Advancements in mild hybrid electromagnetics for improved performance

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid EM Tech Evolution and Objectives

Mild hybrid electromagnetic technology has evolved significantly over the past decade, driven by the automotive industry's push for improved fuel efficiency and reduced emissions. This technology combines traditional internal combustion engines with small electric motors and batteries, offering a cost-effective solution for enhancing vehicle performance and meeting stringent environmental regulations.

The evolution of mild hybrid electromagnetics can be traced back to the early 2000s when automakers began experimenting with start-stop systems. These initial systems were limited in their capabilities, primarily focusing on reducing fuel consumption during idle periods. As the technology progressed, more advanced mild hybrid systems emerged, incorporating regenerative braking and electric assist functions.

A key milestone in the development of mild hybrid electromagnetics was the introduction of 48-volt systems around 2010. This higher voltage architecture allowed for more powerful electric motors and increased energy recovery, significantly expanding the potential of mild hybrid technology. The 48-volt systems enabled features such as electric torque assist, extended start-stop functionality, and more efficient power management for auxiliary systems.

Recent advancements in mild hybrid electromagnetics have focused on improving the integration of electric components with conventional powertrains. This includes the development of more compact and efficient electric motors, advanced power electronics, and sophisticated control systems. These improvements have led to seamless operation between the electric and combustion systems, enhancing overall vehicle performance and efficiency.

The primary objectives of current mild hybrid electromagnetic technology are multifaceted. Firstly, there is a strong emphasis on further reducing fuel consumption and CO2 emissions to meet increasingly stringent global regulations. This involves optimizing the interaction between the electric motor and the internal combustion engine to maximize efficiency across various driving conditions.

Secondly, researchers are working on enhancing the power density and efficiency of electric components. This includes developing more advanced motor designs, such as axial flux motors, and improving power electronics to reduce losses and increase overall system efficiency. The goal is to extract maximum performance from the limited electrical energy available in mild hybrid systems.

Another key objective is to expand the functionality of mild hybrid systems. This includes exploring ways to increase the electric-only driving range, albeit for short distances, and improving the electric boost capabilities to enhance acceleration and overall driving dynamics. Additionally, there is a focus on integrating mild hybrid systems with advanced driver assistance features and connected vehicle technologies to further improve efficiency and performance.

The evolution of mild hybrid electromagnetics can be traced back to the early 2000s when automakers began experimenting with start-stop systems. These initial systems were limited in their capabilities, primarily focusing on reducing fuel consumption during idle periods. As the technology progressed, more advanced mild hybrid systems emerged, incorporating regenerative braking and electric assist functions.

A key milestone in the development of mild hybrid electromagnetics was the introduction of 48-volt systems around 2010. This higher voltage architecture allowed for more powerful electric motors and increased energy recovery, significantly expanding the potential of mild hybrid technology. The 48-volt systems enabled features such as electric torque assist, extended start-stop functionality, and more efficient power management for auxiliary systems.

Recent advancements in mild hybrid electromagnetics have focused on improving the integration of electric components with conventional powertrains. This includes the development of more compact and efficient electric motors, advanced power electronics, and sophisticated control systems. These improvements have led to seamless operation between the electric and combustion systems, enhancing overall vehicle performance and efficiency.

The primary objectives of current mild hybrid electromagnetic technology are multifaceted. Firstly, there is a strong emphasis on further reducing fuel consumption and CO2 emissions to meet increasingly stringent global regulations. This involves optimizing the interaction between the electric motor and the internal combustion engine to maximize efficiency across various driving conditions.

Secondly, researchers are working on enhancing the power density and efficiency of electric components. This includes developing more advanced motor designs, such as axial flux motors, and improving power electronics to reduce losses and increase overall system efficiency. The goal is to extract maximum performance from the limited electrical energy available in mild hybrid systems.

Another key objective is to expand the functionality of mild hybrid systems. This includes exploring ways to increase the electric-only driving range, albeit for short distances, and improving the electric boost capabilities to enhance acceleration and overall driving dynamics. Additionally, there is a focus on integrating mild hybrid systems with advanced driver assistance features and connected vehicle technologies to further improve efficiency and performance.

