Material innovations for lightweight mild hybrid vehicle designs

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Evolution and Objectives

The evolution of materials for lightweight mild hybrid vehicle designs has been a critical focus in the automotive industry over the past few decades. This progression has been driven by the increasing demand for fuel efficiency, reduced emissions, and improved performance in hybrid vehicles. The journey began with traditional steel-based structures and has since expanded to include a diverse range of advanced materials and composites.

In the early stages, high-strength steel alloys were introduced to reduce vehicle weight while maintaining structural integrity. This was followed by the incorporation of aluminum alloys, which offered significant weight reduction compared to steel. The use of aluminum in body panels, chassis components, and engine parts became increasingly common in the 1990s and 2000s.

As technology advanced, the automotive industry began exploring more exotic materials. Carbon fiber reinforced polymers (CFRP) emerged as a promising option for further weight reduction. Initially limited to high-end sports cars due to high production costs, CFRP has gradually found its way into more mainstream vehicles, particularly in structural components and body panels.

Magnesium alloys have also gained traction in recent years, offering even greater weight savings than aluminum in certain applications. These alloys have been successfully used in steering wheels, seat frames, and transmission casings. Concurrently, advanced plastics and polymer composites have been developed to replace traditional materials in interior components, further contributing to overall weight reduction.

The objectives of material innovation for lightweight mild hybrid vehicle designs are multifaceted. Primarily, the goal is to significantly reduce vehicle weight without compromising safety or performance. This weight reduction directly translates to improved fuel efficiency and reduced emissions, aligning with increasingly stringent environmental regulations worldwide.

Another key objective is to enhance the overall performance of mild hybrid vehicles. Lighter materials allow for better acceleration, improved handling, and increased range, addressing common concerns associated with hybrid technology. Additionally, there is a focus on developing materials that can withstand the unique stresses and thermal management requirements of hybrid powertrains.

Cost-effectiveness remains a crucial consideration in material innovation. While advanced materials offer superior properties, their widespread adoption hinges on achieving economically viable production processes. Therefore, research efforts are directed towards developing materials and manufacturing techniques that balance performance with affordability.

Sustainability is an increasingly important objective in material innovation. This includes not only the environmental impact of the materials during the vehicle's lifecycle but also their recyclability and the energy efficiency of their production processes. As such, there is growing interest in bio-based materials and recycled composites that can meet the performance requirements of automotive applications while reducing the industry's environmental footprint.

In the early stages, high-strength steel alloys were introduced to reduce vehicle weight while maintaining structural integrity. This was followed by the incorporation of aluminum alloys, which offered significant weight reduction compared to steel. The use of aluminum in body panels, chassis components, and engine parts became increasingly common in the 1990s and 2000s.

As technology advanced, the automotive industry began exploring more exotic materials. Carbon fiber reinforced polymers (CFRP) emerged as a promising option for further weight reduction. Initially limited to high-end sports cars due to high production costs, CFRP has gradually found its way into more mainstream vehicles, particularly in structural components and body panels.

Magnesium alloys have also gained traction in recent years, offering even greater weight savings than aluminum in certain applications. These alloys have been successfully used in steering wheels, seat frames, and transmission casings. Concurrently, advanced plastics and polymer composites have been developed to replace traditional materials in interior components, further contributing to overall weight reduction.

The objectives of material innovation for lightweight mild hybrid vehicle designs are multifaceted. Primarily, the goal is to significantly reduce vehicle weight without compromising safety or performance. This weight reduction directly translates to improved fuel efficiency and reduced emissions, aligning with increasingly stringent environmental regulations worldwide.

Another key objective is to enhance the overall performance of mild hybrid vehicles. Lighter materials allow for better acceleration, improved handling, and increased range, addressing common concerns associated with hybrid technology. Additionally, there is a focus on developing materials that can withstand the unique stresses and thermal management requirements of hybrid powertrains.

Cost-effectiveness remains a crucial consideration in material innovation. While advanced materials offer superior properties, their widespread adoption hinges on achieving economically viable production processes. Therefore, research efforts are directed towards developing materials and manufacturing techniques that balance performance with affordability.

