How to Equip Industries with Effective LDPE Alternatives?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Alternatives Background and Objectives

Low-density polyethylene (LDPE) has been a staple material in various industries for decades due to its versatility, low cost, and ease of processing. However, growing environmental concerns and the need for more sustainable practices have led to an increased focus on finding effective alternatives to LDPE. This technological shift aims to address the environmental impact of plastic waste while maintaining or improving the performance characteristics that have made LDPE so widely used.

The development of LDPE alternatives is driven by several key factors. First, the global push for sustainability and circular economy principles has put pressure on industries to reduce their reliance on traditional plastics. Second, regulatory changes in many countries are mandating the use of more environmentally friendly materials. Third, consumer demand for eco-friendly products is creating market opportunities for companies that can offer viable LDPE substitutes.

The evolution of LDPE alternatives has seen significant progress over the past few decades. Initially, efforts focused on biodegradable plastics derived from renewable resources. These early alternatives often struggled to match the performance and cost-effectiveness of LDPE. However, recent advancements in material science and biotechnology have led to the development of more sophisticated alternatives that can compete with LDPE in terms of functionality and processability.

Current research and development efforts in LDPE alternatives are primarily focused on three main areas: bio-based polymers, recycled plastics, and advanced composites. Bio-based polymers, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), offer biodegradability and reduced carbon footprint. Recycled plastics aim to create a closed-loop system for existing plastic waste. Advanced composites combine different materials to achieve properties similar to LDPE while addressing environmental concerns.

The objective of equipping industries with effective LDPE alternatives is multifaceted. It involves not only developing materials with comparable or superior properties to LDPE but also ensuring these alternatives are economically viable and can be integrated into existing manufacturing processes with minimal disruption. Additionally, there is a need to address the entire lifecycle of these new materials, from production to disposal or recycling.

As the search for LDPE alternatives continues, the industry faces several challenges. These include scaling up production of new materials, optimizing their properties for specific applications, and overcoming potential resistance to change from established supply chains and manufacturing processes. However, the potential benefits of successful LDPE alternatives are significant, ranging from reduced environmental impact to new market opportunities and improved brand perception for companies that adopt these materials.

The development of LDPE alternatives is driven by several key factors. First, the global push for sustainability and circular economy principles has put pressure on industries to reduce their reliance on traditional plastics. Second, regulatory changes in many countries are mandating the use of more environmentally friendly materials. Third, consumer demand for eco-friendly products is creating market opportunities for companies that can offer viable LDPE substitutes.

The evolution of LDPE alternatives has seen significant progress over the past few decades. Initially, efforts focused on biodegradable plastics derived from renewable resources. These early alternatives often struggled to match the performance and cost-effectiveness of LDPE. However, recent advancements in material science and biotechnology have led to the development of more sophisticated alternatives that can compete with LDPE in terms of functionality and processability.

Current research and development efforts in LDPE alternatives are primarily focused on three main areas: bio-based polymers, recycled plastics, and advanced composites. Bio-based polymers, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), offer biodegradability and reduced carbon footprint. Recycled plastics aim to create a closed-loop system for existing plastic waste. Advanced composites combine different materials to achieve properties similar to LDPE while addressing environmental concerns.

The objective of equipping industries with effective LDPE alternatives is multifaceted. It involves not only developing materials with comparable or superior properties to LDPE but also ensuring these alternatives are economically viable and can be integrated into existing manufacturing processes with minimal disruption. Additionally, there is a need to address the entire lifecycle of these new materials, from production to disposal or recycling.

As the search for LDPE alternatives continues, the industry faces several challenges. These include scaling up production of new materials, optimizing their properties for specific applications, and overcoming potential resistance to change from established supply chains and manufacturing processes. However, the potential benefits of successful LDPE alternatives are significant, ranging from reduced environmental impact to new market opportunities and improved brand perception for companies that adopt these materials.

Market Demand Analysis for LDPE Substitutes

The global market for Low-Density Polyethylene (LDPE) alternatives is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. The demand for sustainable packaging solutions has led to a surge in interest for LDPE substitutes across various industries, including food and beverage, consumer goods, and industrial packaging.

One of the primary drivers of this market demand is the growing awareness of the environmental impact of traditional plastics. Consumers are increasingly seeking eco-friendly alternatives, putting pressure on manufacturers to adopt more sustainable packaging materials. This shift in consumer preferences has created a substantial market opportunity for LDPE alternatives, with many companies actively exploring and investing in new materials and technologies.

