The environmental impact of mild hybrid battery disposal

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Battery Evolution and Objectives

Mild hybrid technology has emerged as a significant step in the evolution of automotive powertrains, bridging the gap between conventional internal combustion engines and fully electric vehicles. The development of mild hybrid systems can be traced back to the early 2000s, with the primary objective of improving fuel efficiency and reducing emissions without compromising vehicle performance.

The evolution of mild hybrid batteries has been driven by the need for more compact, efficient, and cost-effective energy storage solutions. Initially, lead-acid batteries were used, but they quickly gave way to nickel-metal hydride (NiMH) and lithium-ion (Li-ion) technologies. These advancements have allowed for increased energy density, faster charging capabilities, and improved cycle life, all of which are crucial for the effective operation of mild hybrid systems.

As the automotive industry faces increasingly stringent emissions regulations and growing consumer demand for more environmentally friendly vehicles, the objectives for mild hybrid battery technology have become more ambitious. Current goals include further reducing the size and weight of battery packs, enhancing their power density to support more advanced regenerative braking systems, and improving their overall lifespan to match or exceed that of the vehicle itself.

Another key objective in the evolution of mild hybrid batteries is to address the environmental concerns associated with their production and disposal. This includes developing more sustainable manufacturing processes, reducing the use of rare earth materials, and improving recycling techniques to minimize the environmental impact at the end of the battery's life cycle.

The future trajectory of mild hybrid battery evolution is likely to focus on the integration of advanced materials and nanotechnology to push the boundaries of energy storage capabilities. Research is ongoing into solid-state batteries, which promise higher energy densities and improved safety profiles. Additionally, there is a growing emphasis on the development of "smart" battery management systems that can optimize performance and longevity through predictive analytics and adaptive charging strategies.

As mild hybrid systems become more prevalent across various vehicle segments, from compact cars to luxury SUVs, the objectives for battery technology continue to expand. Manufacturers are now exploring ways to leverage mild hybrid batteries to support additional vehicle functions, such as powering advanced driver assistance systems and providing auxiliary power for comfort features, further enhancing the value proposition of these hybrid powertrains.

The evolution of mild hybrid batteries has been driven by the need for more compact, efficient, and cost-effective energy storage solutions. Initially, lead-acid batteries were used, but they quickly gave way to nickel-metal hydride (NiMH) and lithium-ion (Li-ion) technologies. These advancements have allowed for increased energy density, faster charging capabilities, and improved cycle life, all of which are crucial for the effective operation of mild hybrid systems.

As the automotive industry faces increasingly stringent emissions regulations and growing consumer demand for more environmentally friendly vehicles, the objectives for mild hybrid battery technology have become more ambitious. Current goals include further reducing the size and weight of battery packs, enhancing their power density to support more advanced regenerative braking systems, and improving their overall lifespan to match or exceed that of the vehicle itself.

Another key objective in the evolution of mild hybrid batteries is to address the environmental concerns associated with their production and disposal. This includes developing more sustainable manufacturing processes, reducing the use of rare earth materials, and improving recycling techniques to minimize the environmental impact at the end of the battery's life cycle.

The future trajectory of mild hybrid battery evolution is likely to focus on the integration of advanced materials and nanotechnology to push the boundaries of energy storage capabilities. Research is ongoing into solid-state batteries, which promise higher energy densities and improved safety profiles. Additionally, there is a growing emphasis on the development of "smart" battery management systems that can optimize performance and longevity through predictive analytics and adaptive charging strategies.

As mild hybrid systems become more prevalent across various vehicle segments, from compact cars to luxury SUVs, the objectives for battery technology continue to expand. Manufacturers are now exploring ways to leverage mild hybrid batteries to support additional vehicle functions, such as powering advanced driver assistance systems and providing auxiliary power for comfort features, further enhancing the value proposition of these hybrid powertrains.