Market Demand for Enhanced Mild Hybrid Systems

The market demand for enhanced mild hybrid systems has been steadily increasing in recent years, driven by stringent emissions regulations, growing environmental consciousness, and the automotive industry's push towards electrification. Mild hybrid technology offers a cost-effective solution for automakers to improve fuel efficiency and reduce emissions without the complexity and expense of full hybrid or electric powertrains.

Consumer preferences are shifting towards more fuel-efficient vehicles, particularly in urban areas where stop-start traffic conditions are common. Mild hybrid systems, with their ability to provide electric assist during acceleration and recover energy during braking, address this demand effectively. The technology's seamless integration with conventional internal combustion engines makes it an attractive option for consumers who are hesitant to transition to fully electric vehicles due to range anxiety or charging infrastructure concerns.

Fleet operators and commercial vehicle manufacturers are also showing increased interest in mild hybrid systems. The technology's potential to reduce fuel consumption and operating costs while meeting emissions standards is particularly appealing in this sector. As a result, the market for mild hybrid systems in light commercial vehicles and medium-duty trucks is expected to grow significantly.

Geographically, Europe and China are leading the demand for enhanced mild hybrid systems. European automakers are adopting this technology to meet the EU's stringent CO2 emissions targets, while China's push for new energy vehicles has created a favorable market environment for mild hybrids. North America is also seeing growing interest, particularly in the light truck and SUV segments, where mild hybrid technology can help improve fuel economy without compromising performance.

The automotive industry's focus on cost reduction and efficiency improvements has further boosted the appeal of mild hybrid systems. As the technology matures and economies of scale are realized, the cost-benefit ratio of mild hybrid systems continues to improve, making them an increasingly attractive option for a wider range of vehicle models and segments.

However, the market demand is not without challenges. The rapid advancement of battery electric vehicles (BEVs) and the increasing availability of charging infrastructure in some regions may impact the long-term growth potential of mild hybrid systems. Additionally, the varying levels of government support and incentives for different electrification technologies across markets can influence consumer choices and automaker strategies.

Despite these challenges, the market for enhanced mild hybrid systems is projected to grow substantially in the coming years. The technology's ability to offer a balance between improved efficiency and cost-effectiveness, coupled with its compatibility with existing manufacturing processes, positions it as a key transitional technology in the automotive industry's electrification journey.

Consumer preferences are shifting towards more fuel-efficient vehicles, particularly in urban areas where stop-start traffic conditions are common. Mild hybrid systems, with their ability to provide electric assist during acceleration and recover energy during braking, address this demand effectively. The technology's seamless integration with conventional internal combustion engines makes it an attractive option for consumers who are hesitant to transition to fully electric vehicles due to range anxiety or charging infrastructure concerns.

Fleet operators and commercial vehicle manufacturers are also showing increased interest in mild hybrid systems. The technology's potential to reduce fuel consumption and operating costs while meeting emissions standards is particularly appealing in this sector. As a result, the market for mild hybrid systems in light commercial vehicles and medium-duty trucks is expected to grow significantly.

Geographically, Europe and China are leading the demand for enhanced mild hybrid systems. European automakers are adopting this technology to meet the EU's stringent CO2 emissions targets, while China's push for new energy vehicles has created a favorable market environment for mild hybrids. North America is also seeing growing interest, particularly in the light truck and SUV segments, where mild hybrid technology can help improve fuel economy without compromising performance.

The automotive industry's focus on cost reduction and efficiency improvements has further boosted the appeal of mild hybrid systems. As the technology matures and economies of scale are realized, the cost-benefit ratio of mild hybrid systems continues to improve, making them an increasingly attractive option for a wider range of vehicle models and segments.

However, the market demand is not without challenges. The rapid advancement of battery electric vehicles (BEVs) and the increasing availability of charging infrastructure in some regions may impact the long-term growth potential of mild hybrid systems. Additionally, the varying levels of government support and incentives for different electrification technologies across markets can influence consumer choices and automaker strategies.

