The feasibility of mild hybrid adoption in heavy-duty trucks

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Tech in HD Trucks: Background and Objectives

Mild hybrid technology has emerged as a promising solution to address the growing environmental concerns and stringent emissions regulations in the heavy-duty truck industry. This technology combines a conventional internal combustion engine with an electric motor and a battery, offering improved fuel efficiency and reduced emissions without the complexity of full hybrid systems.

The evolution of mild hybrid technology in heavy-duty trucks can be traced back to the early 2000s when automotive manufacturers began exploring ways to enhance fuel economy in larger vehicles. Initially, the focus was on passenger cars and light-duty vehicles, but as the technology matured, its potential applications in the heavy-duty sector became apparent.

The primary objective of adopting mild hybrid technology in heavy-duty trucks is to achieve a balance between environmental sustainability and operational efficiency. By integrating electric assistance into traditional powertrains, manufacturers aim to reduce fuel consumption and emissions while maintaining the power and performance required for heavy-duty applications.

One of the key drivers behind the development of mild hybrid systems for heavy-duty trucks is the increasingly stringent emissions regulations worldwide. Governments and regulatory bodies are imposing stricter limits on greenhouse gas emissions and fuel consumption, compelling truck manufacturers to explore innovative solutions to meet these standards.

The mild hybrid approach offers several advantages over full hybrid or pure electric systems in the context of heavy-duty trucks. It provides a cost-effective solution that can be implemented without significant changes to existing vehicle architectures. This allows for a smoother transition towards electrification while leveraging the established infrastructure and supply chains of conventional powertrains.

From a technical perspective, mild hybrid systems in heavy-duty trucks typically employ a 48-volt electrical system, which offers a good balance between power output and cost. This voltage level allows for the integration of various electrical components, such as electric motors, batteries, and power electronics, without requiring extensive modifications to the vehicle's electrical architecture.

The adoption of mild hybrid technology in heavy-duty trucks also aligns with the industry's broader goals of improving overall vehicle efficiency and reducing total cost of ownership for fleet operators. By recuperating energy during braking and providing electric assist during acceleration, mild hybrid systems can significantly reduce fuel consumption, particularly in urban and stop-and-go driving conditions.

As the technology continues to evolve, researchers and engineers are exploring advanced control strategies and system optimizations to maximize the benefits of mild hybridization in heavy-duty applications. This includes the development of intelligent power management algorithms, improved energy storage solutions, and enhanced integration with other vehicle systems.

The evolution of mild hybrid technology in heavy-duty trucks can be traced back to the early 2000s when automotive manufacturers began exploring ways to enhance fuel economy in larger vehicles. Initially, the focus was on passenger cars and light-duty vehicles, but as the technology matured, its potential applications in the heavy-duty sector became apparent.

The primary objective of adopting mild hybrid technology in heavy-duty trucks is to achieve a balance between environmental sustainability and operational efficiency. By integrating electric assistance into traditional powertrains, manufacturers aim to reduce fuel consumption and emissions while maintaining the power and performance required for heavy-duty applications.

One of the key drivers behind the development of mild hybrid systems for heavy-duty trucks is the increasingly stringent emissions regulations worldwide. Governments and regulatory bodies are imposing stricter limits on greenhouse gas emissions and fuel consumption, compelling truck manufacturers to explore innovative solutions to meet these standards.

The mild hybrid approach offers several advantages over full hybrid or pure electric systems in the context of heavy-duty trucks. It provides a cost-effective solution that can be implemented without significant changes to existing vehicle architectures. This allows for a smoother transition towards electrification while leveraging the established infrastructure and supply chains of conventional powertrains.

From a technical perspective, mild hybrid systems in heavy-duty trucks typically employ a 48-volt electrical system, which offers a good balance between power output and cost. This voltage level allows for the integration of various electrical components, such as electric motors, batteries, and power electronics, without requiring extensive modifications to the vehicle's electrical architecture.

