Liquid metal cooling qualification standards in nuclear safety regulations

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Cooling Technology Background and Objectives

Liquid metal cooling technology has evolved significantly since its inception in the 1950s, primarily driven by the nuclear industry's need for efficient heat transfer systems. Initially developed for fast breeder reactors, liquid metals such as sodium, lead, lead-bismuth eutectic (LBE), and more recently gallium alloys have been utilized due to their exceptional thermal conductivity properties and low vapor pressure at high temperatures. These characteristics enable operation at atmospheric pressure while achieving high power density, making them particularly valuable for nuclear applications.

The historical progression of liquid metal cooling technology has been marked by significant milestones, including the operation of experimental reactors like EBR-I and EBR-II in the United States, BN-series reactors in Russia, and Phénix and Superphénix in France. These implementations have provided valuable operational experience while simultaneously highlighting challenges related to safety standards and qualification protocols.

Current technological trends indicate a renewed interest in liquid metal cooling systems, particularly for Generation IV nuclear reactors and small modular reactors (SMRs). This resurgence is driven by the inherent safety features and improved efficiency these cooling systems offer compared to traditional water-cooled reactors. The technology is evolving toward enhanced safety features, improved materials compatibility, and more sophisticated monitoring systems to address historical concerns regarding reactivity with water and air.

The primary technical objectives for liquid metal cooling qualification standards include establishing comprehensive safety parameters that address the unique properties of different liquid metal coolants. These standards must encompass normal operation conditions, anticipated operational occurrences, and design basis accidents specific to liquid metal systems. Additionally, there is a critical need to harmonize qualification standards internationally to facilitate global deployment of this technology.

Another key objective is developing robust testing methodologies that can accurately predict long-term behavior of materials in liquid metal environments, particularly under radiation exposure. This includes standardized protocols for assessing corrosion resistance, mechanical property degradation, and component reliability over the projected operational lifetime of nuclear facilities.

Furthermore, the technology aims to integrate advanced monitoring and control systems that can provide real-time data on coolant chemistry, flow parameters, and early detection of potential anomalies. These systems must be qualified to operate reliably in the harsh environments typical of nuclear applications while meeting increasingly stringent regulatory requirements for nuclear safety.

The historical progression of liquid metal cooling technology has been marked by significant milestones, including the operation of experimental reactors like EBR-I and EBR-II in the United States, BN-series reactors in Russia, and Phénix and Superphénix in France. These implementations have provided valuable operational experience while simultaneously highlighting challenges related to safety standards and qualification protocols.

Current technological trends indicate a renewed interest in liquid metal cooling systems, particularly for Generation IV nuclear reactors and small modular reactors (SMRs). This resurgence is driven by the inherent safety features and improved efficiency these cooling systems offer compared to traditional water-cooled reactors. The technology is evolving toward enhanced safety features, improved materials compatibility, and more sophisticated monitoring systems to address historical concerns regarding reactivity with water and air.

The primary technical objectives for liquid metal cooling qualification standards include establishing comprehensive safety parameters that address the unique properties of different liquid metal coolants. These standards must encompass normal operation conditions, anticipated operational occurrences, and design basis accidents specific to liquid metal systems. Additionally, there is a critical need to harmonize qualification standards internationally to facilitate global deployment of this technology.

Another key objective is developing robust testing methodologies that can accurately predict long-term behavior of materials in liquid metal environments, particularly under radiation exposure. This includes standardized protocols for assessing corrosion resistance, mechanical property degradation, and component reliability over the projected operational lifetime of nuclear facilities.

Furthermore, the technology aims to integrate advanced monitoring and control systems that can provide real-time data on coolant chemistry, flow parameters, and early detection of potential anomalies. These systems must be qualified to operate reliably in the harsh environments typical of nuclear applications while meeting increasingly stringent regulatory requirements for nuclear safety.

