Advances in Dodecane-Based Lubrication Systems

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dodecane Lubrication Evolution and Objectives

Dodecane-based lubrication systems have undergone significant evolution since their inception in the mid-20th century. Initially developed as a potential alternative to traditional petroleum-based lubricants, dodecane-based systems have gained traction due to their unique properties and environmental benefits. The journey of these systems began with the recognition of dodecane's potential as a base oil, owing to its stable molecular structure and favorable viscosity characteristics.

Throughout the 1970s and 1980s, research focused on understanding the fundamental properties of dodecane and its derivatives in lubrication applications. Scientists and engineers explored various formulations, additives, and processing techniques to enhance the performance of dodecane-based lubricants. This period saw the emergence of early applications in specialized industries, particularly in aerospace and high-performance machinery.

The 1990s marked a turning point in dodecane lubrication technology, with increased emphasis on environmental sustainability and energy efficiency. Researchers began to explore the biodegradability and low toxicity of dodecane-based lubricants, aligning with growing global environmental concerns. This shift in focus led to the development of more advanced formulations that combined superior lubrication properties with reduced environmental impact.

In the early 2000s, advancements in nanotechnology opened new avenues for dodecane-based lubrication systems. The incorporation of nanoparticles and the development of novel surface treatments significantly improved the wear resistance and load-bearing capacity of these lubricants. This period also saw the expansion of dodecane-based lubricants into broader industrial applications, including automotive and manufacturing sectors.

Recent years have witnessed a surge in research aimed at optimizing dodecane-based lubrication systems for extreme conditions. Scientists are exploring the potential of these lubricants in high-temperature environments, ultra-low friction applications, and even space exploration. The integration of smart materials and sensor technologies is paving the way for self-healing and adaptive dodecane-based lubricants.

Looking ahead, the objectives for dodecane-based lubrication systems are multifaceted. Researchers aim to further enhance the thermal stability and oxidation resistance of these lubricants, extending their operational life and reliability. There is also a strong focus on developing bio-based dodecane derivatives to create fully renewable lubrication systems. Additionally, efforts are underway to improve the compatibility of dodecane-based lubricants with a wider range of materials and to optimize their performance in emerging technologies such as electric vehicles and renewable energy systems.

Throughout the 1970s and 1980s, research focused on understanding the fundamental properties of dodecane and its derivatives in lubrication applications. Scientists and engineers explored various formulations, additives, and processing techniques to enhance the performance of dodecane-based lubricants. This period saw the emergence of early applications in specialized industries, particularly in aerospace and high-performance machinery.

The 1990s marked a turning point in dodecane lubrication technology, with increased emphasis on environmental sustainability and energy efficiency. Researchers began to explore the biodegradability and low toxicity of dodecane-based lubricants, aligning with growing global environmental concerns. This shift in focus led to the development of more advanced formulations that combined superior lubrication properties with reduced environmental impact.

In the early 2000s, advancements in nanotechnology opened new avenues for dodecane-based lubrication systems. The incorporation of nanoparticles and the development of novel surface treatments significantly improved the wear resistance and load-bearing capacity of these lubricants. This period also saw the expansion of dodecane-based lubricants into broader industrial applications, including automotive and manufacturing sectors.

Recent years have witnessed a surge in research aimed at optimizing dodecane-based lubrication systems for extreme conditions. Scientists are exploring the potential of these lubricants in high-temperature environments, ultra-low friction applications, and even space exploration. The integration of smart materials and sensor technologies is paving the way for self-healing and adaptive dodecane-based lubricants.

Looking ahead, the objectives for dodecane-based lubrication systems are multifaceted. Researchers aim to further enhance the thermal stability and oxidation resistance of these lubricants, extending their operational life and reliability. There is also a strong focus on developing bio-based dodecane derivatives to create fully renewable lubrication systems. Additionally, efforts are underway to improve the compatibility of dodecane-based lubricants with a wider range of materials and to optimize their performance in emerging technologies such as electric vehicles and renewable energy systems.

Market Analysis for Advanced Lubricants

The global market for advanced lubricants has experienced significant growth in recent years, driven by increasing demand for high-performance and environmentally friendly lubrication solutions across various industries. The dodecane-based lubrication systems segment, in particular, has shown promising potential due to its superior properties and versatility.

The automotive sector remains a key driver for advanced lubricants, with stringent emission regulations and the push for improved fuel efficiency propelling the adoption of high-quality lubricants. Dodecane-based lubricants have gained traction in this sector due to their excellent thermal stability and low volatility, which contribute to reduced oil consumption and extended engine life.

