Energy-saving potential of mild hybrids in refrigerated transport

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Refrigeration Background and Objectives

Mild hybrid technology has emerged as a promising solution for enhancing energy efficiency in various transportation sectors, including refrigerated transport. This innovative approach combines conventional internal combustion engines with electric propulsion systems, offering a balance between performance and fuel economy. The evolution of mild hybrid systems in refrigerated transport has been driven by the increasing demand for sustainable logistics solutions and stricter environmental regulations.

The primary objective of implementing mild hybrid technology in refrigerated transport is to significantly reduce fuel consumption and greenhouse gas emissions while maintaining optimal temperature control for perishable goods. This technology aims to address the unique challenges faced by the cold chain industry, where energy-intensive refrigeration units are essential for preserving product quality during transit.

The development of mild hybrid systems for refrigerated transport has been influenced by advancements in automotive hybrid technology. However, the application in refrigerated vehicles presents distinct technical challenges due to the additional power requirements of cooling systems. The integration of electric motors and energy storage systems with traditional refrigeration units has opened new possibilities for energy optimization and load management.

One of the key goals of mild hybrid refrigeration is to leverage regenerative braking and start-stop systems to capture and reuse energy that would otherwise be lost. This recovered energy can be utilized to power the refrigeration unit during idle periods or assist the main engine during acceleration, thereby reducing the overall fuel consumption of the vehicle.

Another critical objective is to enhance the operational flexibility of refrigerated transport. Mild hybrid systems enable the use of electric-only modes for short periods, allowing vehicles to operate in low-emission zones or during nighttime deliveries with reduced noise pollution. This capability is particularly valuable in urban environments where stringent noise and emission regulations are increasingly common.

The technology also aims to improve the reliability and longevity of refrigeration systems by reducing the load on the main engine and allowing for more efficient temperature control. By optimizing the power distribution between the internal combustion engine and the electric system, mild hybrid refrigeration seeks to maintain consistent cooling performance while minimizing wear and tear on components.

As the transportation industry moves towards greater sustainability, the development of mild hybrid refrigeration technology aligns with broader trends in electrification and energy efficiency. The ultimate goal is to create a more sustainable cold chain that can meet the growing demand for fresh and frozen goods while reducing the environmental impact of refrigerated transport operations.

The primary objective of implementing mild hybrid technology in refrigerated transport is to significantly reduce fuel consumption and greenhouse gas emissions while maintaining optimal temperature control for perishable goods. This technology aims to address the unique challenges faced by the cold chain industry, where energy-intensive refrigeration units are essential for preserving product quality during transit.

The development of mild hybrid systems for refrigerated transport has been influenced by advancements in automotive hybrid technology. However, the application in refrigerated vehicles presents distinct technical challenges due to the additional power requirements of cooling systems. The integration of electric motors and energy storage systems with traditional refrigeration units has opened new possibilities for energy optimization and load management.

One of the key goals of mild hybrid refrigeration is to leverage regenerative braking and start-stop systems to capture and reuse energy that would otherwise be lost. This recovered energy can be utilized to power the refrigeration unit during idle periods or assist the main engine during acceleration, thereby reducing the overall fuel consumption of the vehicle.

Another critical objective is to enhance the operational flexibility of refrigerated transport. Mild hybrid systems enable the use of electric-only modes for short periods, allowing vehicles to operate in low-emission zones or during nighttime deliveries with reduced noise pollution. This capability is particularly valuable in urban environments where stringent noise and emission regulations are increasingly common.

The technology also aims to improve the reliability and longevity of refrigeration systems by reducing the load on the main engine and allowing for more efficient temperature control. By optimizing the power distribution between the internal combustion engine and the electric system, mild hybrid refrigeration seeks to maintain consistent cooling performance while minimizing wear and tear on components.

As the transportation industry moves towards greater sustainability, the development of mild hybrid refrigeration technology aligns with broader trends in electrification and energy efficiency. The ultimate goal is to create a more sustainable cold chain that can meet the growing demand for fresh and frozen goods while reducing the environmental impact of refrigerated transport operations.

