How to Strengthen LDPE's Market Presence?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Market Evolution

Low-density polyethylene (LDPE) has undergone significant market evolution since its introduction in the 1930s. Initially developed as a versatile and cost-effective plastic, LDPE quickly gained traction in various industries due to its unique properties, including flexibility, transparency, and moisture resistance.

The 1950s and 1960s saw a rapid expansion of LDPE applications, particularly in packaging and consumer goods. This growth was driven by the post-war economic boom and the increasing demand for convenient, disposable products. During this period, LDPE became a staple material in the production of plastic bags, food packaging, and household items.

The 1970s and 1980s marked a period of technological advancements in LDPE production. Improved manufacturing processes led to enhanced product quality and increased production efficiency. This era also witnessed the emergence of environmental concerns, prompting the industry to focus on recyclability and sustainability initiatives.

In the 1990s and early 2000s, LDPE faced growing competition from other polyethylene variants, such as linear low-density polyethylene (LLDPE) and high-density polyethylene (HDPE). These materials offered improved strength and barrier properties, challenging LDPE's market share in certain applications. However, LDPE maintained its position in specific sectors due to its unique combination of properties and cost-effectiveness.

The past two decades have seen a renewed focus on LDPE's environmental impact. With increasing global awareness of plastic pollution, the LDPE industry has been compelled to innovate in areas of biodegradability, recycling, and sustainable production methods. This shift has led to the development of bio-based LDPE and improved recycling technologies, aiming to address environmental concerns while maintaining the material's utility.

Currently, the LDPE market is at a critical juncture. While facing challenges from environmental regulations and alternative materials, it continues to find new applications in emerging industries. The packaging sector remains a key driver of LDPE demand, particularly in food packaging and e-commerce applications. Additionally, LDPE is finding new roles in sectors such as agriculture, healthcare, and construction, demonstrating its ongoing relevance and adaptability.

Looking ahead, the evolution of the LDPE market will likely be shaped by several factors. These include advancements in recycling technologies, the development of more sustainable production methods, and the exploration of novel applications that leverage LDPE's unique properties. The industry's ability to address environmental concerns while maintaining performance and cost-effectiveness will be crucial in determining LDPE's future market presence and competitiveness.

The 1950s and 1960s saw a rapid expansion of LDPE applications, particularly in packaging and consumer goods. This growth was driven by the post-war economic boom and the increasing demand for convenient, disposable products. During this period, LDPE became a staple material in the production of plastic bags, food packaging, and household items.

The 1970s and 1980s marked a period of technological advancements in LDPE production. Improved manufacturing processes led to enhanced product quality and increased production efficiency. This era also witnessed the emergence of environmental concerns, prompting the industry to focus on recyclability and sustainability initiatives.

In the 1990s and early 2000s, LDPE faced growing competition from other polyethylene variants, such as linear low-density polyethylene (LLDPE) and high-density polyethylene (HDPE). These materials offered improved strength and barrier properties, challenging LDPE's market share in certain applications. However, LDPE maintained its position in specific sectors due to its unique combination of properties and cost-effectiveness.

The past two decades have seen a renewed focus on LDPE's environmental impact. With increasing global awareness of plastic pollution, the LDPE industry has been compelled to innovate in areas of biodegradability, recycling, and sustainable production methods. This shift has led to the development of bio-based LDPE and improved recycling technologies, aiming to address environmental concerns while maintaining the material's utility.

Currently, the LDPE market is at a critical juncture. While facing challenges from environmental regulations and alternative materials, it continues to find new applications in emerging industries. The packaging sector remains a key driver of LDPE demand, particularly in food packaging and e-commerce applications. Additionally, LDPE is finding new roles in sectors such as agriculture, healthcare, and construction, demonstrating its ongoing relevance and adaptability.

Looking ahead, the evolution of the LDPE market will likely be shaped by several factors. These include advancements in recycling technologies, the development of more sustainable production methods, and the exploration of novel applications that leverage LDPE's unique properties. The industry's ability to address environmental concerns while maintaining performance and cost-effectiveness will be crucial in determining LDPE's future market presence and competitiveness.