Sustainability is an increasingly important objective in material innovation. This includes not only the environmental impact of the materials during the vehicle's lifecycle but also their recyclability and the energy efficiency of their production processes. As such, there is growing interest in bio-based materials and recycled composites that can meet the performance requirements of automotive applications while reducing the industry's environmental footprint.

Market Demand Analysis

The market demand for lightweight materials in mild hybrid vehicle designs has been steadily increasing in recent years, driven by stringent environmental regulations and consumer preferences for fuel-efficient vehicles. As governments worldwide implement stricter emissions standards, automakers are under pressure to reduce vehicle weight to improve fuel economy and decrease carbon emissions. This has led to a growing interest in innovative materials that can significantly reduce vehicle mass without compromising safety or performance.

The global automotive lightweight materials market is experiencing robust growth, with a particular focus on mild hybrid vehicles. These vehicles, which combine a conventional internal combustion engine with an electric motor, require a delicate balance between weight reduction and power management. The demand for advanced materials in this sector is expected to continue its upward trajectory as more automakers invest in mild hybrid technology as a stepping stone towards full electrification.

Aluminum alloys, high-strength steels, and carbon fiber reinforced polymers (CFRP) are among the most sought-after materials for lightweight vehicle construction. The aluminum market for automotive applications has seen substantial growth, with manufacturers increasingly adopting aluminum for body panels, chassis components, and structural elements. High-strength steels, particularly advanced high-strength steels (AHSS), are also gaining traction due to their excellent strength-to-weight ratio and cost-effectiveness compared to more exotic materials.

The market for carbon fiber composites in automotive applications, while still relatively small, is showing promising growth potential. As production costs decrease and manufacturing processes improve, CFRP is becoming a more viable option for mass-market vehicles, particularly in critical structural components where weight savings are most impactful.

Magnesium alloys and polymer composites are also seeing increased demand, albeit to a lesser extent than aluminum and high-strength steels. These materials offer unique properties that make them suitable for specific applications in mild hybrid vehicles, such as powertrain components and interior parts.

The trend towards vehicle electrification is further amplifying the need for lightweight materials. As mild hybrid systems add weight to vehicles through batteries and electric motors, there is a greater imperative to offset this additional mass in other areas of the vehicle. This has led to increased research and development efforts in multi-material design approaches, where different materials are strategically combined to optimize weight, strength, and cost.

Market analysts predict that the automotive lightweight materials market will continue to expand, with a particular emphasis on solutions tailored for mild hybrid and electric vehicles. The industry is likely to see further innovations in material science, manufacturing processes, and joining technologies to meet the evolving demands of automakers and consumers alike.

The global automotive lightweight materials market is experiencing robust growth, with a particular focus on mild hybrid vehicles. These vehicles, which combine a conventional internal combustion engine with an electric motor, require a delicate balance between weight reduction and power management. The demand for advanced materials in this sector is expected to continue its upward trajectory as more automakers invest in mild hybrid technology as a stepping stone towards full electrification.

Aluminum alloys, high-strength steels, and carbon fiber reinforced polymers (CFRP) are among the most sought-after materials for lightweight vehicle construction. The aluminum market for automotive applications has seen substantial growth, with manufacturers increasingly adopting aluminum for body panels, chassis components, and structural elements. High-strength steels, particularly advanced high-strength steels (AHSS), are also gaining traction due to their excellent strength-to-weight ratio and cost-effectiveness compared to more exotic materials.

The market for carbon fiber composites in automotive applications, while still relatively small, is showing promising growth potential. As production costs decrease and manufacturing processes improve, CFRP is becoming a more viable option for mass-market vehicles, particularly in critical structural components where weight savings are most impactful.

Magnesium alloys and polymer composites are also seeing increased demand, albeit to a lesser extent than aluminum and high-strength steels. These materials offer unique properties that make them suitable for specific applications in mild hybrid vehicles, such as powertrain components and interior parts.