The adoption of mild hybrid technology in heavy-duty trucks also aligns with the industry's broader goals of improving overall vehicle efficiency and reducing total cost of ownership for fleet operators. By recuperating energy during braking and providing electric assist during acceleration, mild hybrid systems can significantly reduce fuel consumption, particularly in urban and stop-and-go driving conditions.

As the technology continues to evolve, researchers and engineers are exploring advanced control strategies and system optimizations to maximize the benefits of mild hybridization in heavy-duty applications. This includes the development of intelligent power management algorithms, improved energy storage solutions, and enhanced integration with other vehicle systems.

Market Analysis for Mild Hybrid HD Trucks

The market for mild hybrid heavy-duty trucks is experiencing significant growth, driven by increasing environmental regulations and the need for improved fuel efficiency in the transportation sector. As governments worldwide implement stricter emissions standards, fleet operators are seeking cost-effective solutions to reduce their carbon footprint and operational expenses.

The global heavy-duty truck market is projected to reach a substantial value in the coming years, with mild hybrid technology poised to capture a growing share. This technology offers a balance between performance improvements and cost considerations, making it an attractive option for fleet operators looking to transition towards more sustainable vehicles without the high initial investment associated with full electric or hydrogen fuel cell trucks.

Key market drivers include the potential for fuel savings, which can range from 5% to 15% depending on the specific mild hybrid system and driving conditions. This translates to significant cost reductions for fleet operators, especially considering the high annual mileage of heavy-duty trucks. Additionally, mild hybrid systems can help reduce maintenance costs by optimizing engine operation and reducing wear on components such as brakes through regenerative braking systems.

The market for mild hybrid heavy-duty trucks is segmented by vehicle type, including long-haul trucks, regional delivery trucks, and vocational vehicles. Long-haul trucks are expected to see the highest adoption rates due to their high mileage and potential for fuel savings. Regional delivery and vocational vehicles may also benefit from mild hybrid technology, particularly in urban environments where start-stop operations are frequent.

Geographically, Europe and North America are leading the adoption of mild hybrid technology in heavy-duty trucks, driven by stringent emissions regulations and government incentives. Asia-Pacific is expected to show rapid growth in the coming years, particularly in countries like China and India, where urbanization and e-commerce are driving demand for more efficient transportation solutions.

Major truck manufacturers are investing heavily in mild hybrid technology, recognizing its potential as a stepping stone towards full electrification. This has led to increased competition and innovation in the market, with companies developing proprietary systems or partnering with technology suppliers to gain a competitive edge.

Despite the promising outlook, challenges remain in the widespread adoption of mild hybrid technology in heavy-duty trucks. These include the need for standardization of components, concerns about system reliability and longevity, and the requirement for specialized maintenance and repair skills. However, as the technology matures and economies of scale are achieved, these barriers are expected to diminish, further accelerating market growth.

The global heavy-duty truck market is projected to reach a substantial value in the coming years, with mild hybrid technology poised to capture a growing share. This technology offers a balance between performance improvements and cost considerations, making it an attractive option for fleet operators looking to transition towards more sustainable vehicles without the high initial investment associated with full electric or hydrogen fuel cell trucks.

Key market drivers include the potential for fuel savings, which can range from 5% to 15% depending on the specific mild hybrid system and driving conditions. This translates to significant cost reductions for fleet operators, especially considering the high annual mileage of heavy-duty trucks. Additionally, mild hybrid systems can help reduce maintenance costs by optimizing engine operation and reducing wear on components such as brakes through regenerative braking systems.

The market for mild hybrid heavy-duty trucks is segmented by vehicle type, including long-haul trucks, regional delivery trucks, and vocational vehicles. Long-haul trucks are expected to see the highest adoption rates due to their high mileage and potential for fuel savings. Regional delivery and vocational vehicles may also benefit from mild hybrid technology, particularly in urban environments where start-stop operations are frequent.

Geographically, Europe and North America are leading the adoption of mild hybrid technology in heavy-duty trucks, driven by stringent emissions regulations and government incentives. Asia-Pacific is expected to show rapid growth in the coming years, particularly in countries like China and India, where urbanization and e-commerce are driving demand for more efficient transportation solutions.

