Advanced laser integration techniques in silicon photonics.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Photonics Laser Integration Background

Silicon photonics has emerged as a transformative technology in the field of integrated optics, offering the potential to revolutionize data communication and processing. At the heart of this technology lies the challenge of integrating efficient light sources onto silicon-based platforms. The background of laser integration in silicon photonics spans several decades of research and development, driven by the need for high-performance, low-cost optical components in telecommunications and data centers.

The journey began in the 1980s with the realization that silicon, despite its dominance in electronics, was an inefficient light emitter due to its indirect bandgap. This fundamental limitation sparked a quest for innovative solutions to incorporate light sources into silicon-based photonic circuits. Early attempts focused on hybrid integration techniques, where III-V semiconductor lasers were bonded or attached to silicon substrates.

As the field progressed, researchers explored various approaches to overcome silicon's inherent limitations. These included the development of Raman lasers, which leveraged silicon's nonlinear optical properties, and the incorporation of rare-earth-doped materials to create light-emitting regions within silicon. However, these methods faced challenges in terms of efficiency, scalability, and compatibility with existing CMOS fabrication processes.

The breakthrough came with the advent of heterogeneous integration techniques in the early 2000s. This approach involved bonding III-V semiconductor materials, such as indium phosphide, onto silicon substrates using wafer bonding technologies. This method allowed for the creation of efficient lasers directly integrated with silicon waveguides, marking a significant milestone in silicon photonics.

Concurrent with these developments, researchers also explored the potential of germanium as a light-emitting material compatible with silicon. By engineering the band structure of germanium through strain and doping, scientists demonstrated the feasibility of creating lasers directly on silicon substrates.

The evolution of laser integration techniques in silicon photonics has been driven by the increasing demand for higher bandwidth, lower power consumption, and greater integration density in optical communication systems. As data centers and telecommunications networks face exponential growth in data traffic, the need for compact, efficient, and cost-effective photonic integrated circuits has become more pressing than ever.

Today, advanced laser integration techniques in silicon photonics continue to push the boundaries of performance and scalability. Researchers are exploring novel materials, innovative device architectures, and sophisticated fabrication processes to enhance the efficiency, reliability, and integration density of lasers on silicon platforms. The ongoing efforts aim to realize the full potential of silicon photonics in applications ranging from high-speed optical interconnects to quantum computing and sensing technologies.

The journey began in the 1980s with the realization that silicon, despite its dominance in electronics, was an inefficient light emitter due to its indirect bandgap. This fundamental limitation sparked a quest for innovative solutions to incorporate light sources into silicon-based photonic circuits. Early attempts focused on hybrid integration techniques, where III-V semiconductor lasers were bonded or attached to silicon substrates.

As the field progressed, researchers explored various approaches to overcome silicon's inherent limitations. These included the development of Raman lasers, which leveraged silicon's nonlinear optical properties, and the incorporation of rare-earth-doped materials to create light-emitting regions within silicon. However, these methods faced challenges in terms of efficiency, scalability, and compatibility with existing CMOS fabrication processes.

The breakthrough came with the advent of heterogeneous integration techniques in the early 2000s. This approach involved bonding III-V semiconductor materials, such as indium phosphide, onto silicon substrates using wafer bonding technologies. This method allowed for the creation of efficient lasers directly integrated with silicon waveguides, marking a significant milestone in silicon photonics.

Concurrent with these developments, researchers also explored the potential of germanium as a light-emitting material compatible with silicon. By engineering the band structure of germanium through strain and doping, scientists demonstrated the feasibility of creating lasers directly on silicon substrates.

The evolution of laser integration techniques in silicon photonics has been driven by the increasing demand for higher bandwidth, lower power consumption, and greater integration density in optical communication systems. As data centers and telecommunications networks face exponential growth in data traffic, the need for compact, efficient, and cost-effective photonic integrated circuits has become more pressing than ever.

Today, advanced laser integration techniques in silicon photonics continue to push the boundaries of performance and scalability. Researchers are exploring novel materials, innovative device architectures, and sophisticated fabrication processes to enhance the efficiency, reliability, and integration density of lasers on silicon platforms. The ongoing efforts aim to realize the full potential of silicon photonics in applications ranging from high-speed optical interconnects to quantum computing and sensing technologies.