Market Analysis for Energy-Efficient Transport Refrigeration

The refrigerated transport market is experiencing significant growth driven by increasing demand for temperature-sensitive goods, particularly in the food and pharmaceutical sectors. This growth is coupled with a rising emphasis on energy efficiency and sustainability, creating a fertile ground for energy-saving technologies such as mild hybrids in refrigerated transport.

The global refrigerated transport market was valued at approximately $15 billion in 2020 and is projected to reach $23 billion by 2026, growing at a CAGR of around 7%. This growth is primarily fueled by the expansion of cold chain logistics, urbanization, and changing consumer preferences for fresh and frozen products. The COVID-19 pandemic has further accelerated this trend, highlighting the importance of efficient and reliable cold chain transportation for vaccines and other medical supplies.

Within this market, there is a growing demand for energy-efficient solutions. Traditional refrigerated transport systems are energy-intensive, contributing significantly to operational costs and environmental impact. Mild hybrid technologies offer a promising solution to address these challenges, potentially reducing fuel consumption and emissions by 10-20% compared to conventional systems.

The market for energy-efficient transport refrigeration is segmented by vehicle type, including trucks, trailers, and vans. Trucks hold the largest market share, followed by trailers. However, the van segment is expected to witness the highest growth rate due to increasing last-mile delivery demands in urban areas.

Geographically, North America and Europe currently dominate the market for energy-efficient refrigerated transport solutions. This is attributed to stringent environmental regulations, higher adoption rates of advanced technologies, and well-established cold chain infrastructure. However, the Asia-Pacific region is emerging as a high-growth market, driven by rapid urbanization, increasing disposable incomes, and growing demand for perishable goods.

Key market drivers include regulatory pressures to reduce emissions, rising fuel costs, and increasing corporate sustainability initiatives. The European Union's ambitious targets for reducing CO2 emissions in the transport sector are particularly influential, pushing manufacturers and fleet operators to adopt more efficient technologies.

Despite the promising outlook, several challenges persist in the market. These include high initial investment costs for hybrid systems, concerns about reliability and performance in extreme conditions, and the need for specialized maintenance and training. Additionally, the fragmented nature of the transport industry, with many small and medium-sized operators, can slow the adoption of new technologies.

The global refrigerated transport market was valued at approximately $15 billion in 2020 and is projected to reach $23 billion by 2026, growing at a CAGR of around 7%. This growth is primarily fueled by the expansion of cold chain logistics, urbanization, and changing consumer preferences for fresh and frozen products. The COVID-19 pandemic has further accelerated this trend, highlighting the importance of efficient and reliable cold chain transportation for vaccines and other medical supplies.

Within this market, there is a growing demand for energy-efficient solutions. Traditional refrigerated transport systems are energy-intensive, contributing significantly to operational costs and environmental impact. Mild hybrid technologies offer a promising solution to address these challenges, potentially reducing fuel consumption and emissions by 10-20% compared to conventional systems.

The market for energy-efficient transport refrigeration is segmented by vehicle type, including trucks, trailers, and vans. Trucks hold the largest market share, followed by trailers. However, the van segment is expected to witness the highest growth rate due to increasing last-mile delivery demands in urban areas.

Geographically, North America and Europe currently dominate the market for energy-efficient refrigerated transport solutions. This is attributed to stringent environmental regulations, higher adoption rates of advanced technologies, and well-established cold chain infrastructure. However, the Asia-Pacific region is emerging as a high-growth market, driven by rapid urbanization, increasing disposable incomes, and growing demand for perishable goods.

Key market drivers include regulatory pressures to reduce emissions, rising fuel costs, and increasing corporate sustainability initiatives. The European Union's ambitious targets for reducing CO2 emissions in the transport sector are particularly influential, pushing manufacturers and fleet operators to adopt more efficient technologies.

Despite the promising outlook, several challenges persist in the market. These include high initial investment costs for hybrid systems, concerns about reliability and performance in extreme conditions, and the need for specialized maintenance and training. Additionally, the fragmented nature of the transport industry, with many small and medium-sized operators, can slow the adoption of new technologies.