Despite these challenges, the market for enhanced mild hybrid systems is projected to grow substantially in the coming years. The technology's ability to offer a balance between improved efficiency and cost-effectiveness, coupled with its compatibility with existing manufacturing processes, positions it as a key transitional technology in the automotive industry's electrification journey.

Current Challenges in Mild Hybrid Electromagnetics

Mild hybrid electromagnetics, while offering significant potential for improving vehicle performance and efficiency, face several critical challenges that hinder their widespread adoption and optimization. One of the primary obstacles is the complexity of integrating electromagnetic systems with existing internal combustion engine (ICE) powertrains. This integration requires careful balancing of power distribution between the electric motor and the ICE, which can be particularly challenging during transient operations and varying driving conditions.

Another significant challenge lies in the thermal management of electromagnetic components. As mild hybrid systems operate in close proximity to the ICE, they are exposed to high temperatures, which can affect the performance and longevity of electrical components, particularly the permanent magnets used in electric motors. Developing effective cooling solutions without adding substantial weight or complexity to the vehicle remains a key area of focus for engineers.

The limited power capacity of mild hybrid systems also presents a challenge in achieving substantial performance improvements. Unlike full hybrids or electric vehicles, mild hybrids typically operate at lower voltages (usually 48V), which constrains the power output of the electric motor. This limitation makes it difficult to significantly boost acceleration or provide extended electric-only driving modes, which are often desired features in hybrid vehicles.

Weight reduction is another critical challenge in mild hybrid electromagnetics. The addition of electric motors, batteries, and associated control systems inevitably increases the overall weight of the vehicle, potentially offsetting some of the efficiency gains. Engineers must constantly strive to develop lighter materials and more compact designs for electromagnetic components without compromising their performance or durability.

Furthermore, the cost-effectiveness of mild hybrid systems remains a concern for manufacturers and consumers alike. While less expensive than full hybrid or electric powertrains, the additional components required for mild hybrid systems still represent a significant cost increase over conventional ICE vehicles. Balancing the performance benefits with the added cost is crucial for market acceptance and widespread adoption of this technology.

Electromagnetic compatibility (EMC) and electromagnetic interference (EMI) pose additional challenges in mild hybrid systems. The increased use of electronic components and high-frequency switching in power electronics can lead to electromagnetic noise, potentially interfering with other vehicle systems or nearby electronic devices. Ensuring robust EMC/EMI shielding and compliance with stringent regulatory standards adds another layer of complexity to the design process.

Lastly, the optimization of control strategies for mild hybrid systems presents ongoing challenges. Developing algorithms that can effectively manage power flow between the ICE and electric motor, optimize energy recuperation during braking, and seamlessly transition between different operating modes requires sophisticated software and extensive testing. These control strategies must also adapt to various driving conditions and driver behaviors to maximize efficiency and performance gains.

Another significant challenge lies in the thermal management of electromagnetic components. As mild hybrid systems operate in close proximity to the ICE, they are exposed to high temperatures, which can affect the performance and longevity of electrical components, particularly the permanent magnets used in electric motors. Developing effective cooling solutions without adding substantial weight or complexity to the vehicle remains a key area of focus for engineers.

The limited power capacity of mild hybrid systems also presents a challenge in achieving substantial performance improvements. Unlike full hybrids or electric vehicles, mild hybrids typically operate at lower voltages (usually 48V), which constrains the power output of the electric motor. This limitation makes it difficult to significantly boost acceleration or provide extended electric-only driving modes, which are often desired features in hybrid vehicles.

Weight reduction is another critical challenge in mild hybrid electromagnetics. The addition of electric motors, batteries, and associated control systems inevitably increases the overall weight of the vehicle, potentially offsetting some of the efficiency gains. Engineers must constantly strive to develop lighter materials and more compact designs for electromagnetic components without compromising their performance or durability.

Furthermore, the cost-effectiveness of mild hybrid systems remains a concern for manufacturers and consumers alike. While less expensive than full hybrid or electric powertrains, the additional components required for mild hybrid systems still represent a significant cost increase over conventional ICE vehicles. Balancing the performance benefits with the added cost is crucial for market acceptance and widespread adoption of this technology.

