Innovations in mild hybrid systems for commercial aviation applications

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aviation Hybrid Tech Evolution and Objectives

The evolution of hybrid technology in aviation has been driven by the increasing demand for more fuel-efficient and environmentally friendly aircraft. The industry's primary objective is to reduce carbon emissions and operating costs while maintaining or improving performance. Mild hybrid systems for commercial aviation applications represent a significant step towards achieving these goals.

The development of hybrid propulsion systems in aviation can be traced back to the early 2000s when researchers began exploring the potential of combining conventional jet engines with electric motors. Initially, these efforts focused on small aircraft and unmanned aerial vehicles (UAVs). However, as technology advanced, the scope expanded to include larger commercial aircraft.

One of the key milestones in this evolution was the introduction of the more electric aircraft (MEA) concept. This approach aimed to replace hydraulic and pneumatic systems with electrical alternatives, laying the groundwork for future hybrid propulsion systems. The Boeing 787 Dreamliner, introduced in 2011, was one of the first commercial aircraft to incorporate significant MEA technologies.

As battery technology improved and electric motors became more powerful and efficient, the aviation industry began to seriously consider hybrid-electric propulsion for commercial aircraft. In 2017, Airbus, Rolls-Royce, and Siemens announced a joint project to develop a hybrid-electric demonstrator aircraft, marking a significant step towards the commercialization of this technology.

The current objectives for mild hybrid systems in commercial aviation focus on several key areas. Firstly, there is a push to reduce fuel consumption and emissions during various phases of flight, particularly during taxiing, takeoff, and landing. Secondly, researchers aim to optimize the overall energy efficiency of aircraft by integrating electric systems with conventional jet engines.

Another important goal is to develop scalable hybrid technologies that can be applied to a range of aircraft sizes, from regional jets to narrow-body airliners. This scalability is crucial for widespread adoption across the industry. Additionally, there is a focus on improving the power density and reliability of electric components to meet the stringent safety and performance requirements of commercial aviation.

Looking ahead, the industry is setting ambitious targets for hybrid-electric aircraft. These include achieving a 20-30% reduction in fuel consumption for short to medium-range flights by 2035 and developing fully electric aircraft for short-haul routes. To reach these objectives, ongoing research is addressing challenges such as battery weight, thermal management, and the integration of hybrid systems with existing aircraft architectures.

The development of hybrid propulsion systems in aviation can be traced back to the early 2000s when researchers began exploring the potential of combining conventional jet engines with electric motors. Initially, these efforts focused on small aircraft and unmanned aerial vehicles (UAVs). However, as technology advanced, the scope expanded to include larger commercial aircraft.

One of the key milestones in this evolution was the introduction of the more electric aircraft (MEA) concept. This approach aimed to replace hydraulic and pneumatic systems with electrical alternatives, laying the groundwork for future hybrid propulsion systems. The Boeing 787 Dreamliner, introduced in 2011, was one of the first commercial aircraft to incorporate significant MEA technologies.

As battery technology improved and electric motors became more powerful and efficient, the aviation industry began to seriously consider hybrid-electric propulsion for commercial aircraft. In 2017, Airbus, Rolls-Royce, and Siemens announced a joint project to develop a hybrid-electric demonstrator aircraft, marking a significant step towards the commercialization of this technology.

The current objectives for mild hybrid systems in commercial aviation focus on several key areas. Firstly, there is a push to reduce fuel consumption and emissions during various phases of flight, particularly during taxiing, takeoff, and landing. Secondly, researchers aim to optimize the overall energy efficiency of aircraft by integrating electric systems with conventional jet engines.

Another important goal is to develop scalable hybrid technologies that can be applied to a range of aircraft sizes, from regional jets to narrow-body airliners. This scalability is crucial for widespread adoption across the industry. Additionally, there is a focus on improving the power density and reliability of electric components to meet the stringent safety and performance requirements of commercial aviation.

Looking ahead, the industry is setting ambitious targets for hybrid-electric aircraft. These include achieving a 20-30% reduction in fuel consumption for short to medium-range flights by 2035 and developing fully electric aircraft for short-haul routes. To reach these objectives, ongoing research is addressing challenges such as battery weight, thermal management, and the integration of hybrid systems with existing aircraft architectures.

