Addressing Sustainability Concerns in LDPE Packaging

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Packaging Evolution

Low-density polyethylene (LDPE) packaging has undergone significant evolution since its introduction in the 1930s. Initially developed as a flexible and durable material for various packaging applications, LDPE quickly gained popularity due to its low cost, ease of processing, and excellent barrier properties against moisture and gases.

In the early stages of its development, LDPE packaging was primarily used for food packaging and industrial applications. The material's versatility allowed for the creation of various packaging formats, including bags, films, and containers. As manufacturing processes improved, LDPE packaging became thinner and more efficient, reducing material usage while maintaining strength and functionality.

The 1960s and 1970s saw a rapid increase in LDPE packaging adoption across multiple industries. This period marked the beginning of widespread use in consumer goods packaging, particularly in the food and beverage sector. The material's ability to preserve freshness and extend shelf life made it an attractive option for manufacturers and retailers alike.

However, as environmental concerns began to emerge in the late 20th century, the sustainability of LDPE packaging came under scrutiny. The material's durability, once considered an advantage, became a significant drawback due to its slow degradation rate in the environment. This led to increased focus on recycling and waste management strategies for LDPE packaging.

In response to these concerns, the packaging industry began exploring modifications to LDPE to enhance its environmental profile. Research into biodegradable additives and the development of recycling-friendly LDPE formulations gained momentum. Additionally, efforts to reduce the overall thickness of LDPE packaging without compromising performance became a key area of innovation.

The 21st century has seen a continued evolution of LDPE packaging, with a strong emphasis on sustainability. Manufacturers have invested in developing LDPE blends that incorporate recycled content, improving the material's circularity. Advanced recycling technologies, such as chemical recycling, have also emerged as potential solutions to address the end-of-life challenges associated with LDPE packaging.

Recent years have witnessed a shift towards more sustainable alternatives, including bio-based LDPE derived from renewable resources. These innovations aim to maintain the desirable properties of traditional LDPE while reducing reliance on fossil fuels and minimizing environmental impact. The packaging industry has also focused on designing LDPE products that are more easily recyclable, aligning with the principles of a circular economy.

As sustainability concerns continue to drive innovation in the packaging sector, the evolution of LDPE packaging remains ongoing. The industry is exploring novel approaches to address environmental challenges while preserving the material's beneficial properties that have made it a staple in packaging applications for decades.

In the early stages of its development, LDPE packaging was primarily used for food packaging and industrial applications. The material's versatility allowed for the creation of various packaging formats, including bags, films, and containers. As manufacturing processes improved, LDPE packaging became thinner and more efficient, reducing material usage while maintaining strength and functionality.

The 1960s and 1970s saw a rapid increase in LDPE packaging adoption across multiple industries. This period marked the beginning of widespread use in consumer goods packaging, particularly in the food and beverage sector. The material's ability to preserve freshness and extend shelf life made it an attractive option for manufacturers and retailers alike.

However, as environmental concerns began to emerge in the late 20th century, the sustainability of LDPE packaging came under scrutiny. The material's durability, once considered an advantage, became a significant drawback due to its slow degradation rate in the environment. This led to increased focus on recycling and waste management strategies for LDPE packaging.

In response to these concerns, the packaging industry began exploring modifications to LDPE to enhance its environmental profile. Research into biodegradable additives and the development of recycling-friendly LDPE formulations gained momentum. Additionally, efforts to reduce the overall thickness of LDPE packaging without compromising performance became a key area of innovation.

The 21st century has seen a continued evolution of LDPE packaging, with a strong emphasis on sustainability. Manufacturers have invested in developing LDPE blends that incorporate recycled content, improving the material's circularity. Advanced recycling technologies, such as chemical recycling, have also emerged as potential solutions to address the end-of-life challenges associated with LDPE packaging.

