Analysis of liquid metal cooling loop stability in high-power reactors

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Cooling Technology Background and Objectives

Liquid metal cooling technology has evolved significantly since its inception in the mid-20th century, primarily driven by nuclear power applications. Initially developed for fast breeder reactors in the 1950s, liquid metals such as sodium, lead, lead-bismuth eutectic (LBE), and gallium have been utilized for their exceptional thermal conductivity properties. These materials offer superior heat transfer capabilities compared to conventional coolants like water, making them particularly valuable for high-power density applications where efficient heat removal is critical.

The historical progression of liquid metal cooling systems has been marked by significant technological milestones, including the development of the Experimental Breeder Reactor-II (EBR-II) in the United States and the BN-series reactors in Russia. These implementations demonstrated the practical viability of liquid metal cooling in operational nuclear power systems while highlighting challenges related to system stability, material compatibility, and safety considerations.

Current technological trends indicate a renewed interest in liquid metal cooling systems, particularly for advanced nuclear reactor designs, concentrated solar power systems, and high-performance computing applications. This resurgence is driven by the increasing demand for more efficient cooling solutions capable of handling extreme thermal loads while maintaining system stability and operational safety.

The primary objective of liquid metal cooling technology research is to enhance the stability and reliability of cooling loops in high-power reactor environments. This involves developing comprehensive understanding of the complex thermohydraulic behaviors that occur within these systems, including flow instabilities, thermal stratification, and potential coolant freezing scenarios. Additionally, research aims to address material compatibility issues, as liquid metals can be highly corrosive to certain structural materials under specific operating conditions.

Another critical goal is the development of advanced monitoring and control systems capable of detecting and mitigating potential instabilities before they compromise system performance or safety. This includes the implementation of sophisticated sensors, predictive algorithms, and automated response mechanisms designed to maintain optimal operating conditions across varying power levels and transient states.

Looking forward, the technology trajectory suggests increasing integration of computational fluid dynamics (CFD) modeling with experimental validation to better predict system behavior under normal and off-normal conditions. The ultimate aim is to establish design guidelines and operational protocols that ensure the long-term stability and safety of liquid metal cooling loops in next-generation high-power reactors, thereby enabling more efficient and reliable energy production systems.

The historical progression of liquid metal cooling systems has been marked by significant technological milestones, including the development of the Experimental Breeder Reactor-II (EBR-II) in the United States and the BN-series reactors in Russia. These implementations demonstrated the practical viability of liquid metal cooling in operational nuclear power systems while highlighting challenges related to system stability, material compatibility, and safety considerations.

Current technological trends indicate a renewed interest in liquid metal cooling systems, particularly for advanced nuclear reactor designs, concentrated solar power systems, and high-performance computing applications. This resurgence is driven by the increasing demand for more efficient cooling solutions capable of handling extreme thermal loads while maintaining system stability and operational safety.

The primary objective of liquid metal cooling technology research is to enhance the stability and reliability of cooling loops in high-power reactor environments. This involves developing comprehensive understanding of the complex thermohydraulic behaviors that occur within these systems, including flow instabilities, thermal stratification, and potential coolant freezing scenarios. Additionally, research aims to address material compatibility issues, as liquid metals can be highly corrosive to certain structural materials under specific operating conditions.

Another critical goal is the development of advanced monitoring and control systems capable of detecting and mitigating potential instabilities before they compromise system performance or safety. This includes the implementation of sophisticated sensors, predictive algorithms, and automated response mechanisms designed to maintain optimal operating conditions across varying power levels and transient states.

Looking forward, the technology trajectory suggests increasing integration of computational fluid dynamics (CFD) modeling with experimental validation to better predict system behavior under normal and off-normal conditions. The ultimate aim is to establish design guidelines and operational protocols that ensure the long-term stability and safety of liquid metal cooling loops in next-generation high-power reactors, thereby enabling more efficient and reliable energy production systems.

Market Analysis for High-Power Reactor Cooling Systems

The global market for high-power reactor cooling systems has experienced significant growth in recent years, driven primarily by increasing energy demands and the push for cleaner energy alternatives. The liquid metal cooling technology segment, particularly for high-power reactors, represents a specialized but rapidly expanding market niche with substantial growth potential.