The trend towards vehicle electrification is further amplifying the need for lightweight materials. As mild hybrid systems add weight to vehicles through batteries and electric motors, there is a greater imperative to offset this additional mass in other areas of the vehicle. This has led to increased research and development efforts in multi-material design approaches, where different materials are strategically combined to optimize weight, strength, and cost.

Market analysts predict that the automotive lightweight materials market will continue to expand, with a particular emphasis on solutions tailored for mild hybrid and electric vehicles. The industry is likely to see further innovations in material science, manufacturing processes, and joining technologies to meet the evolving demands of automakers and consumers alike.

Current Challenges

The development of lightweight mild hybrid vehicle designs faces several significant challenges in terms of material innovations. One of the primary obstacles is the need for materials that can simultaneously reduce vehicle weight while maintaining or improving structural integrity and safety standards. Traditional materials used in automotive manufacturing, such as steel and aluminum, have limitations in achieving the desired weight reduction without compromising strength and durability.

Another challenge lies in the integration of hybrid powertrain components with lightweight materials. The additional weight of batteries, electric motors, and associated electronics in mild hybrid systems necessitates even greater emphasis on weight reduction in other areas of the vehicle. This creates a complex balancing act between power delivery, energy efficiency, and overall vehicle mass.

Cost-effectiveness remains a significant hurdle in the adoption of advanced lightweight materials. Many innovative materials, such as carbon fiber composites and advanced high-strength steels, come with higher production costs compared to conventional materials. This cost factor can limit their widespread implementation, especially in mass-market vehicles where price sensitivity is a crucial consideration.

The manufacturing processes for these advanced materials also present challenges. Many lightweight materials require specialized production techniques, which may not be easily integrated into existing automotive manufacturing lines. This necessitates significant investments in new equipment and training, potentially slowing down the adoption of these materials in vehicle designs.

Recyclability and environmental impact of new materials pose another set of challenges. As the automotive industry moves towards more sustainable practices, there is a growing need for materials that not only reduce weight but also have a minimal environmental footprint throughout their lifecycle. This includes considerations for production energy requirements, recyclability at end-of-life, and the overall carbon footprint of the material.

Thermal management is an additional concern, particularly in the context of hybrid powertrains. Lightweight materials must be able to effectively dissipate heat generated by both conventional and electric propulsion systems, which can be more challenging with certain lightweight materials that have different thermal properties compared to traditional metals.

Lastly, the durability and long-term performance of lightweight materials in real-world conditions remain areas of ongoing research and development. Factors such as fatigue resistance, corrosion resistance, and impact performance over the vehicle's lifetime need to be thoroughly addressed to ensure that lightweight designs do not compromise the longevity and reliability of mild hybrid vehicles.

Another challenge lies in the integration of hybrid powertrain components with lightweight materials. The additional weight of batteries, electric motors, and associated electronics in mild hybrid systems necessitates even greater emphasis on weight reduction in other areas of the vehicle. This creates a complex balancing act between power delivery, energy efficiency, and overall vehicle mass.

Cost-effectiveness remains a significant hurdle in the adoption of advanced lightweight materials. Many innovative materials, such as carbon fiber composites and advanced high-strength steels, come with higher production costs compared to conventional materials. This cost factor can limit their widespread implementation, especially in mass-market vehicles where price sensitivity is a crucial consideration.

The manufacturing processes for these advanced materials also present challenges. Many lightweight materials require specialized production techniques, which may not be easily integrated into existing automotive manufacturing lines. This necessitates significant investments in new equipment and training, potentially slowing down the adoption of these materials in vehicle designs.

Recyclability and environmental impact of new materials pose another set of challenges. As the automotive industry moves towards more sustainable practices, there is a growing need for materials that not only reduce weight but also have a minimal environmental footprint throughout their lifecycle. This includes considerations for production energy requirements, recyclability at end-of-life, and the overall carbon footprint of the material.

Thermal management is an additional concern, particularly in the context of hybrid powertrains. Lightweight materials must be able to effectively dissipate heat generated by both conventional and electric propulsion systems, which can be more challenging with certain lightweight materials that have different thermal properties compared to traditional metals.