Current Challenges in Refrigerated Transport Efficiency

Refrigerated transport plays a crucial role in the global food supply chain, ensuring perishable goods reach consumers in optimal condition. However, this sector faces significant challenges in terms of energy efficiency and environmental impact. The current refrigeration systems in transport vehicles are energy-intensive, contributing to high operational costs and substantial greenhouse gas emissions.

One of the primary challenges is the continuous power demand of refrigeration units. These systems require constant energy input to maintain the desired temperature, even when the vehicle is stationary. This leads to excessive fuel consumption and increased emissions, particularly during idle periods or in urban environments with frequent stops.

The integration of refrigeration systems with vehicle engines presents another hurdle. Traditional setups often rely on the main engine to power the refrigeration unit, resulting in suboptimal energy utilization. This arrangement can lead to increased wear on the main engine and reduced overall efficiency, especially during low-speed operations or when the vehicle is stationary.

Temperature control precision is another critical issue. Fluctuations in ambient conditions, frequent door openings during deliveries, and varying load conditions make it challenging to maintain consistent temperatures. This not only affects the quality of transported goods but also leads to increased energy consumption as the system works harder to compensate for these variations.

The insulation of refrigerated compartments poses a significant challenge. While improved insulation can reduce the energy required to maintain low temperatures, it often comes at the cost of increased vehicle weight. This trade-off between insulation efficiency and payload capacity is a constant balancing act for manufacturers and operators.

Moreover, the refrigerants used in these systems are a growing concern. Many traditional refrigerants have high global warming potential, contributing to climate change when leaked. The industry is under pressure to transition to more environmentally friendly alternatives, but this shift presents technical challenges and potential increases in system costs.

The diverse nature of refrigerated transport operations further complicates efficiency improvements. Different products require varying temperature ranges, and routes can include long-haul journeys as well as frequent urban deliveries. Developing systems that can efficiently adapt to these diverse operational profiles remains a significant challenge.

Lastly, the high initial cost of advanced, energy-efficient refrigeration technologies often deters widespread adoption, particularly among smaller operators. This creates a barrier to implementing more sustainable solutions across the industry, slowing the overall progress towards improved energy efficiency in refrigerated transport.

One of the primary challenges is the continuous power demand of refrigeration units. These systems require constant energy input to maintain the desired temperature, even when the vehicle is stationary. This leads to excessive fuel consumption and increased emissions, particularly during idle periods or in urban environments with frequent stops.

The integration of refrigeration systems with vehicle engines presents another hurdle. Traditional setups often rely on the main engine to power the refrigeration unit, resulting in suboptimal energy utilization. This arrangement can lead to increased wear on the main engine and reduced overall efficiency, especially during low-speed operations or when the vehicle is stationary.

Temperature control precision is another critical issue. Fluctuations in ambient conditions, frequent door openings during deliveries, and varying load conditions make it challenging to maintain consistent temperatures. This not only affects the quality of transported goods but also leads to increased energy consumption as the system works harder to compensate for these variations.

The insulation of refrigerated compartments poses a significant challenge. While improved insulation can reduce the energy required to maintain low temperatures, it often comes at the cost of increased vehicle weight. This trade-off between insulation efficiency and payload capacity is a constant balancing act for manufacturers and operators.

Moreover, the refrigerants used in these systems are a growing concern. Many traditional refrigerants have high global warming potential, contributing to climate change when leaked. The industry is under pressure to transition to more environmentally friendly alternatives, but this shift presents technical challenges and potential increases in system costs.

The diverse nature of refrigerated transport operations further complicates efficiency improvements. Different products require varying temperature ranges, and routes can include long-haul journeys as well as frequent urban deliveries. Developing systems that can efficiently adapt to these diverse operational profiles remains a significant challenge.

Lastly, the high initial cost of advanced, energy-efficient refrigeration technologies often deters widespread adoption, particularly among smaller operators. This creates a barrier to implementing more sustainable solutions across the industry, slowing the overall progress towards improved energy efficiency in refrigerated transport.