LDPE Demand Analysis

The global demand for Low-Density Polyethylene (LDPE) continues to grow, driven by its versatile applications across various industries. LDPE's unique properties, including flexibility, transparency, and moisture resistance, make it a preferred choice in packaging, agriculture, and construction sectors. The packaging industry remains the largest consumer of LDPE, accounting for a significant portion of its market share. This demand is fueled by the increasing need for flexible packaging solutions in food, beverage, and consumer goods industries.

In recent years, the e-commerce boom has further accelerated the demand for LDPE in packaging applications. The rise of online shopping has led to an increased need for protective packaging materials, where LDPE films and bags play a crucial role. Additionally, the agricultural sector has shown a growing appetite for LDPE products, particularly in greenhouse films and mulch films, as farmers seek to improve crop yields and reduce water consumption.

The construction industry also contributes to the steady demand for LDPE, utilizing it in vapor barriers, geomembranes, and insulation materials. As urbanization continues and infrastructure projects expand globally, this sector is expected to maintain its demand for LDPE products. Furthermore, the automotive industry has been incorporating LDPE in various components, such as wire insulation and interior trims, due to its lightweight properties and cost-effectiveness.

Despite the growing environmental concerns surrounding plastic usage, LDPE maintains its market presence due to its recyclability and ongoing efforts to improve its eco-friendly profile. Many manufacturers are investing in recycling technologies and developing bio-based LDPE alternatives to address sustainability issues, which could potentially open new market opportunities.

Regionally, Asia-Pacific leads the LDPE market, with China being the largest consumer and producer. The region's rapid industrialization, population growth, and increasing disposable income drive the demand for LDPE-based products. North America and Europe follow, with mature markets focusing on high-value applications and sustainable solutions. Emerging economies in Latin America and Africa are also showing increased demand for LDPE, particularly in packaging and agricultural applications.

To strengthen LDPE's market presence, industry players must focus on innovation in product development, emphasizing enhanced properties and sustainability. Developing LDPE grades with improved strength, barrier properties, and processability can open new application areas and maintain competitiveness against alternative materials. Additionally, investing in recycling infrastructure and promoting the circular economy for LDPE products will be crucial in addressing environmental concerns and ensuring long-term market viability.

In recent years, the e-commerce boom has further accelerated the demand for LDPE in packaging applications. The rise of online shopping has led to an increased need for protective packaging materials, where LDPE films and bags play a crucial role. Additionally, the agricultural sector has shown a growing appetite for LDPE products, particularly in greenhouse films and mulch films, as farmers seek to improve crop yields and reduce water consumption.

The construction industry also contributes to the steady demand for LDPE, utilizing it in vapor barriers, geomembranes, and insulation materials. As urbanization continues and infrastructure projects expand globally, this sector is expected to maintain its demand for LDPE products. Furthermore, the automotive industry has been incorporating LDPE in various components, such as wire insulation and interior trims, due to its lightweight properties and cost-effectiveness.

Despite the growing environmental concerns surrounding plastic usage, LDPE maintains its market presence due to its recyclability and ongoing efforts to improve its eco-friendly profile. Many manufacturers are investing in recycling technologies and developing bio-based LDPE alternatives to address sustainability issues, which could potentially open new market opportunities.

Regionally, Asia-Pacific leads the LDPE market, with China being the largest consumer and producer. The region's rapid industrialization, population growth, and increasing disposable income drive the demand for LDPE-based products. North America and Europe follow, with mature markets focusing on high-value applications and sustainable solutions. Emerging economies in Latin America and Africa are also showing increased demand for LDPE, particularly in packaging and agricultural applications.

To strengthen LDPE's market presence, industry players must focus on innovation in product development, emphasizing enhanced properties and sustainability. Developing LDPE grades with improved strength, barrier properties, and processability can open new application areas and maintain competitiveness against alternative materials. Additionally, investing in recycling infrastructure and promoting the circular economy for LDPE products will be crucial in addressing environmental concerns and ensuring long-term market viability.

LDPE Technical Challenges

Low-density polyethylene (LDPE) faces several technical challenges that impact its market presence and competitiveness. One of the primary issues is its limited mechanical strength compared to other polyethylene grades, such as high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE). This weakness restricts LDPE's application in areas requiring higher tensile strength and impact resistance, potentially limiting its market expansion.

Another significant challenge is LDPE's relatively low heat resistance. The material's low melting point and softening temperature make it unsuitable for applications involving high temperatures or prolonged heat exposure. This limitation narrows LDPE's potential use in certain packaging and industrial applications, where heat resistance is crucial.

