Liquid metal cooling compatibility with advanced nuclear reactor fuels

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Cooling Technology Background and Objectives

Liquid metal cooling technology has evolved significantly since its inception in the 1950s, initially developed for fast neutron reactors due to its superior heat transfer capabilities compared to water-based coolants. The historical progression began with sodium-cooled reactors such as EBR-I in the United States, followed by more advanced implementations in Russia's BN-series reactors and France's Phénix and Superphénix. This evolution demonstrates a continuous refinement in understanding the complex interactions between liquid metals and nuclear fuel materials.

The primary liquid metals utilized in nuclear cooling applications include sodium, lead, lead-bismuth eutectic (LBE), and more recently, gallium-based alloys. Each coolant presents unique thermophysical properties that influence reactor design and operational parameters. Sodium offers excellent thermal conductivity but reacts violently with water and air, while lead-based coolants provide enhanced safety features but introduce corrosion challenges that must be addressed through material science innovations.

Current technological trends are moving toward advanced reactor designs that require higher operating temperatures and increased power densities, necessitating coolants capable of maintaining efficiency under extreme conditions. Generation IV reactor concepts, including Sodium-cooled Fast Reactors (SFR), Lead-cooled Fast Reactors (LFR), and Lead-Bismuth-cooled Fast Reactors, represent the frontier of this technological progression, demanding comprehensive compatibility studies with advanced nuclear fuels.

The primary objective of liquid metal cooling research is to establish definitive compatibility parameters between various liquid metal coolants and next-generation nuclear fuels, including advanced uranium-plutonium mixed oxides, nitrides, carbides, and metallic fuel forms. This research aims to identify optimal coolant-fuel combinations that maximize thermal efficiency while minimizing corrosion, mass transfer phenomena, and potential chemical interactions that could compromise fuel integrity or reactor safety systems.

Secondary objectives include developing predictive models for long-term behavior of fuel-coolant systems, establishing standardized testing protocols for compatibility assessment, and creating comprehensive databases of material interactions under various operational conditions. These resources will enable more efficient reactor design processes and support regulatory frameworks for advanced nuclear systems.

The technological goals extend to addressing specific challenges such as mitigating liquid metal embrittlement of structural materials, controlling oxygen content in coolant systems to minimize corrosion, and developing advanced cladding materials that resist degradation in liquid metal environments while maintaining excellent neutron economy. Success in these areas will significantly advance nuclear energy technology toward more efficient, safer, and more sustainable power generation systems.

The primary liquid metals utilized in nuclear cooling applications include sodium, lead, lead-bismuth eutectic (LBE), and more recently, gallium-based alloys. Each coolant presents unique thermophysical properties that influence reactor design and operational parameters. Sodium offers excellent thermal conductivity but reacts violently with water and air, while lead-based coolants provide enhanced safety features but introduce corrosion challenges that must be addressed through material science innovations.

Current technological trends are moving toward advanced reactor designs that require higher operating temperatures and increased power densities, necessitating coolants capable of maintaining efficiency under extreme conditions. Generation IV reactor concepts, including Sodium-cooled Fast Reactors (SFR), Lead-cooled Fast Reactors (LFR), and Lead-Bismuth-cooled Fast Reactors, represent the frontier of this technological progression, demanding comprehensive compatibility studies with advanced nuclear fuels.

The primary objective of liquid metal cooling research is to establish definitive compatibility parameters between various liquid metal coolants and next-generation nuclear fuels, including advanced uranium-plutonium mixed oxides, nitrides, carbides, and metallic fuel forms. This research aims to identify optimal coolant-fuel combinations that maximize thermal efficiency while minimizing corrosion, mass transfer phenomena, and potential chemical interactions that could compromise fuel integrity or reactor safety systems.

Secondary objectives include developing predictive models for long-term behavior of fuel-coolant systems, establishing standardized testing protocols for compatibility assessment, and creating comprehensive databases of material interactions under various operational conditions. These resources will enable more efficient reactor design processes and support regulatory frameworks for advanced nuclear systems.

The technological goals extend to addressing specific challenges such as mitigating liquid metal embrittlement of structural materials, controlling oxygen content in coolant systems to minimize corrosion, and developing advanced cladding materials that resist degradation in liquid metal environments while maintaining excellent neutron economy. Success in these areas will significantly advance nuclear energy technology toward more efficient, safer, and more sustainable power generation systems.

