Changan, and Nissan are also making significant strides in this field. The competitive landscape is diverse, featuring traditional automakers, suppliers, and new entrants, all vying for market share in this emerging technology space. As the industry evolves, collaborations and partnerships between OEMs and technology providers are becoming increasingly common to accelerate innovation and market penetration.

Valeo Thermal Systems Japan Corp.

Technical Solution: Valeo has developed an advanced thermal management system for mild hybrid vehicles that integrates multiple cooling circuits. Their solution utilizes a centralized cooling module with smart valve control to optimize coolant flow between the engine, battery, and power electronics[1]. The system incorporates a low-temperature circuit for the battery and power electronics, and a high-temperature circuit for the engine. Valeo's thermal management system also features an intelligent heat pump that can recover waste heat from the powertrain to improve overall system efficiency[2]. Additionally, they have implemented predictive thermal management algorithms that anticipate cooling needs based on driving conditions and route information[3].

Strengths: Integrated approach, efficient heat recovery, and predictive control. Weaknesses: Complexity may lead to higher costs and potential reliability issues in the long term.

Zhejiang Geely Holding Group Co., Ltd.

Technical Solution: Geely has developed a comprehensive thermal management solution for their mild hybrid vehicles, focusing on optimizing the interaction between the internal combustion engine and the electric components. Their system utilizes a split cooling architecture with separate circuits for the engine and the electric powertrain[4]. Geely's approach incorporates a smart coolant distribution system that dynamically adjusts flow rates based on real-time thermal loads. The company has also implemented advanced thermal materials in their battery packs to enhance heat dissipation and maintain optimal operating temperatures[5]. Furthermore, Geely's thermal management system includes an innovative cabin preconditioning feature that utilizes waste heat from the powertrain to improve energy efficiency and passenger comfort[6].

Strengths: Efficient use of waste heat, dynamic thermal load management. Weaknesses: May require more complex control systems, potentially increasing manufacturing costs.

Innovative Approaches in Mild Hybrid Cooling

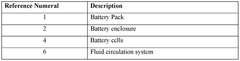

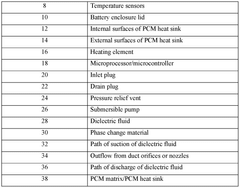

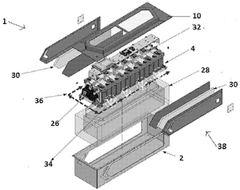

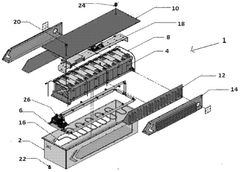

A hybrid system for thermal management of battery pack with immersion and phase change techniques

PatentWO2025046616A1

Innovation

- A hybrid system combining immersion cooling with a dielectric fluid and phase change techniques, utilizing a battery enclosure with a fluid circulation system, a heat sink integrated with phase change material, an immersed heating system, and an external airflow system, controlled by a microcontroller to manage temperature effectively.

Hybrid thermal management system

PatentPendingUS20240347813A1

Innovation

- A thermal management system utilizing three interconnected cooling circuits: a dielectric thermal fluid circuit for batteries, an electrically conductive fluid circuit for electronic units, and a vapor-compression refrigerant circuit, allowing for efficient heat transfer and management without the need for a dedicated radiator, thereby reducing component count and space requirements.

Environmental Impact and Regulations

The environmental impact and regulatory landscape surrounding mild hybrid system thermal management are becoming increasingly significant as the automotive industry shifts towards more sustainable technologies. Mild hybrid systems, while offering improved fuel efficiency and reduced emissions compared to conventional internal combustion engines, still face challenges in terms of their environmental footprint and compliance with evolving regulations.

One of the primary environmental concerns associated with mild hybrid system thermal management is the use of refrigerants in cooling systems. Many current systems rely on hydrofluorocarbon (HFC) refrigerants, which have high global warming potential (GWP). As a result, there is growing pressure from regulatory bodies to transition to low-GWP alternatives, such as R-1234yf or CO2-based systems. This shift necessitates redesigning thermal management systems to accommodate these new refrigerants while maintaining optimal performance.