Recent years have witnessed a shift towards more sustainable alternatives, including bio-based LDPE derived from renewable resources. These innovations aim to maintain the desirable properties of traditional LDPE while reducing reliance on fossil fuels and minimizing environmental impact. The packaging industry has also focused on designing LDPE products that are more easily recyclable, aligning with the principles of a circular economy.

As sustainability concerns continue to drive innovation in the packaging sector, the evolution of LDPE packaging remains ongoing. The industry is exploring novel approaches to address environmental challenges while preserving the material's beneficial properties that have made it a staple in packaging applications for decades.

Sustainable Packaging Market

The sustainable packaging market has experienced significant growth in recent years, driven by increasing environmental awareness and regulatory pressures. This market segment encompasses a wide range of eco-friendly packaging solutions, including biodegradable materials, recyclable plastics, and innovative designs that minimize waste. The demand for sustainable packaging is particularly strong in industries such as food and beverage, personal care, and e-commerce.

Consumer preferences have shifted towards more environmentally responsible products, leading to a surge in demand for sustainable packaging options. This trend is further reinforced by government regulations and corporate sustainability initiatives, which are pushing companies to adopt more eco-friendly packaging solutions. As a result, the sustainable packaging market has seen substantial investments in research and development, leading to the emergence of new materials and technologies.

One of the key drivers of the sustainable packaging market is the growing concern over plastic pollution, particularly in oceans and landfills. This has led to increased focus on alternatives to traditional plastics, such as bioplastics, paper-based materials, and compostable packaging. The market has also seen a rise in the use of recycled materials, as companies strive to create closed-loop systems and reduce their reliance on virgin resources.

The food and beverage industry has been at the forefront of adopting sustainable packaging solutions, driven by consumer demand for fresh, natural products with minimal environmental impact. This has led to innovations in areas such as edible packaging, plant-based materials, and smart packaging that extends shelf life and reduces food waste. The personal care and cosmetics industry has also embraced sustainable packaging, with many brands introducing refillable containers and packaging made from recycled or renewable materials.

E-commerce has emerged as a significant driver of the sustainable packaging market, as the rapid growth of online shopping has highlighted the need for more efficient and environmentally friendly packaging solutions. This has led to innovations in areas such as right-sized packaging, protective materials made from renewable resources, and reusable shipping containers.

The sustainable packaging market faces several challenges, including higher costs compared to traditional packaging materials and the need for infrastructure development to support recycling and composting. However, ongoing technological advancements and economies of scale are expected to gradually reduce these barriers. Additionally, collaborations between packaging manufacturers, brand owners, and recycling companies are helping to create more integrated and efficient sustainable packaging ecosystems.

As the sustainable packaging market continues to evolve, it is likely to see further innovations in materials science, design, and manufacturing processes. This includes the development of advanced biodegradable materials, smart packaging technologies that enhance product preservation and reduce waste, and more efficient recycling and upcycling processes. The market is also expected to benefit from increased consumer education and awareness, as well as the implementation of more stringent environmental regulations worldwide.

Consumer preferences have shifted towards more environmentally responsible products, leading to a surge in demand for sustainable packaging options. This trend is further reinforced by government regulations and corporate sustainability initiatives, which are pushing companies to adopt more eco-friendly packaging solutions. As a result, the sustainable packaging market has seen substantial investments in research and development, leading to the emergence of new materials and technologies.

One of the key drivers of the sustainable packaging market is the growing concern over plastic pollution, particularly in oceans and landfills. This has led to increased focus on alternatives to traditional plastics, such as bioplastics, paper-based materials, and compostable packaging. The market has also seen a rise in the use of recycled materials, as companies strive to create closed-loop systems and reduce their reliance on virgin resources.

The food and beverage industry has been at the forefront of adopting sustainable packaging solutions, driven by consumer demand for fresh, natural products with minimal environmental impact. This has led to innovations in areas such as edible packaging, plant-based materials, and smart packaging that extends shelf life and reduces food waste. The personal care and cosmetics industry has also embraced sustainable packaging, with many brands introducing refillable containers and packaging made from recycled or renewable materials.

