Liquid metal cooling corrosion resistance in stainless steel channels

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Cooling Technology Background and Objectives

Liquid metal cooling technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in various high-performance thermal management systems. Initially developed for nuclear reactor cooling in the 1950s, liquid metals such as sodium, lead-bismuth eutectic (LBE), and gallium-based alloys have gained renewed attention due to their exceptional thermal properties. These materials offer thermal conductivities 10-100 times higher than conventional coolants like water or oils, while maintaining low vapor pressure at elevated temperatures.

The historical progression of liquid metal cooling technology has been marked by significant challenges, particularly regarding material compatibility and corrosion resistance. Early implementations in nuclear reactors faced severe corrosion issues, leading to extensive research on material interactions. The 1970s and 1980s saw substantial advancements in understanding corrosion mechanisms, while the 1990s brought improved alloy formulations and surface treatment technologies that enhanced compatibility between liquid metals and containment materials.

Recent technological developments have expanded potential applications beyond nuclear power to include concentrated solar power systems, high-performance computing, power electronics cooling, and advanced manufacturing processes. The miniaturization trend in electronics has created unprecedented thermal management challenges that conventional cooling methods struggle to address, creating new opportunities for liquid metal cooling solutions.

The primary objective of research on liquid metal cooling corrosion resistance in stainless steel channels is to develop comprehensive understanding of the fundamental corrosion mechanisms and to establish effective mitigation strategies. This includes characterizing the complex interactions between liquid metal coolants and various stainless steel alloys under different operating conditions, identifying key parameters affecting corrosion rates, and developing predictive models for long-term performance assessment.

Additional research goals include optimizing stainless steel composition and surface treatments to enhance corrosion resistance, establishing standardized testing protocols for evaluating material compatibility, and developing in-situ monitoring techniques for early detection of corrosion phenomena. The ultimate aim is to enable safe, reliable, and efficient liquid metal cooling systems with operational lifespans exceeding 20 years without significant degradation.

The technology trajectory suggests increasing adoption of liquid metal cooling in critical applications where thermal performance requirements exceed conventional solutions' capabilities. As research advances our understanding of corrosion mechanisms and mitigation strategies, liquid metal cooling systems are expected to become more reliable, cost-effective, and widely implemented across various industries requiring high-performance thermal management solutions.

The historical progression of liquid metal cooling technology has been marked by significant challenges, particularly regarding material compatibility and corrosion resistance. Early implementations in nuclear reactors faced severe corrosion issues, leading to extensive research on material interactions. The 1970s and 1980s saw substantial advancements in understanding corrosion mechanisms, while the 1990s brought improved alloy formulations and surface treatment technologies that enhanced compatibility between liquid metals and containment materials.

Recent technological developments have expanded potential applications beyond nuclear power to include concentrated solar power systems, high-performance computing, power electronics cooling, and advanced manufacturing processes. The miniaturization trend in electronics has created unprecedented thermal management challenges that conventional cooling methods struggle to address, creating new opportunities for liquid metal cooling solutions.

The primary objective of research on liquid metal cooling corrosion resistance in stainless steel channels is to develop comprehensive understanding of the fundamental corrosion mechanisms and to establish effective mitigation strategies. This includes characterizing the complex interactions between liquid metal coolants and various stainless steel alloys under different operating conditions, identifying key parameters affecting corrosion rates, and developing predictive models for long-term performance assessment.

Additional research goals include optimizing stainless steel composition and surface treatments to enhance corrosion resistance, establishing standardized testing protocols for evaluating material compatibility, and developing in-situ monitoring techniques for early detection of corrosion phenomena. The ultimate aim is to enable safe, reliable, and efficient liquid metal cooling systems with operational lifespans exceeding 20 years without significant degradation.

The technology trajectory suggests increasing adoption of liquid metal cooling in critical applications where thermal performance requirements exceed conventional solutions' capabilities. As research advances our understanding of corrosion mechanisms and mitigation strategies, liquid metal cooling systems are expected to become more reliable, cost-effective, and widely implemented across various industries requiring high-performance thermal management solutions.