Lastly, the durability and long-term performance of lightweight materials in real-world conditions remain areas of ongoing research and development. Factors such as fatigue resistance, corrosion resistance, and impact performance over the vehicle's lifetime need to be thoroughly addressed to ensure that lightweight designs do not compromise the longevity and reliability of mild hybrid vehicles.

Existing Lightweight Solutions

01 Lightweight composite materials

Composite materials are developed to reduce weight while maintaining strength. These materials often combine different components like fibers and resins to create structures that are lighter than traditional materials but still meet performance requirements. Applications include aerospace, automotive, and sporting goods industries.- Lightweight composite materials: Composite materials are used to create lightweight structures with high strength-to-weight ratios. These materials often combine different components, such as fibers and resins, to achieve desired properties. They are widely used in industries like aerospace, automotive, and sports equipment manufacturing to reduce overall weight while maintaining structural integrity.

- Lightweight alloys and metals: Specialized alloys and metals are developed to provide lightweight solutions for various applications. These materials often include aluminum, magnesium, or titanium-based alloys, which offer reduced weight compared to traditional metals while maintaining necessary strength and durability. They are commonly used in transportation, construction, and consumer products.

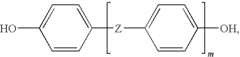

- Lightweight polymers and plastics: Advanced polymers and plastics are engineered to offer lightweight alternatives to traditional materials. These synthetic materials can be tailored to have specific properties such as high strength, flexibility, or chemical resistance while maintaining a low weight. They are used in a wide range of applications, from packaging to automotive components.

- Lightweight foam and cellular materials: Foam and cellular materials are designed to provide extremely low-density structures with good insulation properties. These materials can be made from various base substances, including metals, polymers, or ceramics, and are characterized by their high porosity. They are used in applications requiring thermal insulation, energy absorption, or buoyancy.

- Lightweight nanomaterials: Nanomaterials are engineered at the molecular scale to create ultra-lightweight structures with unique properties. These materials can include carbon nanotubes, graphene, or nanocomposites, which offer exceptional strength-to-weight ratios and other advanced characteristics. They are being researched and developed for use in cutting-edge applications across various industries.

02 Lightweight metal alloys

Advanced metal alloys are engineered to reduce weight while preserving mechanical properties. These alloys often incorporate elements like aluminum, magnesium, or titanium to achieve a lower density. They find applications in various industries where weight reduction is crucial, such as transportation and construction.Expand Specific Solutions03 Foam-based lightweight materials

Foam materials are utilized to create lightweight structures with excellent insulation properties. These materials can be made from various polymers or metals and are characterized by their low density and high strength-to-weight ratio. They are commonly used in packaging, construction, and automotive industries.Expand Specific Solutions04 Lightweight nanomaterials

Nanomaterials are engineered at the molecular level to create ultra-lightweight structures. These materials, such as carbon nanotubes or graphene, offer exceptional strength and stiffness despite their minimal weight. They have potential applications in electronics, energy storage, and advanced composites.Expand Specific Solutions05 Lightweight textile materials

Advanced textiles are developed to reduce weight in applications such as protective gear, clothing, and technical fabrics. These materials often incorporate synthetic fibers or special weaving techniques to achieve high strength and durability with minimal weight. They find use in sports equipment, military gear, and aerospace applications.Expand Specific Solutions

Key Industry Players

The material innovation landscape for lightweight mild hybrid vehicle designs is in a dynamic growth phase, with a market size expected to expand significantly in the coming years. The technology is maturing rapidly, driven by stringent emissions regulations and consumer demand for fuel-efficient vehicles. Key players like LANXESS, Dow Global Technologies, and Evonik Operations are at the forefront, developing advanced lightweight materials and composites. Automotive giants such as Hyundai, Volkswagen, and BMW are integrating these innovations into their vehicle designs, while suppliers like Schaeffler and HBPO are contributing specialized components. The competition is intensifying as both established companies and new entrants like Softcar SA strive to gain a competitive edge in this evolving market.