LDPE also faces challenges in terms of its barrier properties. While it provides good moisture resistance, its gas permeability is higher compared to other packaging materials. This characteristic can be a drawback in food packaging applications where oxygen barrier properties are essential for preserving product freshness and extending shelf life.

The production process of LDPE, which typically involves high-pressure polymerization, presents its own set of challenges. The energy-intensive nature of this process contributes to higher production costs and increased carbon footprint, making LDPE less competitive in an increasingly environmentally conscious market.

Recyclability is another area where LDPE faces technical hurdles. While the material is recyclable, the process can be complicated by the presence of additives and contaminants. Improving the recyclability and developing more efficient recycling processes for LDPE is crucial for enhancing its sustainability profile and market appeal.

LDPE's limited compatibility with certain additives and fillers poses challenges in enhancing its properties or creating specialized formulations. This restriction can hinder innovation and the development of new LDPE-based products with improved characteristics.

Lastly, LDPE faces competition from bio-based and biodegradable alternatives in various applications, particularly in packaging. The growing demand for more sustainable materials puts pressure on LDPE manufacturers to innovate and improve the material's environmental profile.

Addressing these technical challenges is crucial for strengthening LDPE's market presence. Innovations in polymer science, process engineering, and material formulation will be key to overcoming these limitations and expanding LDPE's applicability across various industries.

Another significant challenge is LDPE's relatively low heat resistance. The material's low melting point and softening temperature make it unsuitable for applications involving high temperatures or prolonged heat exposure. This limitation narrows LDPE's potential use in certain packaging and industrial applications, where heat resistance is crucial.

LDPE also faces challenges in terms of its barrier properties. While it provides good moisture resistance, its gas permeability is higher compared to other packaging materials. This characteristic can be a drawback in food packaging applications where oxygen barrier properties are essential for preserving product freshness and extending shelf life.

The production process of LDPE, which typically involves high-pressure polymerization, presents its own set of challenges. The energy-intensive nature of this process contributes to higher production costs and increased carbon footprint, making LDPE less competitive in an increasingly environmentally conscious market.

Recyclability is another area where LDPE faces technical hurdles. While the material is recyclable, the process can be complicated by the presence of additives and contaminants. Improving the recyclability and developing more efficient recycling processes for LDPE is crucial for enhancing its sustainability profile and market appeal.

LDPE's limited compatibility with certain additives and fillers poses challenges in enhancing its properties or creating specialized formulations. This restriction can hinder innovation and the development of new LDPE-based products with improved characteristics.

Lastly, LDPE faces competition from bio-based and biodegradable alternatives in various applications, particularly in packaging. The growing demand for more sustainable materials puts pressure on LDPE manufacturers to innovate and improve the material's environmental profile.

Addressing these technical challenges is crucial for strengthening LDPE's market presence. Innovations in polymer science, process engineering, and material formulation will be key to overcoming these limitations and expanding LDPE's applicability across various industries.

LDPE Enhancement Strategies

01 LDPE market growth and applications

The LDPE market is experiencing growth due to its wide range of applications in various industries. LDPE is used in packaging, agriculture, construction, and consumer goods. Its properties such as flexibility, durability, and chemical resistance make it a popular choice for many products.- Market growth and applications: The LDPE market is experiencing growth due to its wide range of applications in various industries. LDPE is commonly used in packaging, agriculture, construction, and consumer goods. Its properties such as flexibility, durability, and chemical resistance make it a popular choice for many products.

- Production processes and technology advancements: Advancements in production processes and technology are contributing to the LDPE market presence. Improved manufacturing techniques, such as high-pressure tubular reactors and autoclave processes, are enhancing the quality and efficiency of LDPE production. These developments are driving market growth and expanding the potential applications of LDPE.

- Environmental concerns and recycling initiatives: The LDPE market is addressing environmental concerns through recycling initiatives and the development of more sustainable production methods. Efforts are being made to improve the recyclability of LDPE products and reduce their environmental impact. This focus on sustainability is influencing market trends and consumer preferences.

- Competitive landscape and market players: The LDPE market is characterized by a competitive landscape with several key players. Major companies are investing in research and development to improve product quality and expand their market share. Strategic partnerships and mergers are also shaping the market dynamics.