Market Analysis for Mild Hybrid Vehicles

The mild hybrid vehicle market has experienced significant growth in recent years, driven by increasing environmental concerns and stricter emissions regulations worldwide. This segment bridges the gap between conventional internal combustion engine vehicles and full hybrids, offering improved fuel efficiency and reduced emissions at a lower cost point.

Market demand for mild hybrid vehicles has been steadily rising, particularly in regions with stringent emission standards such as Europe and China. The global mild hybrid market size was valued at approximately $20 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 10% from 2021 to 2026. This growth is attributed to the increasing adoption of 48V systems in vehicles and the push for electrification across the automotive industry.

Consumer preferences are shifting towards more fuel-efficient and environmentally friendly vehicles, with mild hybrids offering an attractive compromise between performance and sustainability. The technology's ability to provide improved fuel economy without the complexity and cost associated with full hybrid systems has made it appealing to both manufacturers and consumers.

Key market drivers include government incentives for low-emission vehicles, rising fuel prices, and growing awareness of environmental issues. Many countries have implemented tax benefits and subsidies for hybrid vehicles, further stimulating market growth. Additionally, the relatively lower production costs of mild hybrid systems compared to full hybrids make them an attractive option for automakers looking to meet emissions targets while maintaining competitive pricing.

The market landscape is characterized by intense competition among major automotive manufacturers, with companies like Volkswagen, BMW, Mercedes-Benz, and Toyota investing heavily in mild hybrid technology. These manufacturers are expanding their mild hybrid offerings across various vehicle segments, from compact cars to SUVs and luxury vehicles.

Regional market analysis reveals that Europe currently leads in mild hybrid adoption, followed closely by Asia-Pacific. North America is also showing increasing interest, with several automakers introducing mild hybrid models to meet Corporate Average Fuel Economy (CAFE) standards. Emerging markets in Asia and Latin America are expected to contribute significantly to future growth as urbanization and environmental concerns drive demand for more efficient vehicles.

Despite the positive outlook, challenges remain in the mild hybrid market. These include the need for further cost reductions to make the technology more accessible to mass-market vehicles, potential supply chain disruptions affecting battery and electrical component availability, and the rapid advancement of full electric vehicle technology, which may impact long-term market dynamics for mild hybrids.

Market demand for mild hybrid vehicles has been steadily rising, particularly in regions with stringent emission standards such as Europe and China. The global mild hybrid market size was valued at approximately $20 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 10% from 2021 to 2026. This growth is attributed to the increasing adoption of 48V systems in vehicles and the push for electrification across the automotive industry.

Consumer preferences are shifting towards more fuel-efficient and environmentally friendly vehicles, with mild hybrids offering an attractive compromise between performance and sustainability. The technology's ability to provide improved fuel economy without the complexity and cost associated with full hybrid systems has made it appealing to both manufacturers and consumers.

Key market drivers include government incentives for low-emission vehicles, rising fuel prices, and growing awareness of environmental issues. Many countries have implemented tax benefits and subsidies for hybrid vehicles, further stimulating market growth. Additionally, the relatively lower production costs of mild hybrid systems compared to full hybrids make them an attractive option for automakers looking to meet emissions targets while maintaining competitive pricing.

The market landscape is characterized by intense competition among major automotive manufacturers, with companies like Volkswagen, BMW, Mercedes-Benz, and Toyota investing heavily in mild hybrid technology. These manufacturers are expanding their mild hybrid offerings across various vehicle segments, from compact cars to SUVs and luxury vehicles.

Regional market analysis reveals that Europe currently leads in mild hybrid adoption, followed closely by Asia-Pacific. North America is also showing increasing interest, with several automakers introducing mild hybrid models to meet Corporate Average Fuel Economy (CAFE) standards. Emerging markets in Asia and Latin America are expected to contribute significantly to future growth as urbanization and environmental concerns drive demand for more efficient vehicles.

Despite the positive outlook, challenges remain in the mild hybrid market. These include the need for further cost reductions to make the technology more accessible to mass-market vehicles, potential supply chain disruptions affecting battery and electrical component availability, and the rapid advancement of full electric vehicle technology, which may impact long-term market dynamics for mild hybrids.