E-commerce has emerged as a significant driver of the sustainable packaging market, as the rapid growth of online shopping has highlighted the need for more efficient and environmentally friendly packaging solutions. This has led to innovations in areas such as right-sized packaging, protective materials made from renewable resources, and reusable shipping containers.

The sustainable packaging market faces several challenges, including higher costs compared to traditional packaging materials and the need for infrastructure development to support recycling and composting. However, ongoing technological advancements and economies of scale are expected to gradually reduce these barriers. Additionally, collaborations between packaging manufacturers, brand owners, and recycling companies are helping to create more integrated and efficient sustainable packaging ecosystems.

As the sustainable packaging market continues to evolve, it is likely to see further innovations in materials science, design, and manufacturing processes. This includes the development of advanced biodegradable materials, smart packaging technologies that enhance product preservation and reduce waste, and more efficient recycling and upcycling processes. The market is also expected to benefit from increased consumer education and awareness, as well as the implementation of more stringent environmental regulations worldwide.

LDPE Sustainability Challenges

Low-density polyethylene (LDPE) packaging has been widely used in various industries due to its versatility, durability, and cost-effectiveness. However, the increasing global focus on environmental sustainability has brought significant challenges to the LDPE packaging sector. The primary concern stems from LDPE's petroleum-based origin and its persistence in the environment, contributing to plastic pollution and greenhouse gas emissions.

One of the major sustainability challenges facing LDPE packaging is its end-of-life management. LDPE is not biodegradable and can persist in the environment for hundreds of years. This longevity leads to accumulation in landfills and natural ecosystems, causing harm to wildlife and marine life. The improper disposal of LDPE packaging has resulted in the formation of massive garbage patches in oceans, further exacerbating the environmental impact.

Recycling LDPE presents another significant challenge. While technically recyclable, the process is often economically unfeasible due to contamination issues and the low value of recycled LDPE. Many recycling facilities lack the necessary infrastructure to efficiently sort and process LDPE packaging, leading to a large portion ending up in landfills or incineration plants. This not only wastes valuable resources but also contributes to increased carbon emissions.

The production of LDPE itself poses sustainability concerns. The manufacturing process relies heavily on fossil fuels, both as a raw material and energy source. This dependence contributes to the depletion of non-renewable resources and significant greenhouse gas emissions. The carbon footprint associated with LDPE production and transportation further compounds its environmental impact.

Consumer perception and behavior also present challenges to LDPE sustainability. Despite growing environmental awareness, many consumers still prioritize convenience over sustainability when it comes to packaging. This mindset makes it difficult to implement more sustainable alternatives or encourage proper disposal practices. Additionally, the lack of standardized labeling and disposal instructions for LDPE packaging often leads to confusion and improper waste management.

Regulatory pressures are mounting on the LDPE packaging industry. Many countries and regions are implementing stricter regulations on single-use plastics, including LDPE packaging. These regulations range from outright bans to increased taxes and extended producer responsibility schemes. Adapting to this evolving regulatory landscape while maintaining product functionality and economic viability is a significant challenge for manufacturers and users of LDPE packaging.

Addressing these sustainability challenges requires a multifaceted approach involving technological innovation, policy changes, and shifts in consumer behavior. The industry must focus on developing more sustainable alternatives, improving recycling infrastructure, and implementing circular economy principles to mitigate the environmental impact of LDPE packaging.

One of the major sustainability challenges facing LDPE packaging is its end-of-life management. LDPE is not biodegradable and can persist in the environment for hundreds of years. This longevity leads to accumulation in landfills and natural ecosystems, causing harm to wildlife and marine life. The improper disposal of LDPE packaging has resulted in the formation of massive garbage patches in oceans, further exacerbating the environmental impact.