- Regional market trends and demand patterns: Regional variations in LDPE market presence are observed due to differences in industrial development, regulations, and consumer behavior. Emerging economies are showing increased demand for LDPE products, while mature markets are focusing on high-performance and specialty grades. These regional trends are influencing global market strategies and supply chains.

02 LDPE production processes and improvements

Advancements in LDPE production processes are contributing to market growth. These improvements include enhanced polymerization techniques, catalyst innovations, and more efficient reactor designs. Such developments are leading to higher quality LDPE and increased production capacity.Expand Specific Solutions03 LDPE blends and composites

The development of LDPE blends and composites is expanding its market presence. By combining LDPE with other materials, manufacturers are creating products with improved properties such as increased strength, better barrier properties, or enhanced biodegradability. This is opening up new applications and markets for LDPE-based materials.Expand Specific Solutions04 Recycling and sustainability of LDPE

The focus on recycling and sustainability is impacting the LDPE market. Efforts to improve LDPE recycling processes, develop bio-based LDPE alternatives, and create more sustainable packaging solutions are influencing market trends and consumer preferences.Expand Specific Solutions05 LDPE in specialized applications

LDPE is finding new market opportunities in specialized applications. These include medical devices, 3D printing filaments, and advanced coatings. The material's versatility and customizable properties are driving its adoption in these niche markets, further expanding its market presence.Expand Specific Solutions

LDPE Industry Players

The market for strengthening LDPE's presence is in a mature stage, characterized by established players and steady growth. The global LDPE market size is projected to reach $50 billion by 2027, driven by packaging and construction applications. Technologically, LDPE production is well-developed, with major companies like ExxonMobil, Dow, and SABIC leading innovation. These firms are focusing on enhancing LDPE properties and sustainability through advanced catalysts and processes. Emerging players like PetroChina and Sinopec are also making strides in LDPE technology, intensifying competition. The industry is shifting towards more specialized LDPE grades and eco-friendly solutions to maintain market relevance and meet evolving consumer demands.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced LDPE resins with enhanced properties to strengthen market presence. Their AGILITY™ Performance LDPE resins offer improved processability, higher melt strength, and better optical properties[1]. They've also introduced DOWLEX™ polyethylene resins, which combine LDPE's processability with LLDPE's strength, creating a hybrid solution for flexible packaging[2]. Dow's innovation extends to sustainable solutions, developing bio-based LDPE from renewable feedstocks, addressing growing environmental concerns[3]. Their INNATE™ precision packaging resins provide superior toughness and optics for demanding packaging applications, further solidifying their market position[4].

Strengths: Broad product portfolio, strong R&D capabilities, and focus on sustainability. Weaknesses: Dependence on petrochemical feedstocks and potential vulnerability to oil price fluctuations.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed Exceed™ XP performance polymers, which combine the easy processing of LDPE with the strength and toughness of LLDPE[5]. This innovation allows for downgauging in packaging applications, reducing material use while maintaining performance. They've also introduced Enable™ performance polyethylene, which offers improved tear and puncture resistance for heavy-duty packaging[6]. ExxonMobil's dual reactor technology allows for the production of bimodal LDPE resins, providing a balance of processability and mechanical properties[7]. Their focus on metallocene catalysts has led to more precise control over polymer architecture, enhancing LDPE's performance in specific applications.

Strengths: Advanced catalyst technology, extensive global production capacity, and strong brand recognition. Weaknesses: High capital intensity and potential environmental concerns associated with fossil fuel-based production.

LDPE Property Improvements

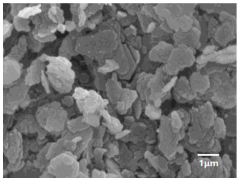

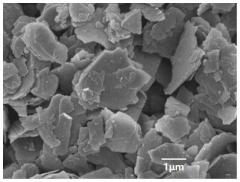

Efficient composite additive and LLDPE (Linear Low Density Polyethylene) composition for blown film

PatentInactiveCN114685857A

Innovation

- Use high-efficiency composite additives, including synthetic spherical silica and zeolite as anti-adhesive agents, optimize the ratio of slip agents and anti-adhesive agents, and add hindered phenol antioxidants, phosphite antioxidants, acid scavengers, and antistatic agents , colorants and fluoropolymer processing aids to form a spherical anti-blocking agent to improve the film's anti-blocking and slippery properties while improving color and processing performance.