Energy efficiency is another crucial aspect of environmental impact. Mild hybrid systems must balance the thermal management needs of both the internal combustion engine and the electric components. Inefficient thermal management can lead to increased fuel consumption and higher emissions, negating some of the environmental benefits of hybrid technology. Consequently, regulations are becoming more stringent regarding the overall efficiency of hybrid vehicles, pushing manufacturers to innovate in thermal management solutions.

The disposal and recycling of components used in mild hybrid thermal management systems also face increasing scrutiny. Coolants, batteries, and electronic components all have potential environmental impacts at the end of their lifecycle. Regulations are evolving to address these concerns, with some jurisdictions implementing extended producer responsibility (EPR) programs that require manufacturers to manage the entire lifecycle of their products, including disposal and recycling.

Water consumption in manufacturing and maintenance processes is another environmental consideration. As water scarcity becomes a more pressing global issue, regulations are beginning to address water usage in automotive production and servicing. This includes the water required for cooling systems in mild hybrid vehicles, pushing for more water-efficient designs and processes.

Noise pollution regulations are also impacting thermal management system design. Electric components in mild hybrid systems can produce high-frequency noise, which may be more noticeable due to the reduced engine noise. As a result, thermal management systems must not only be efficient but also operate quietly to comply with increasingly strict noise regulations in urban areas.

As the automotive industry continues to evolve, the regulatory landscape for mild hybrid system thermal management is likely to become more complex and demanding. Manufacturers will need to stay ahead of these changes, investing in research and development to create innovative solutions that not only meet current standards but also anticipate future environmental regulations.

One of the primary environmental concerns associated with mild hybrid system thermal management is the use of refrigerants in cooling systems. Many current systems rely on hydrofluorocarbon (HFC) refrigerants, which have high global warming potential (GWP). As a result, there is growing pressure from regulatory bodies to transition to low-GWP alternatives, such as R-1234yf or CO2-based systems. This shift necessitates redesigning thermal management systems to accommodate these new refrigerants while maintaining optimal performance.

Energy efficiency is another crucial aspect of environmental impact. Mild hybrid systems must balance the thermal management needs of both the internal combustion engine and the electric components. Inefficient thermal management can lead to increased fuel consumption and higher emissions, negating some of the environmental benefits of hybrid technology. Consequently, regulations are becoming more stringent regarding the overall efficiency of hybrid vehicles, pushing manufacturers to innovate in thermal management solutions.

The disposal and recycling of components used in mild hybrid thermal management systems also face increasing scrutiny. Coolants, batteries, and electronic components all have potential environmental impacts at the end of their lifecycle. Regulations are evolving to address these concerns, with some jurisdictions implementing extended producer responsibility (EPR) programs that require manufacturers to manage the entire lifecycle of their products, including disposal and recycling.

Water consumption in manufacturing and maintenance processes is another environmental consideration. As water scarcity becomes a more pressing global issue, regulations are beginning to address water usage in automotive production and servicing. This includes the water required for cooling systems in mild hybrid vehicles, pushing for more water-efficient designs and processes.

Noise pollution regulations are also impacting thermal management system design. Electric components in mild hybrid systems can produce high-frequency noise, which may be more noticeable due to the reduced engine noise. As a result, thermal management systems must not only be efficient but also operate quietly to comply with increasingly strict noise regulations in urban areas.

As the automotive industry continues to evolve, the regulatory landscape for mild hybrid system thermal management is likely to become more complex and demanding. Manufacturers will need to stay ahead of these changes, investing in research and development to create innovative solutions that not only meet current standards but also anticipate future environmental regulations.

Cost-Benefit Analysis of Advanced Thermal Management

The cost-benefit analysis of advanced thermal management systems in mild hybrid vehicles is a critical consideration for automotive manufacturers and suppliers. These systems aim to optimize the performance and efficiency of hybrid powertrains while managing the thermal challenges associated with electrification.