Market Analysis for Advanced Nuclear Reactor Systems

The global market for advanced nuclear reactor systems is experiencing significant growth, driven by increasing energy demands and the push for cleaner energy sources. The current market size for advanced nuclear technologies is estimated at $30 billion, with projections indicating growth to reach $70 billion by 2035. This represents a compound annual growth rate of approximately 6.8%, significantly outpacing traditional nuclear technologies.

Advanced nuclear reactor systems utilizing liquid metal cooling technologies are gaining particular attention from investors and energy stakeholders. Countries including the United States, Russia, China, France, and South Korea are making substantial investments in this sector, with combined government funding exceeding $15 billion over the past five years.

The market demand for these advanced systems stems from several key factors. First, there is growing recognition of nuclear energy's role in achieving carbon neutrality goals, with advanced reactors offering enhanced safety features that address public concerns following incidents like Fukushima. Second, liquid metal-cooled reactors provide superior thermal efficiency compared to traditional water-cooled systems, potentially reducing operational costs by 15-20%.

Market segmentation reveals distinct customer groups: national governments seeking energy security and decarbonization, utility companies looking to diversify generation portfolios, and industrial facilities requiring reliable high-temperature process heat. The compatibility of liquid metal cooling with advanced nuclear fuels represents a critical value proposition, as it enables higher operating temperatures and improved fuel utilization.

Competitive analysis indicates that while traditional light water reactors still dominate installed capacity, liquid metal-cooled designs are capturing an increasing share of new projects. Sodium-cooled fast reactors currently lead the liquid metal segment with 65% market share, followed by lead-cooled (20%) and lead-bismuth eutectic designs (15%).

Regional market assessment shows Asia-Pacific as the fastest-growing region with 8.2% annual growth, driven primarily by China's aggressive nuclear expansion. North America and Europe follow with 5.7% and 5.1% growth rates respectively, focused more on replacing aging infrastructure with advanced designs.

The economic viability of these systems continues to improve, with recent cost reductions of approximately 22% over the past decade due to standardized designs and manufacturing improvements. This trend is expected to continue as supply chains mature and regulatory frameworks adapt to these innovative technologies.

Advanced nuclear reactor systems utilizing liquid metal cooling technologies are gaining particular attention from investors and energy stakeholders. Countries including the United States, Russia, China, France, and South Korea are making substantial investments in this sector, with combined government funding exceeding $15 billion over the past five years.

The market demand for these advanced systems stems from several key factors. First, there is growing recognition of nuclear energy's role in achieving carbon neutrality goals, with advanced reactors offering enhanced safety features that address public concerns following incidents like Fukushima. Second, liquid metal-cooled reactors provide superior thermal efficiency compared to traditional water-cooled systems, potentially reducing operational costs by 15-20%.

Market segmentation reveals distinct customer groups: national governments seeking energy security and decarbonization, utility companies looking to diversify generation portfolios, and industrial facilities requiring reliable high-temperature process heat. The compatibility of liquid metal cooling with advanced nuclear fuels represents a critical value proposition, as it enables higher operating temperatures and improved fuel utilization.

Competitive analysis indicates that while traditional light water reactors still dominate installed capacity, liquid metal-cooled designs are capturing an increasing share of new projects. Sodium-cooled fast reactors currently lead the liquid metal segment with 65% market share, followed by lead-cooled (20%) and lead-bismuth eutectic designs (15%).

Regional market assessment shows Asia-Pacific as the fastest-growing region with 8.2% annual growth, driven primarily by China's aggressive nuclear expansion. North America and Europe follow with 5.7% and 5.1% growth rates respectively, focused more on replacing aging infrastructure with advanced designs.

The economic viability of these systems continues to improve, with recent cost reductions of approximately 22% over the past decade due to standardized designs and manufacturing improvements. This trend is expected to continue as supply chains mature and regulatory frameworks adapt to these innovative technologies.

Current Status and Technical Challenges in Liquid Metal Cooling

Liquid metal cooling technology has evolved significantly over the past decades, with sodium, lead, lead-bismuth eutectic (LBE), and sodium-potassium (NaK) alloys emerging as primary coolants for advanced nuclear reactors. Currently, sodium-cooled fast reactors (SFRs) represent the most mature technology, with operational experience in countries including Russia, France, Japan, and China. The BN-800 reactor in Russia and the China Experimental Fast Reactor (CEFR) demonstrate the viability of sodium cooling at commercial and experimental scales respectively.

