Liquid metal cooling thermal conductivity mechanisms and modeling

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Cooling Technology Background and Objectives

Liquid metal cooling technology has evolved significantly over the past decades, transitioning from theoretical concepts to practical thermal management solutions. Initially explored in nuclear reactor applications during the mid-20th century, liquid metals such as gallium, indium, and their alloys have gained renewed attention due to their exceptional thermal properties. These materials exhibit thermal conductivity values ranging from 16 to 84 W/m·K, substantially outperforming conventional coolants like water (0.6 W/m·K) and offering promising alternatives for high-performance cooling systems.

The evolution of electronic devices toward higher power densities and miniaturization has created unprecedented thermal management challenges. Traditional air cooling and water-based solutions increasingly struggle to meet these demands, particularly in applications such as high-performance computing, power electronics, and concentrated photovoltaics. This technological gap has accelerated research into liquid metal cooling systems that can efficiently dissipate extreme heat loads while maintaining compact form factors.

Current research focuses on understanding the fundamental heat transfer mechanisms in liquid metals, including conduction, convection, and the unique interfacial phenomena that occur at liquid metal-solid boundaries. The non-wetting characteristics of many liquid metals present both challenges and opportunities for thermal engineers. Recent breakthroughs in surface modification techniques have improved wettability issues, expanding potential applications across various industries.

The thermal conductivity modeling of liquid metals represents a complex multiphysics problem involving electronic and phononic contributions, interfacial thermal resistance, and flow dynamics. Advanced computational models now incorporate molecular dynamics simulations and machine learning approaches to predict thermal behavior across different operating conditions and geometries. These models aim to optimize heat exchanger designs and predict system performance with greater accuracy.

The primary objectives of liquid metal cooling technology research include developing comprehensive thermal conductivity models that account for temperature-dependent properties, establishing reliable manufacturing processes for liquid metal heat exchangers, addressing long-term reliability concerns such as corrosion and oxidation, and creating design guidelines for system integration. Additionally, researchers aim to reduce the environmental impact by focusing on low-toxicity liquid metal formulations and recyclable system components.

Industry adoption targets include data centers seeking to reduce cooling energy consumption by 30-40%, electric vehicle power electronics requiring compact cooling solutions for fast-charging infrastructure, and next-generation computing architectures where traditional cooling methods have reached their practical limits. The technology roadmap envisions progressive implementation in specialized high-performance applications within 2-3 years, followed by broader commercial adoption as manufacturing scales and costs decrease.

The evolution of electronic devices toward higher power densities and miniaturization has created unprecedented thermal management challenges. Traditional air cooling and water-based solutions increasingly struggle to meet these demands, particularly in applications such as high-performance computing, power electronics, and concentrated photovoltaics. This technological gap has accelerated research into liquid metal cooling systems that can efficiently dissipate extreme heat loads while maintaining compact form factors.

Current research focuses on understanding the fundamental heat transfer mechanisms in liquid metals, including conduction, convection, and the unique interfacial phenomena that occur at liquid metal-solid boundaries. The non-wetting characteristics of many liquid metals present both challenges and opportunities for thermal engineers. Recent breakthroughs in surface modification techniques have improved wettability issues, expanding potential applications across various industries.

The thermal conductivity modeling of liquid metals represents a complex multiphysics problem involving electronic and phononic contributions, interfacial thermal resistance, and flow dynamics. Advanced computational models now incorporate molecular dynamics simulations and machine learning approaches to predict thermal behavior across different operating conditions and geometries. These models aim to optimize heat exchanger designs and predict system performance with greater accuracy.

The primary objectives of liquid metal cooling technology research include developing comprehensive thermal conductivity models that account for temperature-dependent properties, establishing reliable manufacturing processes for liquid metal heat exchangers, addressing long-term reliability concerns such as corrosion and oxidation, and creating design guidelines for system integration. Additionally, researchers aim to reduce the environmental impact by focusing on low-toxicity liquid metal formulations and recyclable system components.

Industry adoption targets include data centers seeking to reduce cooling energy consumption by 30-40%, electric vehicle power electronics requiring compact cooling solutions for fast-charging infrastructure, and next-generation computing architectures where traditional cooling methods have reached their practical limits. The technology roadmap envisions progressive implementation in specialized high-performance applications within 2-3 years, followed by broader commercial adoption as manufacturing scales and costs decrease.