Current Challenges in Battery Disposal

The disposal of mild hybrid batteries presents significant environmental challenges that require immediate attention and innovative solutions. As these batteries become more prevalent in the automotive industry, the volume of waste generated at the end of their lifecycle is rapidly increasing, putting pressure on existing disposal infrastructure and raising concerns about potential environmental contamination.

One of the primary challenges in mild hybrid battery disposal is the complexity of their composition. These batteries typically contain a mix of materials, including lithium, nickel, cobalt, and other rare earth elements. The intricate combination of these materials makes it difficult to separate and recycle them efficiently, leading to potential resource wastage and environmental pollution if not handled properly.

The lack of standardized disposal protocols across different regions and manufacturers further complicates the issue. Without clear guidelines and regulations, there is a risk of improper disposal methods being employed, which could result in hazardous materials leaching into soil and water systems. This not only poses a threat to local ecosystems but also to human health through potential contamination of food and water sources.

Another significant challenge is the limited capacity of existing recycling facilities to handle the increasing volume of mild hybrid batteries reaching their end-of-life. Many recycling plants are not equipped with the specialized technology required to process these batteries safely and efficiently. This bottleneck in the recycling infrastructure could lead to stockpiling of used batteries, increasing the risk of accidents and environmental damage.

The energy-intensive nature of current recycling processes also presents an environmental concern. The high temperatures and chemical treatments required to break down and recover materials from mild hybrid batteries can result in significant carbon emissions and energy consumption, potentially offsetting some of the environmental benefits gained from using hybrid vehicles in the first place.

Furthermore, the global distribution of battery production and disposal facilities creates logistical challenges. Transporting end-of-life batteries over long distances for proper recycling not only increases costs but also contributes to carbon emissions, contradicting the eco-friendly intentions behind hybrid technology.

Addressing these challenges requires a multifaceted approach involving collaboration between manufacturers, policymakers, and recycling industries. Developing more efficient and environmentally friendly recycling technologies, establishing comprehensive regulations for battery disposal, and creating incentives for proper recycling practices are crucial steps towards mitigating the environmental impact of mild hybrid battery disposal.

One of the primary challenges in mild hybrid battery disposal is the complexity of their composition. These batteries typically contain a mix of materials, including lithium, nickel, cobalt, and other rare earth elements. The intricate combination of these materials makes it difficult to separate and recycle them efficiently, leading to potential resource wastage and environmental pollution if not handled properly.

The lack of standardized disposal protocols across different regions and manufacturers further complicates the issue. Without clear guidelines and regulations, there is a risk of improper disposal methods being employed, which could result in hazardous materials leaching into soil and water systems. This not only poses a threat to local ecosystems but also to human health through potential contamination of food and water sources.

Another significant challenge is the limited capacity of existing recycling facilities to handle the increasing volume of mild hybrid batteries reaching their end-of-life. Many recycling plants are not equipped with the specialized technology required to process these batteries safely and efficiently. This bottleneck in the recycling infrastructure could lead to stockpiling of used batteries, increasing the risk of accidents and environmental damage.

The energy-intensive nature of current recycling processes also presents an environmental concern. The high temperatures and chemical treatments required to break down and recover materials from mild hybrid batteries can result in significant carbon emissions and energy consumption, potentially offsetting some of the environmental benefits gained from using hybrid vehicles in the first place.

Furthermore, the global distribution of battery production and disposal facilities creates logistical challenges. Transporting end-of-life batteries over long distances for proper recycling not only increases costs but also contributes to carbon emissions, contradicting the eco-friendly intentions behind hybrid technology.

Addressing these challenges requires a multifaceted approach involving collaboration between manufacturers, policymakers, and recycling industries. Developing more efficient and environmentally friendly recycling technologies, establishing comprehensive regulations for battery disposal, and creating incentives for proper recycling practices are crucial steps towards mitigating the environmental impact of mild hybrid battery disposal.