Market Demand Analysis

The market demand for advanced laser integration techniques in silicon photonics has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for high-speed data transmission, efficient computing, and advanced sensing applications across various industries.

In the telecommunications sector, the demand for silicon photonics-based transceivers has been steadily rising. These transceivers, which incorporate integrated lasers, offer higher data rates and lower power consumption compared to traditional electronic solutions. As global internet traffic continues to grow exponentially, telecom companies are increasingly adopting silicon photonics technologies to meet the bandwidth demands of 5G networks and beyond.

The data center market represents another major driver for advanced laser integration in silicon photonics. With the rapid expansion of cloud computing and big data analytics, data centers require ever-increasing data transfer speeds and reduced power consumption. Integrated laser solutions in silicon photonics offer a promising approach to address these challenges, leading to a growing demand from major cloud service providers and data center operators.

In the automotive industry, the development of autonomous vehicles has created a new market for advanced sensing technologies. LiDAR systems, which rely on integrated lasers for precise distance measurement, are becoming essential components in self-driving cars. This has led to increased interest in silicon photonics-based LiDAR solutions, driving demand for advanced laser integration techniques.

The healthcare sector is also emerging as a significant market for silicon photonics with integrated lasers. Applications such as optical coherence tomography (OCT) for medical imaging and biosensors for point-of-care diagnostics are gaining traction. These technologies benefit from the miniaturization and cost-effectiveness offered by integrated laser solutions in silicon photonics.

In the consumer electronics market, there is growing interest in augmented reality (AR) and virtual reality (VR) devices. Advanced laser integration techniques in silicon photonics can enable compact, energy-efficient display technologies for these applications, potentially driving significant demand in the coming years.

The aerospace and defense industries are also showing increased demand for silicon photonics with integrated lasers. Applications include high-speed optical interconnects for avionics systems and advanced sensing technologies for surveillance and reconnaissance.

Overall, the market for advanced laser integration techniques in silicon photonics is expected to continue its growth trajectory. The technology's ability to offer high performance, energy efficiency, and scalability makes it attractive across multiple industries. As research and development efforts intensify, and manufacturing processes improve, the market is likely to expand further, opening up new applications and opportunities in various sectors.

In the telecommunications sector, the demand for silicon photonics-based transceivers has been steadily rising. These transceivers, which incorporate integrated lasers, offer higher data rates and lower power consumption compared to traditional electronic solutions. As global internet traffic continues to grow exponentially, telecom companies are increasingly adopting silicon photonics technologies to meet the bandwidth demands of 5G networks and beyond.

The data center market represents another major driver for advanced laser integration in silicon photonics. With the rapid expansion of cloud computing and big data analytics, data centers require ever-increasing data transfer speeds and reduced power consumption. Integrated laser solutions in silicon photonics offer a promising approach to address these challenges, leading to a growing demand from major cloud service providers and data center operators.

In the automotive industry, the development of autonomous vehicles has created a new market for advanced sensing technologies. LiDAR systems, which rely on integrated lasers for precise distance measurement, are becoming essential components in self-driving cars. This has led to increased interest in silicon photonics-based LiDAR solutions, driving demand for advanced laser integration techniques.

The healthcare sector is also emerging as a significant market for silicon photonics with integrated lasers. Applications such as optical coherence tomography (OCT) for medical imaging and biosensors for point-of-care diagnostics are gaining traction. These technologies benefit from the miniaturization and cost-effectiveness offered by integrated laser solutions in silicon photonics.

In the consumer electronics market, there is growing interest in augmented reality (AR) and virtual reality (VR) devices. Advanced laser integration techniques in silicon photonics can enable compact, energy-efficient display technologies for these applications, potentially driving significant demand in the coming years.

The aerospace and defense industries are also showing increased demand for silicon photonics with integrated lasers. Applications include high-speed optical interconnects for avionics systems and advanced sensing technologies for surveillance and reconnaissance.