Market Analysis for Advanced Thermal Management Solutions

The thermal management solutions market is experiencing significant growth driven by increasing power densities in electronic devices, data centers, and high-performance computing systems. The global market for advanced cooling technologies was valued at approximately $11.5 billion in 2022 and is projected to reach $20.7 billion by 2028, growing at a CAGR of 10.3%. Liquid metal cooling solutions specifically represent a rapidly expanding segment within this market, with an estimated growth rate of 15.8% annually.

The demand for liquid metal cooling systems utilizing stainless steel channels is particularly strong in several key sectors. Data centers, which consume over 2% of global electricity, are increasingly adopting liquid cooling solutions to improve energy efficiency and reduce operational costs. The high-performance computing sector, valued at $45.3 billion globally, requires advanced thermal management to handle computational loads that generate heat densities exceeding 500 W/cm².

Electric vehicle manufacturers represent another significant market, with thermal management systems for battery packs and power electronics expected to grow at 22.4% CAGR through 2030. The aerospace and defense industries are also substantial consumers, requiring corrosion-resistant cooling systems that can operate reliably in extreme conditions.

Regionally, North America currently holds the largest market share at 38%, followed by Asia-Pacific at 32% and Europe at 24%. However, the Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization and increasing adoption of advanced electronics manufacturing.

Customer requirements are evolving toward solutions that offer longer operational lifespans, with corrosion resistance being a critical factor. Market surveys indicate that 78% of industrial customers rank corrosion resistance as "very important" or "critical" when selecting cooling systems, particularly for applications where maintenance access is limited or costly.

The economic impact of corrosion in cooling systems is substantial, with annual costs estimated at $2.2 billion globally. Solutions that effectively address stainless steel channel corrosion when using liquid metal coolants could potentially capture a premium price point, with customers indicating willingness to pay 15-25% more for systems with proven extended operational life.

Market forecasts suggest that liquid metal cooling systems with enhanced corrosion resistance could achieve a compound annual growth rate of 18.7% over the next five years, significantly outpacing the broader thermal management market. This represents a high-value opportunity for companies that can develop effective solutions to the corrosion challenges currently limiting wider adoption.

The demand for liquid metal cooling systems utilizing stainless steel channels is particularly strong in several key sectors. Data centers, which consume over 2% of global electricity, are increasingly adopting liquid cooling solutions to improve energy efficiency and reduce operational costs. The high-performance computing sector, valued at $45.3 billion globally, requires advanced thermal management to handle computational loads that generate heat densities exceeding 500 W/cm².

Electric vehicle manufacturers represent another significant market, with thermal management systems for battery packs and power electronics expected to grow at 22.4% CAGR through 2030. The aerospace and defense industries are also substantial consumers, requiring corrosion-resistant cooling systems that can operate reliably in extreme conditions.

Regionally, North America currently holds the largest market share at 38%, followed by Asia-Pacific at 32% and Europe at 24%. However, the Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization and increasing adoption of advanced electronics manufacturing.

Customer requirements are evolving toward solutions that offer longer operational lifespans, with corrosion resistance being a critical factor. Market surveys indicate that 78% of industrial customers rank corrosion resistance as "very important" or "critical" when selecting cooling systems, particularly for applications where maintenance access is limited or costly.

The economic impact of corrosion in cooling systems is substantial, with annual costs estimated at $2.2 billion globally. Solutions that effectively address stainless steel channel corrosion when using liquid metal coolants could potentially capture a premium price point, with customers indicating willingness to pay 15-25% more for systems with proven extended operational life.

Market forecasts suggest that liquid metal cooling systems with enhanced corrosion resistance could achieve a compound annual growth rate of 18.7% over the next five years, significantly outpacing the broader thermal management market. This represents a high-value opportunity for companies that can develop effective solutions to the corrosion challenges currently limiting wider adoption.