Major truck manufacturers are investing heavily in mild hybrid technology, recognizing its potential as a stepping stone towards full electrification. This has led to increased competition and innovation in the market, with companies developing proprietary systems or partnering with technology suppliers to gain a competitive edge.

Despite the promising outlook, challenges remain in the widespread adoption of mild hybrid technology in heavy-duty trucks. These include the need for standardization of components, concerns about system reliability and longevity, and the requirement for specialized maintenance and repair skills. However, as the technology matures and economies of scale are achieved, these barriers are expected to diminish, further accelerating market growth.

Current Challenges in Mild Hybrid HD Truck Implementation

The implementation of mild hybrid technology in heavy-duty trucks faces several significant challenges that need to be addressed for widespread adoption. One of the primary obstacles is the integration of hybrid systems into existing truck designs. Heavy-duty trucks have complex powertrains and limited space for additional components, making it difficult to incorporate hybrid elements without compromising cargo capacity or vehicle performance.

Another major challenge is the cost-effectiveness of mild hybrid systems for heavy-duty applications. While the technology has shown promise in passenger vehicles, the return on investment for truck operators is less clear. The initial cost of hybrid components, such as electric motors and batteries, can be substantial, and the fuel savings may not offset these expenses quickly enough in the heavy-duty sector, where profit margins are often tight.

The durability and reliability of mild hybrid systems in the demanding environment of heavy-duty trucking also pose significant concerns. Trucks operate under extreme conditions, including heavy loads, long distances, and varied terrains. Ensuring that hybrid components can withstand these rigors over the long operational life of a truck is crucial for adoption.

Battery technology presents another set of challenges. Current battery systems may not provide sufficient power density or longevity for heavy-duty applications. The added weight of batteries can reduce payload capacity, a critical factor for freight operators. Additionally, the charging infrastructure for large fleets of hybrid trucks is not yet widely available, potentially limiting operational flexibility.

Regulatory uncertainties surrounding emissions standards and incentives for hybrid technology in the heavy-duty sector create hesitation among manufacturers and fleet operators. Without clear long-term policies, investing in mild hybrid technology may be perceived as risky.

The complexity of mild hybrid systems also raises concerns about maintenance and repair. Truck operators and service centers need specialized training and equipment to handle these advanced powertrains, which can increase operational costs and downtime.

Lastly, the diverse nature of heavy-duty truck applications, from long-haul to urban delivery, makes it challenging to develop a one-size-fits-all mild hybrid solution. Different use cases may require varying levels of hybridization, complicating the design and manufacturing processes for truck makers.

Another major challenge is the cost-effectiveness of mild hybrid systems for heavy-duty applications. While the technology has shown promise in passenger vehicles, the return on investment for truck operators is less clear. The initial cost of hybrid components, such as electric motors and batteries, can be substantial, and the fuel savings may not offset these expenses quickly enough in the heavy-duty sector, where profit margins are often tight.

The durability and reliability of mild hybrid systems in the demanding environment of heavy-duty trucking also pose significant concerns. Trucks operate under extreme conditions, including heavy loads, long distances, and varied terrains. Ensuring that hybrid components can withstand these rigors over the long operational life of a truck is crucial for adoption.

Battery technology presents another set of challenges. Current battery systems may not provide sufficient power density or longevity for heavy-duty applications. The added weight of batteries can reduce payload capacity, a critical factor for freight operators. Additionally, the charging infrastructure for large fleets of hybrid trucks is not yet widely available, potentially limiting operational flexibility.

Regulatory uncertainties surrounding emissions standards and incentives for hybrid technology in the heavy-duty sector create hesitation among manufacturers and fleet operators. Without clear long-term policies, investing in mild hybrid technology may be perceived as risky.

The complexity of mild hybrid systems also raises concerns about maintenance and repair. Truck operators and service centers need specialized training and equipment to handle these advanced powertrains, which can increase operational costs and downtime.

Lastly, the diverse nature of heavy-duty truck applications, from long-haul to urban delivery, makes it challenging to develop a one-size-fits-all mild hybrid solution. Different use cases may require varying levels of hybridization, complicating the design and manufacturing processes for truck makers.