Lead and LBE cooling systems have gained renewed interest due to their favorable neutronics properties and reduced chemical reactivity with air and water compared to sodium. The BREST-OD-300 lead-cooled fast reactor under construction in Russia and the MYRRHA LBE-cooled accelerator-driven system in Belgium represent significant advancements in these technologies. However, these systems remain less mature than sodium-cooled alternatives.

Despite progress, liquid metal cooling faces substantial technical challenges when paired with advanced nuclear fuels. Corrosion mechanisms represent a primary concern, particularly in lead and LBE systems where structural materials experience dissolution, oxidation, and liquid metal embrittlement. Even sodium systems face compatibility issues with certain advanced fuel cladding materials, especially at elevated temperatures exceeding 550°C.

Mass transfer phenomena present another significant challenge, as dissolved structural components can precipitate in cooler regions of the cooling circuit, potentially causing flow restrictions and heat transfer degradation. This is particularly problematic in systems utilizing advanced fuels with higher operating temperatures that accelerate corrosion processes.

Oxygen control methodology remains underdeveloped for lead and LBE systems, where precise oxygen concentration management is critical to form protective oxide layers on structural materials without causing excessive oxidation of the coolant itself. Current monitoring technologies lack the precision and reliability required for long-term operation.

Irradiation effects compound these challenges, as neutron bombardment alters material properties and accelerates degradation mechanisms. Advanced fuels with higher burnup rates intensify this issue, creating more challenging radiation environments for both coolant and structural materials.

Instrumentation and monitoring systems for liquid metal environments remain limited in capability and longevity. Sensors for real-time monitoring of coolant chemistry, particularly in high-radiation environments, lack sufficient development for reliable long-term deployment with advanced fuels that may introduce additional contaminants into the coolant stream.

Lead and LBE cooling systems have gained renewed interest due to their favorable neutronics properties and reduced chemical reactivity with air and water compared to sodium. The BREST-OD-300 lead-cooled fast reactor under construction in Russia and the MYRRHA LBE-cooled accelerator-driven system in Belgium represent significant advancements in these technologies. However, these systems remain less mature than sodium-cooled alternatives.

Despite progress, liquid metal cooling faces substantial technical challenges when paired with advanced nuclear fuels. Corrosion mechanisms represent a primary concern, particularly in lead and LBE systems where structural materials experience dissolution, oxidation, and liquid metal embrittlement. Even sodium systems face compatibility issues with certain advanced fuel cladding materials, especially at elevated temperatures exceeding 550°C.

Mass transfer phenomena present another significant challenge, as dissolved structural components can precipitate in cooler regions of the cooling circuit, potentially causing flow restrictions and heat transfer degradation. This is particularly problematic in systems utilizing advanced fuels with higher operating temperatures that accelerate corrosion processes.

Oxygen control methodology remains underdeveloped for lead and LBE systems, where precise oxygen concentration management is critical to form protective oxide layers on structural materials without causing excessive oxidation of the coolant itself. Current monitoring technologies lack the precision and reliability required for long-term operation.

Irradiation effects compound these challenges, as neutron bombardment alters material properties and accelerates degradation mechanisms. Advanced fuels with higher burnup rates intensify this issue, creating more challenging radiation environments for both coolant and structural materials.

Instrumentation and monitoring systems for liquid metal environments remain limited in capability and longevity. Sensors for real-time monitoring of coolant chemistry, particularly in high-radiation environments, lack sufficient development for reliable long-term deployment with advanced fuels that may introduce additional contaminants into the coolant stream.