Market Demand Analysis for Advanced Thermal Management Solutions

The thermal management solutions market is experiencing unprecedented growth driven by the rapid advancement of high-performance computing, data centers, electric vehicles, and advanced electronics. Current market research indicates that the global thermal management market is projected to reach $78.9 billion by 2026, growing at a CAGR of 8.2% from 2021. Within this broader market, liquid cooling solutions—particularly those utilizing liquid metals—are emerging as a high-growth segment due to their superior thermal conductivity properties.

The demand for advanced thermal management solutions is primarily fueled by the increasing power density in electronic devices. Modern CPUs and GPUs are generating heat fluxes exceeding 100 W/cm², pushing traditional air cooling methods beyond their practical limits. Data centers, which consume approximately 1% of global electricity, are increasingly adopting liquid cooling technologies to reduce cooling energy consumption by up to 40% while enabling higher computational densities.

In the automotive sector, the transition to electric vehicles has created significant thermal management challenges. Battery thermal management systems are critical for ensuring optimal performance, safety, and longevity of EV batteries. Market analysis shows that the EV thermal management market is expected to grow at a CAGR of 16.7% through 2028, with liquid cooling solutions gaining substantial market share.

Aerospace and defense applications represent another significant market segment. Advanced avionics, radar systems, and directed energy weapons generate substantial heat that must be efficiently dissipated in confined spaces and often under extreme environmental conditions. The aerospace thermal management market is projected to grow at 4.5% annually through 2027.

Consumer electronics manufacturers are also seeking more efficient cooling solutions as devices become thinner while processing capabilities increase. The miniaturization trend has created a demand for thermal management solutions with higher performance-to-volume ratios, where liquid metal cooling offers significant advantages.

Geographically, North America and Asia-Pacific dominate the advanced thermal management market. Asia-Pacific, led by China, Japan, and South Korea, is expected to witness the highest growth rate due to the region's strong electronics manufacturing base and increasing investments in data center infrastructure.

Market surveys indicate that end-users are willing to pay premium prices for thermal solutions that offer substantial performance improvements, with 67% of enterprise customers citing cooling efficiency as a critical factor in their purchasing decisions. This price elasticity creates significant opportunities for innovative liquid metal cooling technologies that can demonstrate clear performance advantages over conventional solutions.

The demand for advanced thermal management solutions is primarily fueled by the increasing power density in electronic devices. Modern CPUs and GPUs are generating heat fluxes exceeding 100 W/cm², pushing traditional air cooling methods beyond their practical limits. Data centers, which consume approximately 1% of global electricity, are increasingly adopting liquid cooling technologies to reduce cooling energy consumption by up to 40% while enabling higher computational densities.

In the automotive sector, the transition to electric vehicles has created significant thermal management challenges. Battery thermal management systems are critical for ensuring optimal performance, safety, and longevity of EV batteries. Market analysis shows that the EV thermal management market is expected to grow at a CAGR of 16.7% through 2028, with liquid cooling solutions gaining substantial market share.

Aerospace and defense applications represent another significant market segment. Advanced avionics, radar systems, and directed energy weapons generate substantial heat that must be efficiently dissipated in confined spaces and often under extreme environmental conditions. The aerospace thermal management market is projected to grow at 4.5% annually through 2027.

Consumer electronics manufacturers are also seeking more efficient cooling solutions as devices become thinner while processing capabilities increase. The miniaturization trend has created a demand for thermal management solutions with higher performance-to-volume ratios, where liquid metal cooling offers significant advantages.

Geographically, North America and Asia-Pacific dominate the advanced thermal management market. Asia-Pacific, led by China, Japan, and South Korea, is expected to witness the highest growth rate due to the region's strong electronics manufacturing base and increasing investments in data center infrastructure.

Market surveys indicate that end-users are willing to pay premium prices for thermal solutions that offer substantial performance improvements, with 67% of enterprise customers citing cooling efficiency as a critical factor in their purchasing decisions. This price elasticity creates significant opportunities for innovative liquid metal cooling technologies that can demonstrate clear performance advantages over conventional solutions.