Existing Mild Hybrid Solutions for HD Trucks

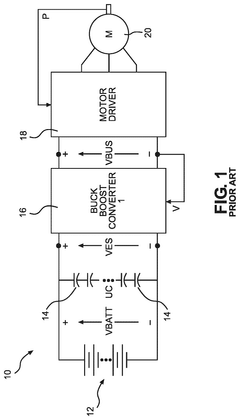

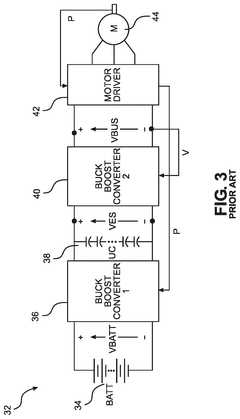

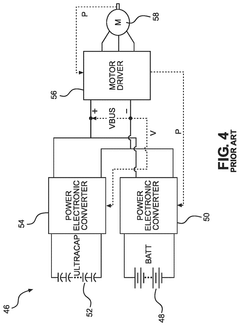

01 Mild hybrid system architecture

Mild hybrid systems typically integrate an electric motor/generator with a conventional internal combustion engine. This architecture allows for energy recovery during braking, engine start-stop functionality, and electric assist during acceleration, improving fuel efficiency and reducing emissions without the complexity of full hybrid systems.- Mild hybrid system architecture: Mild hybrid systems integrate an electric motor/generator with a conventional internal combustion engine to improve fuel efficiency and reduce emissions. The system typically includes a small battery pack and can provide functions such as engine start-stop, regenerative braking, and electric assist during acceleration.

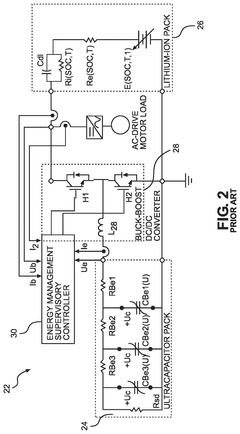

- Energy management strategies: Efficient energy management strategies are crucial for optimizing the performance of mild hybrid systems. These strategies involve controlling the power distribution between the electric motor and the internal combustion engine, managing battery state of charge, and implementing intelligent control algorithms to maximize fuel economy and reduce emissions.

- Integration with transmission systems: Mild hybrid systems can be integrated with various transmission types, including manual, automatic, and continuously variable transmissions (CVT). The integration aims to optimize power delivery, improve shift quality, and enhance overall drivetrain efficiency. Some designs incorporate the electric motor directly into the transmission housing for compact packaging.

- Cost-effectiveness and market feasibility: The feasibility of mild hybrid systems depends on their cost-effectiveness and market acceptance. Factors such as production costs, fuel savings, emission reduction benefits, and consumer demand are considered. Manufacturers are developing affordable mild hybrid solutions that offer a balance between performance improvements and implementation costs.

- Compatibility with existing vehicle platforms: Mild hybrid systems are designed to be compatible with existing vehicle platforms, allowing for easier integration into current production lines. This approach enables automakers to introduce hybrid technology across their model ranges without significant redesigns, facilitating a faster transition to more fuel-efficient vehicles.

02 Energy management strategies

Effective energy management is crucial for mild hybrid system feasibility. This involves optimizing the use of recovered energy, balancing power distribution between the electric motor and combustion engine, and implementing intelligent control strategies to maximize efficiency gains while maintaining performance.Expand Specific Solutions03 Integration with existing vehicle systems

The feasibility of mild hybrid systems depends on their seamless integration with existing vehicle components and systems. This includes adapting the powertrain, modifying the transmission, and ensuring compatibility with the vehicle's electrical system and control units to achieve optimal performance and reliability.Expand Specific Solutions04 Cost-effectiveness and manufacturing considerations

For mild hybrid systems to be feasible, they must be cost-effective to produce and integrate into vehicle manufacturing processes. This involves optimizing component design, leveraging existing production infrastructure, and balancing system complexity with performance benefits to ensure a competitive price point in the market.Expand Specific Solutions05 Regulatory compliance and emissions reduction