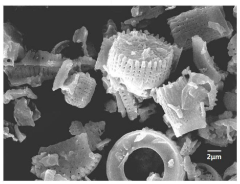

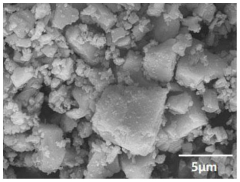

Antistatic adhesion-resistant slippery linear low density polyethylene composition and method of making the same

PatentInactiveCN101012322B

Innovation

- Add low-dose opening agent, slip agent, antistatic agent and heat stabilizer to LLDPE. Through uniform mixing and prefabricating masterbatch technology, an antistatic reactant sticking smooth linear low-density polyethylene composition is formed to reduce the surface resistance And maintain the original performance.

LDPE Sustainability Aspects

Sustainability has become a critical factor in strengthening LDPE's market presence. As environmental concerns grow, the plastics industry faces increasing pressure to adopt more sustainable practices. LDPE, being a widely used plastic, is at the forefront of this sustainability challenge.

One key aspect of LDPE sustainability is its recyclability. LDPE can be recycled multiple times without significant degradation of its properties, making it an attractive option for circular economy initiatives. However, the recycling rates for LDPE remain relatively low globally. Improving collection and recycling infrastructure, as well as increasing consumer awareness about LDPE recycling, are crucial steps in enhancing its sustainability profile.

The production process of LDPE also presents opportunities for sustainability improvements. Traditional LDPE manufacturing relies heavily on fossil fuels, contributing to carbon emissions. Innovations in production technologies, such as the use of renewable energy sources or the development of bio-based LDPE, can significantly reduce the environmental impact of LDPE production. Some companies are already exploring the use of bio-ethylene derived from sugarcane or other plant-based sources to produce more sustainable LDPE.

LDPE's lightweight nature contributes to its sustainability advantages in certain applications. In packaging, for instance, LDPE can reduce transportation costs and fuel consumption compared to heavier alternatives. This aspect can be further leveraged to strengthen LDPE's market position, especially in sectors where weight reduction is a priority.

The durability and reusability of LDPE products also play a role in its sustainability profile. Many LDPE items, such as reusable shopping bags, can replace single-use alternatives, potentially reducing overall plastic waste. Promoting the longevity and multiple-use capabilities of LDPE products can enhance its perception as a more sustainable material choice.

Addressing end-of-life issues is another critical sustainability aspect for LDPE. While recycling is preferable, not all LDPE waste is recycled. Research into biodegradable additives for LDPE or the development of more easily degradable LDPE variants could provide solutions for non-recycled waste. However, these innovations must be carefully balanced with maintaining LDPE's desirable properties and ensuring that they do not interfere with existing recycling streams.

Collaboration across the value chain is essential for improving LDPE's sustainability. Partnerships between resin producers, converters, brand owners, and waste management companies can lead to more effective recycling programs and the development of closed-loop systems for LDPE. Such initiatives not only improve sustainability but also create new market opportunities and strengthen LDPE's position in various industries.

One key aspect of LDPE sustainability is its recyclability. LDPE can be recycled multiple times without significant degradation of its properties, making it an attractive option for circular economy initiatives. However, the recycling rates for LDPE remain relatively low globally. Improving collection and recycling infrastructure, as well as increasing consumer awareness about LDPE recycling, are crucial steps in enhancing its sustainability profile.

The production process of LDPE also presents opportunities for sustainability improvements. Traditional LDPE manufacturing relies heavily on fossil fuels, contributing to carbon emissions. Innovations in production technologies, such as the use of renewable energy sources or the development of bio-based LDPE, can significantly reduce the environmental impact of LDPE production. Some companies are already exploring the use of bio-ethylene derived from sugarcane or other plant-based sources to produce more sustainable LDPE.

LDPE's lightweight nature contributes to its sustainability advantages in certain applications. In packaging, for instance, LDPE can reduce transportation costs and fuel consumption compared to heavier alternatives. This aspect can be further leveraged to strengthen LDPE's market position, especially in sectors where weight reduction is a priority.

The durability and reusability of LDPE products also play a role in its sustainability profile. Many LDPE items, such as reusable shopping bags, can replace single-use alternatives, potentially reducing overall plastic waste. Promoting the longevity and multiple-use capabilities of LDPE products can enhance its perception as a more sustainable material choice.