Existing Battery Disposal Methods

01 Battery recycling and disposal

Mild hybrid batteries have environmental impacts related to their end-of-life management. Proper recycling and disposal methods are crucial to minimize negative effects on the environment. This includes recovering valuable materials and safely handling potentially hazardous components. Efficient recycling processes can reduce the need for raw material extraction and decrease overall environmental impact.- Battery recycling and disposal: Mild hybrid batteries have environmental impacts related to their end-of-life management. Proper recycling and disposal methods are crucial to minimize negative effects on the environment. This includes recovering valuable materials and safely handling potentially hazardous components. Efficient recycling processes can reduce the need for raw material extraction and decrease overall environmental impact.

- Energy efficiency and fuel consumption reduction: Mild hybrid systems, including their batteries, contribute to improved energy efficiency and reduced fuel consumption in vehicles. This leads to lower greenhouse gas emissions and decreased reliance on fossil fuels. The environmental impact is positive as it helps in reducing the overall carbon footprint of transportation.

- Battery production and material sourcing: The production of mild hybrid batteries involves sourcing raw materials and manufacturing processes that can have environmental implications. Sustainable sourcing practices and eco-friendly production methods are essential to minimize negative impacts. This includes considering the environmental effects of mining, processing, and transporting battery materials.

- Battery lifespan and durability: The lifespan and durability of mild hybrid batteries affect their overall environmental impact. Longer-lasting batteries reduce the frequency of replacement and disposal, thereby minimizing waste generation and resource consumption. Improving battery durability through advanced technologies and materials can contribute to a more sustainable automotive industry.

- Integration with renewable energy systems: Mild hybrid batteries can be integrated with renewable energy systems to further reduce environmental impact. This includes using solar or wind power for charging and exploring vehicle-to-grid technologies. Such integration can enhance the overall sustainability of transportation systems and contribute to a cleaner energy ecosystem.

02 Energy efficiency and fuel consumption reduction

Mild hybrid systems, including their batteries, contribute to improved energy efficiency and reduced fuel consumption in vehicles. This leads to lower greenhouse gas emissions and reduced environmental impact during the vehicle's operational life. The integration of these systems helps optimize engine performance and recover energy during braking, further enhancing overall efficiency.Expand Specific Solutions03 Battery production and material sourcing

The environmental impact of mild hybrid batteries is influenced by their production processes and material sourcing. Sustainable manufacturing practices and responsible sourcing of raw materials can significantly reduce the ecological footprint. This includes considering the environmental effects of mining, processing, and transporting battery materials.Expand Specific Solutions04 Battery lifespan and durability

The lifespan and durability of mild hybrid batteries affect their overall environmental impact. Longer-lasting batteries reduce the frequency of replacement and associated waste. Improved battery management systems and thermal control can extend battery life, reducing the need for premature replacements and minimizing environmental burden over the vehicle's lifetime.Expand Specific Solutions05 Integration with renewable energy systems

Mild hybrid batteries can be integrated with renewable energy systems to further reduce environmental impact. This includes using renewable energy sources for battery charging and exploring vehicle-to-grid (V2G) technologies. Such integration can help balance the electrical grid and support the wider adoption of clean energy, contributing to overall emissions reduction.Expand Specific Solutions