The feasibility of mild hybrid systems is closely tied to their ability to meet increasingly stringent emissions regulations. These systems must demonstrate significant reductions in CO2 emissions and fuel consumption while complying with various regional and global environmental standards to ensure market viability.Expand Specific Solutions

Key Players in Mild Hybrid HD Truck Development

The adoption of mild hybrid technology in heavy-duty trucks is in its early stages, with the market showing significant growth potential. The industry is transitioning from traditional powertrains to more fuel-efficient and environmentally friendly solutions. Key players like Cummins, ZF Friedrichshafen, and Volvo Lastvagnar are investing heavily in research and development to advance this technology. The market size is expected to expand rapidly as regulations on emissions become stricter. While the technology is not yet fully mature, companies such as Hyliion and BYD are making strides in developing innovative mild hybrid systems specifically for heavy-duty applications. The competitive landscape is diverse, with both established automotive manufacturers and new entrants vying for market share in this emerging sector.

Hyliion, Inc.

Technical Solution: Hyliion has developed a hybrid electric powertrain system specifically designed for Class 8 commercial vehicles. Their solution integrates an electric motor with an intelligent powertrain controller and a natural gas-powered onboard generator. This system can be installed on new trucks or retrofitted to existing vehicles, providing up to 30% fuel savings and significant emissions reductions[1]. The technology uses regenerative braking to capture energy during deceleration, which is then stored in a battery pack and used to assist the engine during acceleration or climbing hills, reducing the load on the main diesel engine[2].

Strengths: Retrofittable solution, significant fuel savings, and emissions reduction. Weaknesses: Dependency on natural gas infrastructure, potential added weight to the vehicle.

Cummins, Inc.

Technical Solution: Cummins has developed a range of mild hybrid solutions for heavy-duty trucks, including the PowerDrive Hybrid system. This system integrates an electric motor between the engine and transmission, allowing for electric assist during acceleration, regenerative braking, and engine-off coasting. The PowerDrive system can improve fuel efficiency by up to 10% in heavy-duty applications[3]. Cummins also offers a 48V mild hybrid system that can be integrated with their X15 engine, providing additional fuel savings and emissions reductions without significant changes to the existing powertrain architecture[4].

Strengths: Established brand in heavy-duty engines, scalable solutions. Weaknesses: May require significant integration with existing vehicle systems.

Core Innovations in Mild Hybrid Systems for HD Trucks

Supplemental electric drive with primary engine recognition for electric drive controller adaptation and crowdsourced hybrid system customization

PatentWO2019133957A1

Innovation

- A through-the-road hybridization strategy that supplements motive forces with electric drive axles, adapting control strategies using brake-specific fuel consumption (BSFC) data to optimize torque delivery and implement equivalent consumption minimization strategies, allowing for pairing with various fuel-fed engines and enabling over-the-air updates based on crowdsourced insights.

Battery-ultracapacitor hybrid energy storage system architecture for mild-hybrid power systems

PatentPendingUS20250192601A1

Innovation

- A mild-hybrid energy storage system architecture that includes a battery, an ultracapacitor connected in parallel, dedicated pre-charge circuits, and main contactors, along with a control module to independently manage the operation of these components, optimizing energy storage and release for efficient engine starting and operation.

Regulatory Framework for Mild Hybrid HD Trucks

The regulatory framework for mild hybrid heavy-duty trucks is evolving rapidly as governments worldwide seek to reduce emissions and improve fuel efficiency in the transportation sector. In the United States, the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) have jointly established greenhouse gas emissions and fuel efficiency standards for medium- and heavy-duty vehicles. These regulations, known as the Phase 2 standards, set increasingly stringent targets for manufacturers to meet between 2021 and 2027.

Under these standards, mild hybrid systems are recognized as a viable technology to help achieve compliance. The regulations provide manufacturers with flexibility in how they meet the targets, allowing them to choose the most cost-effective technologies for their specific vehicle models. This approach has encouraged the adoption of mild hybrid systems in heavy-duty trucks, as they offer a balance between improved efficiency and manageable implementation costs.