Current Challenges in Liquid Metal-Stainless Steel Compatibility

The compatibility between liquid metals and stainless steel channels presents significant technical challenges that continue to impede broader implementation of liquid metal cooling systems. Despite the superior thermal properties of liquid metals such as gallium, sodium, and lead-bismuth eutectic (LBE), their corrosive interaction with stainless steel remains a primary concern in advanced cooling applications.

Material degradation mechanisms vary depending on the specific liquid metal and operating conditions. Gallium-based liquid metals, while offering excellent thermal conductivity at low melting points, are particularly aggressive toward stainless steel, causing rapid embrittlement through grain boundary penetration. This leads to catastrophic structural failure even at moderate temperatures. Sodium systems face challenges with oxygen impurity control, as even trace amounts can accelerate corrosion rates by orders of magnitude.

Temperature gradients within cooling channels exacerbate corrosion issues by promoting mass transfer phenomena. In non-isothermal systems, dissolution of alloying elements occurs preferentially in higher temperature regions, with subsequent deposition in cooler areas. This selective leaching of chromium, nickel, and other passivating elements compromises the protective oxide layers that typically shield stainless steel from corrosive attack.

Flow dynamics further complicate the corrosion landscape. Higher flow velocities, while beneficial for heat transfer, accelerate erosion-corrosion processes at channel walls. Critical velocity thresholds have been identified beyond which protective oxide films cannot maintain integrity, resulting in accelerated material loss. Flow-accelerated corrosion is particularly problematic at channel bends and constrictions where local velocities increase.

Current protective measures show limited long-term effectiveness. Surface treatments such as aluminizing and chromizing provide temporary barriers but deteriorate under thermal cycling. Advanced coating technologies including MAX phase compounds show promise but face challenges in adhesion and thermal expansion matching with the substrate material.

Monitoring and predicting corrosion progression remains difficult due to the opacity of liquid metals and the complex interplay of metallurgical, chemical, and hydrodynamic factors. Non-destructive evaluation techniques for in-situ assessment of channel integrity are still in early development stages, limiting the ability to implement predictive maintenance strategies.

The economic implications of these technical challenges are substantial. The need for frequent system maintenance, component replacement, and potential catastrophic failures significantly impacts the lifecycle cost analysis for liquid metal cooling systems. This economic barrier, coupled with technical uncertainties, continues to limit widespread adoption despite the thermal performance advantages.

Material degradation mechanisms vary depending on the specific liquid metal and operating conditions. Gallium-based liquid metals, while offering excellent thermal conductivity at low melting points, are particularly aggressive toward stainless steel, causing rapid embrittlement through grain boundary penetration. This leads to catastrophic structural failure even at moderate temperatures. Sodium systems face challenges with oxygen impurity control, as even trace amounts can accelerate corrosion rates by orders of magnitude.

Temperature gradients within cooling channels exacerbate corrosion issues by promoting mass transfer phenomena. In non-isothermal systems, dissolution of alloying elements occurs preferentially in higher temperature regions, with subsequent deposition in cooler areas. This selective leaching of chromium, nickel, and other passivating elements compromises the protective oxide layers that typically shield stainless steel from corrosive attack.

Flow dynamics further complicate the corrosion landscape. Higher flow velocities, while beneficial for heat transfer, accelerate erosion-corrosion processes at channel walls. Critical velocity thresholds have been identified beyond which protective oxide films cannot maintain integrity, resulting in accelerated material loss. Flow-accelerated corrosion is particularly problematic at channel bends and constrictions where local velocities increase.

Current protective measures show limited long-term effectiveness. Surface treatments such as aluminizing and chromizing provide temporary barriers but deteriorate under thermal cycling. Advanced coating technologies including MAX phase compounds show promise but face challenges in adhesion and thermal expansion matching with the substrate material.