Volkswagen AG

Technical Solution: Volkswagen AG has developed innovative lightweight materials for mild hybrid vehicles, focusing on advanced high-strength steels (AHSS) and aluminum alloys. Their approach includes using hot-formed steel for critical structural components, reducing weight by up to 20% compared to conventional steel[1]. For body panels, they've implemented aluminum alloys that offer a 40% weight reduction over steel counterparts[2]. Volkswagen has also pioneered the use of carbon fiber reinforced polymers (CFRP) in select components, such as roof panels, achieving weight savings of up to 60%[3]. Their material strategy extends to the powertrain, where they've integrated lightweight magnesium alloys for engine blocks, reducing engine weight by 25%[4]. Additionally, Volkswagen has developed a proprietary polymer composite for interior components, offering a 30% weight reduction while maintaining structural integrity[5].

Strengths: Comprehensive approach to lightweight design across multiple vehicle systems; significant weight reductions achieved; expertise in integrating diverse materials. Weaknesses: Higher production costs associated with advanced materials; potential challenges in large-scale implementation of CFRP components.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz Group AG has pioneered material innovations for lightweight mild hybrid vehicles through their "Intelligent Lightweight Design" strategy. They've developed a multi-material approach, combining high-strength steels, aluminum, and carbon fiber reinforced plastics (CFRP). For the vehicle structure, they use ultra-high-strength steel grades, reducing weight by up to 40% compared to conventional steel[1]. In body panels, they've implemented aluminum alloys with advanced forming techniques, achieving a 50% weight reduction[2]. Mercedes has also developed a proprietary CFRP manufacturing process for complex structural components, reducing weight by up to 70% compared to steel alternatives[3]. For the powertrain, they've introduced a lightweight hybrid transmission system using magnesium alloys, cutting weight by 25%[4]. Additionally, they've developed eco-friendly natural fiber composites for interior components, offering a 20% weight reduction while improving sustainability[5].

Strengths: Holistic approach to lightweight design; significant weight reductions across various vehicle systems; leadership in CFRP manufacturing processes. Weaknesses: Higher production costs; potential challenges in recycling multi-material components.

Innovative Material Technologies

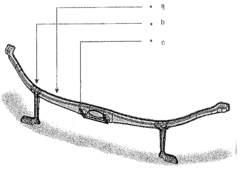

Lightweight component of hybrid design

PatentInactiveUS20090202761A1

Innovation

- The use of polymer moulding compositions comprising semicrystalline thermoplastic polymers, specifically polyamides or polyesters, combined with copolymers of olefins and methacrylates or acrylates, and highly branched polycarbonates or polyesters, which are processed to create reinforcing structures within a shell-type parent body, ensuring secure interlock bonds at discrete connection sites.

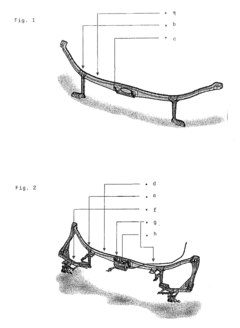

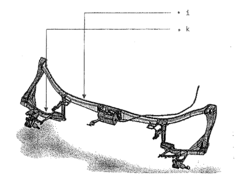

Lightweight component in hybrid construction

PatentWO2008095845A1

Innovation

- Development of lightweight components with a shell-shaped base body reinforced by injection-molded thermoplastics, comprising 55-10 parts by weight of linear, unbranched, semi-crystalline polyamide, 48-80 parts by weight of filler, and 0.01-10 parts by weight of elastomer modifier, processed through methods like injection molding, melt extrusion, or pressing, to achieve a firm form fit and enhanced mechanical and thermal properties.

Environmental Impact Assessment

The environmental impact assessment of material innovations for lightweight mild hybrid vehicle designs is a critical aspect of sustainable automotive development. These innovations aim to reduce vehicle weight, thereby improving fuel efficiency and reducing emissions. However, their environmental implications extend beyond the use phase and must be evaluated across the entire lifecycle.