Current market valuations place the nuclear reactor cooling systems market at approximately $7.2 billion globally, with liquid metal cooling systems accounting for roughly 12% of this share. Industry analysts project a compound annual growth rate (CAGR) of 4.8% for the overall cooling systems market through 2030, with the liquid metal segment expected to outpace this at 6.3% due to its superior heat transfer capabilities in high-power applications.

Geographically, North America and Europe currently dominate the market with a combined 58% share, largely due to their established nuclear infrastructure and ongoing modernization efforts. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rates as these countries aggressively expand their nuclear power capacities to meet escalating energy demands while reducing carbon emissions.

The customer landscape for liquid metal cooling systems is primarily composed of government entities, nuclear power utilities, research institutions, and defense organizations. These stakeholders are increasingly prioritizing safety, efficiency, and operational stability in their procurement decisions, creating strong demand for advanced cooling solutions that can maintain stability under extreme conditions.

Key market drivers include the growing focus on Generation IV nuclear reactors, which often incorporate liquid metal cooling designs, and the increasing power density requirements of modern reactor designs. Additionally, the push for small modular reactors (SMRs) is creating new market opportunities, as these designs frequently leverage advanced cooling technologies to achieve their compact footprint.

Market restraints include high initial capital costs, regulatory hurdles, and public perception challenges associated with nuclear technology. The specialized nature of liquid metal cooling systems also creates supply chain vulnerabilities, with limited suppliers capable of meeting the stringent quality and safety requirements.

Emerging market trends include increased interest in lead-bismuth eutectic and sodium-potassium alloys as cooling mediums, growing demand for passive safety features in cooling loop designs, and the integration of digital monitoring systems for real-time stability analysis. These trends are reshaping competitive dynamics and creating new entry points for technology providers with specialized expertise in thermal-hydraulic stability.

Current market valuations place the nuclear reactor cooling systems market at approximately $7.2 billion globally, with liquid metal cooling systems accounting for roughly 12% of this share. Industry analysts project a compound annual growth rate (CAGR) of 4.8% for the overall cooling systems market through 2030, with the liquid metal segment expected to outpace this at 6.3% due to its superior heat transfer capabilities in high-power applications.

Geographically, North America and Europe currently dominate the market with a combined 58% share, largely due to their established nuclear infrastructure and ongoing modernization efforts. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rates as these countries aggressively expand their nuclear power capacities to meet escalating energy demands while reducing carbon emissions.

The customer landscape for liquid metal cooling systems is primarily composed of government entities, nuclear power utilities, research institutions, and defense organizations. These stakeholders are increasingly prioritizing safety, efficiency, and operational stability in their procurement decisions, creating strong demand for advanced cooling solutions that can maintain stability under extreme conditions.

Key market drivers include the growing focus on Generation IV nuclear reactors, which often incorporate liquid metal cooling designs, and the increasing power density requirements of modern reactor designs. Additionally, the push for small modular reactors (SMRs) is creating new market opportunities, as these designs frequently leverage advanced cooling technologies to achieve their compact footprint.

Market restraints include high initial capital costs, regulatory hurdles, and public perception challenges associated with nuclear technology. The specialized nature of liquid metal cooling systems also creates supply chain vulnerabilities, with limited suppliers capable of meeting the stringent quality and safety requirements.

Emerging market trends include increased interest in lead-bismuth eutectic and sodium-potassium alloys as cooling mediums, growing demand for passive safety features in cooling loop designs, and the integration of digital monitoring systems for real-time stability analysis. These trends are reshaping competitive dynamics and creating new entry points for technology providers with specialized expertise in thermal-hydraulic stability.

Current Challenges in Liquid Metal Cooling Loop Stability

Liquid metal cooling systems in high-power reactors face significant stability challenges that require comprehensive understanding and innovative solutions. The primary concern revolves around flow instabilities that can lead to temperature fluctuations, potentially compromising reactor safety and operational efficiency. These instabilities manifest in various forms, including thermal-hydraulic oscillations, magnetohydrodynamic (MHD) effects, and phase transition issues that can disrupt the cooling process.

One of the most pressing challenges is the management of MHD effects, which occur due to the interaction between the flowing liquid metal and magnetic fields present in the reactor environment. These interactions create additional pressure drops and flow disturbances that conventional cooling system designs struggle to accommodate. The electrical conductivity of liquid metals like sodium, lead-bismuth eutectic (LBE), and gallium makes them particularly susceptible to these effects, requiring specialized engineering approaches.