In the European Union, the regulatory landscape is shaped by the European Commission's CO2 emission standards for heavy-duty vehicles. These regulations set specific targets for reducing CO2 emissions from new trucks, with the first set of targets to be met by 2025 and more stringent targets for 2030. The EU regulations also include incentives for zero- and low-emission vehicles, which can indirectly benefit mild hybrid technologies as a stepping stone towards full electrification.

China, another major market for heavy-duty trucks, has implemented its own set of fuel consumption standards for commercial vehicles. The country's Stage 3 fuel consumption standards, which came into effect in 2019, have pushed manufacturers to explore various efficiency-improving technologies, including mild hybridization. The Chinese government has also introduced incentives for new energy vehicles, which may include certain categories of hybrid trucks.

Globally, there is a trend towards harmonization of regulatory frameworks, as evidenced by the United Nations Economic Commission for Europe (UNECE) World Forum for Harmonization of Vehicle Regulations. This forum works to develop uniform technical prescriptions for vehicles, including those related to energy efficiency and environmental performance. Such harmonization efforts can potentially streamline the adoption of mild hybrid technologies across different markets.

However, the regulatory landscape is not without challenges. The complexity of heavy-duty truck operations, with varying load conditions and duty cycles, makes it difficult to establish one-size-fits-all standards. Regulators must balance the need for emissions reductions with the practical realities of the trucking industry. Additionally, the pace of technological advancement in hybrid systems sometimes outstrips the regulatory process, necessitating frequent updates to ensure regulations remain relevant and effective.

Under these standards, mild hybrid systems are recognized as a viable technology to help achieve compliance. The regulations provide manufacturers with flexibility in how they meet the targets, allowing them to choose the most cost-effective technologies for their specific vehicle models. This approach has encouraged the adoption of mild hybrid systems in heavy-duty trucks, as they offer a balance between improved efficiency and manageable implementation costs.

In the European Union, the regulatory landscape is shaped by the European Commission's CO2 emission standards for heavy-duty vehicles. These regulations set specific targets for reducing CO2 emissions from new trucks, with the first set of targets to be met by 2025 and more stringent targets for 2030. The EU regulations also include incentives for zero- and low-emission vehicles, which can indirectly benefit mild hybrid technologies as a stepping stone towards full electrification.

China, another major market for heavy-duty trucks, has implemented its own set of fuel consumption standards for commercial vehicles. The country's Stage 3 fuel consumption standards, which came into effect in 2019, have pushed manufacturers to explore various efficiency-improving technologies, including mild hybridization. The Chinese government has also introduced incentives for new energy vehicles, which may include certain categories of hybrid trucks.

Globally, there is a trend towards harmonization of regulatory frameworks, as evidenced by the United Nations Economic Commission for Europe (UNECE) World Forum for Harmonization of Vehicle Regulations. This forum works to develop uniform technical prescriptions for vehicles, including those related to energy efficiency and environmental performance. Such harmonization efforts can potentially streamline the adoption of mild hybrid technologies across different markets.

However, the regulatory landscape is not without challenges. The complexity of heavy-duty truck operations, with varying load conditions and duty cycles, makes it difficult to establish one-size-fits-all standards. Regulators must balance the need for emissions reductions with the practical realities of the trucking industry. Additionally, the pace of technological advancement in hybrid systems sometimes outstrips the regulatory process, necessitating frequent updates to ensure regulations remain relevant and effective.

Total Cost of Ownership Analysis for Mild Hybrid HD Trucks

The Total Cost of Ownership (TCO) analysis for mild hybrid heavy-duty trucks is a crucial component in evaluating the feasibility of this technology adoption. This analysis encompasses various factors that contribute to the overall cost of owning and operating a mild hybrid truck throughout its lifecycle.