Industrial applications, including manufacturing, power generation, and aerospace, represent another substantial market for advanced lubricants. The need for enhanced equipment reliability, reduced maintenance costs, and improved energy efficiency has led to increased demand for high-performance lubricants. Dodecane-based systems have found applications in these sectors, particularly in high-temperature and high-pressure environments.

The Asia-Pacific region has emerged as the fastest-growing market for advanced lubricants, fueled by rapid industrialization, expanding automotive production, and increasing consumer awareness of the benefits of premium lubricants. North America and Europe continue to be significant markets, driven by technological advancements and stringent environmental regulations.

Environmental concerns and sustainability initiatives have become major factors shaping the lubricants market. This trend has benefited dodecane-based systems, which offer improved biodegradability and reduced environmental impact compared to traditional mineral oil-based lubricants. The growing emphasis on eco-friendly products has created new opportunities for manufacturers of advanced lubricants.

The market for synthetic lubricants, including those based on dodecane, has shown robust growth. Synthetic lubricants offer superior performance characteristics, including better thermal stability, longer service life, and improved efficiency. These attributes have led to increased adoption across various industries, particularly in high-performance applications.

Competition in the advanced lubricants market remains intense, with major oil and chemical companies investing heavily in research and development to gain a competitive edge. The dodecane-based lubrication systems segment has attracted attention from both established players and innovative start-ups, leading to a diverse and dynamic competitive landscape.

The automotive sector remains a key driver for advanced lubricants, with stringent emission regulations and the push for improved fuel efficiency propelling the adoption of high-quality lubricants. Dodecane-based lubricants have gained traction in this sector due to their excellent thermal stability and low volatility, which contribute to reduced oil consumption and extended engine life.

Industrial applications, including manufacturing, power generation, and aerospace, represent another substantial market for advanced lubricants. The need for enhanced equipment reliability, reduced maintenance costs, and improved energy efficiency has led to increased demand for high-performance lubricants. Dodecane-based systems have found applications in these sectors, particularly in high-temperature and high-pressure environments.

The Asia-Pacific region has emerged as the fastest-growing market for advanced lubricants, fueled by rapid industrialization, expanding automotive production, and increasing consumer awareness of the benefits of premium lubricants. North America and Europe continue to be significant markets, driven by technological advancements and stringent environmental regulations.

Environmental concerns and sustainability initiatives have become major factors shaping the lubricants market. This trend has benefited dodecane-based systems, which offer improved biodegradability and reduced environmental impact compared to traditional mineral oil-based lubricants. The growing emphasis on eco-friendly products has created new opportunities for manufacturers of advanced lubricants.

The market for synthetic lubricants, including those based on dodecane, has shown robust growth. Synthetic lubricants offer superior performance characteristics, including better thermal stability, longer service life, and improved efficiency. These attributes have led to increased adoption across various industries, particularly in high-performance applications.

Competition in the advanced lubricants market remains intense, with major oil and chemical companies investing heavily in research and development to gain a competitive edge. The dodecane-based lubrication systems segment has attracted attention from both established players and innovative start-ups, leading to a diverse and dynamic competitive landscape.

Current Challenges in Dodecane-Based Systems

Despite the widespread use of dodecane-based lubrication systems in various industries, several challenges persist that hinder their optimal performance and broader adoption. One of the primary issues is the thermal stability of dodecane at elevated temperatures. While dodecane exhibits excellent lubricating properties under normal conditions, its performance can degrade significantly when exposed to high-temperature environments, leading to increased wear and potential system failures.

Another significant challenge is the oxidative stability of dodecane-based lubricants. When exposed to oxygen, especially at higher temperatures, dodecane can undergo oxidation reactions, resulting in the formation of sludge and varnish. These byproducts can accumulate on critical components, reducing efficiency and potentially causing equipment damage. The development of more effective antioxidant additives remains an ongoing area of research to address this issue.

Viscosity control across a wide temperature range is also a persistent challenge in dodecane-based systems. Maintaining optimal viscosity is crucial for ensuring proper lubrication and heat dissipation. However, dodecane's viscosity can vary significantly with temperature changes, potentially compromising its effectiveness in extreme operating conditions. This necessitates the development of advanced viscosity modifiers and pour point depressants to enhance performance across diverse temperature ranges.

