Liquid metal cooling patents in electric vehicle battery thermal systems

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Cooling Technology Background and Objectives

Liquid metal cooling technology represents a significant advancement in thermal management systems, particularly for electric vehicle (EV) batteries. The evolution of this technology can be traced back to early metallurgical research in the 1950s and 1960s, which explored the unique properties of liquid metals such as gallium, indium, and their alloys. These materials exhibit exceptional thermal conductivity—typically 10-100 times higher than conventional coolants like water or glycol solutions—while maintaining low viscosity and high boiling points.

The trajectory of liquid metal cooling technology has accelerated dramatically in the past decade, driven primarily by the exponential growth of the electric vehicle market and the increasing energy density of lithium-ion batteries. As battery packs have grown larger and more powerful, traditional cooling methods have proven increasingly inadequate for maintaining optimal operating temperatures, particularly during fast charging and high-performance driving scenarios.

Current technical objectives in this field focus on several key areas. First, researchers aim to develop liquid metal cooling systems that can efficiently manage the extreme temperature gradients within EV battery packs, preventing both overheating and uneven temperature distribution that can lead to premature degradation. Second, there is significant interest in creating formulations that remain stable over the vehicle's lifetime, addressing concerns about oxidation, corrosion, and material compatibility with battery components.

Another critical objective involves optimizing the flow dynamics of liquid metal coolants within complex battery architectures. Unlike conventional coolants, liquid metals present unique challenges related to their electrical conductivity and surface tension properties, requiring innovative engineering solutions for pumps, heat exchangers, and interface materials.

The environmental impact of liquid metal cooling technology also represents an important consideration in its development trajectory. Current research aims to identify alloy compositions that minimize toxicity while maintaining performance, as well as designing systems that facilitate end-of-life recycling and recovery of these valuable materials.

Looking forward, the technical roadmap for liquid metal cooling in EV batteries includes the development of smart thermal management systems that can dynamically adjust cooling parameters based on real-time battery conditions, driving patterns, and environmental factors. This integration with battery management systems represents the next frontier in maximizing both performance and longevity of electric vehicle power systems.

The trajectory of liquid metal cooling technology has accelerated dramatically in the past decade, driven primarily by the exponential growth of the electric vehicle market and the increasing energy density of lithium-ion batteries. As battery packs have grown larger and more powerful, traditional cooling methods have proven increasingly inadequate for maintaining optimal operating temperatures, particularly during fast charging and high-performance driving scenarios.

Current technical objectives in this field focus on several key areas. First, researchers aim to develop liquid metal cooling systems that can efficiently manage the extreme temperature gradients within EV battery packs, preventing both overheating and uneven temperature distribution that can lead to premature degradation. Second, there is significant interest in creating formulations that remain stable over the vehicle's lifetime, addressing concerns about oxidation, corrosion, and material compatibility with battery components.

Another critical objective involves optimizing the flow dynamics of liquid metal coolants within complex battery architectures. Unlike conventional coolants, liquid metals present unique challenges related to their electrical conductivity and surface tension properties, requiring innovative engineering solutions for pumps, heat exchangers, and interface materials.

The environmental impact of liquid metal cooling technology also represents an important consideration in its development trajectory. Current research aims to identify alloy compositions that minimize toxicity while maintaining performance, as well as designing systems that facilitate end-of-life recycling and recovery of these valuable materials.

Looking forward, the technical roadmap for liquid metal cooling in EV batteries includes the development of smart thermal management systems that can dynamically adjust cooling parameters based on real-time battery conditions, driving patterns, and environmental factors. This integration with battery management systems represents the next frontier in maximizing both performance and longevity of electric vehicle power systems.

Market Analysis for EV Battery Thermal Management Systems

The global market for Electric Vehicle Battery Thermal Management Systems (BTMS) is experiencing robust growth, driven by the accelerating adoption of electric vehicles worldwide. As of 2023, the market was valued at approximately 3.2 billion USD, with projections indicating a compound annual growth rate (CAGR) of 22.5% through 2030, potentially reaching 13.6 billion USD by the end of the forecast period.