The food and beverage industry represents a significant portion of the demand for LDPE alternatives. As concerns over food safety and sustainability grow, there is a rising need for packaging materials that can maintain product freshness while being environmentally friendly. This has led to increased research and development in biodegradable and compostable materials that can match the performance characteristics of LDPE in food packaging applications.

In the consumer goods sector, the demand for LDPE alternatives is being fueled by brand commitments to sustainability and circular economy principles. Many major consumer brands have pledged to reduce their plastic usage and increase the use of recycled or renewable materials in their packaging. This has created a substantial market for innovative materials that can replace LDPE in applications such as flexible packaging, bottles, and containers.

The industrial packaging segment is also showing a growing interest in LDPE alternatives, particularly in sectors where durability and chemical resistance are crucial. There is a rising demand for bio-based polymers and advanced recycled materials that can meet the stringent performance requirements of industrial applications while offering improved environmental credentials.

Geographically, the demand for LDPE alternatives is particularly strong in regions with strict environmental regulations, such as Europe and North America. However, emerging economies in Asia-Pacific and Latin America are also showing increased interest in sustainable packaging solutions, driven by both regulatory pressures and changing consumer preferences.

The market for LDPE alternatives is expected to continue its growth trajectory in the coming years, with projections indicating a compound annual growth rate (CAGR) well above that of traditional plastics. This growth is supported by ongoing technological advancements in material science and manufacturing processes, which are continually improving the performance and cost-effectiveness of LDPE substitutes.

One of the primary drivers of this market demand is the growing awareness of the environmental impact of traditional plastics. Consumers are increasingly seeking eco-friendly alternatives, putting pressure on manufacturers to adopt more sustainable packaging materials. This shift in consumer preferences has created a substantial market opportunity for LDPE alternatives, with many companies actively exploring and investing in new materials and technologies.

The food and beverage industry represents a significant portion of the demand for LDPE alternatives. As concerns over food safety and sustainability grow, there is a rising need for packaging materials that can maintain product freshness while being environmentally friendly. This has led to increased research and development in biodegradable and compostable materials that can match the performance characteristics of LDPE in food packaging applications.

In the consumer goods sector, the demand for LDPE alternatives is being fueled by brand commitments to sustainability and circular economy principles. Many major consumer brands have pledged to reduce their plastic usage and increase the use of recycled or renewable materials in their packaging. This has created a substantial market for innovative materials that can replace LDPE in applications such as flexible packaging, bottles, and containers.

The industrial packaging segment is also showing a growing interest in LDPE alternatives, particularly in sectors where durability and chemical resistance are crucial. There is a rising demand for bio-based polymers and advanced recycled materials that can meet the stringent performance requirements of industrial applications while offering improved environmental credentials.

Geographically, the demand for LDPE alternatives is particularly strong in regions with strict environmental regulations, such as Europe and North America. However, emerging economies in Asia-Pacific and Latin America are also showing increased interest in sustainable packaging solutions, driven by both regulatory pressures and changing consumer preferences.

The market for LDPE alternatives is expected to continue its growth trajectory in the coming years, with projections indicating a compound annual growth rate (CAGR) well above that of traditional plastics. This growth is supported by ongoing technological advancements in material science and manufacturing processes, which are continually improving the performance and cost-effectiveness of LDPE substitutes.

Current Status and Challenges of LDPE Alternatives

The current status of LDPE alternatives reflects a dynamic landscape of innovation and challenges. Globally, there is a growing shift towards sustainable packaging solutions, driven by environmental concerns and regulatory pressures. This has led to increased research and development in biodegradable and compostable materials, as well as improved recycling technologies for conventional plastics.

One of the primary challenges in developing effective LDPE alternatives is achieving comparable performance characteristics. LDPE is valued for its flexibility, durability, and moisture resistance, making it difficult to replicate these properties with more environmentally friendly materials. Many current alternatives struggle to match LDPE's barrier properties, which are crucial for food packaging and other applications requiring protection from moisture and oxygen.

Cost remains a significant hurdle for widespread adoption of LDPE alternatives. Most sustainable options are more expensive to produce, making them less economically viable for many industries. This price differential is slowly narrowing as production scales up and technologies improve, but it continues to be a major factor limiting market penetration.