Market Demand for Greener Commercial Aviation

The aviation industry is experiencing a significant shift towards greener technologies, driven by increasing environmental concerns and regulatory pressures. This trend has created a robust market demand for more fuel-efficient and environmentally friendly commercial aircraft. Airlines and aircraft manufacturers are actively seeking innovative solutions to reduce carbon emissions and operational costs, making mild hybrid systems an attractive option for the commercial aviation sector.

The global push for sustainability in air travel has been reinforced by international agreements such as the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), which aims to stabilize CO2 emissions at 2020 levels. This regulatory landscape has intensified the need for airlines to adopt cleaner technologies, including hybrid propulsion systems. As a result, the market for greener aviation solutions is projected to grow substantially in the coming years.

Passengers are also becoming increasingly environmentally conscious, with many expressing a preference for airlines that demonstrate a commitment to reducing their carbon footprint. This shift in consumer behavior is creating additional market pressure for airlines to invest in greener technologies, including mild hybrid systems. Airlines that can showcase their environmental initiatives are likely to gain a competitive edge in attracting eco-conscious travelers.

The economic benefits of adopting mild hybrid systems in commercial aviation are compelling. With fuel costs representing a significant portion of airline operating expenses, any technology that can reduce fuel consumption offers substantial cost-saving potential. Mild hybrid systems, which can improve fuel efficiency without requiring a complete overhaul of existing aircraft designs, present an attractive solution for airlines looking to balance environmental responsibility with economic viability.

Moreover, the aviation industry's recovery from the COVID-19 pandemic has accelerated the demand for more efficient aircraft. As airlines seek to rebuild their fleets and routes, there is a growing emphasis on incorporating technologies that can provide long-term operational and environmental benefits. This has created a favorable market environment for innovations in mild hybrid systems, as they offer a pathway to improved efficiency without the need for radical changes in aircraft design or infrastructure.

The market demand for greener commercial aviation is further bolstered by government incentives and support programs aimed at promoting sustainable air travel. Many countries are offering tax breaks, research grants, and other financial incentives to airlines and manufacturers that invest in green technologies. This supportive policy environment is expected to drive increased investment and innovation in mild hybrid systems for commercial aviation applications.

The global push for sustainability in air travel has been reinforced by international agreements such as the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), which aims to stabilize CO2 emissions at 2020 levels. This regulatory landscape has intensified the need for airlines to adopt cleaner technologies, including hybrid propulsion systems. As a result, the market for greener aviation solutions is projected to grow substantially in the coming years.

Passengers are also becoming increasingly environmentally conscious, with many expressing a preference for airlines that demonstrate a commitment to reducing their carbon footprint. This shift in consumer behavior is creating additional market pressure for airlines to invest in greener technologies, including mild hybrid systems. Airlines that can showcase their environmental initiatives are likely to gain a competitive edge in attracting eco-conscious travelers.

The economic benefits of adopting mild hybrid systems in commercial aviation are compelling. With fuel costs representing a significant portion of airline operating expenses, any technology that can reduce fuel consumption offers substantial cost-saving potential. Mild hybrid systems, which can improve fuel efficiency without requiring a complete overhaul of existing aircraft designs, present an attractive solution for airlines looking to balance environmental responsibility with economic viability.

Moreover, the aviation industry's recovery from the COVID-19 pandemic has accelerated the demand for more efficient aircraft. As airlines seek to rebuild their fleets and routes, there is a growing emphasis on incorporating technologies that can provide long-term operational and environmental benefits. This has created a favorable market environment for innovations in mild hybrid systems, as they offer a pathway to improved efficiency without the need for radical changes in aircraft design or infrastructure.

The market demand for greener commercial aviation is further bolstered by government incentives and support programs aimed at promoting sustainable air travel. Many countries are offering tax breaks, research grants, and other financial incentives to airlines and manufacturers that invest in green technologies. This supportive policy environment is expected to drive increased investment and innovation in mild hybrid systems for commercial aviation applications.