Existing Compatibility Solutions for Liquid Metal-Fuel Interfaces

01 Material compatibility with liquid metal coolants

Compatibility between liquid metal coolants and container materials is crucial for cooling system efficiency and longevity. Certain materials may experience corrosion, erosion, or other degradation when in contact with liquid metals such as gallium, indium, or their alloys. Selecting appropriate container materials, surface treatments, or protective coatings can mitigate these compatibility issues and prevent system failure. Understanding the chemical interactions between liquid metals and various materials enables the design of more reliable cooling systems.- Material compatibility with liquid metal coolants: Compatibility between liquid metal coolants and container materials is crucial for cooling system efficiency and longevity. Certain materials may experience corrosion, erosion, or other degradation when in contact with liquid metals such as gallium, indium, or their alloys. Selecting appropriate container materials, surface treatments, or protective coatings can mitigate these compatibility issues and prevent system failure. Research focuses on identifying materials that maintain structural integrity while in prolonged contact with liquid metal coolants under various operating conditions.

- Thermal interface materials for liquid metal cooling: Specialized thermal interface materials are developed to enhance heat transfer between components and liquid metal coolants. These materials improve thermal conductivity at the interface, reducing thermal resistance and enhancing cooling efficiency. Innovations include composite materials, surface treatments, and engineered structures that maximize contact area while maintaining compatibility with liquid metals. These interface materials are particularly important in electronic cooling applications where efficient heat dissipation is critical for performance and reliability.

- Liquid metal cooling system designs: Advanced cooling system designs incorporate liquid metals as heat transfer media due to their superior thermal conductivity compared to conventional coolants. These systems include specialized pumps, heat exchangers, and flow channels designed to handle the unique properties of liquid metals. Innovations focus on preventing oxidation, managing the high density of liquid metals, and ensuring uniform flow distribution. System designs must account for the electrical conductivity of liquid metals, particularly in electronic cooling applications, to prevent short circuits and electrical interference.

- Additives and formulations for liquid metal coolants: Chemical additives and specialized formulations enhance the performance and compatibility of liquid metal coolants. These additives can modify surface tension, prevent oxidation, reduce corrosion, or improve wetting characteristics. Formulations may include surfactants, anti-oxidants, or other compounds that stabilize the liquid metal and improve its interaction with container materials. Research in this area aims to develop coolant compositions that maintain optimal thermal properties while minimizing compatibility issues with system components.

- Maintenance and handling procedures for liquid metal cooling systems: Specialized maintenance and handling procedures are essential for liquid metal cooling systems due to their unique properties and compatibility challenges. These procedures include methods for filling and draining systems, cleaning techniques, monitoring for contamination or degradation, and safety protocols. Proper handling is critical as many liquid metals react with moisture or oxygen, potentially causing system damage or safety hazards. Maintenance strategies focus on preventing oxidation, managing potential leaks, and ensuring long-term system reliability through regular inspection and preventive measures.

02 Liquid metal cooling system design considerations

Designing effective liquid metal cooling systems requires consideration of specific physical properties and behaviors of liquid metals. These include thermal conductivity, viscosity, wetting characteristics, and flow dynamics. Proper system design must account for heat transfer efficiency, pump compatibility, and thermal expansion. Specialized components such as heat exchangers, pumps, and flow channels need to be engineered to handle the unique properties of liquid metals, ensuring optimal cooling performance while preventing issues like metal freezing or channel blockage.Expand Specific Solutions03 Liquid metal alloy formulations for cooling applications

Various liquid metal alloy formulations have been developed specifically for cooling applications, each with distinct properties and compatibility profiles. These formulations typically include gallium-based alloys (such as galinstan), indium alloys, or other eutectic metal combinations with low melting points. The composition of these alloys can be tailored to achieve specific thermal conductivity, melting point, viscosity, and compatibility characteristics. Additives may be incorporated to improve wetting behavior, reduce oxidation, or enhance compatibility with container materials.Expand Specific Solutions04 Surface treatments and coatings for liquid metal compatibility

Surface treatments and specialized coatings can significantly improve compatibility between liquid metals and cooling system components. These treatments modify surface properties to prevent liquid metal penetration, reduce corrosion, or enhance wetting characteristics. Techniques include passivation layers, ceramic coatings, metal alloy treatments, and polymer barriers. The selection of appropriate surface treatments depends on the specific liquid metal composition, operating temperature range, and base material of the cooling system components.Expand Specific Solutions05 Thermal interface materials for liquid metal cooling

Specialized thermal interface materials (TIMs) have been developed to enhance heat transfer between heat sources and liquid metal cooling systems. These materials improve thermal conductivity at the interface while maintaining compatibility with liquid metals. Some TIMs incorporate liquid metal particles or are designed to work alongside liquid metal coolants without degradation. The development of compatible TIMs addresses challenges such as pump-out, dry-out, and long-term stability when used with liquid metal cooling solutions, particularly in high-performance computing and electronics applications.Expand Specific Solutions