Advanced thermal management solutions often involve the integration of sophisticated cooling circuits, heat exchangers, and intelligent control systems. While these technologies can significantly improve vehicle efficiency and performance, they also come with increased complexity and cost. The primary benefits of advanced thermal management include improved fuel economy, reduced emissions, enhanced battery life, and increased overall system reliability.

One of the key cost considerations is the additional hardware required for advanced thermal management. This may include dedicated cooling loops for the electric motor and power electronics, as well as more complex radiators and pumps. The integration of these components can lead to higher material and manufacturing costs. Additionally, the development and calibration of advanced control algorithms for thermal management systems represent a significant investment in engineering resources.

However, these costs must be weighed against the potential benefits. Improved thermal management can lead to substantial gains in fuel efficiency, potentially reducing fuel consumption by 3-5% in mild hybrid systems. This translates to direct cost savings for consumers and helps manufacturers meet increasingly stringent emissions regulations. Furthermore, effective thermal management can extend the lifespan of expensive components such as batteries and power electronics, reducing long-term warranty and replacement costs.

Another important factor in the cost-benefit analysis is the potential for weight reduction. Advanced thermal management systems may allow for downsizing of certain components, such as the internal combustion engine, due to improved overall system efficiency. This weight reduction can further contribute to fuel economy improvements and may offset some of the additional costs associated with the thermal management system.

The scalability of advanced thermal management solutions across different vehicle platforms is also a crucial consideration. While initial development costs may be high, the ability to adapt these systems to multiple vehicle models can significantly improve the return on investment. This scalability can lead to economies of scale in production, potentially reducing per-unit costs over time.

In conclusion, while advanced thermal management systems for mild hybrid vehicles represent a significant upfront investment, the long-term benefits in terms of improved efficiency, reduced emissions, and enhanced component longevity can justify the costs. As the technology matures and production volumes increase, the cost-benefit ratio is likely to improve further, making advanced thermal management an increasingly attractive option for automotive manufacturers.

Advanced thermal management solutions often involve the integration of sophisticated cooling circuits, heat exchangers, and intelligent control systems. While these technologies can significantly improve vehicle efficiency and performance, they also come with increased complexity and cost. The primary benefits of advanced thermal management include improved fuel economy, reduced emissions, enhanced battery life, and increased overall system reliability.

One of the key cost considerations is the additional hardware required for advanced thermal management. This may include dedicated cooling loops for the electric motor and power electronics, as well as more complex radiators and pumps. The integration of these components can lead to higher material and manufacturing costs. Additionally, the development and calibration of advanced control algorithms for thermal management systems represent a significant investment in engineering resources.

However, these costs must be weighed against the potential benefits. Improved thermal management can lead to substantial gains in fuel efficiency, potentially reducing fuel consumption by 3-5% in mild hybrid systems. This translates to direct cost savings for consumers and helps manufacturers meet increasingly stringent emissions regulations. Furthermore, effective thermal management can extend the lifespan of expensive components such as batteries and power electronics, reducing long-term warranty and replacement costs.

Another important factor in the cost-benefit analysis is the potential for weight reduction. Advanced thermal management systems may allow for downsizing of certain components, such as the internal combustion engine, due to improved overall system efficiency. This weight reduction can further contribute to fuel economy improvements and may offset some of the additional costs associated with the thermal management system.

The scalability of advanced thermal management solutions across different vehicle platforms is also a crucial consideration. While initial development costs may be high, the ability to adapt these systems to multiple vehicle models can significantly improve the return on investment. This scalability can lead to economies of scale in production, potentially reducing per-unit costs over time.

In conclusion, while advanced thermal management systems for mild hybrid vehicles represent a significant upfront investment, the long-term benefits in terms of improved efficiency, reduced emissions, and enhanced component longevity can justify the costs. As the technology matures and production volumes increase, the cost-benefit ratio is likely to improve further, making advanced thermal management an increasingly attractive option for automotive manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!