Existing Mild Hybrid Solutions for Refrigerated Transport

01 Regenerative braking systems

Mild hybrid vehicles utilize regenerative braking systems to recover and store energy during deceleration. This energy is then used to assist the internal combustion engine during acceleration, reducing fuel consumption and improving overall energy efficiency.- Regenerative braking systems: Mild hybrid vehicles utilize regenerative braking systems to capture and store energy typically lost during deceleration. This recovered energy is then used to assist the internal combustion engine, reducing fuel consumption and improving overall energy efficiency. The system can provide significant energy savings, especially in urban driving conditions with frequent stops and starts.

- Start-stop technology: Mild hybrids often incorporate start-stop technology, which automatically shuts off the engine when the vehicle comes to a stop and restarts it when the driver releases the brake pedal. This feature helps to reduce fuel consumption and emissions, particularly in city driving scenarios where vehicles frequently come to a stop at traffic lights or in congested areas.

- Electric motor assist: Mild hybrid systems use an electric motor to assist the internal combustion engine during acceleration and other high-power demand situations. This electric boost allows for the use of smaller, more efficient engines without sacrificing performance. The electric motor can also help maintain vehicle speed during cruising, further improving fuel economy.

- Energy management strategies: Advanced energy management strategies are employed in mild hybrid systems to optimize the use of electric and combustion power. These strategies consider factors such as driving conditions, battery state of charge, and power demands to determine the most efficient way to distribute power between the electric motor and the internal combustion engine, maximizing energy savings potential.

- Lightweight design and aerodynamics: Mild hybrid vehicles often incorporate lightweight materials and improved aerodynamics to enhance their energy-saving potential. Reducing vehicle weight and air resistance helps to decrease the overall energy required for propulsion, complementing the hybrid powertrain's efficiency and further improving fuel economy and reducing emissions.

02 Start-stop technology

Mild hybrids incorporate start-stop technology, which automatically shuts off the engine when the vehicle is stationary and restarts it when needed. This feature significantly reduces fuel consumption and emissions, particularly in urban driving conditions with frequent stops.Expand Specific Solutions03 Electric motor assist

Mild hybrid systems use an electric motor to assist the internal combustion engine during acceleration and high-load situations. This reduces the load on the engine, leading to improved fuel efficiency and reduced emissions without compromising performance.Expand Specific Solutions04 Battery management and power electronics

Advanced battery management systems and power electronics are crucial components in mild hybrid vehicles. These systems optimize the use of electrical energy, manage the charging and discharging of the battery, and ensure efficient power distribution between the electric motor and the internal combustion engine.Expand Specific Solutions05 Intelligent energy management strategies

Mild hybrids employ sophisticated energy management strategies that continuously monitor driving conditions, vehicle load, and energy demands. These systems dynamically adjust the power split between the electric motor and the internal combustion engine to maximize energy efficiency and minimize fuel consumption.Expand Specific Solutions

Key Players in Mild Hybrid Refrigeration Systems

The energy-saving potential of mild hybrids in refrigerated transport is an emerging field with growing market potential. The industry is in its early development stage, with increasing interest driven by environmental regulations and cost-saving opportunities. The market size is expanding as more companies recognize the benefits of hybrid technology in reducing fuel consumption and emissions. Technologically, the sector is progressing rapidly, with companies like Carrier Corp., Thermo King LLC, and Hyundai Motor Co., Ltd. leading innovation. These firms are developing advanced mild hybrid systems specifically tailored for refrigerated transport, integrating energy-efficient cooling technologies with hybrid powertrains. The involvement of major automotive players such as Cummins, Inc. and AUDI AG suggests a trend towards more sophisticated and integrated solutions in this niche market.

Carrier Corp.

Technical Solution: Carrier Corp. has developed advanced mild hybrid systems for refrigerated transport, focusing on energy efficiency and sustainability. Their solution integrates a high-efficiency electric compressor with a compact lithium-ion battery pack, allowing the refrigeration unit to operate independently of the vehicle's engine. This system can reduce fuel consumption by up to 30% compared to conventional diesel-powered units [1]. The mild hybrid technology also incorporates smart power management algorithms that optimize the balance between battery power and engine operation, further enhancing energy savings. Additionally, Carrier has implemented regenerative braking technology to capture and store energy typically lost during vehicle deceleration, which can then be used to power the refrigeration unit [3].