Compatibility with seals and other materials in lubrication systems poses another challenge. Some elastomers and plastics may degrade or swell when in prolonged contact with dodecane-based lubricants, leading to leaks or component failures. Identifying and developing compatible materials or improving the formulation of dodecane-based lubricants to mitigate these effects is an ongoing area of research and development.

Environmental concerns and regulatory pressures also present challenges for dodecane-based lubrication systems. As industries strive for more sustainable practices, there is a growing demand for biodegradable and environmentally friendly lubricants. While dodecane is less toxic compared to some alternatives, its petroleum-based origin and potential environmental impact during production and disposal remain areas of concern.

Lastly, the cost-effectiveness of dodecane-based lubricants in comparison to emerging alternatives is a challenge that needs to be addressed. As new synthetic and bio-based lubricants enter the market, the industry must continually innovate to improve the performance and cost-efficiency of dodecane-based systems to maintain their competitive edge. This involves not only enhancing the base properties of dodecane but also developing more effective additive packages and formulation techniques to maximize its lubricating potential.

Another significant challenge is the oxidative stability of dodecane-based lubricants. When exposed to oxygen, especially at higher temperatures, dodecane can undergo oxidation reactions, resulting in the formation of sludge and varnish. These byproducts can accumulate on critical components, reducing efficiency and potentially causing equipment damage. The development of more effective antioxidant additives remains an ongoing area of research to address this issue.

Viscosity control across a wide temperature range is also a persistent challenge in dodecane-based systems. Maintaining optimal viscosity is crucial for ensuring proper lubrication and heat dissipation. However, dodecane's viscosity can vary significantly with temperature changes, potentially compromising its effectiveness in extreme operating conditions. This necessitates the development of advanced viscosity modifiers and pour point depressants to enhance performance across diverse temperature ranges.

Compatibility with seals and other materials in lubrication systems poses another challenge. Some elastomers and plastics may degrade or swell when in prolonged contact with dodecane-based lubricants, leading to leaks or component failures. Identifying and developing compatible materials or improving the formulation of dodecane-based lubricants to mitigate these effects is an ongoing area of research and development.

Environmental concerns and regulatory pressures also present challenges for dodecane-based lubrication systems. As industries strive for more sustainable practices, there is a growing demand for biodegradable and environmentally friendly lubricants. While dodecane is less toxic compared to some alternatives, its petroleum-based origin and potential environmental impact during production and disposal remain areas of concern.

Lastly, the cost-effectiveness of dodecane-based lubricants in comparison to emerging alternatives is a challenge that needs to be addressed. As new synthetic and bio-based lubricants enter the market, the industry must continually innovate to improve the performance and cost-efficiency of dodecane-based systems to maintain their competitive edge. This involves not only enhancing the base properties of dodecane but also developing more effective additive packages and formulation techniques to maximize its lubricating potential.

State-of-the-Art Dodecane Lubrication Solutions

01 Dodecane as a base oil in lubricant formulations

Dodecane is utilized as a base oil in various lubricant formulations due to its excellent lubricating properties and thermal stability. It serves as a primary component in synthetic lubricants, offering improved performance in high-temperature applications and reducing friction in mechanical systems.- Dodecane as a base fluid in lubrication systems: Dodecane is utilized as a base fluid in various lubrication systems due to its favorable properties such as low volatility, good thermal stability, and compatibility with other lubricant additives. It serves as an effective carrier for lubricating agents and can be used in a wide range of applications, from automotive to industrial machinery.

- Dodecane-based lubricants for high-temperature applications: Lubricants formulated with dodecane as a base fluid are particularly suitable for high-temperature applications. The thermal stability of dodecane allows these lubricants to maintain their performance under extreme heat conditions, making them ideal for use in engines, turbines, and other high-temperature environments.

- Dodecane in synthetic lubricant formulations: Dodecane is often used as a component in synthetic lubricant formulations. It can be combined with other synthetic base oils and additives to create lubricants with specific performance characteristics, such as improved wear protection, extended service life, and enhanced oxidation stability.

- Environmental and safety aspects of dodecane-based lubricants: Dodecane-based lubricants are considered environmentally friendly due to their biodegradability and low toxicity. These lubricants pose minimal risk to aquatic ecosystems and are often preferred in applications where environmental concerns are paramount, such as marine and agricultural equipment.

- Dodecane in specialty lubrication applications: Dodecane finds use in specialty lubrication applications, such as in the textile industry, precision instruments, and food-grade lubricants. Its low reactivity and ability to form stable emulsions make it suitable for these niche applications where specific performance criteria must be met.