Lightweight materials such as advanced high-strength steels, aluminum alloys, and carbon fiber reinforced polymers offer significant weight reduction potential. This translates to lower fuel consumption and reduced greenhouse gas emissions during vehicle operation. Studies indicate that a 10% reduction in vehicle weight can lead to a 6-8% improvement in fuel economy. For mild hybrid vehicles, this weight reduction compounds the efficiency gains from the hybrid powertrain, further decreasing environmental impact.

However, the production of these advanced materials often requires more energy-intensive processes compared to conventional materials. For instance, carbon fiber production is particularly energy-intensive, potentially offsetting some of the environmental benefits gained during the vehicle's use phase. Life cycle assessments (LCAs) are crucial to understanding the net environmental impact of these material innovations.

Recycling and end-of-life considerations are also paramount. While metals like aluminum and steel are widely recycled, composite materials present challenges. The difficulty in separating and recycling carbon fibers from polymer matrices can lead to increased waste and environmental burden at the end of a vehicle's life. Innovations in recycling technologies and design for disassembly are essential to mitigate these issues.

The shift towards lightweight materials also impacts the supply chain and resource extraction. Increased demand for certain materials may lead to intensified mining activities, potentially causing habitat destruction and biodiversity loss. Sustainable sourcing practices and responsible supply chain management are necessary to minimize these negative impacts.

Water consumption and pollution are additional factors to consider. Some lightweight material production processes require significant water usage or may generate pollutants that affect water quality if not properly managed. Implementing water-efficient manufacturing processes and effective wastewater treatment systems is crucial for minimizing the water footprint of these innovations.

In conclusion, while material innovations for lightweight mild hybrid vehicles offer promising environmental benefits, particularly in terms of reduced emissions during use, a holistic approach is necessary to ensure net positive environmental outcomes. This includes considering production energy, recyclability, resource extraction, and water impacts. Continuous improvement in manufacturing processes, recycling technologies, and sustainable design practices will be key to maximizing the environmental benefits of these material innovations in the automotive industry.

Lightweight materials such as advanced high-strength steels, aluminum alloys, and carbon fiber reinforced polymers offer significant weight reduction potential. This translates to lower fuel consumption and reduced greenhouse gas emissions during vehicle operation. Studies indicate that a 10% reduction in vehicle weight can lead to a 6-8% improvement in fuel economy. For mild hybrid vehicles, this weight reduction compounds the efficiency gains from the hybrid powertrain, further decreasing environmental impact.

However, the production of these advanced materials often requires more energy-intensive processes compared to conventional materials. For instance, carbon fiber production is particularly energy-intensive, potentially offsetting some of the environmental benefits gained during the vehicle's use phase. Life cycle assessments (LCAs) are crucial to understanding the net environmental impact of these material innovations.

Recycling and end-of-life considerations are also paramount. While metals like aluminum and steel are widely recycled, composite materials present challenges. The difficulty in separating and recycling carbon fibers from polymer matrices can lead to increased waste and environmental burden at the end of a vehicle's life. Innovations in recycling technologies and design for disassembly are essential to mitigate these issues.

The shift towards lightweight materials also impacts the supply chain and resource extraction. Increased demand for certain materials may lead to intensified mining activities, potentially causing habitat destruction and biodiversity loss. Sustainable sourcing practices and responsible supply chain management are necessary to minimize these negative impacts.

Water consumption and pollution are additional factors to consider. Some lightweight material production processes require significant water usage or may generate pollutants that affect water quality if not properly managed. Implementing water-efficient manufacturing processes and effective wastewater treatment systems is crucial for minimizing the water footprint of these innovations.

In conclusion, while material innovations for lightweight mild hybrid vehicles offer promising environmental benefits, particularly in terms of reduced emissions during use, a holistic approach is necessary to ensure net positive environmental outcomes. This includes considering production energy, recyclability, resource extraction, and water impacts. Continuous improvement in manufacturing processes, recycling technologies, and sustainable design practices will be key to maximizing the environmental benefits of these material innovations in the automotive industry.