Recycling LDPE presents another significant challenge. While technically recyclable, the process is often economically unfeasible due to contamination issues and the low value of recycled LDPE. Many recycling facilities lack the necessary infrastructure to efficiently sort and process LDPE packaging, leading to a large portion ending up in landfills or incineration plants. This not only wastes valuable resources but also contributes to increased carbon emissions.

The production of LDPE itself poses sustainability concerns. The manufacturing process relies heavily on fossil fuels, both as a raw material and energy source. This dependence contributes to the depletion of non-renewable resources and significant greenhouse gas emissions. The carbon footprint associated with LDPE production and transportation further compounds its environmental impact.

Consumer perception and behavior also present challenges to LDPE sustainability. Despite growing environmental awareness, many consumers still prioritize convenience over sustainability when it comes to packaging. This mindset makes it difficult to implement more sustainable alternatives or encourage proper disposal practices. Additionally, the lack of standardized labeling and disposal instructions for LDPE packaging often leads to confusion and improper waste management.

Regulatory pressures are mounting on the LDPE packaging industry. Many countries and regions are implementing stricter regulations on single-use plastics, including LDPE packaging. These regulations range from outright bans to increased taxes and extended producer responsibility schemes. Adapting to this evolving regulatory landscape while maintaining product functionality and economic viability is a significant challenge for manufacturers and users of LDPE packaging.

Addressing these sustainability challenges requires a multifaceted approach involving technological innovation, policy changes, and shifts in consumer behavior. The industry must focus on developing more sustainable alternatives, improving recycling infrastructure, and implementing circular economy principles to mitigate the environmental impact of LDPE packaging.

Current Eco-LDPE Solutions

01 Biodegradable LDPE blends

Developing biodegradable LDPE blends by incorporating natural polymers or additives to enhance the material's environmental sustainability. These blends aim to maintain the desirable properties of LDPE while improving its end-of-life degradation, reducing environmental impact.- Biodegradable LDPE blends: Developing biodegradable LDPE blends by incorporating natural or synthetic biodegradable polymers to enhance the sustainability of packaging materials. These blends aim to maintain the desirable properties of LDPE while improving its environmental impact through increased biodegradability.

- Recycling and upcycling LDPE packaging: Implementing advanced recycling technologies and processes to efficiently recycle LDPE packaging materials. This includes developing methods for upcycling LDPE waste into higher-value products, reducing the environmental impact of packaging waste and promoting a circular economy approach.

- Sustainable LDPE production methods: Exploring and implementing more sustainable production methods for LDPE, such as using renewable feedstocks or developing energy-efficient manufacturing processes. These approaches aim to reduce the carbon footprint associated with LDPE production and improve overall sustainability.

- LDPE packaging design optimization: Optimizing the design of LDPE packaging to reduce material usage while maintaining or improving functionality. This includes developing thinner films, innovative packaging structures, and multi-functional designs that minimize waste and improve the overall sustainability of LDPE packaging solutions.

- Life cycle assessment and sustainability metrics: Implementing comprehensive life cycle assessments and developing sustainability metrics specific to LDPE packaging. These tools help evaluate the environmental impact of LDPE packaging throughout its lifecycle, from production to disposal, and guide decision-making for more sustainable packaging solutions.

02 Recycling and upcycling LDPE packaging

Implementing advanced recycling technologies and processes to efficiently recycle LDPE packaging materials. This includes developing methods for sorting, cleaning, and reprocessing LDPE waste into new products or raw materials, promoting a circular economy approach.Expand Specific Solutions03 Sustainable LDPE production methods

Exploring alternative production methods for LDPE that reduce energy consumption and carbon emissions. This may involve using renewable energy sources, optimizing manufacturing processes, or developing bio-based feedstocks for LDPE production.Expand Specific Solutions04 Lightweight LDPE packaging design

Designing lightweight LDPE packaging solutions that maintain product protection while using less material. This approach reduces raw material consumption and transportation-related emissions, improving overall sustainability of LDPE packaging.Expand Specific Solutions05 LDPE packaging life cycle assessment