Strengths: Significant fuel savings, reduced emissions, and improved operational flexibility. Weaknesses: Higher initial cost and potential complexity in maintenance compared to traditional systems.

Thermo King LLC

Technical Solution: Thermo King LLC has pioneered a mild hybrid solution for refrigerated transport that combines electric and diesel power sources. Their system utilizes a variable speed diesel engine coupled with an electric generator and advanced battery technology. This configuration allows for precise temperature control while minimizing fuel consumption. The mild hybrid system can switch seamlessly between diesel and electric power, depending on the cooling demand and available battery charge. Thermo King's solution also incorporates start-stop technology, which automatically shuts off the diesel engine during idle periods, reducing unnecessary fuel consumption and emissions [2]. The company has reported fuel savings of up to 25% in real-world applications, with some customers experiencing even greater efficiency gains in urban delivery scenarios [4].

Strengths: Flexible power management, reduced idle time, and proven fuel savings. Weaknesses: Dependency on battery life and potential for increased system complexity.

Core Innovations in Energy-Saving Refrigeration Technologies

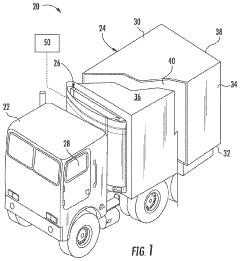

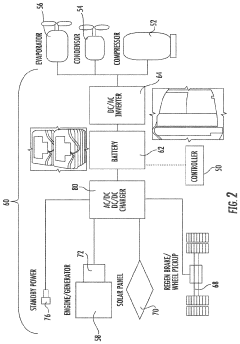

Hybrid power conversion system for a refrigerated transport vehicle and method

PatentActiveUS20200198519A1

Innovation

- A hybrid power conversion system incorporating a battery, supplemental power sources such as solar panels, regenerative braking systems, wheel hub generators, and generators coupled to the tractor's engine, along with a power converter to provide efficient DC to AC power for refrigeration components, minimizing the need for the refrigeration system engine and reducing fuel consumption.

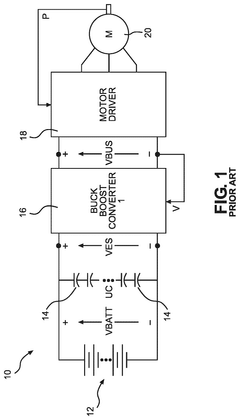

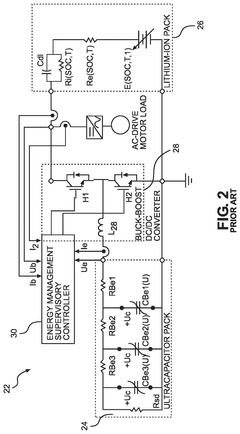

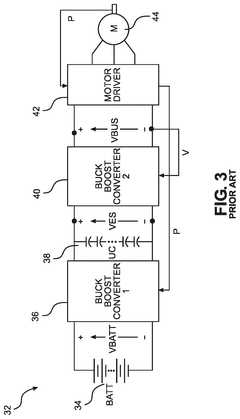

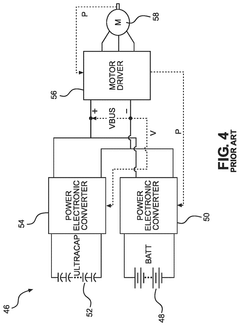

Battery-ultracapacitor hybrid energy storage system architecture for mild-hybrid power systems

PatentPendingUS20250192601A1

Innovation

- A mild-hybrid energy storage system architecture that includes a battery, an ultracapacitor connected in parallel, dedicated pre-charge circuits, and main contactors, along with a control module to independently manage the operation of these components, optimizing energy storage and release for efficient engine starting and operation.

Environmental Impact and Regulations

The environmental impact of refrigerated transport has become a significant concern in recent years, prompting the development of more sustainable solutions such as mild hybrid systems. These systems offer substantial energy-saving potential while helping to reduce greenhouse gas emissions and other pollutants associated with traditional refrigerated transport vehicles.