Mild Hybrid Systems in Aviation: Current State

Mild hybrid systems in commercial aviation have gained significant attention in recent years as the industry seeks to reduce emissions and improve fuel efficiency. These systems typically combine conventional jet engines with electric motors, allowing for more efficient power distribution and energy recovery during various flight phases.

The current state of mild hybrid systems in aviation is characterized by ongoing research and development, with several major aircraft manufacturers and engine suppliers actively pursuing this technology. While full electric propulsion remains challenging for large commercial aircraft due to battery limitations, mild hybrid systems offer a promising intermediate step towards greener aviation.

One of the primary approaches in mild hybrid aviation systems involves the integration of electric motors into existing turbofan engines. These motors can provide additional thrust during takeoff and climb, reducing the load on the main engine and potentially allowing for smaller, more efficient core engines. During cruise, the electric motors can operate as generators, harvesting energy that would otherwise be wasted and storing it for later use.

Another area of focus is the electrification of auxiliary systems. Traditional pneumatic and hydraulic systems are being replaced with electric alternatives, powered by the hybrid system. This not only reduces overall weight but also improves energy efficiency and allows for more flexible power management throughout the aircraft.

Several key players in the aviation industry have made significant strides in mild hybrid technology. For instance, Rolls-Royce has been developing its E-Fan X demonstrator in collaboration with Airbus, showcasing the potential of hybrid-electric propulsion in regional aircraft. Similarly, Pratt & Whitney has been working on hybrid-electric propulsion systems for smaller commercial aircraft, aiming to reduce fuel consumption by up to 30%.

The current state of mild hybrid systems in aviation also includes advancements in power electronics and thermal management. As these systems generate and distribute large amounts of electrical power, efficient and lightweight power conversion and cooling solutions are crucial. Innovations in wide-bandgap semiconductors and advanced cooling techniques are enabling more compact and efficient power systems.

While mild hybrid systems show great promise, challenges remain in terms of system integration, certification, and scaling up to larger aircraft. The aviation industry is known for its stringent safety requirements, and the introduction of new propulsion technologies requires extensive testing and validation. However, the potential benefits in terms of fuel efficiency and emissions reduction continue to drive investment and research in this field.

The current state of mild hybrid systems in aviation is characterized by ongoing research and development, with several major aircraft manufacturers and engine suppliers actively pursuing this technology. While full electric propulsion remains challenging for large commercial aircraft due to battery limitations, mild hybrid systems offer a promising intermediate step towards greener aviation.

One of the primary approaches in mild hybrid aviation systems involves the integration of electric motors into existing turbofan engines. These motors can provide additional thrust during takeoff and climb, reducing the load on the main engine and potentially allowing for smaller, more efficient core engines. During cruise, the electric motors can operate as generators, harvesting energy that would otherwise be wasted and storing it for later use.

Another area of focus is the electrification of auxiliary systems. Traditional pneumatic and hydraulic systems are being replaced with electric alternatives, powered by the hybrid system. This not only reduces overall weight but also improves energy efficiency and allows for more flexible power management throughout the aircraft.

Several key players in the aviation industry have made significant strides in mild hybrid technology. For instance, Rolls-Royce has been developing its E-Fan X demonstrator in collaboration with Airbus, showcasing the potential of hybrid-electric propulsion in regional aircraft. Similarly, Pratt & Whitney has been working on hybrid-electric propulsion systems for smaller commercial aircraft, aiming to reduce fuel consumption by up to 30%.

The current state of mild hybrid systems in aviation also includes advancements in power electronics and thermal management. As these systems generate and distribute large amounts of electrical power, efficient and lightweight power conversion and cooling solutions are crucial. Innovations in wide-bandgap semiconductors and advanced cooling techniques are enabling more compact and efficient power systems.

While mild hybrid systems show great promise, challenges remain in terms of system integration, certification, and scaling up to larger aircraft. The aviation industry is known for its stringent safety requirements, and the introduction of new propulsion technologies requires extensive testing and validation. However, the potential benefits in terms of fuel efficiency and emissions reduction continue to drive investment and research in this field.