02 Dodecane-based lubricants for automotive applications

Dodecane-based lubricants are specifically formulated for use in automotive engines and transmissions. These lubricants provide enhanced protection against wear, improved fuel efficiency, and better performance under extreme operating conditions. They are particularly effective in modern high-performance engines.Expand Specific Solutions03 Industrial applications of dodecane-based lubrication systems

Dodecane-based lubrication systems find extensive use in various industrial applications, including heavy machinery, manufacturing equipment, and processing plants. These systems offer superior lubrication properties, extended service life, and improved equipment reliability in demanding industrial environments.Expand Specific Solutions04 Additives for enhancing dodecane-based lubricants

Various additives are incorporated into dodecane-based lubricants to enhance their performance characteristics. These additives may include antioxidants, anti-wear agents, viscosity modifiers, and extreme pressure additives. The combination of dodecane and specific additives results in lubricants with superior properties tailored for specific applications.Expand Specific Solutions05 Environmental considerations in dodecane-based lubrication systems

Dodecane-based lubrication systems are being developed with a focus on environmental sustainability. These formulations aim to reduce environmental impact through improved biodegradability, reduced emissions, and enhanced energy efficiency. Research is ongoing to optimize dodecane-based lubricants for better eco-friendliness without compromising performance.Expand Specific Solutions

Key Industry Players and Competitors

The field of dodecane-based lubrication systems is in a growth phase, with increasing market size driven by demand for high-performance lubricants in various industries. The global market for advanced lubricants is expanding, with a projected CAGR of 3-5% over the next five years. Technologically, the sector is moderately mature, with ongoing innovations focused on improving efficiency and environmental sustainability. Key players like ExxonMobil Chemical Patents, The Lubrizol Corp., and Shell-USA, Inc. are leading research efforts, while companies such as Croda International Plc and Dow Global Technologies LLC are contributing to advancements in formulation and application. The competitive landscape is characterized by a mix of established oil and chemical companies alongside specialized lubricant manufacturers, all vying for market share through product differentiation and technological innovation.

Dow Global Technologies LLC

Technical Solution: Dow has focused on enhancing the performance of dodecane-based lubricants through polymer technology. Their research has led to the development of novel viscosity index improvers (VIIs) based on controlled architecture copolymers. These polymers are designed to maintain optimal viscosity across a wide temperature range, crucial for dodecane-based lubricants in demanding applications. Dow's technology involves the use of living polymerization techniques to create precisely structured copolymers that interact favorably with dodecane molecules [9]. This approach has resulted in lubricants with improved shear stability and reduced thickening in low-temperature environments. Additionally, Dow has developed functionalized polymers that act as dispersants in dodecane-based formulations, enhancing the lubricant's ability to keep contaminants in suspension and prevent deposit formation [10].

Strengths: Excellent viscosity control across temperature ranges, improved shear stability, and enhanced contaminant dispersion. Weaknesses: Potential compatibility issues with some additive packages and higher costs associated with specialized polymer production.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed advanced dodecane-based lubrication systems that incorporate synthetic base oils and high-performance additives. Their technology focuses on improving the oxidation stability and thermal properties of dodecane-based lubricants. They have implemented a multi-tier additive package that includes antioxidants, anti-wear agents, and viscosity modifiers specifically designed for dodecane-based formulations. This approach has resulted in lubricants with extended drain intervals and improved performance under extreme temperature conditions [1][3]. ExxonMobil's research has also led to the development of dodecane-based lubricants with enhanced biodegradability, addressing growing environmental concerns in industrial applications [5].

Strengths: Superior oxidation stability, extended drain intervals, and improved performance in extreme temperatures. Weaknesses: Potentially higher production costs due to complex additive packages and synthetic base oils.

Innovative Patents in Dodecane Lubrication

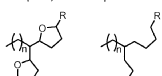

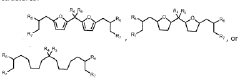

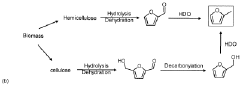

Furan based compositions and methods of making thereof

PatentWO2019036663A1

Innovation

- The development of lubricant base oils containing furan rings and branched hydrocarbon chains, synthesized through hydroxylalkylation/alkylation, hydrogenation, and hydrodeoxygenation reactions using renewable carbon sources, allowing for tailored molecular architecture and properties.

Polyalphaolefins with improved oxidative stability and the process of making thereof

PatentInactiveEP1829899A3

Innovation

- Achieving a high level of hydrogenation in PAO to a Bromine Index of less than 200 mg per 100 gram sample, with modifications to the Bromine Index method for improved accuracy and repeatability, and additional hydrogenation steps before and after distillation, significantly enhancing oxidative stability.