Developing comprehensive life cycle assessment tools and methodologies specific to LDPE packaging. These assessments help identify environmental hotspots in the packaging life cycle and guide decision-making for more sustainable packaging solutions.Expand Specific Solutions

Key LDPE Packaging Players

The market for sustainable LDPE packaging is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size for eco-friendly packaging is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with major players like Dow Global Technologies, SABIC, and Braskem leading innovation. These companies are developing bio-based and recyclable LDPE alternatives, improving material properties, and enhancing production efficiency. Emerging players such as Northern Technologies International Corp. and Huajing Weina Technology are also contributing to technological advancements, particularly in biodegradable plastics. The competitive landscape is characterized by a mix of established petrochemical giants and innovative startups, all vying to capture market share in this evolving sector.

Dow Global Technologies LLC

Technical Solution: Dow has developed a range of sustainable LDPE solutions for packaging. Their INNATE™ TF Polyethylene Resins for Tenter Frame Biaxial Orientation offer improved packaging performance and reduced material usage. These resins enable the production of films that are up to 80% thinner than traditional LDPE films while maintaining strength and durability[1]. Dow has also introduced bio-based LDPE, made from renewable feedstocks, which can reduce carbon footprint by up to 75% compared to fossil-fuel based LDPE[2]. Additionally, their RETAIN™ Polymer Modifiers enhance the recyclability of multi-layer flexible packaging films by compatibilizing different polymer layers, improving the quality of recycled materials[3].

Strengths: Strong R&D capabilities, wide range of sustainable solutions, significant reduction in material usage and carbon footprint. Weaknesses: Higher initial costs for bio-based materials, potential limitations in certain high-performance applications.

Braskem SA

Technical Solution: Braskem has pioneered the development of bio-based polyethylene, including LDPE, derived from sugarcane ethanol. Their I'm green™ Polyethylene captures up to 3.09 tons of CO2 for every ton of product made, significantly reducing the carbon footprint of packaging materials[8]. Braskem has also developed a portfolio of recycled polyethylene resins, including LDPE, under the I'm green™ Recycled brand. These resins incorporate up to 100% post-consumer recycled content, addressing the issue of plastic waste[9]. Additionally, Braskem is investing in chemical recycling technologies to convert plastic waste back into feedstock for new plastics production, potentially creating a closed-loop system for LDPE packaging[10]. The company has also developed additives that enhance the biodegradability of conventional polyethylene without compromising its recyclability[11].

Strengths: Leader in bio-based PE production, comprehensive recycling solutions, innovative additives for enhanced biodegradability. Weaknesses: Limited availability of bio-based feedstock, potential higher costs compared to conventional LDPE.

Innovations in Green LDPE

Plastic modification method for enhancing transparency of LLDPE (Linear Low Density Polyethylene) packaging bag

PatentPendingCN112940386A

Innovation

- Using LLDPE linear low-density polyethylene, LDPE low-density polyethylene and PC polycarbonate and other materials mixed and heat-treated, combined with calcium carbonate, light stabilizer, coupling agent, dispersant and antioxidant, through extrusion and blown film Craftsmanship improves transparency.

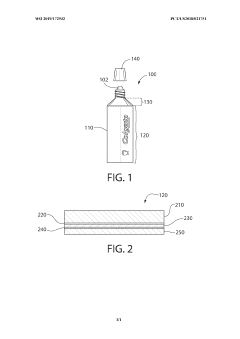

Recyclable plastic package

PatentWO2019172932A1

Innovation

- A recyclable flexible package design using an outer layer of high-density polyethylene (HDPE) with a barrier and bonding layers, excluding low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and polypropylene (PP), allowing compatibility with existing HDPE bottle recycling streams.