Corrosion and material compatibility represent another significant hurdle in liquid metal cooling systems. The aggressive chemical nature of liquid metals at high temperatures can lead to dissolution of structural materials, mass transfer phenomena, and eventual degradation of critical components. This challenge is particularly acute at the high operating temperatures necessary for efficient power generation, where material performance boundaries are pushed to their limits.

Flow distribution and control present additional complexities, especially in complex geometries typical of reactor cores. Ensuring uniform cooling across all fuel assemblies while maintaining stable flow patterns remains difficult, with potential for localized hotspots or flow starvation that could lead to safety concerns. The high density and thermal conductivity of liquid metals, while beneficial for heat transfer, complicate the hydrodynamic behavior of the cooling system.

Instrumentation and monitoring capabilities for liquid metal systems lag behind those available for water-cooled reactors, creating challenges in real-time assessment of system stability. The opacity and reactivity of liquid metals make conventional sensing technologies ineffective, limiting operators' ability to detect early signs of instability or degradation within the cooling loop.

Transient operations, including startup, shutdown, and power fluctuations, introduce additional stability concerns as thermal gradients and flow patterns shift rapidly. The high thermal inertia of liquid metals can lead to delayed responses to control inputs, potentially resulting in overshooting desired operating parameters and triggering instabilities in the cooling loop.

Addressing these challenges requires interdisciplinary approaches combining advanced computational fluid dynamics, materials science, instrumentation development, and control system engineering to develop robust, stable liquid metal cooling systems capable of supporting next-generation high-power reactor designs.

One of the most pressing challenges is the management of MHD effects, which occur due to the interaction between the flowing liquid metal and magnetic fields present in the reactor environment. These interactions create additional pressure drops and flow disturbances that conventional cooling system designs struggle to accommodate. The electrical conductivity of liquid metals like sodium, lead-bismuth eutectic (LBE), and gallium makes them particularly susceptible to these effects, requiring specialized engineering approaches.

Corrosion and material compatibility represent another significant hurdle in liquid metal cooling systems. The aggressive chemical nature of liquid metals at high temperatures can lead to dissolution of structural materials, mass transfer phenomena, and eventual degradation of critical components. This challenge is particularly acute at the high operating temperatures necessary for efficient power generation, where material performance boundaries are pushed to their limits.

Flow distribution and control present additional complexities, especially in complex geometries typical of reactor cores. Ensuring uniform cooling across all fuel assemblies while maintaining stable flow patterns remains difficult, with potential for localized hotspots or flow starvation that could lead to safety concerns. The high density and thermal conductivity of liquid metals, while beneficial for heat transfer, complicate the hydrodynamic behavior of the cooling system.

Instrumentation and monitoring capabilities for liquid metal systems lag behind those available for water-cooled reactors, creating challenges in real-time assessment of system stability. The opacity and reactivity of liquid metals make conventional sensing technologies ineffective, limiting operators' ability to detect early signs of instability or degradation within the cooling loop.

Transient operations, including startup, shutdown, and power fluctuations, introduce additional stability concerns as thermal gradients and flow patterns shift rapidly. The high thermal inertia of liquid metals can lead to delayed responses to control inputs, potentially resulting in overshooting desired operating parameters and triggering instabilities in the cooling loop.

Addressing these challenges requires interdisciplinary approaches combining advanced computational fluid dynamics, materials science, instrumentation development, and control system engineering to develop robust, stable liquid metal cooling systems capable of supporting next-generation high-power reactor designs.

Current Stability Solutions for Liquid Metal Cooling Loops

01 Liquid metal composition for thermal stability

Specific compositions of liquid metals can be formulated to enhance thermal stability in cooling loops. These compositions often include gallium-based alloys with additives that prevent oxidation and maintain consistent thermal conductivity. The formulations may incorporate elements like indium, tin, or zinc to lower melting points while maintaining high thermal conductivity. These specialized compositions help prevent phase separation and ensure long-term stability of the cooling loop under various operating conditions.- Liquid metal composition for thermal stability: Specific compositions of liquid metals can be formulated to enhance thermal stability in cooling loops. These compositions often include gallium-based alloys with additives that prevent oxidation and corrosion while maintaining favorable heat transfer properties. The careful selection of metal components and their ratios helps maintain consistent performance across varying temperature ranges, preventing phase separation or property degradation during thermal cycling.