Nuclear Industry Demand for Advanced Cooling Solutions

The nuclear industry has witnessed a significant shift towards advanced cooling technologies in recent years, driven by the need for enhanced safety, efficiency, and operational longevity of nuclear power plants. Liquid metal cooling systems, particularly those utilizing sodium, lead, or lead-bismuth eutectic (LBE), have emerged as promising alternatives to conventional water-based cooling systems for next-generation nuclear reactors.

The demand for these advanced cooling solutions stems primarily from the inherent limitations of water-based systems in high-temperature applications. Generation IV nuclear reactor designs, including fast neutron reactors and small modular reactors (SMRs), require cooling systems capable of operating at temperatures exceeding 500°C while maintaining low pressure conditions. Liquid metals offer superior thermal conductivity and natural circulation capabilities that address these requirements effectively.

Safety considerations represent another critical driver for liquid metal cooling adoption. Following the Fukushima Daiichi accident in 2011, regulatory bodies worldwide have intensified their focus on passive safety systems that can function without external power sources during emergency situations. Liquid metal coolants provide advantageous natural circulation properties that enhance passive safety features, reducing reliance on active cooling systems during abnormal operating conditions.

Economic factors also contribute significantly to the growing interest in liquid metal cooling technologies. The nuclear industry faces intense competition from other energy sources, particularly natural gas and renewables. Advanced cooling systems that improve thermal efficiency can potentially reduce the levelized cost of electricity (LCOE) from nuclear power plants, enhancing their economic competitiveness in increasingly deregulated energy markets.

Operational flexibility represents another market demand driving liquid metal cooling adoption. As power grids incorporate higher percentages of intermittent renewable energy sources, nuclear plants are increasingly required to operate in load-following modes rather than solely as baseload providers. Liquid metal cooling systems offer improved transient response characteristics that better accommodate these changing operational requirements.

The extended plant lifetime potential offered by liquid metal cooling systems also addresses a key industry need. With many existing nuclear facilities approaching or exceeding their originally planned operational lifespans, technologies that can extend service life while maintaining safety margins have become increasingly valuable. Liquid metal coolants typically cause less corrosion and mechanical stress on primary system components, potentially extending operational lifetimes.

Research institutions and regulatory bodies are responding to these market demands by developing comprehensive qualification standards for liquid metal cooling systems that address their unique properties while ensuring they meet or exceed existing safety requirements for nuclear applications.

The demand for these advanced cooling solutions stems primarily from the inherent limitations of water-based systems in high-temperature applications. Generation IV nuclear reactor designs, including fast neutron reactors and small modular reactors (SMRs), require cooling systems capable of operating at temperatures exceeding 500°C while maintaining low pressure conditions. Liquid metals offer superior thermal conductivity and natural circulation capabilities that address these requirements effectively.

Safety considerations represent another critical driver for liquid metal cooling adoption. Following the Fukushima Daiichi accident in 2011, regulatory bodies worldwide have intensified their focus on passive safety systems that can function without external power sources during emergency situations. Liquid metal coolants provide advantageous natural circulation properties that enhance passive safety features, reducing reliance on active cooling systems during abnormal operating conditions.

Economic factors also contribute significantly to the growing interest in liquid metal cooling technologies. The nuclear industry faces intense competition from other energy sources, particularly natural gas and renewables. Advanced cooling systems that improve thermal efficiency can potentially reduce the levelized cost of electricity (LCOE) from nuclear power plants, enhancing their economic competitiveness in increasingly deregulated energy markets.

Operational flexibility represents another market demand driving liquid metal cooling adoption. As power grids incorporate higher percentages of intermittent renewable energy sources, nuclear plants are increasingly required to operate in load-following modes rather than solely as baseload providers. Liquid metal cooling systems offer improved transient response characteristics that better accommodate these changing operational requirements.