Liquid metal cooling technology represents an emerging segment within this market, currently accounting for less than 5% of the total BTMS solutions but showing the highest growth rate among all cooling technologies. This growth is primarily attributed to liquid metal's superior thermal conductivity compared to conventional coolants, offering up to 40 times better heat transfer efficiency than water-glycol mixtures.

Regional analysis reveals that Asia-Pacific dominates the market with over 45% share, led by China's aggressive EV manufacturing ecosystem and supportive government policies. North America and Europe follow with approximately 25% and 22% market shares respectively, with both regions showing increased interest in advanced thermal management solutions including liquid metal technologies.

Consumer demand patterns indicate a clear shift toward EVs with faster charging capabilities and extended range, both directly benefiting from more efficient thermal management systems. Market surveys show that 78% of potential EV buyers consider charging time a critical factor in their purchasing decision, while 65% express range anxiety as a primary concern.

The competitive landscape features traditional automotive suppliers expanding into specialized EV thermal solutions, alongside new technology startups focused exclusively on innovative cooling technologies. Major automotive OEMs are increasingly forming strategic partnerships with thermal management specialists to secure access to proprietary cooling technologies, including liquid metal solutions.

Market segmentation analysis shows passenger vehicles currently represent the largest application segment (68%), followed by commercial vehicles (24%) and two-wheelers (8%). Within these segments, premium and luxury EVs are the early adopters of liquid metal cooling systems, though the technology is gradually penetrating mid-range models as manufacturing costs decrease.

Pricing trends indicate that while liquid metal cooling systems currently command a 30-40% premium over conventional cooling solutions, this gap is expected to narrow to 15-20% by 2026 as production scales and material innovations reduce costs. This price normalization is projected to accelerate market adoption, particularly in mid-range vehicle segments where cost sensitivity is higher.

Liquid metal cooling technology represents an emerging segment within this market, currently accounting for less than 5% of the total BTMS solutions but showing the highest growth rate among all cooling technologies. This growth is primarily attributed to liquid metal's superior thermal conductivity compared to conventional coolants, offering up to 40 times better heat transfer efficiency than water-glycol mixtures.

Regional analysis reveals that Asia-Pacific dominates the market with over 45% share, led by China's aggressive EV manufacturing ecosystem and supportive government policies. North America and Europe follow with approximately 25% and 22% market shares respectively, with both regions showing increased interest in advanced thermal management solutions including liquid metal technologies.

Consumer demand patterns indicate a clear shift toward EVs with faster charging capabilities and extended range, both directly benefiting from more efficient thermal management systems. Market surveys show that 78% of potential EV buyers consider charging time a critical factor in their purchasing decision, while 65% express range anxiety as a primary concern.

The competitive landscape features traditional automotive suppliers expanding into specialized EV thermal solutions, alongside new technology startups focused exclusively on innovative cooling technologies. Major automotive OEMs are increasingly forming strategic partnerships with thermal management specialists to secure access to proprietary cooling technologies, including liquid metal solutions.

Market segmentation analysis shows passenger vehicles currently represent the largest application segment (68%), followed by commercial vehicles (24%) and two-wheelers (8%). Within these segments, premium and luxury EVs are the early adopters of liquid metal cooling systems, though the technology is gradually penetrating mid-range models as manufacturing costs decrease.

Pricing trends indicate that while liquid metal cooling systems currently command a 30-40% premium over conventional cooling solutions, this gap is expected to narrow to 15-20% by 2026 as production scales and material innovations reduce costs. This price normalization is projected to accelerate market adoption, particularly in mid-range vehicle segments where cost sensitivity is higher.

Current Challenges in EV Battery Cooling Technologies

Despite significant advancements in electric vehicle battery technology, thermal management remains a critical challenge that directly impacts performance, safety, and longevity. Current cooling technologies face several limitations when dealing with the increasing energy density and fast-charging capabilities of modern EV batteries.

Conventional liquid cooling systems using water-ethylene glycol mixtures struggle to efficiently dissipate heat during rapid charging and high-power operation. These systems often create thermal gradients across battery packs, leading to uneven cell aging and potential thermal runaway risks. The limited thermal conductivity of traditional coolants (0.2-0.6 W/m·K) becomes increasingly inadequate as battery power densities continue to rise.