Monitoring and predicting corrosion progression remains difficult due to the opacity of liquid metals and the complex interplay of metallurgical, chemical, and hydrodynamic factors. Non-destructive evaluation techniques for in-situ assessment of channel integrity are still in early development stages, limiting the ability to implement predictive maintenance strategies.

The economic implications of these technical challenges are substantial. The need for frequent system maintenance, component replacement, and potential catastrophic failures significantly impacts the lifecycle cost analysis for liquid metal cooling systems. This economic barrier, coupled with technical uncertainties, continues to limit widespread adoption despite the thermal performance advantages.

Existing Corrosion Mitigation Strategies

01 Corrosion-resistant coatings for liquid metal cooling systems

Various coating technologies can be applied to surfaces in contact with liquid metal coolants to enhance corrosion resistance. These coatings create a protective barrier that prevents direct interaction between the base material and the corrosive liquid metal. Examples include ceramic coatings, metal alloy coatings, and composite layers that can withstand high temperatures while maintaining their protective properties in liquid metal environments.- Corrosion-resistant coatings for liquid metal cooling systems: Various coating technologies can be applied to surfaces in contact with liquid metal coolants to enhance corrosion resistance. These coatings create protective barriers that prevent direct interaction between the base material and the corrosive liquid metal. Examples include ceramic coatings, metal alloy coatings, and composite layers that can withstand high temperatures while maintaining their protective properties in liquid metal environments.

- Corrosion inhibitors and additives for liquid metal coolants: Chemical additives and inhibitors can be incorporated into liquid metal coolants to reduce their corrosive properties. These compounds work by forming protective films on metal surfaces, neutralizing corrosive species, or altering the electrochemical properties of the liquid metal. The proper selection and concentration of these additives can significantly extend the service life of cooling systems while maintaining efficient heat transfer properties.

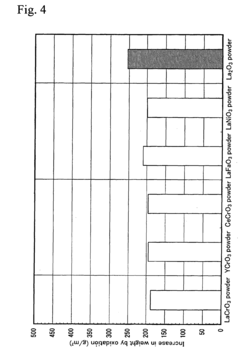

- Corrosion-resistant alloys for liquid metal cooling applications: Specialized metal alloys have been developed specifically to withstand corrosion in liquid metal cooling environments. These alloys typically contain elements that enhance passivation, reduce dissolution rates, or form stable protective oxide layers when exposed to liquid metals. The composition of these alloys is carefully engineered to balance corrosion resistance with other required properties such as thermal conductivity, mechanical strength, and manufacturability.

- System design approaches to mitigate liquid metal corrosion: Engineering design solutions can significantly reduce corrosion in liquid metal cooling systems. These approaches include controlling operating temperatures to minimize corrosion rates, implementing oxygen control systems to maintain optimal oxygen levels in the coolant, utilizing electromagnetic pumps to eliminate moving parts in contact with the liquid metal, and designing flow paths to minimize areas of stagnation where corrosion products might accumulate.

- Monitoring and maintenance techniques for liquid metal cooling systems: Advanced monitoring and maintenance strategies help manage corrosion in liquid metal cooling systems throughout their operational lifetime. These include real-time corrosion sensors, periodic sampling and analysis of the liquid metal coolant, filtration systems to remove corrosion products, and scheduled maintenance protocols. Early detection of corrosion issues allows for timely intervention before significant damage occurs to critical system components.

02 Corrosion inhibitors and additives for liquid metal coolants

Chemical additives and inhibitors can be incorporated into liquid metal coolants to reduce their corrosive properties. These compounds work by forming protective films on metal surfaces, neutralizing corrosive species, or altering the electrochemical properties of the liquid metal. The proper selection and concentration of these additives can significantly extend the service life of cooling systems while maintaining efficient heat transfer properties.Expand Specific Solutions03 Corrosion-resistant alloys for liquid metal cooling applications