Overall, the market for advanced laser integration techniques in silicon photonics is expected to continue its growth trajectory. The technology's ability to offer high performance, energy efficiency, and scalability makes it attractive across multiple industries. As research and development efforts intensify, and manufacturing processes improve, the market is likely to expand further, opening up new applications and opportunities in various sectors.

Current Challenges in Laser-Silicon Integration

The integration of lasers with silicon photonics remains a significant challenge in the field, despite substantial progress in recent years. One of the primary obstacles is the fundamental incompatibility between silicon and traditional III-V semiconductor materials used for efficient light emission. Silicon's indirect bandgap makes it an inefficient light emitter, necessitating the incorporation of III-V materials for laser sources.

The heterogeneous integration of III-V materials on silicon substrates presents several technical hurdles. Lattice mismatch between these materials can lead to defects and dislocations, compromising the performance and reliability of integrated lasers. Additionally, thermal management becomes critical due to the different thermal expansion coefficients of silicon and III-V materials, potentially causing stress and degradation over time.

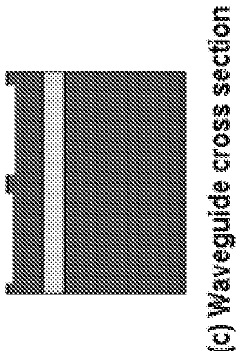

Another challenge lies in achieving efficient coupling between the laser source and silicon waveguides. The mode size mismatch between III-V lasers and silicon photonic circuits requires sophisticated mode converters or tapers, which can introduce additional complexity and potential losses in the system.

The scalability of laser integration techniques is also a concern for large-scale manufacturing. Current methods often involve complex bonding processes or epitaxial growth techniques that may not be easily adaptable to high-volume production. Ensuring consistent performance and yield across large wafers remains a significant challenge for the industry.

Power efficiency and heat dissipation are critical factors in laser-silicon integration. The power consumption of integrated lasers can be a limiting factor in the overall energy efficiency of silicon photonic systems. Effective heat management strategies are essential to maintain stable laser operation and prevent thermal crosstalk with adjacent photonic components.

Lastly, the long-term reliability and stability of integrated lasers in silicon photonic circuits are ongoing concerns. Environmental factors, such as temperature fluctuations and mechanical stress, can affect the performance and lifetime of integrated lasers. Developing robust packaging solutions that protect the sensitive III-V materials while maintaining optical alignment is crucial for the commercial viability of integrated photonic systems.

The heterogeneous integration of III-V materials on silicon substrates presents several technical hurdles. Lattice mismatch between these materials can lead to defects and dislocations, compromising the performance and reliability of integrated lasers. Additionally, thermal management becomes critical due to the different thermal expansion coefficients of silicon and III-V materials, potentially causing stress and degradation over time.

Another challenge lies in achieving efficient coupling between the laser source and silicon waveguides. The mode size mismatch between III-V lasers and silicon photonic circuits requires sophisticated mode converters or tapers, which can introduce additional complexity and potential losses in the system.

The scalability of laser integration techniques is also a concern for large-scale manufacturing. Current methods often involve complex bonding processes or epitaxial growth techniques that may not be easily adaptable to high-volume production. Ensuring consistent performance and yield across large wafers remains a significant challenge for the industry.

Power efficiency and heat dissipation are critical factors in laser-silicon integration. The power consumption of integrated lasers can be a limiting factor in the overall energy efficiency of silicon photonic systems. Effective heat management strategies are essential to maintain stable laser operation and prevent thermal crosstalk with adjacent photonic components.

Lastly, the long-term reliability and stability of integrated lasers in silicon photonic circuits are ongoing concerns. Environmental factors, such as temperature fluctuations and mechanical stress, can affect the performance and lifetime of integrated lasers. Developing robust packaging solutions that protect the sensitive III-V materials while maintaining optical alignment is crucial for the commercial viability of integrated photonic systems.