Leading Organizations in Advanced Nuclear Cooling Research

The liquid metal cooling compatibility with advanced nuclear reactor fuels market is in an early growth phase, characterized by increasing research activities but limited commercial deployment. The global nuclear cooling technology market is projected to expand significantly as next-generation reactor designs gain traction. Key players demonstrate varying levels of technical maturity, with established entities like Westinghouse Electric, GE-Hitachi Nuclear Energy, and China General Nuclear Power leading research efforts. Chinese institutions, including China Nuclear Power Research & Design Institute and China Institute of Atomic Energy, are making substantial investments in this technology. Korean organizations (KAERI, KHNP) and European research bodies (CEA) are also advancing relevant cooling technologies. The competitive landscape reflects a mix of traditional nuclear power companies and specialized research institutes working to overcome material compatibility challenges.

Westinghouse Electric Co. LLC

Technical Solution: Westinghouse has developed advanced liquid metal cooling systems compatible with their EnCore accident tolerant fuel (ATF). Their technology utilizes lead-bismuth eutectic (LBE) as the primary coolant, which offers excellent neutron economy and high thermal conductivity. The company has conducted extensive research on the compatibility between their silicon carbide (SiC) cladding materials and liquid metal coolants, demonstrating minimal corrosion rates at operating temperatures up to 700°C [1]. Westinghouse's approach includes specialized surface treatments and coatings for fuel cladding to prevent liquid metal embrittlement and mass transfer issues. Their research has shown that properly engineered interfaces between LBE coolant and advanced fuel designs can maintain structural integrity for extended operational periods, with corrosion rates below 10 μm/year [3]. The company has also developed advanced monitoring systems to detect early signs of compatibility issues during reactor operation.

Strengths: Superior thermal efficiency compared to water cooling; ability to operate at atmospheric pressure reducing containment requirements; excellent neutron economy improving fuel utilization. Weaknesses: Challenges with oxygen control in the coolant system to prevent excessive oxidation; potential for coolant freezing during maintenance operations; limited operational experience in commercial settings compared to water-cooled systems.

GE-Hitachi Nuclear Energy Americas LLC

Technical Solution: GE-Hitachi has pioneered the PRISM (Power Reactor Innovative Small Module) technology, which utilizes liquid sodium as the primary coolant compatible with advanced metallic fuels. Their research focuses on the interaction between sodium coolant and U-Pu-Zr metallic fuel with HT-9 ferritic-martensitic steel cladding. The company has demonstrated fuel burnup capabilities exceeding 10 at% while maintaining excellent compatibility between the coolant and fuel system [2]. GE-Hitachi's approach includes engineered diffusion barriers between fuel and cladding to prevent the formation of low-melting-point eutectics, which has been a historical challenge in liquid metal cooled systems. Their sodium-bonded fuel design allows for excellent heat transfer while accommodating fuel swelling during irradiation. Recent advancements have focused on optimizing the sodium gap thickness between fuel and cladding to balance thermal performance with mechanical constraints during operation [4]. The company has accumulated over 30 years of experimental data on sodium-fuel compatibility through various test reactors.

Strengths: Exceptional heat transfer properties of liquid sodium; extensive operational experience from EBR-II and FFTF reactors; capability to achieve high burnup rates with metallic fuels. Weaknesses: Chemical reactivity of sodium with air and water requiring specialized handling systems; potential for fuel-cladding chemical interaction at high burnup; challenges with in-service inspection due to sodium opacity.

Critical Patents and Research on Liquid Metal-Fuel Interactions

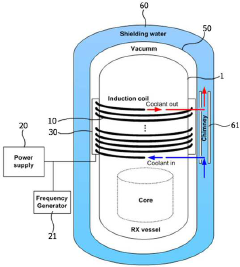

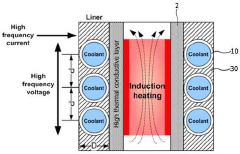

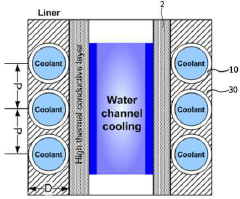

Heating and Cooling Combined System for Liquid Metal Cooled Nuclear Reactor Based on Induction Heating

PatentPendingKR1020210079952A

Innovation

- An induction heating-based reactor liquid metal heating and cooling system using an induction coil outside the reactor vessel, coupled with a high-frequency power supply, frequency generator, and cooling water supply, which prevents solidification and facilitates coolant flow through a flow path, ensuring safety and miniaturization.