Addressing end-of-life issues is another critical sustainability aspect for LDPE. While recycling is preferable, not all LDPE waste is recycled. Research into biodegradable additives for LDPE or the development of more easily degradable LDPE variants could provide solutions for non-recycled waste. However, these innovations must be carefully balanced with maintaining LDPE's desirable properties and ensuring that they do not interfere with existing recycling streams.

Collaboration across the value chain is essential for improving LDPE's sustainability. Partnerships between resin producers, converters, brand owners, and waste management companies can lead to more effective recycling programs and the development of closed-loop systems for LDPE. Such initiatives not only improve sustainability but also create new market opportunities and strengthen LDPE's position in various industries.

LDPE Regulatory Landscape

The regulatory landscape for Low-Density Polyethylene (LDPE) plays a crucial role in shaping its market presence and future growth potential. As environmental concerns continue to rise globally, governments and regulatory bodies are implementing stricter policies and regulations that directly impact the production, use, and disposal of plastic materials, including LDPE.

In recent years, many countries have introduced or tightened regulations on single-use plastics, which has had a significant effect on the LDPE market. These regulations often target plastic bags, packaging materials, and other disposable items, many of which are made from LDPE. For instance, the European Union's Single-Use Plastics Directive, implemented in 2021, aims to reduce the environmental impact of certain plastic products and promote a circular economy.

The regulatory landscape also extends to recycling and waste management practices. Many jurisdictions have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. This has led to increased pressure on LDPE producers to develop more sustainable and recyclable products.

Food contact regulations are another critical aspect of the LDPE regulatory landscape. As LDPE is widely used in food packaging, it must comply with strict safety standards set by regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These regulations govern the composition of LDPE materials and their potential for chemical migration into food products.

Environmental regulations, particularly those related to greenhouse gas emissions and energy efficiency, also impact LDPE production. Many countries have implemented carbon pricing mechanisms or emissions trading schemes that affect the petrochemical industry, including LDPE manufacturers. This has led to increased focus on developing more energy-efficient production processes and exploring alternative feedstocks.

The regulatory landscape for LDPE is not uniform across different regions, which creates both challenges and opportunities for market players. While some countries are implementing stricter regulations, others may have more lenient policies, potentially leading to shifts in production and market dynamics. Understanding and navigating these regional differences is crucial for companies looking to strengthen their LDPE market presence.

As the regulatory landscape continues to evolve, LDPE producers and users must stay informed and adapt their strategies accordingly. This may involve investing in research and development to create more sustainable LDPE formulations, improving recycling technologies, or exploring alternative materials that can meet regulatory requirements while maintaining the desired performance characteristics.

In recent years, many countries have introduced or tightened regulations on single-use plastics, which has had a significant effect on the LDPE market. These regulations often target plastic bags, packaging materials, and other disposable items, many of which are made from LDPE. For instance, the European Union's Single-Use Plastics Directive, implemented in 2021, aims to reduce the environmental impact of certain plastic products and promote a circular economy.

The regulatory landscape also extends to recycling and waste management practices. Many jurisdictions have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. This has led to increased pressure on LDPE producers to develop more sustainable and recyclable products.

Food contact regulations are another critical aspect of the LDPE regulatory landscape. As LDPE is widely used in food packaging, it must comply with strict safety standards set by regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These regulations govern the composition of LDPE materials and their potential for chemical migration into food products.

Environmental regulations, particularly those related to greenhouse gas emissions and energy efficiency, also impact LDPE production. Many countries have implemented carbon pricing mechanisms or emissions trading schemes that affect the petrochemical industry, including LDPE manufacturers. This has led to increased focus on developing more energy-efficient production processes and exploring alternative feedstocks.

The regulatory landscape for LDPE is not uniform across different regions, which creates both challenges and opportunities for market players. While some countries are implementing stricter regulations, others may have more lenient policies, potentially leading to shifts in production and market dynamics. Understanding and navigating these regional differences is crucial for companies looking to strengthen their LDPE market presence.

As the regulatory landscape continues to evolve, LDPE producers and users must stay informed and adapt their strategies accordingly. This may involve investing in research and development to create more sustainable LDPE formulations, improving recycling technologies, or exploring alternative materials that can meet regulatory requirements while maintaining the desired performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!