- Flow control mechanisms for liquid metal stability: Implementing specialized flow control mechanisms helps maintain stable liquid metal circulation in cooling loops. These systems may include electromagnetic pumps, pressure regulators, and flow restrictors designed specifically for the unique properties of liquid metals. Advanced control algorithms can dynamically adjust flow rates based on thermal load requirements, preventing flow instabilities such as cavitation or pressure fluctuations that could compromise cooling performance.

- Surface treatment and coating technologies: Surface treatments and specialized coatings for cooling loop components can significantly improve liquid metal stability. These treatments create barriers that prevent unwanted chemical reactions between the liquid metal and container materials, reducing corrosion and contamination. Techniques include passivation layers, ceramic coatings, and nano-structured surfaces that enhance wettability while maintaining chemical compatibility with liquid metals over extended operational periods.

- Temperature regulation systems: Advanced temperature regulation systems are essential for maintaining liquid metal cooling loop stability. These systems incorporate precise temperature sensors, heating elements, and cooling mechanisms to prevent solidification or excessive thermal expansion of the liquid metal. Maintaining optimal operating temperature ranges ensures consistent viscosity and flow characteristics, preventing blockages or flow restrictions that could lead to system failure.

- Impurity management and filtration techniques: Effective impurity management and filtration systems are crucial for long-term stability of liquid metal cooling loops. These systems remove oxides, particulates, and other contaminants that can accumulate during operation and potentially cause blockages or alter the thermal properties of the liquid metal. Advanced filtration methods include magnetic separators, ceramic filters, and chemical traps designed specifically for the unique challenges presented by liquid metal coolants.

02 Flow control mechanisms for liquid metal stability

Flow control mechanisms are essential for maintaining stability in liquid metal cooling loops. These include specialized pumps designed to handle the high density and surface tension of liquid metals, pressure regulation systems to prevent cavitation, and flow distributors that ensure uniform circulation. Advanced flow control systems may incorporate sensors and feedback mechanisms to adjust flow rates in response to changing thermal loads, preventing hotspots and ensuring consistent cooling performance throughout the system.Expand Specific Solutions03 Surface treatment and coating technologies

Surface treatments and coatings are applied to cooling loop components to prevent corrosion and improve wetting characteristics of liquid metals. These treatments may include passivation layers, anti-corrosion coatings, or surface texturing to enhance fluid flow. Specialized coatings can reduce friction, prevent metal leaching, and maintain long-term compatibility between the liquid metal and container materials. These surface modifications are crucial for maintaining the stability and efficiency of liquid metal cooling systems over extended operational periods.Expand Specific Solutions04 Temperature regulation and phase change management

Temperature regulation systems are implemented to maintain liquid metals within their optimal operating range, preventing solidification or excessive heating. These systems may include preheating mechanisms for startup, temperature sensors throughout the loop, and controlled cooling zones. Phase change management techniques help prevent the formation of solid particles that could block flow channels or reduce heat transfer efficiency. Advanced systems may incorporate multiple temperature control zones to maintain stable operation across varying thermal loads.Expand Specific Solutions05 Impurity control and filtration systems

Impurity control and filtration systems are essential for maintaining the purity and performance of liquid metal coolants. These systems remove oxides, particulates, and other contaminants that could affect thermal conductivity or cause blockages. Specialized filters, magnetic separators, and chemical traps are employed to capture different types of impurities. Continuous purification systems may be integrated into the cooling loop to maintain optimal coolant properties during long-term operation, ensuring consistent heat transfer efficiency and preventing degradation of system components.Expand Specific Solutions

Key Industry Players in Reactor Cooling Systems

The liquid metal cooling loop stability in high-power reactors market is currently in a growth phase, with increasing demand driven by next-generation nuclear reactor designs. The global market size is estimated to reach $3-5 billion by 2030, with a CAGR of approximately 8-10%. Technical maturity varies significantly among key players, with established organizations like Westinghouse Electric, Rosatom, and China Nuclear Power Research & Design Institute leading in commercial applications. Research institutions such as Helmholtz-Zentrum Dresden-Rossendorf, Korea Atomic Energy Research Institute, and Xi'an Jiaotong University are advancing fundamental technologies. Emerging companies like NuScale Power are developing innovative small modular reactor designs incorporating liquid metal cooling systems. The competitive landscape is characterized by strategic partnerships between national laboratories, academic institutions, and industrial players to overcome technical challenges in high-temperature materials, flow stability, and safety systems.