The extended plant lifetime potential offered by liquid metal cooling systems also addresses a key industry need. With many existing nuclear facilities approaching or exceeding their originally planned operational lifespans, technologies that can extend service life while maintaining safety margins have become increasingly valuable. Liquid metal coolants typically cause less corrosion and mechanical stress on primary system components, potentially extending operational lifetimes.

Research institutions and regulatory bodies are responding to these market demands by developing comprehensive qualification standards for liquid metal cooling systems that address their unique properties while ensuring they meet or exceed existing safety requirements for nuclear applications.

Current Status and Technical Challenges in Liquid Metal Cooling

Liquid metal cooling technology in nuclear reactors has evolved significantly since its inception in the 1950s. Currently, several countries including Russia, China, India, and Japan are actively developing and deploying liquid metal cooled reactors. The predominant liquid metals used are sodium, lead, lead-bismuth eutectic (LBE), and to a lesser extent, mercury and gallium. Sodium-cooled fast reactors (SFRs) represent the most mature technology, with Russia's BN-series reactors having accumulated over 200 reactor-years of operational experience.

Despite this progress, significant technical challenges persist in liquid metal cooling systems. Corrosion and material compatibility remain primary concerns, particularly in lead and LBE systems where structural materials can experience severe degradation through dissolution and liquid metal embrittlement. Sodium's high chemical reactivity with water and air necessitates sophisticated safety systems to prevent and mitigate potential reactions, which can be exothermic and generate hydrogen.

Instrumentation and monitoring present another substantial challenge. The opacity of liquid metals complicates visual inspection and maintenance procedures, requiring advanced ultrasonic or electromagnetic techniques for in-service inspection. Additionally, reliable sensors for continuous monitoring of oxygen content, impurities, and flow characteristics in high-temperature liquid metal environments are still under development.

Heat transfer optimization faces challenges related to the formation of oxide layers in liquid metal systems, which can impede thermal conductivity. The management of frozen metal during startup or shutdown operations requires specialized heating systems and operational protocols to prevent blockages in coolant channels.

Internationally, qualification standards for liquid metal cooling systems vary significantly. The Russian Federation has the most comprehensive regulatory framework for sodium-cooled systems, while standards for lead and LBE systems remain less developed. The IAEA has initiated efforts to harmonize these standards, but a unified international approach is still emerging.

In the United States, the Nuclear Regulatory Commission (NRC) is developing advanced reactor design criteria that include provisions for liquid metal cooled systems, though these are not yet finalized. The European Nuclear Safety Regulators Group (ENSREG) has established working groups to address regulatory gaps for Generation IV reactors, including those using liquid metal coolants.

The qualification of computational fluid dynamics (CFD) codes for liquid metal systems presents additional challenges due to the unique thermophysical properties of these coolants and complex phenomena such as thermal stratification and natural circulation under various operational conditions.

Despite this progress, significant technical challenges persist in liquid metal cooling systems. Corrosion and material compatibility remain primary concerns, particularly in lead and LBE systems where structural materials can experience severe degradation through dissolution and liquid metal embrittlement. Sodium's high chemical reactivity with water and air necessitates sophisticated safety systems to prevent and mitigate potential reactions, which can be exothermic and generate hydrogen.

Instrumentation and monitoring present another substantial challenge. The opacity of liquid metals complicates visual inspection and maintenance procedures, requiring advanced ultrasonic or electromagnetic techniques for in-service inspection. Additionally, reliable sensors for continuous monitoring of oxygen content, impurities, and flow characteristics in high-temperature liquid metal environments are still under development.

Heat transfer optimization faces challenges related to the formation of oxide layers in liquid metal systems, which can impede thermal conductivity. The management of frozen metal during startup or shutdown operations requires specialized heating systems and operational protocols to prevent blockages in coolant channels.

Internationally, qualification standards for liquid metal cooling systems vary significantly. The Russian Federation has the most comprehensive regulatory framework for sodium-cooled systems, while standards for lead and LBE systems remain less developed. The IAEA has initiated efforts to harmonize these standards, but a unified international approach is still emerging.