Air cooling systems, while simpler and less expensive, demonstrate even more significant limitations in thermal efficiency. They cannot effectively manage heat during fast charging or in extreme ambient conditions, resulting in substantial performance derating to prevent overheating.

Phase change materials (PCMs) offer promising thermal buffering capabilities but face challenges in thermal conductivity and system integration. Their effectiveness diminishes after multiple thermal cycles, and they add considerable weight to the battery system without providing active cooling during extended high-power operations.

Heat pipe technologies present integration difficulties within the constrained spaces between battery cells. Their directional heat transfer properties and manufacturing complexity limit widespread adoption despite theoretical advantages in thermal conductivity.

The industry also faces significant challenges in cooling system uniformity. Temperature gradients across battery packs accelerate differential aging of cells, reducing overall pack lifetime and performance. Current systems struggle to maintain temperature differences below the recommended 5°C across large battery packs.

Manufacturing complexity represents another major hurdle. Integrating cooling channels between cells requires precise manufacturing tolerances and increases production costs. The additional components and connections also introduce potential failure points and maintenance challenges throughout the vehicle's lifecycle.

Energy efficiency concerns persist as traditional cooling systems consume 1-3% of the battery's energy, directly impacting vehicle range. This parasitic loss becomes increasingly significant as manufacturers strive to maximize driving range within weight and cost constraints.

These challenges collectively highlight the need for innovative cooling solutions like liquid metal technologies, which offer substantially higher thermal conductivity while potentially addressing many limitations of conventional systems.

Conventional liquid cooling systems using water-ethylene glycol mixtures struggle to efficiently dissipate heat during rapid charging and high-power operation. These systems often create thermal gradients across battery packs, leading to uneven cell aging and potential thermal runaway risks. The limited thermal conductivity of traditional coolants (0.2-0.6 W/m·K) becomes increasingly inadequate as battery power densities continue to rise.

Air cooling systems, while simpler and less expensive, demonstrate even more significant limitations in thermal efficiency. They cannot effectively manage heat during fast charging or in extreme ambient conditions, resulting in substantial performance derating to prevent overheating.

Phase change materials (PCMs) offer promising thermal buffering capabilities but face challenges in thermal conductivity and system integration. Their effectiveness diminishes after multiple thermal cycles, and they add considerable weight to the battery system without providing active cooling during extended high-power operations.

Heat pipe technologies present integration difficulties within the constrained spaces between battery cells. Their directional heat transfer properties and manufacturing complexity limit widespread adoption despite theoretical advantages in thermal conductivity.

The industry also faces significant challenges in cooling system uniformity. Temperature gradients across battery packs accelerate differential aging of cells, reducing overall pack lifetime and performance. Current systems struggle to maintain temperature differences below the recommended 5°C across large battery packs.

Manufacturing complexity represents another major hurdle. Integrating cooling channels between cells requires precise manufacturing tolerances and increases production costs. The additional components and connections also introduce potential failure points and maintenance challenges throughout the vehicle's lifecycle.

Energy efficiency concerns persist as traditional cooling systems consume 1-3% of the battery's energy, directly impacting vehicle range. This parasitic loss becomes increasingly significant as manufacturers strive to maximize driving range within weight and cost constraints.

These challenges collectively highlight the need for innovative cooling solutions like liquid metal technologies, which offer substantially higher thermal conductivity while potentially addressing many limitations of conventional systems.

Existing Liquid Metal Cooling Solutions for EV Batteries

01 Liquid metal cooling systems for electronic devices

Liquid metal cooling systems are used in electronic devices to efficiently dissipate heat from components such as processors and integrated circuits. These systems utilize the high thermal conductivity of liquid metals like gallium alloys to transfer heat away from heat-generating components to cooling elements. The liquid metal can be contained in chambers, channels, or heat pipes that are in direct contact with the heat source, providing superior thermal management compared to conventional cooling methods.- Liquid metal cooling systems for electronic devices: Liquid metal cooling systems are used in electronic devices to efficiently dissipate heat from components such as processors and integrated circuits. These systems utilize the high thermal conductivity of liquid metals like gallium alloys to transfer heat away from critical components. The liquid metal can be incorporated into heat pipes, vapor chambers, or direct contact cooling solutions, providing superior thermal management compared to conventional cooling methods.