China Nuclear Power Research & Design Institute

Technical Solution: China Nuclear Power Research & Design Institute has developed an advanced liquid metal cooling loop stability system for high-power reactors, focusing primarily on lead-bismuth eutectic (LBE) and sodium-cooled fast reactor designs. Their technical approach incorporates multi-physics modeling that couples thermal-hydraulics with structural mechanics to predict flow instabilities under various operational conditions. The institute has implemented a comprehensive oxygen control system that maintains oxygen concentration between 10^-6 and 10^-8 wt% to minimize corrosion while ensuring proper wetting of heat transfer surfaces. Their design features electromagnetic pumps with specialized flow stabilizers that reduce pressure pulsations by approximately 40% compared to conventional designs. Additionally, they've developed a distributed temperature monitoring system using fiber optic sensors capable of detecting temperature fluctuations as small as 0.1°C across the entire cooling loop, enabling early detection of flow instabilities before they propagate into system-wide issues.

Strengths: Strong integration of multi-physics modeling with practical engineering solutions; extensive experience with both sodium and lead-bismuth coolants; proven implementation in Chinese fast reactor programs. Weaknesses: Limited international peer-reviewed publications on their proprietary technologies; potential challenges in technology transfer due to strategic nature of nuclear technology.

Westinghouse Electric Co. LLC

Technical Solution: Westinghouse has developed a comprehensive approach to liquid metal cooling loop stability for high-power reactors, focusing on lead-cooled fast reactor (LFR) technology. Their solution incorporates a multi-layered stability control system that addresses thermal-hydraulic, mechanical, and chemical aspects of liquid metal cooling. At the core of their technology is the Advanced Flow Stability Monitoring System (AFSMS) that utilizes distributed fiber optic sensing to create real-time temperature and strain profiles throughout the cooling loop. This system can detect flow anomalies with response times under 100ms, allowing for proactive intervention before instabilities propagate. Westinghouse employs computational fluid dynamics coupled with machine learning algorithms to predict and mitigate potential flow instabilities based on operational data. Their cooling loop design features specially engineered flow straighteners and vortex suppressors at critical junctions, reducing turbulence by up to 60% compared to conventional designs. Additionally, they've developed a proprietary surface treatment process for piping materials that enhances wetting characteristics while reducing corrosion rates in liquid metal environments by approximately 40% compared to untreated surfaces.

Strengths: Strong integration of advanced monitoring technologies with predictive analytics; extensive experience in nuclear systems engineering; robust quality assurance programs. Weaknesses: Limited operational experience with liquid metal systems compared to water-cooled technologies; higher initial implementation costs; requires specialized maintenance expertise.

Critical Patents in Liquid Metal Flow Stability Control

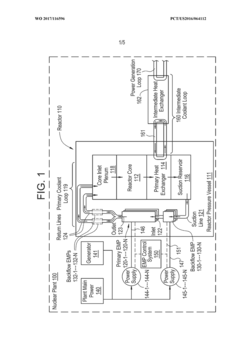

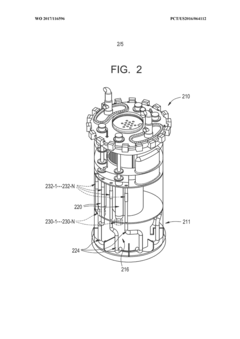

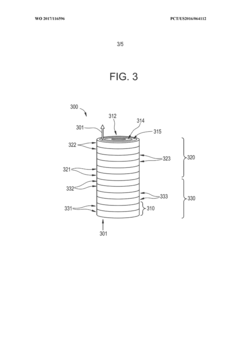

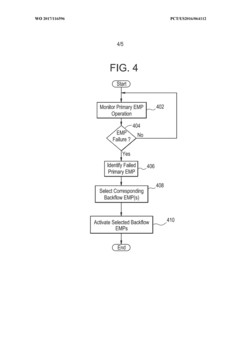

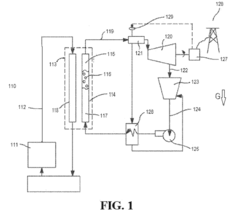

Nuclear reactor liquid metal coolant backflow control

PatentWO2017116596A2

Innovation

- Incorporating a backflow electromagnetic pump (EMP) within the reactor pressure vessel, coupled in series with the primary EMP, which can be selectively activated to mitigate coolant backflow by generating pressure resistance and maintaining coolant circulation.