Existing Laser Integration Solutions

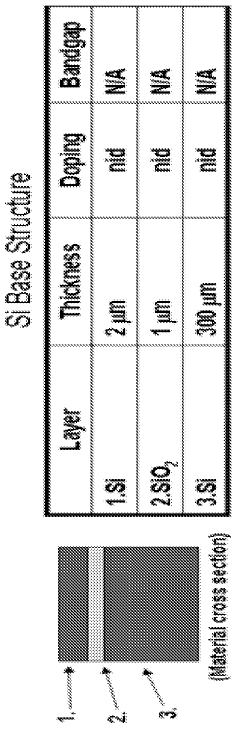

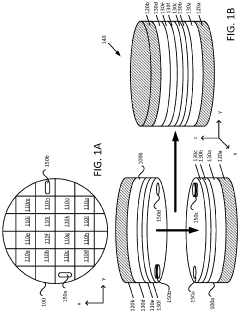

01 Integration of lasers on silicon photonic platforms

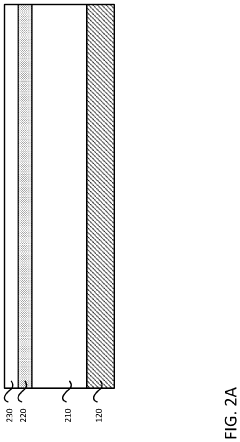

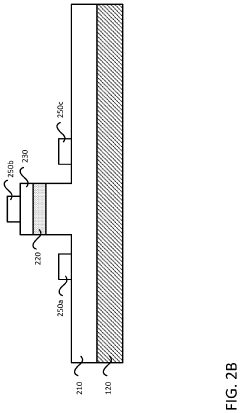

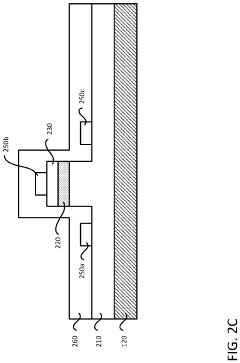

This approach involves the direct integration of lasers onto silicon photonic chips, enabling on-chip light generation. Various methods are employed to overcome the challenges of integrating III-V materials with silicon, including wafer bonding and epitaxial growth techniques. This integration allows for compact and efficient photonic circuits with integrated light sources.- Integration of lasers on silicon photonic platforms: This approach involves the direct integration of laser sources onto silicon photonic chips. It enables the combination of light generation and manipulation on a single substrate, enhancing the functionality and performance of photonic integrated circuits. Various methods are employed to achieve this integration, including wafer bonding, epitaxial growth, and heterogeneous integration techniques.

- Hybrid integration of III-V lasers with silicon photonics: Hybrid integration combines III-V semiconductor lasers with silicon photonic circuits. This method leverages the superior light-emitting properties of III-V materials with the scalability and cost-effectiveness of silicon photonics. Techniques such as flip-chip bonding and transfer printing are used to achieve this integration, allowing for high-performance photonic systems.

- Monolithic integration of lasers in silicon: This approach focuses on developing lasers directly within the silicon material itself. It involves engineering the silicon crystal structure or introducing dopants to create light-emitting regions. While challenging due to silicon's indirect bandgap, advancements in this area promise fully integrated, CMOS-compatible photonic systems with on-chip light sources.

- Novel materials for silicon-compatible lasers: Research into new materials that are compatible with silicon processing yet capable of efficient light emission is ongoing. This includes exploring germanium-tin alloys, rare-earth-doped materials, and quantum dot structures. These materials aim to bridge the gap between silicon's electronic properties and the need for efficient light sources in photonic circuits.

- Packaging and thermal management for integrated lasers: Effective packaging and thermal management are crucial for the performance and reliability of integrated lasers in silicon photonic systems. This involves developing advanced heat dissipation techniques, optimizing the layout of photonic circuits, and creating robust packaging solutions that maintain optical alignment and protect sensitive components from environmental factors.