Electromagnetic compatibility (EMC) and electromagnetic interference (EMI) pose additional challenges in mild hybrid systems. The increased use of electronic components and high-frequency switching in power electronics can lead to electromagnetic noise, potentially interfering with other vehicle systems or nearby electronic devices. Ensuring robust EMC/EMI shielding and compliance with stringent regulatory standards adds another layer of complexity to the design process.

Lastly, the optimization of control strategies for mild hybrid systems presents ongoing challenges. Developing algorithms that can effectively manage power flow between the ICE and electric motor, optimize energy recuperation during braking, and seamlessly transition between different operating modes requires sophisticated software and extensive testing. These control strategies must also adapt to various driving conditions and driver behaviors to maximize efficiency and performance gains.

Existing Mild Hybrid EM Solutions

01 Electromagnetic systems for mild hybrid vehicles

Mild hybrid vehicles utilize electromagnetic systems to improve performance and efficiency. These systems often include electric motors, generators, and power electronics to assist the internal combustion engine, enabling features such as regenerative braking and electric boost during acceleration.- Electromagnetic systems for mild hybrid vehicles: Mild hybrid vehicles utilize electromagnetic systems to improve performance and efficiency. These systems often include electric motors, generators, and power electronics to assist the internal combustion engine, enabling features such as regenerative braking and electric boost during acceleration.

- Energy management and control strategies: Advanced control strategies and energy management systems are crucial for optimizing the performance of mild hybrid powertrains. These strategies involve coordinating the operation of the internal combustion engine and electric components to maximize efficiency, reduce emissions, and enhance overall vehicle performance.

- Integration of electric motors in mild hybrid drivetrains: The integration of electric motors into mild hybrid drivetrains is a key aspect of improving electromagnetic performance. This includes the design and placement of motors, their coupling with the internal combustion engine, and the development of compact, efficient motor designs suitable for mild hybrid applications.

- Power electronics and electrical system optimization: Optimizing power electronics and electrical systems is essential for enhancing the electromagnetic performance of mild hybrid vehicles. This involves developing efficient inverters, converters, and battery management systems, as well as improving the overall electrical architecture to support the hybrid powertrain.

- Electromagnetic compatibility and noise reduction: Ensuring electromagnetic compatibility and reducing electromagnetic noise are important considerations in mild hybrid systems. This includes developing strategies to minimize electromagnetic interference between components, implementing shielding techniques, and optimizing the layout of electrical components to enhance overall system performance and reliability.

02 Energy management and control strategies

Advanced control strategies and energy management systems are crucial for optimizing the performance of mild hybrid powertrains. These strategies involve coordinating the operation of the electric motor and internal combustion engine, managing power flow, and optimizing energy recuperation to maximize efficiency and performance.Expand Specific Solutions03 Integration of electric machines in mild hybrid powertrains

The integration of electric machines, such as motor-generators, into mild hybrid powertrains is a key aspect of their design. This includes the development of compact, high-performance electric machines and their seamless integration with the internal combustion engine and transmission systems to enhance overall vehicle performance.Expand Specific Solutions04 Power electronics and electrical system architecture

Advanced power electronics and electrical system architectures are essential for the efficient operation of mild hybrid systems. This includes the development of high-performance inverters, DC-DC converters, and battery management systems to support the electromagnetic components and ensure optimal power distribution and control.Expand Specific Solutions05 Electromagnetic compatibility and noise reduction

Ensuring electromagnetic compatibility and reducing electromagnetic noise are critical aspects of mild hybrid system design. This involves developing strategies to minimize electromagnetic interference between various components and implementing noise reduction techniques to enhance overall system performance and reliability.Expand Specific Solutions