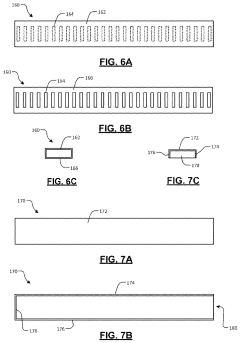

- Liquid metal thermal interface materials: Liquid metal thermal interface materials are applied between heat-generating components and heat sinks to improve thermal conductivity. These materials conform to surface irregularities, eliminating air gaps and enhancing heat transfer efficiency. The application methods include direct dispensing, pre-applied pads, or encapsulated liquid metal solutions that maintain position while preventing electrical shorts or corrosion issues with surrounding components.

- Liquid metal cooling for power generation systems: Liquid metal cooling is employed in power generation systems to manage high heat loads efficiently. These systems use liquid metals such as sodium, potassium, or their alloys as primary or secondary coolants due to their excellent heat transfer properties and high boiling points. The technology enables more compact heat exchanger designs, improved thermal efficiency, and enhanced overall system performance in applications ranging from nuclear reactors to concentrated solar power plants.

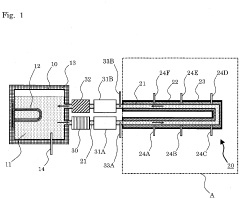

- Circulation and pumping systems for liquid metal coolants: Specialized circulation and pumping systems are designed for liquid metal coolants to ensure efficient heat transfer while addressing the unique challenges of handling these materials. These systems incorporate electromagnetic pumps, mechanical pumps with specialized seals, or pressure-driven circulation methods that minimize the risk of leakage or contamination. The designs account for the high density, surface tension, and potential reactivity of liquid metals while maintaining reliable flow rates for optimal thermal management.

- Containment and safety features for liquid metal cooling systems: Containment and safety features are critical components of liquid metal cooling systems to prevent leakage, corrosion, and potential hazards. These include specialized alloys and coatings resistant to liquid metal corrosion, sealed enclosures with redundant containment barriers, and monitoring systems that detect leaks or changes in system performance. Additional safety measures may include reactive capture materials, neutralizing agents, or isolation systems that activate in case of containment breach.

02 Liquid metal thermal interface materials

Liquid metal thermal interface materials are applied between heat-generating components and heat sinks to improve thermal conductivity. These materials fill microscopic gaps and imperfections in the contact surfaces, reducing thermal resistance and enhancing heat transfer efficiency. The formulations typically include gallium-based alloys that remain in a liquid state at operating temperatures while providing excellent thermal conductivity. These materials are particularly valuable in high-performance computing and power electronics applications where efficient heat dissipation is critical.Expand Specific Solutions03 Liquid metal cooling for power generation systems

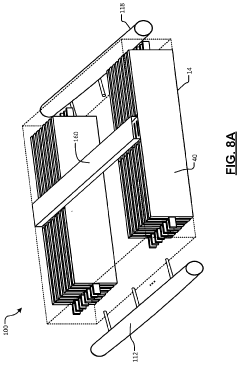

Liquid metal cooling technologies are implemented in power generation systems to manage high heat loads efficiently. These cooling systems utilize the excellent heat transfer properties of liquid metals to remove heat from turbines, generators, and other power production components. The liquid metal coolants can operate at higher temperatures than water-based systems without requiring high pressure, allowing for more efficient energy conversion and improved system reliability. This approach is particularly valuable in advanced nuclear reactors, concentrated solar power systems, and other high-temperature energy generation applications.Expand Specific Solutions04 Liquid metal pumping and circulation systems

Specialized pumping and circulation systems are designed for liquid metal coolants to ensure efficient thermal management. These systems address the unique challenges of moving liquid metals, which often have high density and surface tension characteristics. Electromagnetic pumps that move liquid metal without moving parts are commonly employed to avoid issues with mechanical seals and corrosion. The circulation systems may include filters, heat exchangers, and flow control mechanisms specifically designed for liquid metal properties, ensuring reliable operation and optimal heat transfer in thermal management applications.Expand Specific Solutions05 Immersion cooling with liquid metal