02 Hybrid integration of lasers with silicon photonics

Hybrid integration techniques combine separately fabricated laser components with silicon photonic circuits. This approach allows for the optimization of both the laser and silicon photonic elements independently before integration. Methods such as flip-chip bonding and micro-transfer printing are used to achieve precise alignment and coupling between the laser and silicon waveguides.Expand Specific Solutions03 Novel laser designs for silicon photonics integration

Innovative laser designs are being developed specifically for integration with silicon photonics. These include structures such as distributed feedback (DFB) lasers, vertical-cavity surface-emitting lasers (VCSELs), and micro-ring lasers optimized for silicon substrates. These designs aim to improve coupling efficiency, reduce power consumption, and enhance compatibility with silicon fabrication processes.Expand Specific Solutions04 Wavelength control and tuning in integrated lasers

Techniques for precise wavelength control and tuning of integrated lasers are crucial for silicon photonics applications. This includes methods for temperature stabilization, current injection tuning, and the use of external cavity configurations. These approaches enable the development of tunable laser sources compatible with wavelength division multiplexing (WDM) systems on silicon photonic platforms.Expand Specific Solutions05 Packaging and thermal management for integrated lasers

Advanced packaging and thermal management solutions are essential for the successful integration of lasers in silicon photonics. This involves the development of hermetic sealing techniques, efficient heat dissipation structures, and methods to minimize thermal crosstalk between components. These innovations aim to improve the reliability and performance of integrated laser systems in silicon photonic circuits.Expand Specific Solutions

Key Players in Silicon Photonics

The advanced laser integration techniques in silicon photonics field is currently in a growth phase, with increasing market size and evolving technological maturity. The global market for silicon photonics is projected to expand significantly in the coming years, driven by demand for high-speed data transmission and efficient computing solutions. Key players like Intel, IBM, and STMicroelectronics are advancing the technology, while research institutions such as Shanghai Institute of Microsystem & Information Technology and University of California are contributing to fundamental breakthroughs. The involvement of both established tech giants and innovative startups like Skorpios Technologies and Axalume indicates a competitive landscape with diverse approaches to overcoming integration challenges and improving performance.

The Regents of the University of California

Technical Solution: The University of California has been at the forefront of research in advanced laser integration techniques for silicon photonics. Their approach focuses on heterogeneous integration of III-V materials on silicon using wafer bonding techniques[11]. Researchers have demonstrated the integration of quantum dot lasers on silicon, offering advantages such as low threshold currents and temperature insensitivity[12]. The university has also developed novel techniques for integrating lasers with silicon nitride waveguides, which provide lower propagation losses compared to traditional silicon waveguides[13]. Their work extends to the integration of tunable lasers and the development of photonic integrated circuits that combine lasers with other active and passive components for applications in optical communications and sensing.

Strengths: Cutting-edge research in quantum dot lasers, exploration of novel materials and integration techniques. Weaknesses: Potential challenges in translating research innovations to large-scale commercial production.

Skorpios Technologies, Inc.

Technical Solution: Skorpios Technologies has pioneered a unique approach to laser integration in silicon photonics called Heterogeneous Photonic Integrated Circuit (HPIC) technology. This method involves wafer-scale integration of III-V materials with silicon, allowing for the creation of active photonic devices directly on silicon substrates[4]. Their technique enables the integration of lasers, modulators, and detectors on a single chip while maintaining CMOS compatibility. Skorpios has demonstrated tunable lasers with a wide tuning range and low power consumption using this technology[5]. The company's integration approach allows for the creation of complex photonic circuits that can support high-speed data transmission and optical sensing applications.

Strengths: Wafer-scale integration capability, CMOS compatibility, wide tuning range for lasers. Weaknesses: Potential yield issues in large-scale production, limited public information on long-term reliability.

Core Innovations in Laser-Silicon Coupling

Hybrid silicon laser-quantum well intermixing wafer bonded integration platform for advanced photonic circuits with electroabsorption modulators

PatentWO2009126351A2

Innovation

- A hybrid Silicon Laser-Quantum Well Intermixing (SL-QWI) integration platform that uses plasma-assisted bonding of InGaAsP/InP wafers with silicon-on-insulator (SOI) wafers, allowing for quantum well intermixing and grating patterning, enabling the integration of electroabsorption modulators, lasers, and photodetectors on a silicon-based platform without requiring discrete laser placement or complex growth steps.