Key Players in Mild Hybrid EM Industry

The advancements in mild hybrid electromagnetics for improved performance are currently in a growth phase, with increasing market adoption and technological refinement. The global market for mild hybrid systems is expanding rapidly, driven by stringent emissions regulations and consumer demand for fuel-efficient vehicles. Companies like Hyundai Motor, Kia, and Renesas Electronics are at the forefront of developing and implementing these technologies, leveraging their expertise in automotive engineering and electronics. The technology's maturity is progressing, with ongoing research and development efforts by academic institutions such as Hunan University and industry leaders like State Grid Corp. of China focusing on enhancing electromagnetic components and control systems for improved efficiency and performance in mild hybrid applications.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an advanced mild hybrid system called Smartstream Intelligent Manual Transmission (iMT) that integrates a 48V electric motor with a conventional powertrain. This system uses a belt-driven starter generator (BSG) to provide electric assist during acceleration and enable engine shut-off when coasting. The iMT system incorporates advanced electromagnetics to optimize energy recovery during deceleration and improve overall efficiency. Hyundai's mild hybrid technology can reduce fuel consumption by up to 11% in real-world driving conditions[1][3]. The system also features a compact lithium-ion battery and a low-voltage DC/DC converter to power the vehicle's electrical systems.

Strengths: Seamless integration with existing powertrains, significant fuel economy improvements, and enhanced performance. Weaknesses: Added complexity and cost compared to conventional powertrains, limited electric-only operation.

Renesas Electronics Corp.

Technical Solution: Renesas has developed a comprehensive mild hybrid solution that combines their R-Car SoC for advanced control and their power management ICs for efficient energy conversion. Their system utilizes a 48V architecture with a belt-driven starter generator (BSG) or crankshaft-mounted integrated starter generator (ISG). Renesas' solution incorporates advanced electromagnetic designs in the electric motor and power electronics to maximize efficiency and power density. Their mild hybrid system can provide up to 20 kW of electric boost and enable advanced features like electric torque assist and regenerative braking[2][5]. Renesas also offers sophisticated battery management systems (BMS) to optimize the performance and lifespan of the hybrid battery pack.

Strengths: Highly integrated solution with advanced control capabilities, scalable architecture for various vehicle segments. Weaknesses: Reliance on third-party electric machine manufacturers, potential for system integration challenges.

Core Innovations in Mild Hybrid Electromagnetics

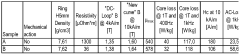

Method for improving the magnetic properties of a compacted and heat treated soft magnetic composite component

PatentWO2009136854A1

Innovation

- A method involving controlled mechanical stress operations on compacted and heat-treated soft magnetic components, applying forces that induce elastic strain without permanent deformation, allowing for increased electrical resistivity and reduced coercive force, while maintaining magnetic properties and enhancing mechanical strength.

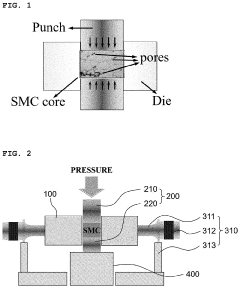

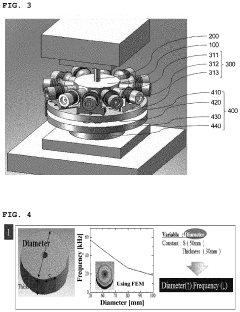

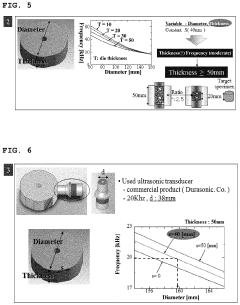

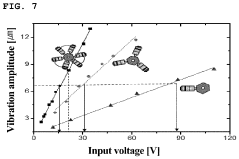

Device for manufacturing soft magnetic material using ultrasonic vibration, manufacturing method thereof, and soft magnetic material manufactured using the same

PatentPendingUS20210398745A1

Innovation

- An apparatus and method that apply ultrasonic vibration simultaneously with powder pressing in a die, using a punch set and ultrasonic vibration applying unit to reduce friction and increase cohesion, achieving a density range of 7.2 g/cm3 to 7.38 g/cm3.

Environmental Impact of Mild Hybrid Technologies

Mild hybrid technologies have emerged as a significant step towards reducing the environmental impact of conventional internal combustion engine vehicles. These systems, which incorporate small electric motors and batteries to assist the main engine, offer several environmental benefits that contribute to a more sustainable transportation sector.