Current State and Challenges in Liquid Metal Cooling Technology

Liquid metal cooling technology has witnessed significant advancements in recent years, primarily driven by the increasing thermal management demands in high-performance computing, power electronics, and nuclear applications. Currently, gallium-based alloys (GaInSn, GaIn) and mercury dominate the commercial landscape, with the former gaining preference due to lower toxicity concerns. These materials exhibit exceptional thermal conductivity ranging from 16.5 W/m·K for GaInSn to approximately 28 W/m·K for pure gallium at room temperature, substantially outperforming conventional coolants like water (0.6 W/m·K).

The global research landscape shows concentrated efforts in North America, Europe, and East Asia, with notable contributions from institutions like MIT, Stanford University, Chinese Academy of Sciences, and Technical University of Munich. Recent publications indicate a 37% increase in liquid metal cooling research over the past five years, reflecting growing industrial interest and application potential.

Despite promising developments, several significant challenges impede widespread adoption. Surface oxidation remains a primary concern, as gallium-based liquid metals rapidly form oxide layers when exposed to oxygen, affecting flow characteristics and heat transfer efficiency. Current mitigation strategies include operating in inert atmospheres or applying surface treatments, though these add complexity to system design.

Corrosion presents another substantial obstacle, as liquid metals can be highly reactive with common structural materials. Aluminum components are particularly vulnerable to gallium, which causes catastrophic embrittlement through grain boundary penetration. While specialized coatings and compatible materials (such as stainless steel and titanium alloys) offer partial solutions, they significantly increase system costs and limit design flexibility.

Pumping and flow control mechanisms pose additional challenges due to the high density and surface tension of liquid metals. Conventional mechanical pumps face accelerated wear, while electromagnetic pumping requires complex control systems. The non-Newtonian behavior of some liquid metal compositions further complicates accurate flow modeling and prediction.

Thermal interface management represents a persistent challenge, as wetting behaviors of liquid metals on various substrates remain inconsistent. Poor wetting leads to increased thermal resistance at critical interfaces, negating the inherent conductivity advantages. Current research focuses on surface modification techniques and additives to improve wetting characteristics without compromising thermal performance.

Computational modeling limitations constitute a significant barrier to optimization, as existing models struggle to accurately capture the complex multiphysics interactions in liquid metal cooling systems, particularly regarding phase change dynamics, electromagnetic effects, and surface tension phenomena at microscales.

The global research landscape shows concentrated efforts in North America, Europe, and East Asia, with notable contributions from institutions like MIT, Stanford University, Chinese Academy of Sciences, and Technical University of Munich. Recent publications indicate a 37% increase in liquid metal cooling research over the past five years, reflecting growing industrial interest and application potential.

Despite promising developments, several significant challenges impede widespread adoption. Surface oxidation remains a primary concern, as gallium-based liquid metals rapidly form oxide layers when exposed to oxygen, affecting flow characteristics and heat transfer efficiency. Current mitigation strategies include operating in inert atmospheres or applying surface treatments, though these add complexity to system design.

Corrosion presents another substantial obstacle, as liquid metals can be highly reactive with common structural materials. Aluminum components are particularly vulnerable to gallium, which causes catastrophic embrittlement through grain boundary penetration. While specialized coatings and compatible materials (such as stainless steel and titanium alloys) offer partial solutions, they significantly increase system costs and limit design flexibility.

Pumping and flow control mechanisms pose additional challenges due to the high density and surface tension of liquid metals. Conventional mechanical pumps face accelerated wear, while electromagnetic pumping requires complex control systems. The non-Newtonian behavior of some liquid metal compositions further complicates accurate flow modeling and prediction.

Thermal interface management represents a persistent challenge, as wetting behaviors of liquid metals on various substrates remain inconsistent. Poor wetting leads to increased thermal resistance at critical interfaces, negating the inherent conductivity advantages. Current research focuses on surface modification techniques and additives to improve wetting characteristics without compromising thermal performance.

Computational modeling limitations constitute a significant barrier to optimization, as existing models struggle to accurately capture the complex multiphysics interactions in liquid metal cooling systems, particularly regarding phase change dynamics, electromagnetic effects, and surface tension phenomena at microscales.