Key Players in Mild Hybrid Battery Industry

The environmental impact of mild hybrid battery disposal is an emerging concern in the automotive industry, currently in its early development stage. The market for mild hybrid technologies is growing, driven by increasing demand for fuel-efficient vehicles and stricter emissions regulations. However, the technology's maturity varies among key players. Companies like LG Energy Solution, Samsung SDI, and CATL are leading in battery technology development, while automotive giants such as Ford, Audi, and Hyundai are integrating these systems into their vehicles. Research institutions like Karlsruhe Institute of Technology and Commonwealth Scientific & Industrial Research Organisation are contributing to advancements in recycling and disposal methods. As the market expands, collaboration between battery manufacturers, automakers, and research entities will be crucial in addressing environmental challenges associated with mild hybrid battery disposal.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive lifecycle management system for mild hybrid batteries, addressing environmental concerns from production to disposal. Their approach includes the use of water-based electrode manufacturing processes, which reduce harmful emissions by up to 70% compared to traditional methods[3]. For end-of-life management, LG has implemented a battery take-back program in partnership with automotive manufacturers, ensuring proper collection and recycling. Their recycling process employs a combination of mechanical and chemical treatments, achieving a material recovery rate of over 90%[4]. Additionally, LG is investing in second-life applications for mild hybrid batteries, repurposing them for stationary energy storage systems, thus extending their useful life and delaying final disposal.

Strengths: Comprehensive lifecycle approach, high material recovery rate, focus on second-life applications. Weaknesses: Dependency on partnerships for collection, potential limitations in scaling up recycling infrastructure.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an innovative recycling process for mild hybrid batteries, focusing on reducing environmental impact. Their approach involves a closed-loop system that recovers up to 95% of key materials such as lithium, cobalt, and nickel[1]. The company utilizes advanced sorting technologies and hydrometallurgical processes to extract and purify these materials, significantly reducing the need for raw material mining. Samsung SDI has also implemented a battery design strategy that facilitates easier disassembly and recycling, incorporating modular components and eco-friendly materials[2]. This design approach reduces the energy required for recycling and minimizes waste generation during the disposal process.

Strengths: High material recovery rate, reduced need for raw materials, eco-friendly design. Weaknesses: Process complexity may increase costs, potential for hazardous waste generation during recycling.

Innovative Recycling Technologies

A method of using a wet method to recycle metal elements in lithium batteries

PatentPendingEP4575022A1

Innovation

- A wet method for recycling lithium batteries involving pretreatment, acid leaching, and extraction processes using agents like diisooctyl phosphate to separate and recover valuable metals such as lithium, nickel, cobalt, and manganese, while minimizing environmental impact.

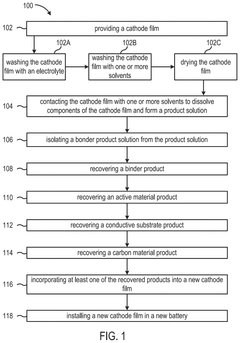

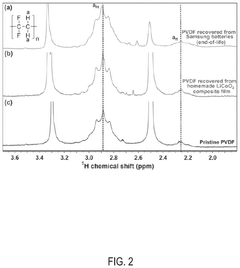

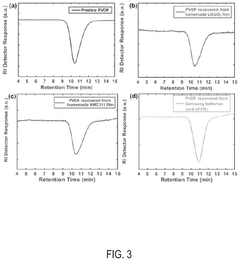

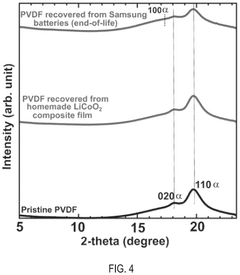

Methods for recovering and reusing polymeric binders from composite cathode films

PatentActiveUS12132176B2

Innovation

- A method involving the use of solvents such as N,N-dimethylformamide (DMF), N-methyl-2-pyrrolidine (NMP), and tetrahydrofuran (THF) mixtures to dissolve and isolate PVDF from cathode films, followed by alumina column separation and precipitation, allowing for the recovery and reuse of PVDF as a binder in new batteries.

Environmental Regulations on Battery Disposal

Environmental regulations on battery disposal have become increasingly stringent in recent years, reflecting growing concerns about the potential ecological impact of improperly discarded batteries. These regulations aim to minimize environmental contamination and promote sustainable practices in the automotive industry, particularly concerning mild hybrid vehicles.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a framework for managing hazardous waste, including batteries. This treaty has been ratified by numerous countries and serves as a foundation for national and regional regulations.