Laser integration into a silicon photonics platform

PatentActiveUS11133645B2

Innovation

- A method involving the formation of active gain media and passive optical elements on separate wafers, followed by wafer-to-wafer bonding, allowing for parallel component formation, separate testing, and wafer-level processing to reduce scrap rates and costs, while enabling the use of mutually incompatible formation processes.

Fabrication Process Optimization

Fabrication process optimization plays a crucial role in advancing laser integration techniques in silicon photonics. The primary challenge lies in seamlessly combining III-V materials, which are essential for efficient light emission, with silicon-based photonic circuits. This integration process demands precise control over material deposition, etching, and bonding techniques.

One key area of focus is the development of improved wafer bonding methods. Direct wafer bonding has emerged as a promising approach, allowing for the integration of III-V lasers onto silicon substrates. Researchers are exploring various bonding techniques, including plasma-activated bonding and oxide-mediated bonding, to enhance the interface quality and reduce defects. These advancements aim to improve the thermal and mechanical stability of the integrated lasers.

Another critical aspect of fabrication process optimization is the refinement of epitaxial growth techniques. Selective area growth and aspect ratio trapping methods are being investigated to achieve high-quality III-V material growth on silicon substrates. These techniques help mitigate issues related to lattice mismatch and thermal expansion coefficient differences between III-V materials and silicon.

Etching processes are also undergoing significant improvements to enable precise definition of laser structures. Advanced dry etching techniques, such as inductively coupled plasma (ICP) etching, are being optimized to achieve smooth sidewalls and accurate feature sizes. This is particularly important for creating distributed feedback (DFB) and distributed Bragg reflector (DBR) structures in integrated lasers.

Furthermore, the development of low-loss waveguide structures is essential for efficient light coupling between the laser and silicon photonic circuits. Researchers are exploring novel waveguide designs and fabrication techniques to minimize propagation losses and improve mode matching between different components.

Packaging and thermal management are also critical considerations in the fabrication process. Advanced packaging techniques, such as flip-chip bonding and through-silicon vias (TSVs), are being developed to improve heat dissipation and electrical connectivity. These innovations are crucial for ensuring the long-term reliability and performance of integrated laser devices.

As fabrication processes continue to evolve, there is an increasing focus on scalability and compatibility with existing CMOS manufacturing infrastructure. This includes the development of large-scale integration techniques and the exploration of novel materials that can be processed using standard semiconductor fabrication equipment.

One key area of focus is the development of improved wafer bonding methods. Direct wafer bonding has emerged as a promising approach, allowing for the integration of III-V lasers onto silicon substrates. Researchers are exploring various bonding techniques, including plasma-activated bonding and oxide-mediated bonding, to enhance the interface quality and reduce defects. These advancements aim to improve the thermal and mechanical stability of the integrated lasers.

Another critical aspect of fabrication process optimization is the refinement of epitaxial growth techniques. Selective area growth and aspect ratio trapping methods are being investigated to achieve high-quality III-V material growth on silicon substrates. These techniques help mitigate issues related to lattice mismatch and thermal expansion coefficient differences between III-V materials and silicon.

Etching processes are also undergoing significant improvements to enable precise definition of laser structures. Advanced dry etching techniques, such as inductively coupled plasma (ICP) etching, are being optimized to achieve smooth sidewalls and accurate feature sizes. This is particularly important for creating distributed feedback (DFB) and distributed Bragg reflector (DBR) structures in integrated lasers.

Furthermore, the development of low-loss waveguide structures is essential for efficient light coupling between the laser and silicon photonic circuits. Researchers are exploring novel waveguide designs and fabrication techniques to minimize propagation losses and improve mode matching between different components.

Packaging and thermal management are also critical considerations in the fabrication process. Advanced packaging techniques, such as flip-chip bonding and through-silicon vias (TSVs), are being developed to improve heat dissipation and electrical connectivity. These innovations are crucial for ensuring the long-term reliability and performance of integrated laser devices.

As fabrication processes continue to evolve, there is an increasing focus on scalability and compatibility with existing CMOS manufacturing infrastructure. This includes the development of large-scale integration techniques and the exploration of novel materials that can be processed using standard semiconductor fabrication equipment.