One of the primary environmental benefits of mild hybrid systems in refrigerated transport is the reduction of fuel consumption. By utilizing regenerative braking and start-stop technology, these systems can capture and reuse energy that would otherwise be lost, leading to improved fuel efficiency. This reduction in fuel consumption directly translates to lower carbon dioxide emissions, a major contributor to climate change.

In addition to CO2 emissions, mild hybrid systems can also help mitigate other harmful pollutants such as nitrogen oxides (NOx) and particulate matter. These pollutants are known to have detrimental effects on air quality and human health, particularly in urban areas where refrigerated transport vehicles frequently operate.

The adoption of mild hybrid technology in refrigerated transport aligns with increasingly stringent environmental regulations worldwide. Many countries and regions have implemented or are in the process of implementing stricter emissions standards for commercial vehicles. For instance, the European Union's Euro VI standards set tight limits on emissions of NOx, particulate matter, and other pollutants from heavy-duty vehicles.

In the United States, the Environmental Protection Agency (EPA) has established greenhouse gas emissions standards for medium- and heavy-duty vehicles, including those used in refrigerated transport. These regulations aim to reduce fuel consumption and emissions through the adoption of more efficient technologies, such as mild hybrid systems.

Furthermore, many local governments are implementing low-emission zones in urban areas, restricting access for vehicles that do not meet certain environmental criteria. Mild hybrid refrigerated transport vehicles are better positioned to comply with these regulations, ensuring continued access to key urban delivery routes.

The environmental benefits of mild hybrid systems in refrigerated transport extend beyond emissions reduction. These systems can also contribute to noise pollution mitigation, particularly in urban environments. The start-stop functionality of mild hybrid systems allows the vehicle's engine to shut off when stationary, reducing noise levels during deliveries and in traffic.

As environmental concerns continue to shape policy and consumer preferences, the adoption of mild hybrid technology in refrigerated transport is likely to accelerate. This trend is further supported by ongoing technological advancements and decreasing costs of hybrid systems, making them an increasingly attractive option for fleet operators seeking to improve their environmental performance and comply with evolving regulations.

One of the primary environmental benefits of mild hybrid systems in refrigerated transport is the reduction of fuel consumption. By utilizing regenerative braking and start-stop technology, these systems can capture and reuse energy that would otherwise be lost, leading to improved fuel efficiency. This reduction in fuel consumption directly translates to lower carbon dioxide emissions, a major contributor to climate change.

In addition to CO2 emissions, mild hybrid systems can also help mitigate other harmful pollutants such as nitrogen oxides (NOx) and particulate matter. These pollutants are known to have detrimental effects on air quality and human health, particularly in urban areas where refrigerated transport vehicles frequently operate.

The adoption of mild hybrid technology in refrigerated transport aligns with increasingly stringent environmental regulations worldwide. Many countries and regions have implemented or are in the process of implementing stricter emissions standards for commercial vehicles. For instance, the European Union's Euro VI standards set tight limits on emissions of NOx, particulate matter, and other pollutants from heavy-duty vehicles.

In the United States, the Environmental Protection Agency (EPA) has established greenhouse gas emissions standards for medium- and heavy-duty vehicles, including those used in refrigerated transport. These regulations aim to reduce fuel consumption and emissions through the adoption of more efficient technologies, such as mild hybrid systems.

Furthermore, many local governments are implementing low-emission zones in urban areas, restricting access for vehicles that do not meet certain environmental criteria. Mild hybrid refrigerated transport vehicles are better positioned to comply with these regulations, ensuring continued access to key urban delivery routes.

The environmental benefits of mild hybrid systems in refrigerated transport extend beyond emissions reduction. These systems can also contribute to noise pollution mitigation, particularly in urban environments. The start-stop functionality of mild hybrid systems allows the vehicle's engine to shut off when stationary, reducing noise levels during deliveries and in traffic.

As environmental concerns continue to shape policy and consumer preferences, the adoption of mild hybrid technology in refrigerated transport is likely to accelerate. This trend is further supported by ongoing technological advancements and decreasing costs of hybrid systems, making them an increasingly attractive option for fleet operators seeking to improve their environmental performance and comply with evolving regulations.