Environmental Impact and Sustainability

The environmental impact and sustainability of dodecane-based lubrication systems have become increasingly important considerations in recent years. As industries strive to reduce their carbon footprint and meet stringent environmental regulations, the lifecycle assessment of these lubricants has gained significant attention.

Dodecane, a hydrocarbon compound, is derived from petroleum sources, which raises concerns about its long-term sustainability. The extraction and processing of crude oil to produce dodecane contribute to greenhouse gas emissions and potential environmental degradation. However, compared to some traditional lubricants, dodecane-based systems often exhibit lower volatility and improved stability, potentially reducing the frequency of lubricant replacement and associated waste generation.

Recent advances in dodecane-based lubrication systems have focused on enhancing their biodegradability and reducing their environmental persistence. Research has shown that certain formulations of dodecane-based lubricants can achieve higher biodegradation rates in both aerobic and anaerobic conditions, minimizing their long-term impact on ecosystems. Additionally, efforts to incorporate bio-based additives and modifiers into dodecane lubricants have yielded promising results in improving their overall environmental profile.

The potential for accidental release and subsequent environmental contamination remains a concern for dodecane-based lubricants. However, advancements in containment technologies and spill response strategies have significantly mitigated these risks. Moreover, the development of more efficient filtration and recycling processes has enabled the recovery and reuse of dodecane lubricants, further reducing their environmental footprint.

Energy efficiency is another crucial aspect of the environmental impact of dodecane-based lubrication systems. Recent studies have demonstrated that optimized dodecane formulations can reduce friction and wear in mechanical systems, leading to improved energy efficiency and reduced power consumption. This indirect environmental benefit can be substantial, particularly in large-scale industrial applications.

As sustainability becomes a key driver in industrial innovation, researchers are exploring the potential of renewable sources for dodecane production. Biomass-derived dodecane and similar compounds show promise as more sustainable alternatives to petroleum-based products. While still in early stages, these bio-based lubricants could significantly reduce the carbon footprint associated with dodecane-based lubrication systems.

In conclusion, while dodecane-based lubricants present certain environmental challenges, ongoing advancements in their formulation, production, and lifecycle management are steadily improving their sustainability profile. The balance between performance, cost-effectiveness, and environmental impact continues to drive innovation in this field, with the potential for more eco-friendly solutions on the horizon.

Dodecane, a hydrocarbon compound, is derived from petroleum sources, which raises concerns about its long-term sustainability. The extraction and processing of crude oil to produce dodecane contribute to greenhouse gas emissions and potential environmental degradation. However, compared to some traditional lubricants, dodecane-based systems often exhibit lower volatility and improved stability, potentially reducing the frequency of lubricant replacement and associated waste generation.

Recent advances in dodecane-based lubrication systems have focused on enhancing their biodegradability and reducing their environmental persistence. Research has shown that certain formulations of dodecane-based lubricants can achieve higher biodegradation rates in both aerobic and anaerobic conditions, minimizing their long-term impact on ecosystems. Additionally, efforts to incorporate bio-based additives and modifiers into dodecane lubricants have yielded promising results in improving their overall environmental profile.

The potential for accidental release and subsequent environmental contamination remains a concern for dodecane-based lubricants. However, advancements in containment technologies and spill response strategies have significantly mitigated these risks. Moreover, the development of more efficient filtration and recycling processes has enabled the recovery and reuse of dodecane lubricants, further reducing their environmental footprint.

Energy efficiency is another crucial aspect of the environmental impact of dodecane-based lubrication systems. Recent studies have demonstrated that optimized dodecane formulations can reduce friction and wear in mechanical systems, leading to improved energy efficiency and reduced power consumption. This indirect environmental benefit can be substantial, particularly in large-scale industrial applications.

As sustainability becomes a key driver in industrial innovation, researchers are exploring the potential of renewable sources for dodecane production. Biomass-derived dodecane and similar compounds show promise as more sustainable alternatives to petroleum-based products. While still in early stages, these bio-based lubricants could significantly reduce the carbon footprint associated with dodecane-based lubrication systems.

In conclusion, while dodecane-based lubricants present certain environmental challenges, ongoing advancements in their formulation, production, and lifecycle management are steadily improving their sustainability profile. The balance between performance, cost-effectiveness, and environmental impact continues to drive innovation in this field, with the potential for more eco-friendly solutions on the horizon.