Existing Mild Hybrid Solutions for Aircraft

01 Electric motor integration in mild hybrid systems

Mild hybrid systems incorporate electric motors to assist the internal combustion engine, improving fuel efficiency and performance. These motors can be integrated in various configurations, such as belt-driven starter generators or integrated starter generators, to provide additional power during acceleration and enable start-stop functionality.- Mild hybrid system architecture: Mild hybrid systems typically consist of a conventional internal combustion engine combined with an electric motor-generator. This setup allows for improved fuel efficiency and reduced emissions through features like engine start-stop, regenerative braking, and electric assist during acceleration. The electric components are generally smaller and less powerful than those in full hybrid systems, making mild hybrids a cost-effective solution for improving vehicle efficiency.

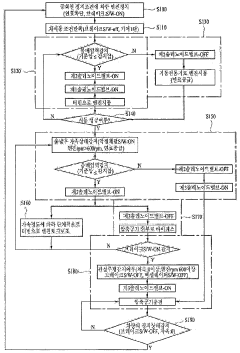

- Energy management and control strategies: Efficient energy management is crucial in mild hybrid systems. Advanced control strategies are employed to optimize the interaction between the internal combustion engine and the electric motor-generator. These strategies may include predictive energy management, adaptive control algorithms, and real-time optimization techniques to maximize fuel efficiency and performance based on driving conditions and driver behavior.

- Integration with transmission systems: Mild hybrid systems can be integrated with various transmission types, including manual, automatic, and continuously variable transmissions (CVT). The integration often involves placing the electric motor-generator between the engine and transmission or incorporating it directly into the transmission housing. This arrangement allows for seamless power blending and enables features like electric creep and smoother gear shifts.

- Battery and power electronics: Mild hybrid systems typically use smaller battery packs compared to full hybrids, often with voltages ranging from 48V to 160V. These batteries are usually lithium-ion or advanced lead-acid types. The power electronics, including DC-DC converters and inverters, are designed to manage the flow of electrical energy between the battery, motor-generator, and vehicle electrical system efficiently.

- Regenerative braking and energy recovery: Regenerative braking is a key feature of mild hybrid systems, allowing the vehicle to recover kinetic energy during deceleration and braking. The electric motor-generator acts as a generator during these events, converting kinetic energy into electrical energy to charge the battery. This recovered energy can then be used to power vehicle accessories or assist the engine during acceleration, further improving overall efficiency.

02 Energy management and power distribution

Mild hybrid systems employ sophisticated energy management strategies to optimize power distribution between the electric motor and internal combustion engine. This includes controlling battery charging, regenerative braking, and power assist functions to maximize efficiency and reduce fuel consumption.Expand Specific Solutions03 Battery and electrical system design

The design of the battery and electrical system is crucial in mild hybrid systems. This includes the selection of appropriate battery chemistry, capacity, and voltage levels to support the electric motor's operation while maintaining a compact and lightweight package suitable for automotive applications.Expand Specific Solutions04 Transmission and drivetrain integration

Mild hybrid systems often require modifications to the transmission and drivetrain to accommodate the electric motor's integration. This may involve the development of specialized transmissions, clutch systems, or power split devices to efficiently transfer power from both the electric motor and internal combustion engine to the wheels.Expand Specific Solutions05 Control strategies and software algorithms

Advanced control strategies and software algorithms are essential for optimizing the performance of mild hybrid systems. These include predictive energy management, adaptive control techniques, and real-time optimization algorithms to ensure seamless operation between the electric motor and internal combustion engine under various driving conditions.Expand Specific Solutions

Key Players in Aviation Hybrid Systems

The aviation industry's mild hybrid systems market is in an early growth stage, with increasing interest driven by environmental regulations and fuel efficiency demands. The market size is expanding, though still relatively small compared to traditional propulsion systems. Technological maturity varies, with companies like Airbus, Boeing, and Rolls-Royce leading in research and development. Smaller firms such as Aura Aero and Lowental Hybrid are also contributing innovative solutions. The competitive landscape is diverse, including established aerospace giants, engine manufacturers, and specialized hybrid technology startups, all vying to advance this emerging technology for commercial aviation applications.