In the United States, the Nuclear Regulatory Commission (NRC) is developing advanced reactor design criteria that include provisions for liquid metal cooled systems, though these are not yet finalized. The European Nuclear Safety Regulators Group (ENSREG) has established working groups to address regulatory gaps for Generation IV reactors, including those using liquid metal coolants.

The qualification of computational fluid dynamics (CFD) codes for liquid metal systems presents additional challenges due to the unique thermophysical properties of these coolants and complex phenomena such as thermal stratification and natural circulation under various operational conditions.

Current Qualification Standards for Liquid Metal Coolants

01 Thermal performance standards for liquid metal cooling systems

Qualification standards for liquid metal cooling systems include specific thermal performance metrics that must be met. These standards define acceptable temperature ranges, heat dissipation rates, and thermal conductivity requirements for liquid metal coolants. Testing procedures involve measuring the cooling efficiency under various load conditions and ensuring consistent performance across operating environments. These standards help ensure that liquid metal cooling solutions provide reliable thermal management for electronic components.- Thermal performance standards for liquid metal cooling systems: Qualification standards for liquid metal cooling systems include specific thermal performance metrics that must be met. These standards define acceptable temperature ranges, heat dissipation capabilities, and thermal conductivity requirements. Testing procedures involve measuring heat transfer efficiency under various operating conditions and ensuring consistent cooling performance across different thermal loads. These standards help ensure that liquid metal cooling solutions provide reliable thermal management for electronic components.

- Safety and material compatibility requirements: Liquid metal cooling systems must meet strict safety and material compatibility standards. These include requirements for non-toxicity, electrical isolation, corrosion resistance, and long-term stability when in contact with various metals and components. Qualification testing involves accelerated aging tests, chemical reactivity assessments, and evaluation of galvanic corrosion potential. Standards also address containment requirements to prevent leakage and specify compatible materials for system components that come into direct contact with the liquid metal coolant.

- Reliability and durability certification: Qualification standards for liquid metal cooling systems include comprehensive reliability and durability testing. These standards specify requirements for operational lifespan, performance under thermal cycling, resistance to pump failure, and maintenance of cooling efficiency over time. Testing protocols involve subjecting systems to extreme operating conditions, vibration testing, and long-term performance monitoring. Certification processes ensure that liquid metal cooling solutions maintain their effectiveness throughout the expected service life of the devices they cool.

- Manufacturing and quality control standards: Liquid metal cooling systems must adhere to strict manufacturing and quality control standards. These include specifications for production consistency, purity levels of liquid metal coolants, assembly tolerances, and quality assurance testing. Standards define acceptable contamination limits, mixing procedures for multi-component liquid metals, and inspection methods to verify proper system assembly. Manufacturing facilities must implement specific quality control processes to ensure that each cooling system meets the required performance and safety specifications.

- Environmental compliance and disposal regulations: Qualification standards for liquid metal cooling systems include environmental compliance requirements throughout the product lifecycle. These standards address the environmental impact of manufacturing processes, operational emissions, and end-of-life disposal procedures. Testing protocols verify that liquid metal coolants and system components comply with regulations regarding hazardous materials, recyclability, and waste management. Certification may require documentation of environmentally responsible manufacturing practices and established procedures for the safe disposal or recycling of liquid metal cooling systems.