Technical challenges also persist in the processing and manufacturing of LDPE alternatives. Many bio-based materials require specialized equipment or modifications to existing production lines, creating additional barriers to adoption. Furthermore, the variability in raw material quality for some bio-based alternatives can lead to inconsistencies in the final product, a critical issue for industries with strict quality control requirements.

The recycling infrastructure for LDPE alternatives is another area of concern. While some alternatives are designed to be biodegradable or compostable, these properties can actually complicate recycling efforts for conventional plastics. There is a need for better sorting technologies and dedicated recycling streams to effectively manage the diverse range of materials entering the waste stream.

Regulatory frameworks and standards for LDPE alternatives are still evolving, creating uncertainty for manufacturers and consumers alike. The lack of consistent global standards for terms like "biodegradable" and "compostable" has led to confusion and potential greenwashing, highlighting the need for clearer guidelines and certification processes.

Despite these challenges, significant progress has been made in developing viable LDPE alternatives. Bio-based plastics derived from sources such as corn starch, sugarcane, and cellulose are gaining traction in various applications. Advanced recycling technologies, including chemical recycling, are also emerging as potential solutions to improve the circularity of plastic materials.

One of the primary challenges in developing effective LDPE alternatives is achieving comparable performance characteristics. LDPE is valued for its flexibility, durability, and moisture resistance, making it difficult to replicate these properties with more environmentally friendly materials. Many current alternatives struggle to match LDPE's barrier properties, which are crucial for food packaging and other applications requiring protection from moisture and oxygen.

Cost remains a significant hurdle for widespread adoption of LDPE alternatives. Most sustainable options are more expensive to produce, making them less economically viable for many industries. This price differential is slowly narrowing as production scales up and technologies improve, but it continues to be a major factor limiting market penetration.

Technical challenges also persist in the processing and manufacturing of LDPE alternatives. Many bio-based materials require specialized equipment or modifications to existing production lines, creating additional barriers to adoption. Furthermore, the variability in raw material quality for some bio-based alternatives can lead to inconsistencies in the final product, a critical issue for industries with strict quality control requirements.

The recycling infrastructure for LDPE alternatives is another area of concern. While some alternatives are designed to be biodegradable or compostable, these properties can actually complicate recycling efforts for conventional plastics. There is a need for better sorting technologies and dedicated recycling streams to effectively manage the diverse range of materials entering the waste stream.

Regulatory frameworks and standards for LDPE alternatives are still evolving, creating uncertainty for manufacturers and consumers alike. The lack of consistent global standards for terms like "biodegradable" and "compostable" has led to confusion and potential greenwashing, highlighting the need for clearer guidelines and certification processes.

Despite these challenges, significant progress has been made in developing viable LDPE alternatives. Bio-based plastics derived from sources such as corn starch, sugarcane, and cellulose are gaining traction in various applications. Advanced recycling technologies, including chemical recycling, are also emerging as potential solutions to improve the circularity of plastic materials.

Existing LDPE Replacement Solutions

01 Biodegradable polymer alternatives

Various biodegradable polymers are being developed as alternatives to LDPE. These materials offer similar properties to LDPE but with improved environmental sustainability. They can be derived from renewable resources and are designed to break down more easily in natural environments, reducing plastic pollution.- Biodegradable polymer alternatives: Various biodegradable polymers are being developed as alternatives to LDPE. These materials offer similar properties to LDPE but with improved environmental sustainability. They can be derived from renewable resources and are designed to break down more easily in natural environments, reducing plastic pollution.

- High-performance composite materials: Advanced composite materials are being engineered to replace LDPE in certain applications. These composites often combine different polymers or incorporate additives to enhance specific properties such as strength, flexibility, or barrier performance. They can offer improved characteristics compared to traditional LDPE while maintaining similar processability.

- Recycled and upcycled plastic alternatives: Innovative technologies are being developed to recycle and upcycle plastic waste into new materials that can serve as alternatives to virgin LDPE. These processes aim to reduce the environmental impact of plastic production while maintaining the desirable properties of LDPE. Some methods involve chemical recycling or the incorporation of recycled content into new polymer blends.

- Bio-based polyethylene alternatives: Research is ongoing into the development of bio-based polyethylene alternatives that have similar properties to LDPE but are derived from renewable resources. These materials aim to reduce dependence on fossil fuels while maintaining the performance characteristics of traditional LDPE. Some approaches involve fermenting plant sugars to produce ethylene, which is then polymerized.