One of the primary environmental advantages of mild hybrid technologies is their ability to reduce fuel consumption and, consequently, lower carbon dioxide emissions. By providing electric assistance during acceleration and allowing the engine to shut off when the vehicle is stationary, mild hybrid systems can improve fuel efficiency by up to 15% in urban driving conditions. This reduction in fuel consumption directly translates to decreased greenhouse gas emissions, helping to mitigate the transportation sector's contribution to climate change.

Furthermore, mild hybrid technologies contribute to improved air quality in urban areas. The start-stop functionality, which is a common feature in mild hybrid vehicles, reduces idling time and minimizes emissions of harmful pollutants such as nitrogen oxides and particulate matter. This is particularly beneficial in congested city environments where air pollution from vehicle emissions is a significant concern for public health.

The regenerative braking systems employed in mild hybrid vehicles also offer environmental benefits. By capturing and storing energy that would otherwise be lost during braking, these systems reduce the overall energy demand of the vehicle. This not only improves efficiency but also reduces wear on traditional friction brakes, potentially extending their lifespan and reducing the environmental impact associated with brake pad production and disposal.

Additionally, the use of mild hybrid technologies can lead to a reduction in noise pollution. Electric assistance during low-speed operations and the ability to operate in electric-only mode for short distances contribute to quieter urban environments. This reduction in noise levels can have positive effects on both human health and urban wildlife.

From a lifecycle perspective, mild hybrid vehicles generally have a lower environmental impact compared to conventional vehicles. While the production of batteries and electric components does have some environmental costs, the overall reduction in fuel consumption and emissions throughout the vehicle's lifespan typically outweighs these initial impacts. Moreover, as the electricity grid becomes cleaner with the integration of more renewable energy sources, the environmental benefits of mild hybrid technologies are expected to increase further.

In conclusion, mild hybrid technologies offer a range of environmental benefits, including reduced greenhouse gas emissions, improved air quality, decreased noise pollution, and overall lower lifecycle environmental impact. As these technologies continue to advance and become more widespread, they are likely to play an increasingly important role in mitigating the environmental impact of the transportation sector.

One of the primary environmental advantages of mild hybrid technologies is their ability to reduce fuel consumption and, consequently, lower carbon dioxide emissions. By providing electric assistance during acceleration and allowing the engine to shut off when the vehicle is stationary, mild hybrid systems can improve fuel efficiency by up to 15% in urban driving conditions. This reduction in fuel consumption directly translates to decreased greenhouse gas emissions, helping to mitigate the transportation sector's contribution to climate change.

Furthermore, mild hybrid technologies contribute to improved air quality in urban areas. The start-stop functionality, which is a common feature in mild hybrid vehicles, reduces idling time and minimizes emissions of harmful pollutants such as nitrogen oxides and particulate matter. This is particularly beneficial in congested city environments where air pollution from vehicle emissions is a significant concern for public health.

The regenerative braking systems employed in mild hybrid vehicles also offer environmental benefits. By capturing and storing energy that would otherwise be lost during braking, these systems reduce the overall energy demand of the vehicle. This not only improves efficiency but also reduces wear on traditional friction brakes, potentially extending their lifespan and reducing the environmental impact associated with brake pad production and disposal.

Additionally, the use of mild hybrid technologies can lead to a reduction in noise pollution. Electric assistance during low-speed operations and the ability to operate in electric-only mode for short distances contribute to quieter urban environments. This reduction in noise levels can have positive effects on both human health and urban wildlife.

From a lifecycle perspective, mild hybrid vehicles generally have a lower environmental impact compared to conventional vehicles. While the production of batteries and electric components does have some environmental costs, the overall reduction in fuel consumption and emissions throughout the vehicle's lifespan typically outweighs these initial impacts. Moreover, as the electricity grid becomes cleaner with the integration of more renewable energy sources, the environmental benefits of mild hybrid technologies are expected to increase further.