02 Safety and compatibility qualification requirements

Liquid metal cooling systems must meet strict safety and material compatibility standards. These include corrosion resistance testing, electrical conductivity assessments, and material interaction evaluations to prevent system damage. Standards specify acceptable levels of reactivity between the liquid metal and container materials, as well as safety protocols for handling potentially hazardous coolants. Qualification processes also include leak detection methodologies and containment requirements to prevent environmental contamination or system failures.Expand Specific Solutions03 Reliability and longevity testing standards

Standards for liquid metal cooling systems include comprehensive reliability and longevity testing requirements. These involve accelerated aging tests, thermal cycling evaluations, and long-term performance stability assessments. Qualification procedures specify minimum operational lifespans, acceptable degradation rates, and maintenance intervals. Testing protocols also address pump reliability, flow consistency, and system integrity under various environmental conditions to ensure the cooling solution maintains effectiveness throughout its intended service life.Expand Specific Solutions04 Quality control and manufacturing standards

Manufacturing and quality control standards for liquid metal cooling systems establish requirements for production consistency, material purity, and assembly techniques. These standards define acceptable impurity levels in liquid metal coolants, precision requirements for cooling channels, and quality assurance testing methodologies. Qualification processes include batch testing procedures, statistical quality control methods, and documentation requirements to ensure manufacturing consistency. Standards also address packaging, transportation, and storage requirements to maintain product integrity.Expand Specific Solutions05 Environmental and regulatory compliance standards

Liquid metal cooling systems must meet environmental and regulatory compliance standards that govern their use, disposal, and environmental impact. These standards specify acceptable emissions levels, recycling requirements, and hazardous material handling protocols. Qualification processes include environmental impact assessments, compliance with electronic waste regulations, and documentation of material safety data. Standards also address energy efficiency requirements, sustainable manufacturing practices, and end-of-life management to minimize environmental footprint.Expand Specific Solutions

Key Industry Players in Nuclear Cooling Systems

The liquid metal cooling qualification standards in nuclear safety regulations are evolving within a maturing industry, with the global market for nuclear safety technologies estimated at several billion dollars. The technology is approaching commercial readiness, with key players demonstrating varying levels of expertise. Established organizations like Commissariat à l'énergie atomique, Westinghouse Electric, and GE-Hitachi Nuclear Energy lead with extensive R&D capabilities, while China's growing nuclear sector includes significant contributions from China General Nuclear Power Corp and China Nuclear Power Engineering. Japanese firms like Mitsubishi Heavy Industries and European entities such as Électricité de France are advancing specialized cooling technologies, creating a competitive landscape where regulatory compliance and safety innovation drive market positioning.

Westinghouse Electric Co. LLC

Technical Solution: Westinghouse has developed comprehensive liquid metal cooling qualification standards for nuclear applications, particularly focusing on lead-bismuth eutectic (LBE) and sodium-based coolants. Their approach includes rigorous materials compatibility testing protocols that evaluate corrosion resistance under various temperature and flow conditions. Westinghouse's qualification framework incorporates accelerated aging tests to simulate decades of operational exposure, with particular attention to structural integrity at temperatures exceeding 500°C. Their standards address oxygen control systems that maintain optimal oxygen concentration to minimize corrosion while preventing oxide formation that could impede heat transfer. The company has established specific guidelines for coolant chemistry monitoring, including real-time impurity detection systems and periodic sampling protocols to ensure compliance with safety parameters throughout the reactor lifecycle. Westinghouse's qualification standards also cover seismic qualification of liquid metal cooling systems, with specialized testing for pump reliability and flow stability under accident scenarios.

Strengths: Extensive operational experience with various coolant technologies and comprehensive testing facilities allow for realistic qualification scenarios. Their standards benefit from decades of nuclear safety regulatory compliance expertise. Weaknesses: Their qualification standards may be overly conservative in some areas, potentially increasing implementation costs, and their approach sometimes lacks flexibility for novel liquid metal coolant compositions.