Cost-Benefit Analysis

The cost-benefit analysis of material innovations for lightweight mild hybrid vehicle designs reveals a complex interplay of factors that influence the overall economic viability of these advancements. Initial investments in research, development, and retooling of manufacturing processes for lightweight materials can be substantial. However, these costs must be weighed against the long-term benefits of improved fuel efficiency, reduced emissions, and enhanced vehicle performance.

One of the primary cost considerations is the price premium associated with advanced lightweight materials such as high-strength steel, aluminum alloys, carbon fiber reinforced polymers (CFRP), and magnesium alloys. These materials often come at a higher cost per unit weight compared to traditional steel, potentially increasing the overall vehicle production costs. However, the weight reduction achieved through these materials can lead to significant fuel savings over the vehicle's lifetime, offsetting the initial cost increase.

The benefits of lightweight design extend beyond fuel economy. Reduced vehicle weight contributes to improved acceleration, handling, and braking performance, enhancing the overall driving experience. This can lead to increased customer satisfaction and potentially higher sales volumes, further justifying the initial investment in lightweight materials.

From an environmental perspective, the reduction in fuel consumption translates to lower greenhouse gas emissions, aligning with increasingly stringent regulatory requirements. This can help manufacturers avoid penalties and potentially qualify for incentives, providing additional financial benefits.

The cost-benefit equation also considers the entire vehicle lifecycle. While lightweight materials may increase initial production costs, they can potentially reduce maintenance and repair costs due to improved durability and corrosion resistance. Additionally, the use of recyclable materials can improve end-of-life vehicle value and reduce environmental impact, factors that are gaining importance in consumer decision-making and regulatory frameworks.

Manufacturing processes for lightweight materials often require significant investments in new equipment and training. However, these investments can lead to long-term cost reductions through improved production efficiency and reduced material waste. As production volumes increase and technologies mature, economies of scale are likely to drive down the costs of lightweight materials and their associated manufacturing processes.

In conclusion, while the upfront costs of implementing lightweight material innovations in mild hybrid vehicle designs can be substantial, the long-term benefits in terms of fuel efficiency, performance, environmental impact, and regulatory compliance present a compelling case for investment. As technology advances and production scales up, the cost-benefit ratio is expected to improve further, making lightweight design an increasingly attractive option for automotive manufacturers.

One of the primary cost considerations is the price premium associated with advanced lightweight materials such as high-strength steel, aluminum alloys, carbon fiber reinforced polymers (CFRP), and magnesium alloys. These materials often come at a higher cost per unit weight compared to traditional steel, potentially increasing the overall vehicle production costs. However, the weight reduction achieved through these materials can lead to significant fuel savings over the vehicle's lifetime, offsetting the initial cost increase.

The benefits of lightweight design extend beyond fuel economy. Reduced vehicle weight contributes to improved acceleration, handling, and braking performance, enhancing the overall driving experience. This can lead to increased customer satisfaction and potentially higher sales volumes, further justifying the initial investment in lightweight materials.

From an environmental perspective, the reduction in fuel consumption translates to lower greenhouse gas emissions, aligning with increasingly stringent regulatory requirements. This can help manufacturers avoid penalties and potentially qualify for incentives, providing additional financial benefits.

The cost-benefit equation also considers the entire vehicle lifecycle. While lightweight materials may increase initial production costs, they can potentially reduce maintenance and repair costs due to improved durability and corrosion resistance. Additionally, the use of recyclable materials can improve end-of-life vehicle value and reduce environmental impact, factors that are gaining importance in consumer decision-making and regulatory frameworks.

Manufacturing processes for lightweight materials often require significant investments in new equipment and training. However, these investments can lead to long-term cost reductions through improved production efficiency and reduced material waste. As production volumes increase and technologies mature, economies of scale are likely to drive down the costs of lightweight materials and their associated manufacturing processes.

In conclusion, while the upfront costs of implementing lightweight material innovations in mild hybrid vehicle designs can be substantial, the long-term benefits in terms of fuel efficiency, performance, environmental impact, and regulatory compliance present a compelling case for investment. As technology advances and production scales up, the cost-benefit ratio is expected to improve further, making lightweight design an increasingly attractive option for automotive manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!