Safran SA

Technical Solution: Safran has been actively developing mild hybrid systems for commercial aviation applications, focusing on their "Electric Green Taxiing System" (EGTS) and more comprehensive hybrid-electric propulsion solutions. The EGTS, developed in partnership with Honeywell, uses electric motors integrated into the main landing gear to enable aircraft to taxi without using their main engines, reducing fuel consumption and emissions during ground operations[1]. Safran is also working on a more advanced hybrid propulsion system called "EcoPulse," in collaboration with Daher and Airbus[2]. This distributed propulsion aircraft demonstrator integrates a dedicated turbogenerator and electric motors, showcasing Safran's expertise in electric motors, power electronics, and energy management systems. Additionally, Safran is developing high-power density electric motors and generators specifically designed for aviation applications, with power outputs ranging from 500kW to 1MW[3].

Strengths: Strong expertise in aircraft systems and propulsion, proven track record in electric taxiing systems, and collaborative approach to innovation. Weaknesses: Dependency on partnerships for full system integration and potential regulatory challenges for new technologies.

Airbus SAS

Technical Solution: Airbus has developed a mild hybrid system for commercial aviation applications, focusing on their A320neo family. The system, known as "E-Taxi," uses electric motors powered by the Auxiliary Power Unit (APU) to drive the main landing gear wheels during taxi operations[1]. This allows the aircraft to move on the ground without using its main engines, significantly reducing fuel consumption and emissions during ground operations. Airbus has also integrated a more electric architecture in their latest aircraft models, incorporating electric environmental control systems and electric backup hydraulic actuators[2]. The company is exploring further hybridization options, including electric propulsion assistance during takeoff and climb phases, which could potentially reduce fuel consumption by up to 4% on short-haul flights[3].

Strengths: Reduced ground emissions, lower noise levels during taxi, and potential for significant fuel savings. Weaknesses: Additional weight from electric motors and power systems, and limited benefits for long-haul flights.

Core Innovations in Aviation Hybrid Tech

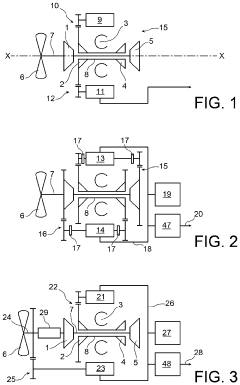

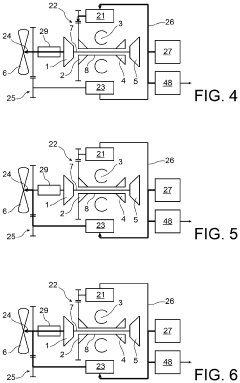

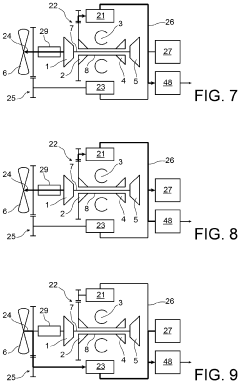

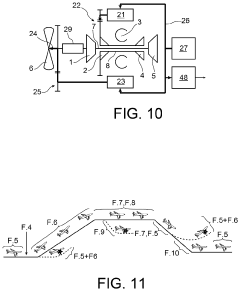

Hybrid propulsion for an aircraft

PatentActiveUS20210039802A1

Innovation

- A hybrid propulsion device featuring a turbomachine with a low pressure shaft and reversible electrical machines, utilizing a single-directional clutch and separate shaft portions that can tilt, allowing independent operation of the fan for additional propulsion and purely electrical thrust, reducing weight and complexity by eliminating the need for a control system or actuator.

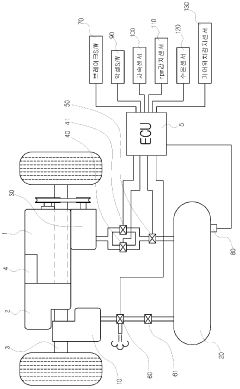

Mild hybrid system

PatentWO2011152619A2

Innovation

- A hybrid engine system utilizing a compressor, compressed air cylinder, turbine, and solenoid valves to control compressed air supply for smooth engine start and acceleration, reducing engine load and maintaining efficient operation without design changes to existing engines.