GE-Hitachi Nuclear Energy Americas LLC

Technical Solution: GE-Hitachi has pioneered PRISM (Power Reactor Innovative Small Module) technology utilizing sodium as a liquid metal coolant, with qualification standards that exceed conventional regulatory requirements. Their qualification framework addresses the unique challenges of sodium coolant, including specialized instrumentation for detecting sodium-water reactions and hydrogen generation. GE-Hitachi's standards incorporate detailed thermal-hydraulic validation protocols that verify cooling efficiency across normal operations and accident scenarios, with particular emphasis on natural circulation capabilities during loss of power events. Their qualification process includes specialized materials testing for high-temperature sodium environments, evaluating factors such as mass transfer effects, thermal aging, and irradiation-assisted stress corrosion cracking. The company has developed specific standards for sodium purification systems, with stringent requirements for oxygen and carbon impurity levels below 2 ppm to prevent corrosion. Their qualification standards also address freeze-thaw cycling effects on system components and specialized inspection techniques for sodium-wetted surfaces.

Strengths: Their standards benefit from extensive sodium-cooled reactor operating experience and incorporate lessons from EBR-II and other experimental reactors. Their qualification approach includes advanced modeling capabilities that reduce physical testing requirements. Weaknesses: Their standards are heavily focused on sodium systems with less coverage of other liquid metal coolants, and implementation requires specialized expertise that may not be widely available in the industry.

Critical Technical Specifications and Safety Parameters

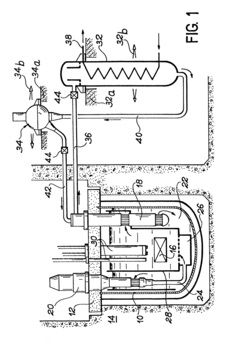

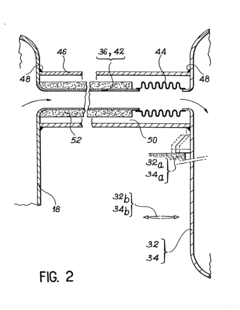

Cooling system for a nuclear reactor cooled with a liquid metal

PatentInactiveEP0114545A1

Innovation

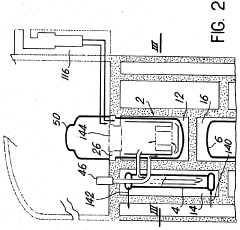

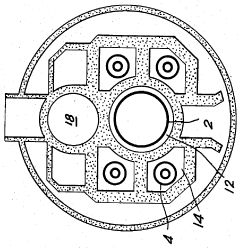

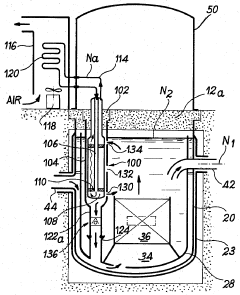

- A cooling circuit design with at least one fixed and one movably supported component, connected by a thin-walled pipe with an expansion compensator and a rigid, sealed outer casing that transmits forces and reduces thermal stresses, allowing for compact and reliable circuits.

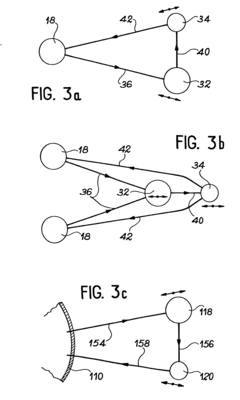

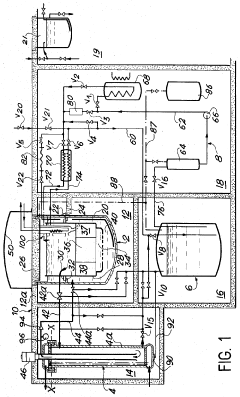

Liquid metal cooled nuclear reactor

PatentInactiveUS4382907A

Innovation

- A semi-integrated nuclear steam supply system design that eliminates the intermediate liquid metal circuit, using a reactor vessel with a primary vessel for neutron shielding and heat exchange, and an external heat exchanger for direct heat transfer between liquid metal and water, with a main storage tank and inert gas system to maintain pressure and safety, and a containment structure for biological and external impact protection.