- Novel polymer blends and alloys: Researchers are exploring new polymer blends and alloys that combine the desirable properties of LDPE with other materials to create improved alternatives. These blends may offer enhanced performance in areas such as strength, barrier properties, or processability while addressing some of the limitations of pure LDPE. The goal is to create materials that can be used as drop-in replacements in existing manufacturing processes.

02 High-performance composite materials

Advanced composite materials are being engineered to replace LDPE in certain applications. These composites often combine different polymers or incorporate additives to enhance specific properties such as strength, flexibility, or barrier performance. They can offer improved characteristics compared to traditional LDPE while maintaining similar processability.Expand Specific Solutions03 Recycled and upcycled plastic alternatives

Innovative processes are being developed to recycle and upcycle existing plastic waste into new materials that can serve as alternatives to virgin LDPE. These methods aim to reduce the demand for new plastic production while finding valuable uses for plastic waste, contributing to a more circular economy.Expand Specific Solutions04 Bio-based polymer substitutes

Research is focused on developing bio-based polymers as substitutes for LDPE. These materials are derived from renewable biological sources such as plant starches or cellulose. They aim to provide similar functional properties to LDPE while reducing dependence on fossil fuel-based plastics.Expand Specific Solutions05 Nanocomposite materials

Nanocomposite materials are being explored as potential alternatives to LDPE. These materials incorporate nanoparticles into polymer matrices to enhance properties such as strength, barrier performance, and thermal stability. They can potentially offer superior performance in certain applications compared to traditional LDPE.Expand Specific Solutions

Key Players in LDPE Alternative Industry

The market for LDPE alternatives is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size for sustainable plastics is projected to reach $100 billion by 2025, with a CAGR of 9.5%. Technologically, LDPE alternatives are advancing rapidly, with companies like Dow Global Technologies, ExxonMobil Chemical Patents, and LG Chem leading innovation. These firms are developing bio-based and recyclable polymers with improved properties. However, the technology is not yet fully mature, as challenges remain in scaling production and matching LDPE's versatility. Emerging players like Zhejiang Walrus New Material and Hunan Yueshengjie Technology are also contributing to the competitive landscape, focusing on niche applications and regional markets.

Dow Global Technologies LLC

Technical Solution: Dow has developed ELITE AT polyethylene resins as an effective LDPE alternative. These resins offer enhanced toughness and processability, making them suitable for various packaging applications. The technology utilizes advanced catalyst systems and process innovations to produce resins with a unique molecular architecture[1]. This results in improved film strength, puncture resistance, and seal performance compared to traditional LDPE. Dow's solution also incorporates sustainability features, with some grades containing post-consumer recycled content and designed for recyclability[2].

Strengths: Superior mechanical properties, improved processability, and enhanced sustainability profile. Weaknesses: Potentially higher production costs and limited availability compared to conventional LDPE.

China Petroleum & Chemical Corp.

Technical Solution: Sinopec has developed a series of metallocene-based polyethylene resins as LDPE alternatives. Their technology utilizes advanced single-site catalysts to produce polymers with controlled molecular architecture and narrow molecular weight distribution[7]. This results in resins with improved toughness, puncture resistance, and optical properties compared to traditional LDPE. Sinopec's solution also focuses on enhancing processability and seal performance, making it suitable for various packaging applications. The company has invested in research to improve the sustainability profile of these resins, including efforts to increase recyclability and reduce overall material usage[8].

Strengths: Enhanced mechanical and optical properties, improved processability, and focus on sustainability. Weaknesses: Potential challenges in scaling production and competing with established global players.

Core Innovations in Sustainable Plastics

Flame-retardant polyolefin composite material as well as preparation method and application thereof

PatentPendingCN117050414A

Innovation

- Using a halogen-free intumescent flame retardant system, combined with polypropylene to improve the compatibility of the flame retardant with low-density polyethylene, piperazine pyrophosphate and melamine polyphosphate are used as flame retardants, and are prepared through a uniform mixing and internal mixing process composite materials to improve their thermal stability and flame retardant properties.