In conclusion, mild hybrid technologies offer a range of environmental benefits, including reduced greenhouse gas emissions, improved air quality, decreased noise pollution, and overall lower lifecycle environmental impact. As these technologies continue to advance and become more widespread, they are likely to play an increasingly important role in mitigating the environmental impact of the transportation sector.

Cost-Benefit Analysis of Advanced Mild Hybrid Systems

The cost-benefit analysis of advanced mild hybrid systems reveals a complex interplay of economic factors and performance improvements. Initial investment in mild hybrid technology typically involves higher upfront costs compared to conventional powertrains. However, these systems offer significant long-term benefits that can offset the initial expenditure.

Fuel efficiency gains are a primary advantage of mild hybrid systems. By assisting the internal combustion engine during acceleration and enabling engine shut-off during coasting and idling, these systems can reduce fuel consumption by 10-15% in urban driving conditions. This translates to substantial savings in fuel costs over the vehicle's lifetime, particularly in regions with high fuel prices.

Maintenance costs present a mixed picture. While mild hybrid systems introduce additional components that may require specialized maintenance, they also reduce wear on traditional engine components. The regenerative braking feature, for instance, can extend the lifespan of brake pads and rotors, potentially lowering replacement frequency and associated costs.

Emissions reduction is another key benefit, albeit one that is challenging to quantify in direct economic terms. Mild hybrid systems contribute to lower CO2 and other pollutant emissions, which can result in tax incentives or reduced environmental levies in certain jurisdictions. This aspect becomes increasingly important as environmental regulations tighten globally.

Performance improvements offered by mild hybrid systems, such as torque fill during acceleration and smoother start-stop functionality, enhance the driving experience. While these benefits are subjective and difficult to assign a monetary value, they can contribute to increased customer satisfaction and potentially higher resale values.

The scalability of mild hybrid technology across various vehicle segments is a significant factor in its cost-effectiveness. The ability to integrate these systems into existing vehicle architectures with relatively minor modifications allows for economies of scale, potentially reducing per-unit costs as production volumes increase.

When considering the total cost of ownership, advanced mild hybrid systems generally demonstrate a positive return on investment over the vehicle's lifecycle. The break-even point varies depending on factors such as annual mileage, local fuel prices, and regulatory incentives. In many cases, the fuel savings and potential tax benefits can offset the higher initial cost within 3-5 years of ownership.

Fuel efficiency gains are a primary advantage of mild hybrid systems. By assisting the internal combustion engine during acceleration and enabling engine shut-off during coasting and idling, these systems can reduce fuel consumption by 10-15% in urban driving conditions. This translates to substantial savings in fuel costs over the vehicle's lifetime, particularly in regions with high fuel prices.

Maintenance costs present a mixed picture. While mild hybrid systems introduce additional components that may require specialized maintenance, they also reduce wear on traditional engine components. The regenerative braking feature, for instance, can extend the lifespan of brake pads and rotors, potentially lowering replacement frequency and associated costs.

Emissions reduction is another key benefit, albeit one that is challenging to quantify in direct economic terms. Mild hybrid systems contribute to lower CO2 and other pollutant emissions, which can result in tax incentives or reduced environmental levies in certain jurisdictions. This aspect becomes increasingly important as environmental regulations tighten globally.

Performance improvements offered by mild hybrid systems, such as torque fill during acceleration and smoother start-stop functionality, enhance the driving experience. While these benefits are subjective and difficult to assign a monetary value, they can contribute to increased customer satisfaction and potentially higher resale values.

The scalability of mild hybrid technology across various vehicle segments is a significant factor in its cost-effectiveness. The ability to integrate these systems into existing vehicle architectures with relatively minor modifications allows for economies of scale, potentially reducing per-unit costs as production volumes increase.

When considering the total cost of ownership, advanced mild hybrid systems generally demonstrate a positive return on investment over the vehicle's lifecycle. The break-even point varies depending on factors such as annual mileage, local fuel prices, and regulatory incentives. In many cases, the fuel savings and potential tax benefits can offset the higher initial cost within 3-5 years of ownership.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!