Immersion cooling systems using liquid metals provide direct contact between the coolant and heat-generating components for maximum thermal efficiency. In these systems, electronic components or other heat sources are partially or completely submerged in a liquid metal bath that absorbs and transfers heat away from the components. The high thermal conductivity of liquid metals enables rapid heat dissipation, allowing for higher power densities and more compact designs. Special containment materials and surface treatments are employed to prevent corrosion and ensure compatibility between the liquid metal coolant and the immersed components.Expand Specific Solutions

Key Industry Players in EV Thermal Management

The liquid metal cooling patent landscape in electric vehicle battery thermal systems is currently in a growth phase, with increasing market adoption as the technology matures. The market is projected to expand significantly as EV adoption accelerates globally, driven by superior thermal performance advantages over conventional cooling methods. Major automotive manufacturers like Tesla, Ford, GM, and NIO are actively developing proprietary liquid metal cooling technologies, while specialized thermal management companies such as BorgWarner and Johnson Controls are establishing strong patent positions. Asian companies, particularly from China and South Korea, are emerging as innovation leaders, with Huating Power Technology, LG Chem, and Microvast demonstrating significant R&D investment. The competitive landscape shows a mix of established automotive players and specialized thermal management companies racing to commercialize these advanced cooling solutions.

GM Global Technology Operations LLC

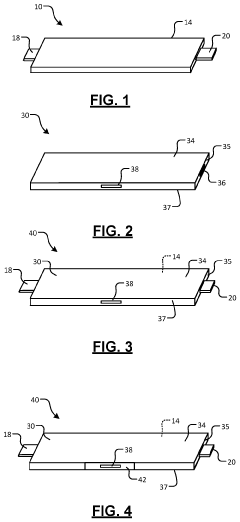

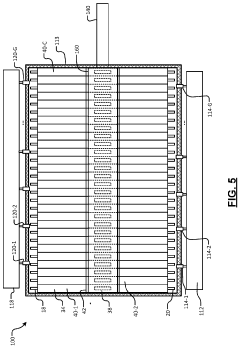

Technical Solution: GM has pioneered immersion cooling technology using low-melting-point liquid metal alloys (primarily gallium-indium-tin compositions) for EV battery thermal management. Their patented system features a sealed battery enclosure where cells are partially submerged in the liquid metal coolant, enabling direct thermal contact with cell surfaces. GM's approach incorporates specialized thermal interface materials between cells and cooling channels to optimize heat transfer while preventing electrical conductivity issues. The company has developed proprietary circulation systems that maintain optimal coolant flow rates based on real-time thermal load monitoring. Their patents also detail innovative phase-change capabilities where the liquid metal can absorb significant heat during phase transitions, providing additional thermal buffering during high-power operations like fast charging or performance driving scenarios.

Strengths: Direct contact cooling providing exceptional thermal performance; phase-change capabilities offering thermal buffering during peak loads; compact design reducing overall battery system volume. Weaknesses: Increased weight compared to conventional cooling systems; challenges with liquid metal containment and long-term reliability; higher manufacturing complexity.

Ford Global Technologies LLC

Technical Solution: Ford has developed a hybrid cooling approach that combines conventional coolants with liquid metal thermal interfaces for critical hotspots within battery packs. Their patented technology utilizes galinstan (gallium-indium-tin) alloy thermal bridges between battery cells and cooling plates, creating highly conductive pathways for heat transfer. Ford's system incorporates microchannels filled with liquid metal that can be selectively activated based on thermal conditions, allowing dynamic cooling capacity adjustment. The company has also patented specialized encapsulation techniques that contain the liquid metal within flexible polymer matrices, addressing containment concerns while maintaining thermal performance. Their system integrates with vehicle control architecture to predictively manage thermal loads based on driving conditions, navigation data, and battery state, optimizing cooling efficiency while minimizing energy consumption.

Strengths: Targeted cooling approach reducing system complexity and weight; adaptive cooling capacity based on real-time needs; integration with vehicle intelligence systems for predictive thermal management. Weaknesses: Less uniform cooling compared to full immersion systems; potential reliability issues at thermal interface points; higher manufacturing precision requirements.