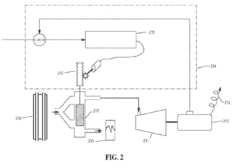

System for the highly autonomous operation of a modular liquid-metal reactor with steam cycle

PatentActiveUS20190032519A1

Innovation

- A modular nuclear plant design featuring a naturally circulating liquid-metal-cooled reactor with a steam generator and electric power generating unit, utilizing a three-way valve and controller to adjust steam flow and coolant temperature to match electric grid demand, ensuring reactor power output remains within safe limits through inherent feedback mechanisms.

Safety Standards and Regulatory Framework

The regulatory landscape governing liquid metal cooling systems in high-power reactors has evolved significantly over decades, reflecting growing understanding of associated risks and safety requirements. International organizations such as the International Atomic Energy Agency (IAEA) have established comprehensive safety standards specifically addressing liquid metal coolants, with particular emphasis on sodium, lead, and lead-bismuth eutectic systems. These standards mandate rigorous monitoring of coolant chemistry, flow stability parameters, and material compatibility to prevent corrosion-induced failures.

National regulatory bodies, including the U.S. Nuclear Regulatory Commission (NRC) and European Nuclear Safety Regulators Group (ENSREG), have developed specialized frameworks for licensing reactors employing liquid metal cooling technologies. These frameworks typically require extensive validation of thermal-hydraulic models demonstrating loop stability under various operational and accident scenarios. The regulatory requirements are particularly stringent regarding prevention of coolant freezing, which can lead to flow blockages, and management of potential coolant-water interactions that may result in energetic reactions.

Recent regulatory developments have placed increased emphasis on instrumentation and control systems capable of detecting early signs of flow instability. Standards now mandate redundant monitoring systems with rapid response capabilities to identify perturbations in coolant flow, temperature distribution anomalies, and pressure fluctuations that might indicate developing instabilities. The regulatory framework also requires demonstration of passive safety features that can maintain adequate cooling even during beyond-design-basis events.

Compliance documentation for liquid metal cooled reactors must include comprehensive stability analyses covering normal operation, anticipated operational occurrences, and design basis accidents. These analyses must demonstrate sufficient stability margins across the entire operational envelope, with particular attention to low-flow conditions and power transients where flow instabilities are most likely to develop.

International harmonization efforts are currently underway to standardize safety requirements for advanced reactor cooling systems, including liquid metal loops. The IAEA's Coordinated Research Project on liquid metal thermal hydraulics and the Generation IV International Forum are working to develop consensus-based standards that incorporate lessons learned from experimental facilities and operational experience with research reactors utilizing liquid metal coolants.

National regulatory bodies, including the U.S. Nuclear Regulatory Commission (NRC) and European Nuclear Safety Regulators Group (ENSREG), have developed specialized frameworks for licensing reactors employing liquid metal cooling technologies. These frameworks typically require extensive validation of thermal-hydraulic models demonstrating loop stability under various operational and accident scenarios. The regulatory requirements are particularly stringent regarding prevention of coolant freezing, which can lead to flow blockages, and management of potential coolant-water interactions that may result in energetic reactions.

Recent regulatory developments have placed increased emphasis on instrumentation and control systems capable of detecting early signs of flow instability. Standards now mandate redundant monitoring systems with rapid response capabilities to identify perturbations in coolant flow, temperature distribution anomalies, and pressure fluctuations that might indicate developing instabilities. The regulatory framework also requires demonstration of passive safety features that can maintain adequate cooling even during beyond-design-basis events.

Compliance documentation for liquid metal cooled reactors must include comprehensive stability analyses covering normal operation, anticipated operational occurrences, and design basis accidents. These analyses must demonstrate sufficient stability margins across the entire operational envelope, with particular attention to low-flow conditions and power transients where flow instabilities are most likely to develop.

International harmonization efforts are currently underway to standardize safety requirements for advanced reactor cooling systems, including liquid metal loops. The IAEA's Coordinated Research Project on liquid metal thermal hydraulics and the Generation IV International Forum are working to develop consensus-based standards that incorporate lessons learned from experimental facilities and operational experience with research reactors utilizing liquid metal coolants.