Initial acquisition costs for mild hybrid heavy-duty trucks are typically higher than their conventional counterparts due to the additional components required for the hybrid system. These components include an electric motor, a battery pack, and associated control systems. However, the price premium for mild hybrid technology is generally lower compared to full hybrid or all-electric alternatives, making it a more accessible option for fleet operators.

Fuel consumption is a significant factor in the TCO analysis. Mild hybrid systems offer fuel savings through various mechanisms, such as regenerative braking, engine start-stop functionality, and electric assist during acceleration. The extent of these savings can vary depending on the specific driving conditions and routes. Urban environments with frequent stops and starts tend to yield higher fuel economy improvements compared to long-haul highway driving.

Maintenance costs for mild hybrid trucks may differ from conventional vehicles. While the hybrid system introduces additional components that require maintenance, it can also reduce wear on traditional mechanical parts. For instance, regenerative braking can extend the life of brake pads and rotors. However, specialized training for technicians and potential battery replacements over the vehicle's lifetime should be factored into the maintenance cost calculations.

Insurance costs may be influenced by the adoption of mild hybrid technology. Some insurance providers offer discounts for hybrid vehicles due to their perceived lower risk and environmental benefits. However, the higher initial value of the vehicle may offset these potential savings.

Resale value is another important consideration in the TCO analysis. As the market for mild hybrid heavy-duty trucks evolves, their residual value may differ from conventional trucks. Factors such as battery life, fuel price trends, and environmental regulations can impact the resale value of these vehicles.

Operational benefits, while not direct costs, can influence the overall TCO. Mild hybrid trucks may offer advantages such as improved low-speed maneuverability, quieter operation in urban areas, and potential access to low-emission zones in certain cities. These benefits can translate into operational efficiencies and potential revenue opportunities for fleet operators.

Government incentives and regulations play a significant role in the TCO analysis. Many regions offer tax credits, grants, or other financial incentives for the adoption of hybrid technologies in commercial vehicles. Additionally, increasingly stringent emissions regulations may favor the adoption of mild hybrid systems, potentially offsetting some of the higher initial costs through compliance benefits.

Initial acquisition costs for mild hybrid heavy-duty trucks are typically higher than their conventional counterparts due to the additional components required for the hybrid system. These components include an electric motor, a battery pack, and associated control systems. However, the price premium for mild hybrid technology is generally lower compared to full hybrid or all-electric alternatives, making it a more accessible option for fleet operators.

Fuel consumption is a significant factor in the TCO analysis. Mild hybrid systems offer fuel savings through various mechanisms, such as regenerative braking, engine start-stop functionality, and electric assist during acceleration. The extent of these savings can vary depending on the specific driving conditions and routes. Urban environments with frequent stops and starts tend to yield higher fuel economy improvements compared to long-haul highway driving.

Maintenance costs for mild hybrid trucks may differ from conventional vehicles. While the hybrid system introduces additional components that require maintenance, it can also reduce wear on traditional mechanical parts. For instance, regenerative braking can extend the life of brake pads and rotors. However, specialized training for technicians and potential battery replacements over the vehicle's lifetime should be factored into the maintenance cost calculations.

Insurance costs may be influenced by the adoption of mild hybrid technology. Some insurance providers offer discounts for hybrid vehicles due to their perceived lower risk and environmental benefits. However, the higher initial value of the vehicle may offset these potential savings.

Resale value is another important consideration in the TCO analysis. As the market for mild hybrid heavy-duty trucks evolves, their residual value may differ from conventional trucks. Factors such as battery life, fuel price trends, and environmental regulations can impact the resale value of these vehicles.

Operational benefits, while not direct costs, can influence the overall TCO. Mild hybrid trucks may offer advantages such as improved low-speed maneuverability, quieter operation in urban areas, and potential access to low-emission zones in certain cities. These benefits can translate into operational efficiencies and potential revenue opportunities for fleet operators.

Government incentives and regulations play a significant role in the TCO analysis. Many regions offer tax credits, grants, or other financial incentives for the adoption of hybrid technologies in commercial vehicles. Additionally, increasingly stringent emissions regulations may favor the adoption of mild hybrid systems, potentially offsetting some of the higher initial costs through compliance benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!