Thermal Management Strategies

Thermal management is a critical aspect of advanced laser integration techniques in silicon photonics. As the density and power of photonic integrated circuits increase, managing heat dissipation becomes paramount for maintaining device performance and reliability. Silicon photonics platforms typically operate at high frequencies and power densities, leading to significant heat generation within compact spaces.

One of the primary thermal management strategies involves the use of heat sinks and spreaders. These components, often made of materials with high thermal conductivity such as copper or diamond, efficiently dissipate heat away from active photonic devices. Advanced designs incorporate micro-channel heat sinks, which allow for enhanced cooling through the circulation of liquid coolants in close proximity to heat sources.

Thermal isolation techniques are also employed to prevent heat from affecting sensitive components. This includes the use of thermal barriers and strategic placement of heat-generating elements away from temperature-sensitive devices. In some cases, thermoelectric coolers (TECs) are integrated to provide localized cooling for critical components, such as lasers or modulators.

Active temperature control systems play a crucial role in maintaining optimal operating conditions. These systems often utilize temperature sensors and feedback loops to adjust cooling mechanisms in real-time, ensuring stable performance across varying environmental conditions. Advanced thermal management strategies also incorporate thermal modeling and simulation tools to predict and optimize heat flow within complex photonic circuits.

Material selection is another key consideration in thermal management. The use of materials with high thermal conductivity for waveguides and substrates can significantly improve heat dissipation. Additionally, novel materials and structures, such as phononic crystals, are being explored for their potential to manipulate and control heat flow at the nanoscale.

Packaging solutions also contribute significantly to thermal management in silicon photonics. Advanced packaging techniques, including flip-chip bonding and 3D integration, allow for improved thermal interfaces and more efficient heat extraction. These approaches often incorporate thermal vias and through-silicon vias (TSVs) to create direct thermal pathways from heat sources to external cooling systems.

As silicon photonics continues to advance, innovative thermal management strategies are being developed to address the increasing thermal challenges. These include the exploration of phase-change materials for dynamic thermal control, the integration of microfluidic cooling channels directly into photonic chips, and the development of AI-driven thermal management systems that can predict and preemptively address potential hotspots in complex photonic circuits.

One of the primary thermal management strategies involves the use of heat sinks and spreaders. These components, often made of materials with high thermal conductivity such as copper or diamond, efficiently dissipate heat away from active photonic devices. Advanced designs incorporate micro-channel heat sinks, which allow for enhanced cooling through the circulation of liquid coolants in close proximity to heat sources.

Thermal isolation techniques are also employed to prevent heat from affecting sensitive components. This includes the use of thermal barriers and strategic placement of heat-generating elements away from temperature-sensitive devices. In some cases, thermoelectric coolers (TECs) are integrated to provide localized cooling for critical components, such as lasers or modulators.

Active temperature control systems play a crucial role in maintaining optimal operating conditions. These systems often utilize temperature sensors and feedback loops to adjust cooling mechanisms in real-time, ensuring stable performance across varying environmental conditions. Advanced thermal management strategies also incorporate thermal modeling and simulation tools to predict and optimize heat flow within complex photonic circuits.

Material selection is another key consideration in thermal management. The use of materials with high thermal conductivity for waveguides and substrates can significantly improve heat dissipation. Additionally, novel materials and structures, such as phononic crystals, are being explored for their potential to manipulate and control heat flow at the nanoscale.

Packaging solutions also contribute significantly to thermal management in silicon photonics. Advanced packaging techniques, including flip-chip bonding and 3D integration, allow for improved thermal interfaces and more efficient heat extraction. These approaches often incorporate thermal vias and through-silicon vias (TSVs) to create direct thermal pathways from heat sources to external cooling systems.

As silicon photonics continues to advance, innovative thermal management strategies are being developed to address the increasing thermal challenges. These include the exploration of phase-change materials for dynamic thermal control, the integration of microfluidic cooling channels directly into photonic chips, and the development of AI-driven thermal management systems that can predict and preemptively address potential hotspots in complex photonic circuits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!