Material Compatibility and Corrosion Management

Material compatibility represents a critical challenge in liquid metal cooling systems for high-power reactors. Liquid metals such as sodium, lead-bismuth eutectic (LBE), and gallium exhibit excellent heat transfer properties but simultaneously present significant corrosion concerns. The interaction between these coolants and structural materials creates complex electrochemical reactions that can compromise system integrity over time. Research indicates that corrosion rates accelerate significantly at elevated temperatures typical in high-power reactor environments, with temperature gradients further exacerbating material degradation through mass transfer mechanisms.

Oxygen control emerges as a fundamental strategy for corrosion management in liquid metal systems. Maintaining precise oxygen concentrations within a narrow operational window allows for the formation of protective oxide layers on structural surfaces without causing excessive oxidation that could lead to flow blockages. Advanced monitoring technologies utilizing electrochemical oxygen sensors have demonstrated reliability in sodium systems, while similar technologies for lead and LBE systems continue to evolve with improved response times and durability.

Material selection represents another cornerstone of compatibility management. Austenitic stainless steels (316L, 304) show acceptable performance in sodium environments but experience accelerated dissolution in lead-bismuth systems. Ferritic-martensitic steels with controlled silicon and aluminum content demonstrate enhanced resistance through the formation of more stable protective layers. Recent developments in surface engineering, including GESA (Gepulste ElektronenStrahlAnlage) treatment and aluminum-based coatings, have shown promising results in extending component lifespans.

Flow velocity control provides an additional dimension to corrosion management strategies. Experimental data reveals that erosion-corrosion effects become particularly pronounced at velocities exceeding 2-3 m/s in lead-bismuth systems. Computational fluid dynamics modeling now enables precise prediction of high-risk zones within complex cooling loop geometries, allowing for targeted design modifications to mitigate localized corrosion.

Long-term material compatibility testing remains essential for validating theoretical models. Accelerated testing protocols using oxygen-controlled capsules provide valuable data, though correlation with actual service conditions requires careful interpretation. International research collaborations, particularly through the OECD/NEA framework, have established standardized testing methodologies that enhance data comparability across different research institutions.

The development of in-situ monitoring capabilities represents the frontier of corrosion management technology. Acoustic emission techniques and electrical resistance measurements show promise for real-time detection of material degradation, potentially enabling predictive maintenance approaches that could significantly enhance operational reliability of liquid metal cooling systems in next-generation high-power reactors.

Oxygen control emerges as a fundamental strategy for corrosion management in liquid metal systems. Maintaining precise oxygen concentrations within a narrow operational window allows for the formation of protective oxide layers on structural surfaces without causing excessive oxidation that could lead to flow blockages. Advanced monitoring technologies utilizing electrochemical oxygen sensors have demonstrated reliability in sodium systems, while similar technologies for lead and LBE systems continue to evolve with improved response times and durability.

Material selection represents another cornerstone of compatibility management. Austenitic stainless steels (316L, 304) show acceptable performance in sodium environments but experience accelerated dissolution in lead-bismuth systems. Ferritic-martensitic steels with controlled silicon and aluminum content demonstrate enhanced resistance through the formation of more stable protective layers. Recent developments in surface engineering, including GESA (Gepulste ElektronenStrahlAnlage) treatment and aluminum-based coatings, have shown promising results in extending component lifespans.

Flow velocity control provides an additional dimension to corrosion management strategies. Experimental data reveals that erosion-corrosion effects become particularly pronounced at velocities exceeding 2-3 m/s in lead-bismuth systems. Computational fluid dynamics modeling now enables precise prediction of high-risk zones within complex cooling loop geometries, allowing for targeted design modifications to mitigate localized corrosion.

Long-term material compatibility testing remains essential for validating theoretical models. Accelerated testing protocols using oxygen-controlled capsules provide valuable data, though correlation with actual service conditions requires careful interpretation. International research collaborations, particularly through the OECD/NEA framework, have established standardized testing methodologies that enhance data comparability across different research institutions.

The development of in-situ monitoring capabilities represents the frontier of corrosion management technology. Acoustic emission techniques and electrical resistance measurements show promise for real-time detection of material degradation, potentially enabling predictive maintenance approaches that could significantly enhance operational reliability of liquid metal cooling systems in next-generation high-power reactors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!