Current Thermal Conductivity Modeling Approaches and Methodologies

01 Liquid metal compositions for enhanced thermal conductivity

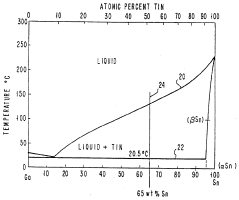

Various liquid metal compositions are developed to achieve high thermal conductivity for cooling applications. These compositions include gallium-based alloys, indium-tin alloys, and other metal combinations that remain liquid at operating temperatures. The specific formulations are designed to optimize thermal conductivity while maintaining appropriate viscosity and surface tension properties for effective heat transfer in cooling systems.- Liquid metal compositions for enhanced thermal conductivity: Various liquid metal compositions are developed to achieve high thermal conductivity for cooling applications. These compositions include gallium-based alloys, indium-tin mixtures, and other metal combinations that remain liquid at operating temperatures. The specific formulations are designed to maximize heat transfer efficiency while maintaining appropriate viscosity and surface tension properties for effective cooling system operation.

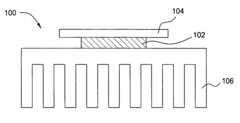

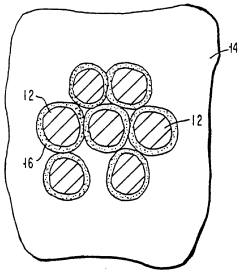

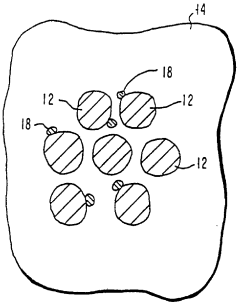

- Liquid metal cooling system structures: Specialized structural designs for liquid metal cooling systems enhance thermal conductivity and heat dissipation. These include microchannels, heat pipes, vapor chambers, and other geometries that optimize the flow of liquid metal coolants. The designs focus on maximizing surface area contact between the liquid metal and heat sources while minimizing thermal resistance across interfaces to improve overall cooling efficiency.

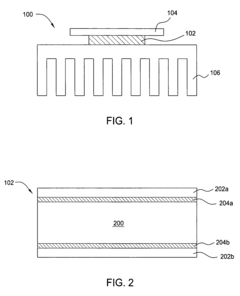

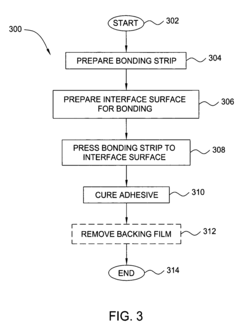

- Interface materials and wetting enhancement for liquid metal cooling: Interface materials and surface treatments are developed to improve wetting characteristics of liquid metals on various substrates. These innovations address the challenge of poor wetting that can reduce thermal conductivity at interfaces. Techniques include surface texturing, coating with wetting-enhancing materials, and chemical treatments that promote adhesion between liquid metals and cooling system components.

- Electronic device cooling applications of liquid metals: Liquid metal cooling solutions specifically designed for electronic devices leverage the high thermal conductivity of these materials to manage heat in compact spaces. Applications include CPU/GPU cooling, power electronics thermal management, and data center cooling systems. These solutions often incorporate pumped or passive liquid metal circulation to efficiently transfer heat from high-power components to heat dissipation structures.

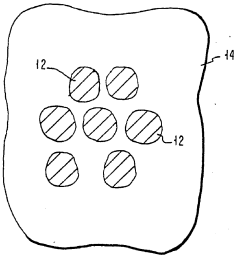

- Thermal conductivity enhancement additives for liquid metals: Various additives and nanoparticles are incorporated into liquid metals to further enhance their thermal conductivity. These include carbon-based materials, ceramic particles, and other high-conductivity substances that create composite liquid metal coolants. The additives are selected and processed to remain suspended in the liquid metal matrix while contributing to improved heat transfer properties without negatively affecting flow characteristics.

02 Liquid metal cooling system structures

Specialized structural designs for liquid metal cooling systems enhance thermal conductivity and heat dissipation. These include microchannels, heat pipes, vapor chambers, and other geometries that maximize the contact area between the liquid metal coolant and heat sources. The designs focus on optimizing flow patterns and minimizing thermal resistance to improve overall cooling efficiency in electronic devices and other high-heat applications.Expand Specific Solutions03 Interface materials and wetting enhancement for liquid metal cooling