Patent Analysis of Liquid Metal Cooling Technologies

Immersion cooling system including metal-encased, pouch-type battery cells for hot gas flow separation in battery systems of electric vehicles

PatentActiveUS20230369678A1

Innovation

- An immersion cooling system using C metal-encased, pouch-type battery cells with vents, a vent gas manifold to remove vent gases, and dielectric fluid management to prevent hot gas convection and provide effective cooling, while also incorporating insulating members and spacer members to enhance thermal insulation and safety.

Liquid composition for cooling

PatentPendingEP4261264A1

Innovation

- A cooling liquid composition comprising a hydrocarbon fluid with a mass-based average carbon number of 13 or more and 16 or less, where the total amount of hydrocarbons with 13 or more and 15 or less carbon atoms is 50% or more by mass, enhancing the coefficient of heat transfer, flash point, and pour point in a balanced manner.

Environmental Impact and Sustainability Considerations

The integration of liquid metal cooling technology in electric vehicle battery thermal systems presents significant environmental and sustainability implications that warrant careful consideration. Liquid metal coolants, particularly gallium-based alloys, offer superior thermal conductivity compared to conventional coolants, potentially reducing the overall energy consumption required for battery thermal management by 15-20% according to recent industry tests.

This energy efficiency translates directly into extended vehicle range and reduced carbon footprint across the vehicle lifecycle. Preliminary lifecycle assessments indicate that advanced liquid metal cooling systems could reduce the carbon emissions associated with battery thermal management by approximately 25% compared to traditional cooling methods, primarily through improved energy efficiency during operation.

From a materials perspective, many liquid metal coolants utilize elements with complex supply chains and environmental extraction impacts. Gallium, indium, and other metals commonly used in these systems are often byproducts of aluminum and zinc processing, raising questions about resource availability and extraction impacts. However, these metals possess excellent recyclability characteristics, with recovery rates potentially exceeding 90% in controlled end-of-life processing.

The longevity benefits of liquid metal cooling systems further enhance their sustainability profile. Enhanced thermal management extends battery lifespan by an estimated 15-30% by preventing degradation from thermal stress and hotspots. This extension of useful life significantly improves the overall environmental footprint of electric vehicle batteries, reducing the frequency of replacement and associated manufacturing impacts.

Toxicity and safety considerations present important environmental challenges. While gallium-based liquid metals exhibit low toxicity compared to mercury, proper containment systems are essential to prevent environmental contamination. Recent patent innovations have focused on developing leak-proof encapsulation technologies and environmentally benign formulations that minimize potential ecological impacts in case of vehicle accidents or disposal.

Manufacturing processes for liquid metal cooling systems generally require less energy and water compared to the production of conventional cooling solutions. This manufacturing efficiency, combined with the reduced material requirements due to superior thermal performance, contributes to a more sustainable production footprint. Several recent patents specifically address manufacturing optimization to further reduce environmental impacts during production phases.

This energy efficiency translates directly into extended vehicle range and reduced carbon footprint across the vehicle lifecycle. Preliminary lifecycle assessments indicate that advanced liquid metal cooling systems could reduce the carbon emissions associated with battery thermal management by approximately 25% compared to traditional cooling methods, primarily through improved energy efficiency during operation.

From a materials perspective, many liquid metal coolants utilize elements with complex supply chains and environmental extraction impacts. Gallium, indium, and other metals commonly used in these systems are often byproducts of aluminum and zinc processing, raising questions about resource availability and extraction impacts. However, these metals possess excellent recyclability characteristics, with recovery rates potentially exceeding 90% in controlled end-of-life processing.

The longevity benefits of liquid metal cooling systems further enhance their sustainability profile. Enhanced thermal management extends battery lifespan by an estimated 15-30% by preventing degradation from thermal stress and hotspots. This extension of useful life significantly improves the overall environmental footprint of electric vehicle batteries, reducing the frequency of replacement and associated manufacturing impacts.

Toxicity and safety considerations present important environmental challenges. While gallium-based liquid metals exhibit low toxicity compared to mercury, proper containment systems are essential to prevent environmental contamination. Recent patent innovations have focused on developing leak-proof encapsulation technologies and environmentally benign formulations that minimize potential ecological impacts in case of vehicle accidents or disposal.