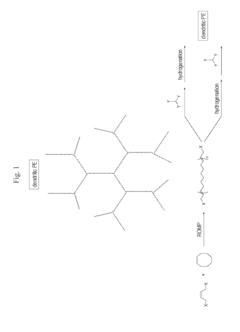

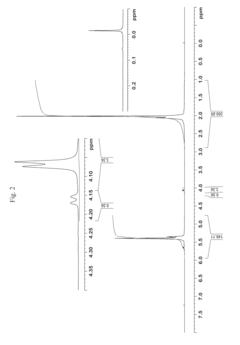

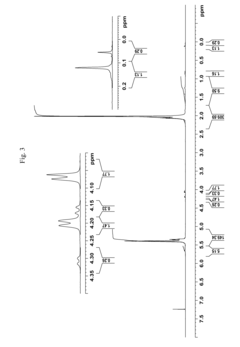

Process for making dendritic polyolefins from telechelic polycyclic olefins

PatentInactiveUS20130172493A1

Innovation

- The synthesis of dendritic polyethylenes through ring opening metathesis polymerization of cyclic olefins with bi-functional alkene chain terminating agents, followed by reaction with multifunctional coupling agents, to produce telechelic hydrocarbon polymers that are then reacted with trifunctional or tetrafunctional coupling agents to create dendritic structures, which can be used as additives in conventional polyethylenes.

Environmental Impact Assessment

The environmental impact assessment of LDPE alternatives is crucial for evaluating their sustainability and potential to mitigate the ecological challenges posed by traditional plastics. LDPE, widely used in packaging and other industrial applications, has significant environmental drawbacks, including long decomposition times and contribution to plastic pollution.

Biodegradable alternatives to LDPE, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), offer promising environmental benefits. These materials decompose more rapidly under specific conditions, potentially reducing long-term environmental accumulation. However, their production and end-of-life management require careful consideration to ensure a net positive environmental impact.

Life cycle assessments (LCAs) of LDPE alternatives reveal complex environmental trade-offs. While biodegradable plastics may reduce plastic pollution, their production often requires more energy and resources compared to traditional LDPE. This increased production footprint must be weighed against the benefits of improved end-of-life outcomes.

Water usage and land use changes associated with bio-based LDPE alternatives are significant factors to consider. The cultivation of crops for bioplastic production can lead to increased water consumption and potential land-use conflicts with food production. These impacts must be carefully managed to ensure the overall sustainability of these alternatives.

Greenhouse gas emissions throughout the lifecycle of LDPE alternatives vary depending on the specific material and production processes. Some alternatives show potential for reduced carbon footprints, particularly when accounting for end-of-life scenarios. However, the net climate impact depends on factors such as feedstock source, production efficiency, and waste management infrastructure.

The end-of-life management of LDPE alternatives presents both opportunities and challenges. While biodegradable plastics offer the potential for composting or anaerobic digestion, these processes require specific conditions and infrastructure that may not be widely available. Improper disposal can lead to similar environmental issues as traditional plastics.

Toxicity and ecosystem impacts of LDPE alternatives must also be thoroughly assessed. Some biodegradable plastics may introduce new compounds into the environment as they break down. Understanding the long-term effects of these materials on ecosystems and potential bioaccumulation is essential for ensuring their safety and sustainability.

In conclusion, the environmental impact assessment of LDPE alternatives reveals a complex landscape of trade-offs and considerations. While these materials offer potential solutions to some of the environmental challenges posed by traditional plastics, their adoption must be guided by comprehensive lifecycle analyses and careful management of production and end-of-life processes to ensure genuine environmental benefits.

Biodegradable alternatives to LDPE, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), offer promising environmental benefits. These materials decompose more rapidly under specific conditions, potentially reducing long-term environmental accumulation. However, their production and end-of-life management require careful consideration to ensure a net positive environmental impact.

Life cycle assessments (LCAs) of LDPE alternatives reveal complex environmental trade-offs. While biodegradable plastics may reduce plastic pollution, their production often requires more energy and resources compared to traditional LDPE. This increased production footprint must be weighed against the benefits of improved end-of-life outcomes.

Water usage and land use changes associated with bio-based LDPE alternatives are significant factors to consider. The cultivation of crops for bioplastic production can lead to increased water consumption and potential land-use conflicts with food production. These impacts must be carefully managed to ensure the overall sustainability of these alternatives.

Greenhouse gas emissions throughout the lifecycle of LDPE alternatives vary depending on the specific material and production processes. Some alternatives show potential for reduced carbon footprints, particularly when accounting for end-of-life scenarios. However, the net climate impact depends on factors such as feedstock source, production efficiency, and waste management infrastructure.