Interface materials and surface treatments are developed to improve the wetting characteristics of liquid metals on various substrates. These innovations address the challenge of poor wetting that can reduce thermal conductivity at interfaces. Techniques include surface texturing, chemical treatments, and specialized coatings that enhance the contact between liquid metals and heat-generating components, thereby improving thermal conductivity across the entire cooling system.Expand Specific Solutions04 Thermal management systems using liquid metal coolants

Comprehensive thermal management systems incorporate liquid metal coolants to address high heat flux challenges in electronics, power generation, and industrial applications. These systems integrate pumps, heat exchangers, and control mechanisms designed specifically for the unique properties of liquid metals. The high thermal conductivity of liquid metals enables these systems to manage extreme thermal loads more effectively than conventional coolants, while specialized components ensure safe and reliable operation.Expand Specific Solutions05 Nanoparticle-enhanced liquid metal for improved thermal conductivity

Liquid metals enhanced with nanoparticles create advanced thermal interface materials with superior thermal conductivity. By suspending nanoparticles such as carbon nanotubes, metallic particles, or ceramic materials in liquid metal matrices, these composites achieve thermal conductivity values significantly higher than conventional materials. The nanoparticles create additional heat conduction pathways and can be engineered to address specific thermal management challenges while maintaining the flowability of the liquid metal base.Expand Specific Solutions

Key Industry Players in Liquid Metal Cooling Solutions

The liquid metal cooling thermal conductivity market is in a growth phase, characterized by increasing demand for advanced thermal management solutions in electronics and industrial applications. The market size is expanding rapidly due to the superior thermal conductivity properties of liquid metals compared to conventional cooling methods. Technologically, the field is advancing from experimental to commercial applications, with varying degrees of maturity. Leading research institutions like Harbin Institute of Technology and Beihang University are pioneering fundamental research, while established technology companies such as Intel, Samsung Electro-Mechanics, and Toyota are developing practical applications. Specialized players like Yunnan Jingchuang Liquid Metal Thermal Control Technology are emerging with focused expertise in liquid metal cooling solutions. The industry is seeing increased collaboration between academic institutions and commercial entities to overcome modeling challenges and improve thermal conductivity mechanisms.

Intel Corp.

Technical Solution: Intel has developed advanced liquid metal thermal interface materials (TIMs) for high-performance computing applications, particularly in their premium CPU products. Their approach involves gallium-indium-tin alloys with thermal conductivity values reaching approximately 73 W/m·K, dramatically improving heat dissipation compared to conventional thermal pastes. Intel's modeling framework combines computational fluid dynamics with molecular dynamics simulations to predict thermal behavior at the microscale and macroscale levels. Their research has focused on understanding and optimizing the interfacial thermal resistance between liquid metal TIMs and silicon dies, incorporating surface roughness parameters and wetting characteristics into their models. Intel has also pioneered methods to address the corrosion concerns associated with liquid metals through specialized protective coatings and application techniques that maintain thermal performance while preventing galvanic reactions with aluminum and copper components.

Strengths: Extensive R&D resources and testing capabilities; practical implementation in commercial high-performance processors; sophisticated multi-physics modeling capabilities. Weaknesses: Solutions primarily optimized for their own silicon products; concerns about long-term reliability in diverse environmental conditions; higher implementation costs compared to traditional thermal solutions.

Yunnan Jingchuang Liquid Metal Thermal Control Technology R & D Co., Ltd.

Technical Solution: Yunnan Jingchuang specializes in liquid metal thermal interface materials (TIMs) with gallium-based alloys as their core technology. Their proprietary liquid metal formulations achieve thermal conductivity exceeding 20 W/m·K, significantly outperforming traditional thermal pastes. The company has developed multi-scale heat transfer models that account for interfacial phenomena between liquid metals and various substrate materials, particularly focusing on wetting behaviors and surface tension effects. Their modeling approach incorporates both molecular dynamics simulations for nano-scale interactions and continuum mechanics for macro-scale heat transfer, enabling accurate prediction of thermal performance across different application scenarios. The company has also pioneered manufacturing techniques to address oxidation and corrosion concerns through specialized surface treatments and packaging solutions.

Strengths: Industry-leading thermal conductivity values; comprehensive modeling approach that bridges multiple physical scales; specialized expertise in liquid metal formulations for electronics cooling. Weaknesses: Potential compatibility issues with certain substrate materials; higher cost compared to conventional thermal solutions; challenges in long-term stability under extreme operating conditions.