Environmental Regulations

Environmental regulations play a crucial role in shaping the sustainability landscape for LDPE packaging. As concerns about plastic pollution and environmental impact grow, governments worldwide have implemented various policies and regulations to address these issues. The European Union has been at the forefront of such initiatives, introducing the Packaging and Packaging Waste Directive (PPWD) and the Single-Use Plastics Directive (SUPD). These regulations set targets for recycling rates, promote the use of recyclable materials, and aim to reduce the overall consumption of single-use plastics.

In the United States, regulations vary by state, with some implementing plastic bag bans and others focusing on extended producer responsibility (EPR) programs. California's Rigid Plastic Packaging Container (RPPC) law, for instance, requires manufacturers to meet specific recycling rates or use recycled content in their packaging. At the federal level, the Environmental Protection Agency (EPA) has introduced guidelines for sustainable packaging practices, although these are not legally binding.

Developing countries are also taking steps to address plastic pollution. India has announced plans to phase out single-use plastics, while China has implemented restrictions on plastic waste imports, forcing many countries to reassess their recycling strategies. These regulatory changes have significant implications for LDPE packaging manufacturers and users, driving innovation in sustainable packaging solutions.

The regulatory landscape is continuously evolving, with new policies being proposed and implemented regularly. The UK's Plastic Packaging Tax, introduced in April 2022, imposes a levy on plastic packaging with less than 30% recycled content, incentivizing the use of recycled materials. Similarly, the EU's proposed Packaging and Packaging Waste Regulation (PPWR) aims to further strengthen sustainability requirements for packaging materials.

Compliance with these regulations presents both challenges and opportunities for the LDPE packaging industry. Manufacturers must invest in research and development to create more sustainable packaging solutions that meet regulatory requirements while maintaining performance standards. This has led to increased focus on biodegradable and compostable alternatives, as well as improved recycling technologies for LDPE.

As regulations become more stringent, companies are also exploring innovative business models, such as packaging-as-a-service and reusable packaging systems, to reduce their environmental footprint and comply with regulatory requirements. The regulatory landscape is thus driving a shift towards circular economy principles in the packaging industry, encouraging the development of more sustainable LDPE packaging solutions and promoting responsible consumption patterns.

In the United States, regulations vary by state, with some implementing plastic bag bans and others focusing on extended producer responsibility (EPR) programs. California's Rigid Plastic Packaging Container (RPPC) law, for instance, requires manufacturers to meet specific recycling rates or use recycled content in their packaging. At the federal level, the Environmental Protection Agency (EPA) has introduced guidelines for sustainable packaging practices, although these are not legally binding.

Developing countries are also taking steps to address plastic pollution. India has announced plans to phase out single-use plastics, while China has implemented restrictions on plastic waste imports, forcing many countries to reassess their recycling strategies. These regulatory changes have significant implications for LDPE packaging manufacturers and users, driving innovation in sustainable packaging solutions.

The regulatory landscape is continuously evolving, with new policies being proposed and implemented regularly. The UK's Plastic Packaging Tax, introduced in April 2022, imposes a levy on plastic packaging with less than 30% recycled content, incentivizing the use of recycled materials. Similarly, the EU's proposed Packaging and Packaging Waste Regulation (PPWR) aims to further strengthen sustainability requirements for packaging materials.

Compliance with these regulations presents both challenges and opportunities for the LDPE packaging industry. Manufacturers must invest in research and development to create more sustainable packaging solutions that meet regulatory requirements while maintaining performance standards. This has led to increased focus on biodegradable and compostable alternatives, as well as improved recycling technologies for LDPE.

As regulations become more stringent, companies are also exploring innovative business models, such as packaging-as-a-service and reusable packaging systems, to reduce their environmental footprint and comply with regulatory requirements. The regulatory landscape is thus driving a shift towards circular economy principles in the packaging industry, encouraging the development of more sustainable LDPE packaging solutions and promoting responsible consumption patterns.