Regulatory Framework and Compliance Requirements

The regulatory landscape for liquid metal cooling systems in nuclear facilities is governed by a complex framework of international standards, national regulations, and industry-specific guidelines. The International Atomic Energy Agency (IAEA) provides foundational safety standards through its Nuclear Safety Standards Series, which establishes fundamental principles for nuclear safety management. These standards serve as reference points for national regulatory bodies when developing country-specific requirements for liquid metal cooled reactors.

In the United States, the Nuclear Regulatory Commission (NRC) has established specific regulatory guides and technical requirements for non-light water reactors, including those utilizing liquid metal cooling technologies. The 10 CFR Part 50 and 10 CFR Part 52 provide the regulatory basis for licensing and safety requirements, while NUREG documents offer detailed technical guidance for compliance verification.

The European regulatory framework is coordinated through the Western European Nuclear Regulators Association (WENRA), which has developed harmonized safety reference levels. The European Nuclear Safety Regulators Group (ENSREG) further supports consistency in regulatory approaches across member states, particularly important for advanced reactor designs using liquid metal coolants.

Compliance requirements for liquid metal cooling systems focus on several critical areas. Coolant chemistry control specifications are stringent, requiring continuous monitoring systems and strict impurity limits to prevent corrosion and maintain heat transfer efficiency. Material qualification standards mandate extensive testing under representative conditions, including compatibility with liquid metals at operating temperatures and radiation environments.

Safety analysis requirements necessitate comprehensive accident scenario modeling specific to liquid metal systems, including considerations for coolant freezing, fire hazards, and potential chemical reactions. Instrumentation and control systems must meet redundancy and diversity requirements while functioning reliably in high-temperature liquid metal environments.

Containment design criteria address unique challenges posed by liquid metal coolants, particularly regarding potential chemical reactions with air, water, or concrete. In-service inspection protocols require specialized techniques for components submerged in opaque liquid metals, often utilizing ultrasonic or electromagnetic methods rather than visual inspection.

Operational procedures must incorporate specific emergency response protocols for liquid metal leaks and fires, with specialized training requirements for personnel. The qualification process typically involves a phased approach with increasing levels of scrutiny as designs progress from conceptual to final stages, often requiring prototype testing before full-scale deployment.

In the United States, the Nuclear Regulatory Commission (NRC) has established specific regulatory guides and technical requirements for non-light water reactors, including those utilizing liquid metal cooling technologies. The 10 CFR Part 50 and 10 CFR Part 52 provide the regulatory basis for licensing and safety requirements, while NUREG documents offer detailed technical guidance for compliance verification.

The European regulatory framework is coordinated through the Western European Nuclear Regulators Association (WENRA), which has developed harmonized safety reference levels. The European Nuclear Safety Regulators Group (ENSREG) further supports consistency in regulatory approaches across member states, particularly important for advanced reactor designs using liquid metal coolants.

Compliance requirements for liquid metal cooling systems focus on several critical areas. Coolant chemistry control specifications are stringent, requiring continuous monitoring systems and strict impurity limits to prevent corrosion and maintain heat transfer efficiency. Material qualification standards mandate extensive testing under representative conditions, including compatibility with liquid metals at operating temperatures and radiation environments.

Safety analysis requirements necessitate comprehensive accident scenario modeling specific to liquid metal systems, including considerations for coolant freezing, fire hazards, and potential chemical reactions. Instrumentation and control systems must meet redundancy and diversity requirements while functioning reliably in high-temperature liquid metal environments.

Containment design criteria address unique challenges posed by liquid metal coolants, particularly regarding potential chemical reactions with air, water, or concrete. In-service inspection protocols require specialized techniques for components submerged in opaque liquid metals, often utilizing ultrasonic or electromagnetic methods rather than visual inspection.

Operational procedures must incorporate specific emergency response protocols for liquid metal leaks and fires, with specialized training requirements for personnel. The qualification process typically involves a phased approach with increasing levels of scrutiny as designs progress from conceptual to final stages, often requiring prototype testing before full-scale deployment.