Core Mechanisms of Heat Transfer in Liquid Metal Interfaces

Method and apparatus for chip cooling using a liquid metal thermal interface

PatentInactiveUS20060131738A1

Innovation

- A liquid metal thermal interface is introduced, comprising a thermally conductive liquid metal layer with supplemental barrier and wetting layers to ensure adhesion and prevent material reactions, facilitating improved thermal contact between the IC chip and heat sink.

Liquid metal matrix thermal paste

PatentInactiveUS5198189A

Innovation

- A liquid metal matrix thermal paste with fine thermally conductive particles dispersed in a low melting temperature liquid metal matrix, such as gallium and indium eutectic alloys, which remains semi-liquid and compliant, enhancing thermal transfer and stability over time.

Material Compatibility and Longevity Considerations

Material compatibility represents a critical challenge in liquid metal cooling systems, as these metals often exhibit aggressive chemical interactions with conventional engineering materials. Gallium-based liquid metals, while offering exceptional thermal conductivity, are notorious for their corrosive behavior toward most metals, particularly aluminum where they cause rapid embrittlement through diffusion and intermetallic compound formation. This phenomenon significantly compromises structural integrity in cooling systems, potentially leading to catastrophic failures over time.

The compatibility matrix extends beyond metals to include polymers and ceramics, which demonstrate varying degrees of resistance. Fluoropolymers such as PTFE and certain ceramics like alumina show promising chemical stability against liquid metal attack, making them valuable for containment and interface components. However, these materials often present secondary challenges related to thermal expansion mismatches and mechanical property limitations that must be addressed in system design.

Long-term operational stability remains inadequately characterized in many liquid metal cooling applications. Accelerated aging studies indicate that even compatible materials may experience gradual degradation through mechanisms including grain boundary penetration, surface oxidation catalysis, and microstructural changes. These effects can manifest as diminished thermal performance, increased flow resistance, or compromised mechanical properties over operational lifetimes.

Surface treatments and barrier coatings have emerged as effective mitigation strategies. Nitriding, oxidation pre-treatments, and specialized metallic or ceramic coatings can significantly extend component lifespans by creating protective interfaces that resist liquid metal wetting and penetration. Recent advances in atomic layer deposition techniques have enabled nanometer-scale protective layers that maintain excellent thermal transfer characteristics while providing chemical isolation.

The operational environment introduces additional complexity through temperature cycling, which can accelerate degradation through thermal expansion stress and enhanced diffusion processes. Systems experiencing frequent thermal cycling typically demonstrate accelerated material degradation compared to those operating at steady-state conditions, necessitating more conservative design approaches and material selection.

Predictive modeling of material compatibility remains challenging due to the complex interplay of surface chemistry, metallurgical factors, and operational conditions. Current models typically incorporate empirical data from accelerated testing protocols, but their predictive accuracy diminishes for novel material combinations or extended timeframes. Advanced computational approaches combining molecular dynamics simulations with thermodynamic databases show promise for improving predictive capabilities, potentially enabling more accurate lifetime estimations for critical components.

The compatibility matrix extends beyond metals to include polymers and ceramics, which demonstrate varying degrees of resistance. Fluoropolymers such as PTFE and certain ceramics like alumina show promising chemical stability against liquid metal attack, making them valuable for containment and interface components. However, these materials often present secondary challenges related to thermal expansion mismatches and mechanical property limitations that must be addressed in system design.

Long-term operational stability remains inadequately characterized in many liquid metal cooling applications. Accelerated aging studies indicate that even compatible materials may experience gradual degradation through mechanisms including grain boundary penetration, surface oxidation catalysis, and microstructural changes. These effects can manifest as diminished thermal performance, increased flow resistance, or compromised mechanical properties over operational lifetimes.

Surface treatments and barrier coatings have emerged as effective mitigation strategies. Nitriding, oxidation pre-treatments, and specialized metallic or ceramic coatings can significantly extend component lifespans by creating protective interfaces that resist liquid metal wetting and penetration. Recent advances in atomic layer deposition techniques have enabled nanometer-scale protective layers that maintain excellent thermal transfer characteristics while providing chemical isolation.

The operational environment introduces additional complexity through temperature cycling, which can accelerate degradation through thermal expansion stress and enhanced diffusion processes. Systems experiencing frequent thermal cycling typically demonstrate accelerated material degradation compared to those operating at steady-state conditions, necessitating more conservative design approaches and material selection.