Regulatory Framework for Hybrid Aircraft

The regulatory framework for hybrid aircraft is evolving rapidly to keep pace with technological advancements in mild hybrid systems for commercial aviation. Regulatory bodies worldwide are working to establish comprehensive guidelines that ensure safety, environmental sustainability, and operational efficiency.

The International Civil Aviation Organization (ICAO) has taken a leading role in developing global standards for hybrid aircraft. These standards focus on key areas such as propulsion system certification, emissions regulations, and noise reduction requirements. ICAO's efforts aim to create a harmonized approach that facilitates international operations of hybrid aircraft while maintaining stringent safety standards.

National aviation authorities, such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA), are adapting their existing regulations to accommodate hybrid propulsion systems. These agencies are developing new certification processes and airworthiness standards specifically tailored to hybrid aircraft technologies.

One of the primary challenges in regulating hybrid aircraft is addressing the unique characteristics of combined electric and conventional propulsion systems. Regulatory bodies are working to establish clear guidelines for system redundancy, failure modes, and emergency procedures specific to hybrid configurations. This includes developing new testing protocols to evaluate the reliability and performance of hybrid propulsion systems under various operating conditions.

Environmental considerations play a significant role in shaping the regulatory landscape for hybrid aircraft. Regulators are implementing more stringent emissions standards to incentivize the adoption of cleaner technologies. These standards typically focus on reducing carbon dioxide emissions, nitrogen oxides, and particulate matter. Hybrid systems are expected to contribute significantly to meeting these environmental targets.

Noise regulations are another critical aspect of the regulatory framework. As hybrid aircraft have the potential to operate more quietly than conventional aircraft, regulators are reassessing noise certification standards to reflect these advancements. This may lead to the creation of new noise categories or the modification of existing ones to accommodate hybrid propulsion systems.

The regulatory framework also addresses the integration of hybrid aircraft into existing air traffic management systems. This includes developing new procedures for air traffic control, flight planning, and airport operations that take into account the unique performance characteristics of hybrid aircraft. Regulators are working closely with industry stakeholders to ensure a smooth transition and integration of hybrid aircraft into commercial aviation operations.

The International Civil Aviation Organization (ICAO) has taken a leading role in developing global standards for hybrid aircraft. These standards focus on key areas such as propulsion system certification, emissions regulations, and noise reduction requirements. ICAO's efforts aim to create a harmonized approach that facilitates international operations of hybrid aircraft while maintaining stringent safety standards.

National aviation authorities, such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA), are adapting their existing regulations to accommodate hybrid propulsion systems. These agencies are developing new certification processes and airworthiness standards specifically tailored to hybrid aircraft technologies.

One of the primary challenges in regulating hybrid aircraft is addressing the unique characteristics of combined electric and conventional propulsion systems. Regulatory bodies are working to establish clear guidelines for system redundancy, failure modes, and emergency procedures specific to hybrid configurations. This includes developing new testing protocols to evaluate the reliability and performance of hybrid propulsion systems under various operating conditions.

Environmental considerations play a significant role in shaping the regulatory landscape for hybrid aircraft. Regulators are implementing more stringent emissions standards to incentivize the adoption of cleaner technologies. These standards typically focus on reducing carbon dioxide emissions, nitrogen oxides, and particulate matter. Hybrid systems are expected to contribute significantly to meeting these environmental targets.

Noise regulations are another critical aspect of the regulatory framework. As hybrid aircraft have the potential to operate more quietly than conventional aircraft, regulators are reassessing noise certification standards to reflect these advancements. This may lead to the creation of new noise categories or the modification of existing ones to accommodate hybrid propulsion systems.

The regulatory framework also addresses the integration of hybrid aircraft into existing air traffic management systems. This includes developing new procedures for air traffic control, flight planning, and airport operations that take into account the unique performance characteristics of hybrid aircraft. Regulators are working closely with industry stakeholders to ensure a smooth transition and integration of hybrid aircraft into commercial aviation operations.