Risk Assessment Methodologies for Liquid Metal Systems

Risk assessment methodologies for liquid metal cooling systems in nuclear facilities require specialized approaches due to the unique properties of these coolants. Traditional probabilistic risk assessment (PRA) frameworks have been adapted to address the specific hazards associated with liquid metals such as sodium, lead, and lead-bismuth eutectic (LBE). These methodologies incorporate both deterministic and probabilistic elements to provide comprehensive safety evaluations.

The primary risk assessment approach involves systematic identification of potential failure modes through techniques such as Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Studies (HAZOP). These methods are particularly important for liquid metal systems due to their chemical reactivity with air and water, which presents unique accident scenarios not encountered in water-cooled reactors.

Event Tree Analysis (ETA) and Fault Tree Analysis (FTA) have been modified to account for liquid metal-specific phenomena, including rapid freezing, thermal stratification, and potential for energetic chemical reactions. These analytical tools help quantify the probability of various accident sequences and identify critical safety functions that must be maintained.

Specialized computational fluid dynamics (CFD) models have been developed to simulate the behavior of liquid metals under both normal and accident conditions. These models incorporate the distinctive thermophysical properties of liquid metals, such as high thermal conductivity and low vapor pressure, to predict system response during transients and accidents.

Experimental validation plays a crucial role in risk assessment methodologies for liquid metal systems. Test facilities like the Sodium Components Test Installation (SCTI) and the Fast Flux Test Facility (FFTF) have provided valuable data for validating analytical models and improving understanding of liquid metal behavior under various conditions.

International collaboration has led to the development of standardized risk assessment methodologies through organizations such as the International Atomic Energy Agency (IAEA) and the Generation IV International Forum (GIF). These collaborative efforts have resulted in guidance documents that establish consistent approaches to evaluating risks associated with liquid metal cooled reactors.

Recent advancements in risk assessment methodologies include the integration of passive safety features evaluation, which is particularly relevant for liquid metal systems that can leverage natural circulation for decay heat removal. Additionally, modern approaches incorporate lessons learned from historical liquid metal reactor operations, including experiences from facilities like Monju, BN-600, and EBR-II.

The primary risk assessment approach involves systematic identification of potential failure modes through techniques such as Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Studies (HAZOP). These methods are particularly important for liquid metal systems due to their chemical reactivity with air and water, which presents unique accident scenarios not encountered in water-cooled reactors.

Event Tree Analysis (ETA) and Fault Tree Analysis (FTA) have been modified to account for liquid metal-specific phenomena, including rapid freezing, thermal stratification, and potential for energetic chemical reactions. These analytical tools help quantify the probability of various accident sequences and identify critical safety functions that must be maintained.

Specialized computational fluid dynamics (CFD) models have been developed to simulate the behavior of liquid metals under both normal and accident conditions. These models incorporate the distinctive thermophysical properties of liquid metals, such as high thermal conductivity and low vapor pressure, to predict system response during transients and accidents.

Experimental validation plays a crucial role in risk assessment methodologies for liquid metal systems. Test facilities like the Sodium Components Test Installation (SCTI) and the Fast Flux Test Facility (FFTF) have provided valuable data for validating analytical models and improving understanding of liquid metal behavior under various conditions.

International collaboration has led to the development of standardized risk assessment methodologies through organizations such as the International Atomic Energy Agency (IAEA) and the Generation IV International Forum (GIF). These collaborative efforts have resulted in guidance documents that establish consistent approaches to evaluating risks associated with liquid metal cooled reactors.

Recent advancements in risk assessment methodologies include the integration of passive safety features evaluation, which is particularly relevant for liquid metal systems that can leverage natural circulation for decay heat removal. Additionally, modern approaches incorporate lessons learned from historical liquid metal reactor operations, including experiences from facilities like Monju, BN-600, and EBR-II.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!