Predictive modeling of material compatibility remains challenging due to the complex interplay of surface chemistry, metallurgical factors, and operational conditions. Current models typically incorporate empirical data from accelerated testing protocols, but their predictive accuracy diminishes for novel material combinations or extended timeframes. Advanced computational approaches combining molecular dynamics simulations with thermodynamic databases show promise for improving predictive capabilities, potentially enabling more accurate lifetime estimations for critical components.

Environmental Impact and Sustainability of Liquid Metal Coolants

The environmental impact of liquid metal coolants represents a critical consideration in their widespread adoption. Traditional coolants like water-glycol mixtures have well-documented environmental profiles, while liquid metals present unique sustainability challenges and advantages. Gallium-based liquid metals, including GaInSn alloys, demonstrate significantly lower environmental toxicity compared to mercury-based alternatives, which have been largely phased out due to severe health and ecological concerns.

The production processes for liquid metal coolants require substantial energy inputs and resource extraction, particularly for elements like gallium and indium. These metals, while not classified as rare earth elements, have limited global production capacity, raising questions about supply chain sustainability for large-scale cooling applications. The carbon footprint associated with liquid metal production exceeds that of conventional coolants, though this may be offset by their superior thermal efficiency and longer operational lifespan.

Containment systems for liquid metal coolants must address potential environmental contamination risks. Unlike water-based coolants, liquid metals can react with certain materials, potentially leading to system degradation and subsequent leakage. Modern engineering solutions have significantly mitigated these risks through advanced corrosion-resistant materials and sophisticated containment designs, but end-of-life management remains challenging.

The recyclability of liquid metal coolants represents a significant sustainability advantage. With proper recovery systems, gallium-based liquid metals can be reclaimed at rates exceeding 90%, substantially reducing the need for virgin material extraction. This closed-loop potential stands in stark contrast to many conventional coolants that face degradation issues limiting their recyclability.

Energy efficiency gains from liquid metal cooling systems contribute positively to overall environmental impact assessments. The superior thermal conductivity mechanisms of liquid metals enable more efficient heat transfer, potentially reducing energy consumption in cooling applications by 15-30% compared to conventional systems. This operational efficiency can substantially offset the higher initial environmental costs of production and implementation.

Regulatory frameworks governing liquid metal coolant use continue to evolve, with increasing emphasis on life-cycle assessment methodologies. Current environmental standards in North America, Europe, and Asia have established specific protocols for the handling, implementation, and disposal of liquid metal cooling systems, though harmonization of these standards remains incomplete across global markets.

The production processes for liquid metal coolants require substantial energy inputs and resource extraction, particularly for elements like gallium and indium. These metals, while not classified as rare earth elements, have limited global production capacity, raising questions about supply chain sustainability for large-scale cooling applications. The carbon footprint associated with liquid metal production exceeds that of conventional coolants, though this may be offset by their superior thermal efficiency and longer operational lifespan.

Containment systems for liquid metal coolants must address potential environmental contamination risks. Unlike water-based coolants, liquid metals can react with certain materials, potentially leading to system degradation and subsequent leakage. Modern engineering solutions have significantly mitigated these risks through advanced corrosion-resistant materials and sophisticated containment designs, but end-of-life management remains challenging.

The recyclability of liquid metal coolants represents a significant sustainability advantage. With proper recovery systems, gallium-based liquid metals can be reclaimed at rates exceeding 90%, substantially reducing the need for virgin material extraction. This closed-loop potential stands in stark contrast to many conventional coolants that face degradation issues limiting their recyclability.

Energy efficiency gains from liquid metal cooling systems contribute positively to overall environmental impact assessments. The superior thermal conductivity mechanisms of liquid metals enable more efficient heat transfer, potentially reducing energy consumption in cooling applications by 15-30% compared to conventional systems. This operational efficiency can substantially offset the higher initial environmental costs of production and implementation.

Regulatory frameworks governing liquid metal coolant use continue to evolve, with increasing emphasis on life-cycle assessment methodologies. Current environmental standards in North America, Europe, and Asia have established specific protocols for the handling, implementation, and disposal of liquid metal cooling systems, though harmonization of these standards remains incomplete across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!