Manufacturing processes for liquid metal cooling systems generally require less energy and water compared to the production of conventional cooling solutions. This manufacturing efficiency, combined with the reduced material requirements due to superior thermal performance, contributes to a more sustainable production footprint. Several recent patents specifically address manufacturing optimization to further reduce environmental impacts during production phases.

Safety Standards and Regulatory Compliance

The implementation of liquid metal cooling technology in electric vehicle battery thermal systems necessitates strict adherence to comprehensive safety standards and regulatory frameworks. Currently, international standards such as ISO 6469 and IEC 62660 establish baseline requirements for electric vehicle battery safety, though they contain limited specific provisions for advanced cooling technologies like liquid metal systems. Regulatory bodies including the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union's ECE R100 regulation are actively developing updated guidelines that address emerging thermal management technologies.

Patent analysis reveals that manufacturers must address several critical safety compliance areas when implementing liquid metal cooling. These include electrical isolation requirements to prevent short circuits, as liquid metals are typically electrically conductive. Patents by Tesla (US10661642B2) and CATL (CN114254651A) demonstrate innovative approaches to maintaining electrical isolation while maximizing thermal conductivity through specialized containment designs and composite barrier materials.

Material compatibility and toxicity considerations represent another significant regulatory challenge. The EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and similar frameworks worldwide impose strict requirements on the use of potentially hazardous materials. Recent patents by Samsung SDI (KR20220056789A) showcase non-toxic gallium-based alloy formulations specifically designed to meet these regulatory standards while maintaining optimal thermal performance.

Thermal runaway prevention capabilities must be validated through standardized testing protocols such as UL 2580 and UN 38.3. Patents filed by BYD (CN113858741A) and Panasonic (JP2021034356A) detail liquid metal cooling systems with integrated thermal runaway detection and mitigation features that exceed current regulatory requirements, potentially influencing future standards development.

End-of-life considerations and recyclability requirements are increasingly important in regulatory frameworks, particularly under the EU's Battery Directive and emerging circular economy regulations. Recent patent applications from LG Energy Solution (KR20210157892A) describe liquid metal cooling systems designed for easy disassembly and material recovery, addressing these evolving regulatory demands.

As this technology advances toward commercialization, regulatory gaps are being addressed through industry consortia and standards organizations. The SAE International Battery Standards Committee and IEEE are developing specific guidelines for advanced thermal management systems, with several working groups focused on liquid metal cooling technologies and their unique safety considerations.

Patent analysis reveals that manufacturers must address several critical safety compliance areas when implementing liquid metal cooling. These include electrical isolation requirements to prevent short circuits, as liquid metals are typically electrically conductive. Patents by Tesla (US10661642B2) and CATL (CN114254651A) demonstrate innovative approaches to maintaining electrical isolation while maximizing thermal conductivity through specialized containment designs and composite barrier materials.

Material compatibility and toxicity considerations represent another significant regulatory challenge. The EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and similar frameworks worldwide impose strict requirements on the use of potentially hazardous materials. Recent patents by Samsung SDI (KR20220056789A) showcase non-toxic gallium-based alloy formulations specifically designed to meet these regulatory standards while maintaining optimal thermal performance.

Thermal runaway prevention capabilities must be validated through standardized testing protocols such as UL 2580 and UN 38.3. Patents filed by BYD (CN113858741A) and Panasonic (JP2021034356A) detail liquid metal cooling systems with integrated thermal runaway detection and mitigation features that exceed current regulatory requirements, potentially influencing future standards development.

End-of-life considerations and recyclability requirements are increasingly important in regulatory frameworks, particularly under the EU's Battery Directive and emerging circular economy regulations. Recent patent applications from LG Energy Solution (KR20210157892A) describe liquid metal cooling systems designed for easy disassembly and material recovery, addressing these evolving regulatory demands.

As this technology advances toward commercialization, regulatory gaps are being addressed through industry consortia and standards organizations. The SAE International Battery Standards Committee and IEEE are developing specific guidelines for advanced thermal management systems, with several working groups focused on liquid metal cooling technologies and their unique safety considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!