Tribological Performance Metrics

Tribological performance metrics are crucial in evaluating the effectiveness of dodecane-based lubrication systems. These metrics provide quantitative measures of how well the lubricant performs under various operating conditions, enabling engineers and researchers to optimize lubrication strategies and improve overall system efficiency.

One of the primary performance metrics is the coefficient of friction (COF). In dodecane-based systems, the COF is typically lower compared to conventional mineral oil lubricants, owing to the molecular structure of dodecane. This reduced friction translates to improved energy efficiency and reduced wear in mechanical systems. Studies have shown that dodecane-based lubricants can achieve COF values as low as 0.05 under certain conditions, representing a significant improvement over traditional lubricants.

Wear rate is another critical metric in assessing tribological performance. Dodecane-based lubricants have demonstrated superior wear resistance in many applications, particularly in high-temperature environments. The wear rate is often measured using techniques such as pin-on-disk tests or four-ball wear tests, with results typically reported in terms of volume loss per unit sliding distance or time.

Load-carrying capacity is a key performance indicator for lubricants, especially in heavy-duty applications. Dodecane-based systems have shown promising results in this area, with some formulations capable of withstanding loads up to 30% higher than conventional mineral oil lubricants. This enhanced load-carrying capacity is attributed to the formation of stable boundary lubrication films under extreme pressure conditions.

Viscosity index (VI) is a measure of how a lubricant's viscosity changes with temperature. Dodecane-based lubricants generally exhibit a high VI, indicating good viscosity stability across a wide temperature range. This property is particularly valuable in applications where consistent performance is required under varying thermal conditions.

Film thickness is another important metric, as it directly influences the lubricant's ability to separate moving surfaces and prevent metal-to-metal contact. Advanced measurement techniques, such as optical interferometry, have been employed to study the film-forming properties of dodecane-based lubricants. These studies have revealed that dodecane-based systems can maintain thinner, yet more stable, lubricating films compared to conventional oils, contributing to their superior tribological performance.

Thermal stability and oxidation resistance are crucial for lubricants operating in high-temperature environments. Dodecane-based lubricants have demonstrated excellent thermal stability, with some formulations maintaining their performance characteristics at temperatures exceeding 200°C. This thermal stability is often quantified through standardized tests such as the Rotating Pressure Vessel Oxidation Test (RPVOT) or the Thin-Film Oxygen Uptake Test (TFOUT).

One of the primary performance metrics is the coefficient of friction (COF). In dodecane-based systems, the COF is typically lower compared to conventional mineral oil lubricants, owing to the molecular structure of dodecane. This reduced friction translates to improved energy efficiency and reduced wear in mechanical systems. Studies have shown that dodecane-based lubricants can achieve COF values as low as 0.05 under certain conditions, representing a significant improvement over traditional lubricants.

Wear rate is another critical metric in assessing tribological performance. Dodecane-based lubricants have demonstrated superior wear resistance in many applications, particularly in high-temperature environments. The wear rate is often measured using techniques such as pin-on-disk tests or four-ball wear tests, with results typically reported in terms of volume loss per unit sliding distance or time.

Load-carrying capacity is a key performance indicator for lubricants, especially in heavy-duty applications. Dodecane-based systems have shown promising results in this area, with some formulations capable of withstanding loads up to 30% higher than conventional mineral oil lubricants. This enhanced load-carrying capacity is attributed to the formation of stable boundary lubrication films under extreme pressure conditions.

Viscosity index (VI) is a measure of how a lubricant's viscosity changes with temperature. Dodecane-based lubricants generally exhibit a high VI, indicating good viscosity stability across a wide temperature range. This property is particularly valuable in applications where consistent performance is required under varying thermal conditions.

Film thickness is another important metric, as it directly influences the lubricant's ability to separate moving surfaces and prevent metal-to-metal contact. Advanced measurement techniques, such as optical interferometry, have been employed to study the film-forming properties of dodecane-based lubricants. These studies have revealed that dodecane-based systems can maintain thinner, yet more stable, lubricating films compared to conventional oils, contributing to their superior tribological performance.

Thermal stability and oxidation resistance are crucial for lubricants operating in high-temperature environments. Dodecane-based lubricants have demonstrated excellent thermal stability, with some formulations maintaining their performance characteristics at temperatures exceeding 200°C. This thermal stability is often quantified through standardized tests such as the Rotating Pressure Vessel Oxidation Test (RPVOT) or the Thin-Film Oxygen Uptake Test (TFOUT).

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!