The end-of-life management of LDPE alternatives presents both opportunities and challenges. While biodegradable plastics offer the potential for composting or anaerobic digestion, these processes require specific conditions and infrastructure that may not be widely available. Improper disposal can lead to similar environmental issues as traditional plastics.

Toxicity and ecosystem impacts of LDPE alternatives must also be thoroughly assessed. Some biodegradable plastics may introduce new compounds into the environment as they break down. Understanding the long-term effects of these materials on ecosystems and potential bioaccumulation is essential for ensuring their safety and sustainability.

In conclusion, the environmental impact assessment of LDPE alternatives reveals a complex landscape of trade-offs and considerations. While these materials offer potential solutions to some of the environmental challenges posed by traditional plastics, their adoption must be guided by comprehensive lifecycle analyses and careful management of production and end-of-life processes to ensure genuine environmental benefits.

Regulatory Framework for Plastic Alternatives

The regulatory framework for plastic alternatives plays a crucial role in shaping the adoption and implementation of Low-Density Polyethylene (LDPE) substitutes across industries. As governments and international bodies increasingly recognize the environmental impact of traditional plastics, they are developing comprehensive policies and regulations to promote sustainable alternatives.

At the forefront of these regulatory efforts is the European Union's Single-Use Plastics Directive, which aims to reduce the consumption of single-use plastic products and promote the use of sustainable alternatives. This directive sets specific targets for member states to achieve by 2026, including a 50% reduction in single-use plastic cups and food containers. Such regulations create a strong incentive for industries to invest in and adopt LDPE alternatives.

In the United States, several states have implemented their own plastic bag bans and restrictions on single-use plastics, driving the demand for alternative materials. California's Senate Bill 54, for instance, requires all packaging in the state to be recyclable or compostable by 2032, further encouraging the development and use of LDPE alternatives.

The regulatory landscape also extends to product labeling and certification standards for plastic alternatives. The International Organization for Standardization (ISO) has developed standards such as ISO 17088 for compostable plastics, providing a framework for industries to verify and communicate the environmental credentials of their alternative materials.

Financial incentives and penalties are increasingly being incorporated into regulatory frameworks to accelerate the transition away from traditional plastics. Some countries have introduced taxes on plastic packaging or implemented extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal.

Emerging regulations are also addressing the potential risks associated with novel plastic alternatives. For example, the U.S. Food and Drug Administration (FDA) has established guidelines for food contact substances, ensuring that new materials used in food packaging meet safety standards. This regulatory oversight is crucial for building consumer trust in LDPE alternatives and facilitating their widespread adoption.

As the regulatory landscape continues to evolve, industries must stay informed and adaptable. Compliance with these regulations not only ensures legal operation but also positions companies as environmentally responsible entities, potentially leading to competitive advantages in an increasingly eco-conscious market.

At the forefront of these regulatory efforts is the European Union's Single-Use Plastics Directive, which aims to reduce the consumption of single-use plastic products and promote the use of sustainable alternatives. This directive sets specific targets for member states to achieve by 2026, including a 50% reduction in single-use plastic cups and food containers. Such regulations create a strong incentive for industries to invest in and adopt LDPE alternatives.

In the United States, several states have implemented their own plastic bag bans and restrictions on single-use plastics, driving the demand for alternative materials. California's Senate Bill 54, for instance, requires all packaging in the state to be recyclable or compostable by 2032, further encouraging the development and use of LDPE alternatives.

The regulatory landscape also extends to product labeling and certification standards for plastic alternatives. The International Organization for Standardization (ISO) has developed standards such as ISO 17088 for compostable plastics, providing a framework for industries to verify and communicate the environmental credentials of their alternative materials.

Financial incentives and penalties are increasingly being incorporated into regulatory frameworks to accelerate the transition away from traditional plastics. Some countries have introduced taxes on plastic packaging or implemented extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal.

Emerging regulations are also addressing the potential risks associated with novel plastic alternatives. For example, the U.S. Food and Drug Administration (FDA) has established guidelines for food contact substances, ensuring that new materials used in food packaging meet safety standards. This regulatory oversight is crucial for building consumer trust in LDPE alternatives and facilitating their widespread adoption.

As the regulatory landscape continues to evolve, industries must stay informed and adaptable. Compliance with these regulations not only ensures legal operation but also positions companies as environmentally responsible entities, potentially leading to competitive advantages in an increasingly eco-conscious market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!