In the European Union, the Directive 2006/66/EC on batteries and accumulators and waste batteries and accumulators sets specific requirements for battery disposal. This directive mandates the collection, recycling, and proper disposal of all types of batteries, including those used in mild hybrid vehicles. It also establishes targets for collection rates and recycling efficiencies.

The United States has implemented the Mercury-Containing and Rechargeable Battery Management Act, which regulates the disposal of certain types of batteries. Additionally, individual states have enacted their own regulations, such as California's Battery Recycling Act, which requires retailers to collect and recycle rechargeable batteries.

In Asia, countries like Japan and South Korea have implemented advanced recycling systems for automotive batteries. Japan's Act on Recycling of End-of-Life Vehicles mandates the proper disposal and recycling of vehicle components, including batteries. South Korea has similar regulations under its Act on the Resource Circulation of Electrical and Electronic Equipment and Vehicles.

These regulations typically require manufacturers and distributors to establish take-back programs for used batteries. They also set standards for the safe handling, transportation, and recycling of batteries to prevent environmental contamination. Many jurisdictions have implemented extended producer responsibility (EPR) policies, which make manufacturers responsible for the entire lifecycle of their products, including disposal.

Compliance with these regulations often involves detailed reporting requirements, documentation of proper disposal procedures, and adherence to specific recycling targets. Penalties for non-compliance can be severe, including fines and potential criminal charges in cases of egregious violations.

As the adoption of mild hybrid vehicles continues to grow, regulators are likely to further refine and strengthen these regulations. Future trends may include more stringent recycling targets, increased focus on the recovery of critical materials from batteries, and the development of standardized labeling systems to facilitate proper disposal and recycling.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a framework for managing hazardous waste, including batteries. This treaty has been ratified by numerous countries and serves as a foundation for national and regional regulations.

In the European Union, the Directive 2006/66/EC on batteries and accumulators and waste batteries and accumulators sets specific requirements for battery disposal. This directive mandates the collection, recycling, and proper disposal of all types of batteries, including those used in mild hybrid vehicles. It also establishes targets for collection rates and recycling efficiencies.

The United States has implemented the Mercury-Containing and Rechargeable Battery Management Act, which regulates the disposal of certain types of batteries. Additionally, individual states have enacted their own regulations, such as California's Battery Recycling Act, which requires retailers to collect and recycle rechargeable batteries.

In Asia, countries like Japan and South Korea have implemented advanced recycling systems for automotive batteries. Japan's Act on Recycling of End-of-Life Vehicles mandates the proper disposal and recycling of vehicle components, including batteries. South Korea has similar regulations under its Act on the Resource Circulation of Electrical and Electronic Equipment and Vehicles.

These regulations typically require manufacturers and distributors to establish take-back programs for used batteries. They also set standards for the safe handling, transportation, and recycling of batteries to prevent environmental contamination. Many jurisdictions have implemented extended producer responsibility (EPR) policies, which make manufacturers responsible for the entire lifecycle of their products, including disposal.

Compliance with these regulations often involves detailed reporting requirements, documentation of proper disposal procedures, and adherence to specific recycling targets. Penalties for non-compliance can be severe, including fines and potential criminal charges in cases of egregious violations.

As the adoption of mild hybrid vehicles continues to grow, regulators are likely to further refine and strengthen these regulations. Future trends may include more stringent recycling targets, increased focus on the recovery of critical materials from batteries, and the development of standardized labeling systems to facilitate proper disposal and recycling.

Life Cycle Assessment of Mild Hybrid Batteries

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of mild hybrid batteries throughout their entire lifecycle, from raw material extraction to disposal. This comprehensive approach allows for a holistic understanding of the battery's environmental footprint and helps identify areas for improvement in sustainability.

The LCA process for mild hybrid batteries typically begins with the extraction and processing of raw materials, including lithium, cobalt, nickel, and other metals. This stage often accounts for a significant portion of the battery's overall environmental impact due to energy-intensive mining and refining processes. The manufacturing phase follows, involving the production of battery cells, modules, and packs, which requires substantial energy input and may result in emissions of greenhouse gases and other pollutants.