Safety and Risk Assessment of Liquid Metal Cooled Reactors

Liquid metal cooled reactors (LMCRs) present unique safety challenges that require comprehensive risk assessment frameworks. The primary safety concern with these reactors involves the chemical reactivity of liquid metal coolants, particularly sodium and lead-bismuth eutectic (LBE), with air, water, and reactor structural materials. Sodium's violent reaction with water necessitates sophisticated leak detection systems and robust containment strategies to prevent potential hydrogen generation and subsequent explosions.

The compatibility between liquid metal coolants and advanced nuclear fuels introduces additional safety considerations. Material degradation mechanisms such as liquid metal embrittlement, corrosion, and erosion can compromise fuel cladding integrity, potentially leading to radioactive material release. Advanced fuels like metallic alloys, nitrides, and carbides exhibit different interaction behaviors with liquid metals compared to traditional oxide fuels, requiring tailored safety approaches.

Operational safety assessment must address thermal-hydraulic phenomena specific to liquid metals, including flow instabilities, natural circulation reliability, and coolant freezing prevention. The high thermal conductivity of liquid metals creates unique heat transfer characteristics that influence accident progression timelines and effectiveness of passive safety systems.

Risk assessment methodologies for LMCRs have evolved significantly, incorporating probabilistic safety assessment (PSA) techniques alongside deterministic analyses. Modern approaches utilize computational fluid dynamics (CFD) coupled with neutronics codes to model complex accident scenarios with higher fidelity than previously possible. These advanced modeling capabilities enable more accurate prediction of severe accident progression and consequences.

Regulatory frameworks for LMCR safety continue to develop internationally, with organizations like the IAEA, NRC, and various national regulatory bodies establishing specialized guidelines. These frameworks increasingly emphasize defense-in-depth strategies, focusing on inherent safety features that leverage the favorable thermal properties of liquid metals while mitigating their chemical risks.

Experience from historical LMCR operations, including incidents at facilities like Monju (Japan) and BN-series reactors (Russia), has informed current safety protocols. Lessons learned from these events highlight the importance of specialized operator training, robust instrumentation for coolant monitoring, and effective emergency response procedures tailored to liquid metal environments.

Future safety enhancements for liquid metal cooled systems will likely incorporate advanced materials with superior compatibility characteristics, improved instrumentation for early detection of potential issues, and refined passive safety systems that can maintain cooling without external intervention during beyond-design-basis events.

The compatibility between liquid metal coolants and advanced nuclear fuels introduces additional safety considerations. Material degradation mechanisms such as liquid metal embrittlement, corrosion, and erosion can compromise fuel cladding integrity, potentially leading to radioactive material release. Advanced fuels like metallic alloys, nitrides, and carbides exhibit different interaction behaviors with liquid metals compared to traditional oxide fuels, requiring tailored safety approaches.

Operational safety assessment must address thermal-hydraulic phenomena specific to liquid metals, including flow instabilities, natural circulation reliability, and coolant freezing prevention. The high thermal conductivity of liquid metals creates unique heat transfer characteristics that influence accident progression timelines and effectiveness of passive safety systems.

Risk assessment methodologies for LMCRs have evolved significantly, incorporating probabilistic safety assessment (PSA) techniques alongside deterministic analyses. Modern approaches utilize computational fluid dynamics (CFD) coupled with neutronics codes to model complex accident scenarios with higher fidelity than previously possible. These advanced modeling capabilities enable more accurate prediction of severe accident progression and consequences.

Regulatory frameworks for LMCR safety continue to develop internationally, with organizations like the IAEA, NRC, and various national regulatory bodies establishing specialized guidelines. These frameworks increasingly emphasize defense-in-depth strategies, focusing on inherent safety features that leverage the favorable thermal properties of liquid metals while mitigating their chemical risks.