Environmental Impact Assessment

The environmental impact of mild hybrid systems in commercial aviation applications is a critical consideration as the industry seeks to reduce its carbon footprint and meet increasingly stringent emissions regulations. These innovative systems offer significant potential for improving fuel efficiency and reducing greenhouse gas emissions, particularly during taxiing, takeoff, and landing phases of flight.

Mild hybrid systems in aviation typically integrate electric motors with conventional jet engines, allowing for more efficient power distribution and energy recovery. This hybridization can lead to substantial reductions in fuel consumption, with estimates ranging from 10% to 20% depending on the specific implementation and flight profile. Consequently, this translates to a proportional decrease in carbon dioxide emissions, which is a primary environmental concern for the aviation sector.

Furthermore, these systems can contribute to noise reduction, especially during ground operations and initial climb. By utilizing electric power for taxiing and providing supplementary thrust during takeoff, mild hybrid systems can potentially lower the acoustic footprint of aircraft in airport vicinities, addressing a longstanding environmental issue for communities near airports.

The use of mild hybrid systems also has implications for local air quality around airports. By reducing the reliance on jet engines during ground operations, these systems can help decrease emissions of nitrogen oxides (NOx) and particulate matter, which are known to have adverse effects on human health and local ecosystems.

However, the environmental benefits of mild hybrid systems must be weighed against the potential impacts of their production and disposal. The manufacturing of additional electrical components, particularly batteries and power electronics, involves energy-intensive processes and the use of rare earth elements. This raises questions about the lifecycle environmental impact of these systems, including issues of resource extraction and end-of-life recycling.

Moreover, the integration of mild hybrid systems may lead to changes in aircraft weight and aerodynamics, which could potentially offset some of the efficiency gains. Careful design and optimization are necessary to ensure that the overall environmental impact remains positive throughout the aircraft's operational life.

In conclusion, while mild hybrid systems show promising potential for reducing the environmental impact of commercial aviation, a comprehensive assessment must consider not only the operational benefits but also the full lifecycle implications of these technologies. As the aviation industry continues to innovate, ongoing research and development will be crucial to maximize the environmental benefits of mild hybrid systems while minimizing any potential negative impacts.

Mild hybrid systems in aviation typically integrate electric motors with conventional jet engines, allowing for more efficient power distribution and energy recovery. This hybridization can lead to substantial reductions in fuel consumption, with estimates ranging from 10% to 20% depending on the specific implementation and flight profile. Consequently, this translates to a proportional decrease in carbon dioxide emissions, which is a primary environmental concern for the aviation sector.

Furthermore, these systems can contribute to noise reduction, especially during ground operations and initial climb. By utilizing electric power for taxiing and providing supplementary thrust during takeoff, mild hybrid systems can potentially lower the acoustic footprint of aircraft in airport vicinities, addressing a longstanding environmental issue for communities near airports.

The use of mild hybrid systems also has implications for local air quality around airports. By reducing the reliance on jet engines during ground operations, these systems can help decrease emissions of nitrogen oxides (NOx) and particulate matter, which are known to have adverse effects on human health and local ecosystems.

However, the environmental benefits of mild hybrid systems must be weighed against the potential impacts of their production and disposal. The manufacturing of additional electrical components, particularly batteries and power electronics, involves energy-intensive processes and the use of rare earth elements. This raises questions about the lifecycle environmental impact of these systems, including issues of resource extraction and end-of-life recycling.

Moreover, the integration of mild hybrid systems may lead to changes in aircraft weight and aerodynamics, which could potentially offset some of the efficiency gains. Careful design and optimization are necessary to ensure that the overall environmental impact remains positive throughout the aircraft's operational life.

In conclusion, while mild hybrid systems show promising potential for reducing the environmental impact of commercial aviation, a comprehensive assessment must consider not only the operational benefits but also the full lifecycle implications of these technologies. As the aviation industry continues to innovate, ongoing research and development will be crucial to maximize the environmental benefits of mild hybrid systems while minimizing any potential negative impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!