During the use phase, mild hybrid batteries contribute to reduced fuel consumption and lower emissions in vehicles. However, the environmental benefits during this stage must be weighed against the impacts of battery production and eventual disposal. The use phase also includes considerations for battery maintenance, potential replacements, and the energy mix used for charging in plug-in hybrid systems.

End-of-life management is a critical aspect of the LCA for mild hybrid batteries. As these batteries reach the end of their useful life in vehicles, proper disposal and recycling become essential to mitigate environmental impacts. Recycling processes aim to recover valuable materials such as lithium, cobalt, and nickel, reducing the need for virgin material extraction and associated environmental burdens.

Advanced recycling technologies are being developed to improve the efficiency and environmental performance of battery recycling. These include hydrometallurgical and pyrometallurgical processes, which can recover a high percentage of battery materials. However, the energy intensity of these processes and potential emissions must be carefully considered in the overall LCA.

The LCA also examines the potential for second-life applications of mild hybrid batteries. After their automotive use, these batteries may still retain sufficient capacity for less demanding applications, such as stationary energy storage. This extended use can significantly improve the overall environmental profile of the batteries by delaying final disposal and offsetting the production of new batteries for these secondary applications.

Transportation and logistics throughout the battery lifecycle are additional factors considered in the LCA. The movement of raw materials, finished batteries, and end-of-life batteries for recycling all contribute to the overall environmental impact through fuel consumption and emissions.

By conducting a thorough LCA, manufacturers and policymakers can identify hotspots in the battery lifecycle where environmental impacts are most significant. This information can guide design improvements, material selection, and policy decisions to enhance the sustainability of mild hybrid battery systems and support the transition to cleaner transportation technologies.

The LCA process for mild hybrid batteries typically begins with the extraction and processing of raw materials, including lithium, cobalt, nickel, and other metals. This stage often accounts for a significant portion of the battery's overall environmental impact due to energy-intensive mining and refining processes. The manufacturing phase follows, involving the production of battery cells, modules, and packs, which requires substantial energy input and may result in emissions of greenhouse gases and other pollutants.

During the use phase, mild hybrid batteries contribute to reduced fuel consumption and lower emissions in vehicles. However, the environmental benefits during this stage must be weighed against the impacts of battery production and eventual disposal. The use phase also includes considerations for battery maintenance, potential replacements, and the energy mix used for charging in plug-in hybrid systems.

End-of-life management is a critical aspect of the LCA for mild hybrid batteries. As these batteries reach the end of their useful life in vehicles, proper disposal and recycling become essential to mitigate environmental impacts. Recycling processes aim to recover valuable materials such as lithium, cobalt, and nickel, reducing the need for virgin material extraction and associated environmental burdens.

Advanced recycling technologies are being developed to improve the efficiency and environmental performance of battery recycling. These include hydrometallurgical and pyrometallurgical processes, which can recover a high percentage of battery materials. However, the energy intensity of these processes and potential emissions must be carefully considered in the overall LCA.

The LCA also examines the potential for second-life applications of mild hybrid batteries. After their automotive use, these batteries may still retain sufficient capacity for less demanding applications, such as stationary energy storage. This extended use can significantly improve the overall environmental profile of the batteries by delaying final disposal and offsetting the production of new batteries for these secondary applications.

Transportation and logistics throughout the battery lifecycle are additional factors considered in the LCA. The movement of raw materials, finished batteries, and end-of-life batteries for recycling all contribute to the overall environmental impact through fuel consumption and emissions.

By conducting a thorough LCA, manufacturers and policymakers can identify hotspots in the battery lifecycle where environmental impacts are most significant. This information can guide design improvements, material selection, and policy decisions to enhance the sustainability of mild hybrid battery systems and support the transition to cleaner transportation technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!