Circular Economy Impact

The circular economy concept has a profound impact on addressing sustainability concerns in LDPE packaging. This approach aims to minimize waste and maximize resource efficiency by promoting the reuse, recycling, and regeneration of materials. In the context of LDPE packaging, the circular economy model presents both challenges and opportunities for sustainable development.

One of the primary impacts of the circular economy on LDPE packaging is the shift towards design for recyclability. Manufacturers are increasingly focusing on creating packaging solutions that can be easily recycled or repurposed at the end of their lifecycle. This involves simplifying packaging designs, reducing the use of mixed materials, and improving the overall recyclability of LDPE products.

The circular economy also encourages the development of more efficient collection and sorting systems for LDPE packaging waste. This has led to innovations in waste management infrastructure and technologies, such as advanced sorting facilities and improved recycling processes. These advancements contribute to higher recovery rates and better quality recycled LDPE materials.

Furthermore, the circular economy model has spurred the growth of recycled LDPE markets. As demand for sustainable packaging solutions increases, there is a growing market for recycled LDPE materials. This has incentivized investments in recycling technologies and infrastructure, creating new economic opportunities within the packaging industry.

The implementation of circular economy principles has also led to the emergence of new business models in the LDPE packaging sector. These include packaging-as-a-service models, where packaging is leased rather than sold, and take-back schemes that encourage consumers to return used packaging for recycling or reuse.

Additionally, the circular economy approach has influenced policy and regulatory frameworks surrounding LDPE packaging. Many governments and regulatory bodies are implementing measures to promote circular economy practices, such as extended producer responsibility schemes and targets for recycled content in packaging materials.

The circular economy's impact extends to consumer behavior and awareness. As sustainability becomes a key concern for consumers, there is increased demand for environmentally friendly packaging solutions. This has driven innovation in LDPE packaging design and production, encouraging the development of more sustainable alternatives.

In conclusion, the circular economy model has significantly influenced the approach to sustainability in LDPE packaging. It has driven innovation, created new market opportunities, and reshaped business models and regulatory frameworks. As the industry continues to evolve, the principles of the circular economy will likely play an increasingly important role in addressing sustainability concerns in LDPE packaging.

One of the primary impacts of the circular economy on LDPE packaging is the shift towards design for recyclability. Manufacturers are increasingly focusing on creating packaging solutions that can be easily recycled or repurposed at the end of their lifecycle. This involves simplifying packaging designs, reducing the use of mixed materials, and improving the overall recyclability of LDPE products.

The circular economy also encourages the development of more efficient collection and sorting systems for LDPE packaging waste. This has led to innovations in waste management infrastructure and technologies, such as advanced sorting facilities and improved recycling processes. These advancements contribute to higher recovery rates and better quality recycled LDPE materials.

Furthermore, the circular economy model has spurred the growth of recycled LDPE markets. As demand for sustainable packaging solutions increases, there is a growing market for recycled LDPE materials. This has incentivized investments in recycling technologies and infrastructure, creating new economic opportunities within the packaging industry.

The implementation of circular economy principles has also led to the emergence of new business models in the LDPE packaging sector. These include packaging-as-a-service models, where packaging is leased rather than sold, and take-back schemes that encourage consumers to return used packaging for recycling or reuse.

Additionally, the circular economy approach has influenced policy and regulatory frameworks surrounding LDPE packaging. Many governments and regulatory bodies are implementing measures to promote circular economy practices, such as extended producer responsibility schemes and targets for recycled content in packaging materials.

The circular economy's impact extends to consumer behavior and awareness. As sustainability becomes a key concern for consumers, there is increased demand for environmentally friendly packaging solutions. This has driven innovation in LDPE packaging design and production, encouraging the development of more sustainable alternatives.

In conclusion, the circular economy model has significantly influenced the approach to sustainability in LDPE packaging. It has driven innovation, created new market opportunities, and reshaped business models and regulatory frameworks. As the industry continues to evolve, the principles of the circular economy will likely play an increasingly important role in addressing sustainability concerns in LDPE packaging.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!