Cost-Benefit Analysis of Mild Hybrid Refrigeration Implementation

The implementation of mild hybrid technology in refrigerated transport systems presents a compelling opportunity for energy savings and cost reduction. This analysis examines the financial implications and potential benefits of integrating mild hybrid systems into refrigerated transport vehicles.

Initial investment costs for mild hybrid refrigeration systems are typically higher than traditional systems. The additional components, such as the electric motor, battery pack, and power electronics, contribute to increased upfront expenses. However, these costs are often offset by long-term savings and operational benefits.

Fuel consumption reduction is a primary advantage of mild hybrid systems in refrigerated transport. By utilizing regenerative braking and providing electric assist during acceleration, these systems can significantly decrease fuel usage. Studies have shown potential fuel savings of 10-20% in urban delivery scenarios, where frequent stops and starts occur.

Maintenance costs may initially increase due to the complexity of the hybrid system. However, over time, the reduced strain on the main engine and decreased wear on brake components can lead to lower overall maintenance expenses. The electric components of mild hybrid systems generally require less frequent servicing compared to traditional mechanical parts.

Operational efficiency improvements contribute to the cost-benefit equation. Mild hybrid systems enable more precise temperature control in refrigerated compartments, potentially reducing food spoilage and associated costs. Additionally, the ability to operate cooling systems with the main engine off during short stops can lead to noise reduction and improved compliance with local regulations.

Environmental benefits, while not directly financial, can translate into economic advantages. Reduced emissions from mild hybrid systems may qualify companies for government incentives or tax breaks. Furthermore, the improved environmental profile can enhance brand image, potentially leading to increased market share and customer loyalty.

The return on investment (ROI) for mild hybrid refrigeration systems varies depending on factors such as vehicle usage patterns, fuel prices, and regulatory environments. In general, fleets operating in urban areas with frequent stops and high annual mileage tend to see faster ROI, often within 2-4 years.

Long-term cost projections indicate that as technology matures and production scales up, the initial cost differential between mild hybrid and conventional systems is likely to decrease. This trend, combined with potential increases in fuel prices, suggests that the economic benefits of mild hybrid refrigeration systems may become even more pronounced in the future.

Initial investment costs for mild hybrid refrigeration systems are typically higher than traditional systems. The additional components, such as the electric motor, battery pack, and power electronics, contribute to increased upfront expenses. However, these costs are often offset by long-term savings and operational benefits.

Fuel consumption reduction is a primary advantage of mild hybrid systems in refrigerated transport. By utilizing regenerative braking and providing electric assist during acceleration, these systems can significantly decrease fuel usage. Studies have shown potential fuel savings of 10-20% in urban delivery scenarios, where frequent stops and starts occur.

Maintenance costs may initially increase due to the complexity of the hybrid system. However, over time, the reduced strain on the main engine and decreased wear on brake components can lead to lower overall maintenance expenses. The electric components of mild hybrid systems generally require less frequent servicing compared to traditional mechanical parts.

Operational efficiency improvements contribute to the cost-benefit equation. Mild hybrid systems enable more precise temperature control in refrigerated compartments, potentially reducing food spoilage and associated costs. Additionally, the ability to operate cooling systems with the main engine off during short stops can lead to noise reduction and improved compliance with local regulations.

Environmental benefits, while not directly financial, can translate into economic advantages. Reduced emissions from mild hybrid systems may qualify companies for government incentives or tax breaks. Furthermore, the improved environmental profile can enhance brand image, potentially leading to increased market share and customer loyalty.

The return on investment (ROI) for mild hybrid refrigeration systems varies depending on factors such as vehicle usage patterns, fuel prices, and regulatory environments. In general, fleets operating in urban areas with frequent stops and high annual mileage tend to see faster ROI, often within 2-4 years.

Long-term cost projections indicate that as technology matures and production scales up, the initial cost differential between mild hybrid and conventional systems is likely to decrease. This trend, combined with potential increases in fuel prices, suggests that the economic benefits of mild hybrid refrigeration systems may become even more pronounced in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!