Experience from historical LMCR operations, including incidents at facilities like Monju (Japan) and BN-series reactors (Russia), has informed current safety protocols. Lessons learned from these events highlight the importance of specialized operator training, robust instrumentation for coolant monitoring, and effective emergency response procedures tailored to liquid metal environments.

Future safety enhancements for liquid metal cooled systems will likely incorporate advanced materials with superior compatibility characteristics, improved instrumentation for early detection of potential issues, and refined passive safety systems that can maintain cooling without external intervention during beyond-design-basis events.

Regulatory Framework for Advanced Nuclear Cooling Technologies

The regulatory landscape for liquid metal cooling technologies in advanced nuclear reactors represents a complex framework that continues to evolve alongside technological innovations. Current regulatory bodies, including the Nuclear Regulatory Commission (NRC) in the United States, the International Atomic Energy Agency (IAEA), and various national nuclear safety authorities, have established guidelines primarily designed for traditional water-cooled reactors, creating significant regulatory gaps for liquid metal cooling systems.

These regulatory frameworks must address unique safety considerations associated with liquid metal coolants such as sodium, lead, and lead-bismuth eutectic (LBE). The chemical reactivity of sodium with water and air necessitates specialized containment protocols, while lead and LBE present different challenges related to corrosion management and activation product handling. Regulatory standards must account for these material-specific behaviors when interfacing with advanced nuclear fuels.

Material qualification standards represent a critical regulatory component, requiring extensive compatibility testing between liquid metal coolants and advanced fuel cladding materials. Current regulations mandate comprehensive corrosion testing, thermal cycling evaluation, and long-term stability assessment under radiation conditions. The qualification process typically requires demonstration of compatibility for the full operational lifetime of reactor components.

Licensing pathways for advanced reactor designs utilizing liquid metal cooling technologies have been streamlined in several jurisdictions through recent regulatory reforms. The NRC's Part 53 framework and similar initiatives in Canada, UK, and other nations have introduced technology-inclusive approaches that accommodate non-traditional cooling systems while maintaining rigorous safety standards.

International harmonization efforts are underway to develop consistent regulatory approaches for liquid metal cooled systems. The IAEA's initiatives on Small Modular Reactors (SMRs) and the Nuclear Energy Agency's working groups on liquid metal technologies aim to establish common safety principles and technical requirements across member states, facilitating global deployment of these advanced systems.

Emerging regulatory considerations include the development of specific standards for fuel-coolant interaction scenarios, operational limits for impurity control in liquid metal systems, and specialized inspection requirements for components exposed to liquid metal environments. These evolving regulations will significantly impact the design and operational parameters of advanced nuclear systems utilizing liquid metal cooling technologies.

These regulatory frameworks must address unique safety considerations associated with liquid metal coolants such as sodium, lead, and lead-bismuth eutectic (LBE). The chemical reactivity of sodium with water and air necessitates specialized containment protocols, while lead and LBE present different challenges related to corrosion management and activation product handling. Regulatory standards must account for these material-specific behaviors when interfacing with advanced nuclear fuels.

Material qualification standards represent a critical regulatory component, requiring extensive compatibility testing between liquid metal coolants and advanced fuel cladding materials. Current regulations mandate comprehensive corrosion testing, thermal cycling evaluation, and long-term stability assessment under radiation conditions. The qualification process typically requires demonstration of compatibility for the full operational lifetime of reactor components.

Licensing pathways for advanced reactor designs utilizing liquid metal cooling technologies have been streamlined in several jurisdictions through recent regulatory reforms. The NRC's Part 53 framework and similar initiatives in Canada, UK, and other nations have introduced technology-inclusive approaches that accommodate non-traditional cooling systems while maintaining rigorous safety standards.

International harmonization efforts are underway to develop consistent regulatory approaches for liquid metal cooled systems. The IAEA's initiatives on Small Modular Reactors (SMRs) and the Nuclear Energy Agency's working groups on liquid metal technologies aim to establish common safety principles and technical requirements across member states, facilitating global deployment of these advanced systems.

Emerging regulatory considerations include the development of specific standards for fuel-coolant interaction scenarios, operational limits for impurity control in liquid metal systems, and specialized inspection requirements for components exposed to liquid metal environments. These evolving regulations will significantly impact the design and operational parameters of advanced nuclear systems utilizing liquid metal cooling technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!