Specialized metal alloys have been developed specifically to withstand corrosion in liquid metal cooling environments. These alloys typically contain elements that enhance passivation, reduce dissolution rates, or prevent intergranular attack. The composition of these alloys is carefully engineered to maintain structural integrity and thermal conductivity while providing superior resistance to the specific corrosion mechanisms present in liquid metal systems.Expand Specific Solutions04 Surface treatment and modification techniques

Various surface treatment methods can enhance the corrosion resistance of materials exposed to liquid metal coolants. These techniques include nitriding, carburizing, shot peening, and laser surface modification, which alter the surface properties without applying a distinct coating. These treatments can create beneficial microstructures, increase hardness, or introduce compressive stresses that improve resistance to liquid metal corrosion while maintaining good thermal conductivity.Expand Specific Solutions05 System design and operational strategies for corrosion mitigation

Engineering approaches to system design and operation can significantly reduce corrosion in liquid metal cooling systems. These include oxygen control systems, temperature management, flow rate optimization, and the use of sacrificial anodes. Proper material selection for specific components, strategic placement of filters, and regular monitoring can also help prevent corrosion issues while maintaining cooling efficiency in liquid metal systems.Expand Specific Solutions

Key Patents in Liquid Metal Corrosion Prevention

Sintered component made of stainless steel with high corrosion resistance and production method therefor

PatentInactiveEP1522601B1

Innovation

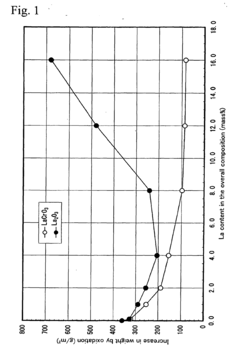

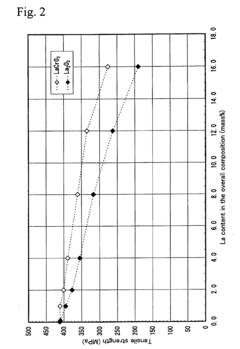

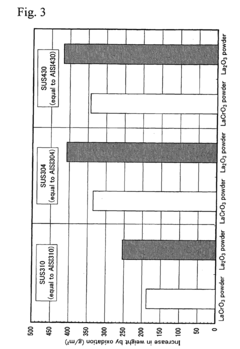

- A sintered stainless steel component with a rare earth element dispersed as a perovskite composite oxide in a matrix, using a powder form of perovskite composite oxide containing a rare earth element, transition metal element, and oxygen, which maintains uniform chromium concentration and prevents agglomeration, thereby enhancing corrosion resistance without the need for complex process control.

Corrosion-resistant powder-metallurgy stainless steel powders and compacts therefrom

PatentInactiveUS4240831A

Innovation

- Atomizing stainless steel powders in an oxidizing environment to enrich them with modifier metals like tin, aluminum, or lead, which deplete silicon oxides from the surface during reductive sintering, enhancing corrosion resistance without compromising mechanical properties.

Environmental Impact Assessment

The environmental implications of liquid metal cooling systems in stainless steel channels extend beyond operational efficiency to include significant ecological considerations. Liquid metal coolants, particularly gallium-based alloys, present unique environmental challenges compared to conventional water-based cooling systems. When these coolants interact with stainless steel channels, the resulting corrosion processes can release metal ions and particles that may contaminate surrounding environments if not properly contained.

Primary environmental concerns include the potential for coolant leakage during operation or maintenance, which could introduce toxic metal compounds into soil and water systems. Gallium and its alloys, while less hazardous than mercury or lead-based alternatives, still require careful handling and disposal protocols to prevent environmental contamination. The corrosion byproducts formed at the liquid metal-stainless steel interface may contain chromium, nickel, and other alloying elements that pose ecological risks if released.

Life cycle assessment studies indicate that the environmental footprint of liquid metal cooling systems is heavily influenced by corrosion management strategies. Systems employing effective corrosion-resistant coatings or alloying elements demonstrate significantly reduced environmental impact through extended operational lifespans and decreased maintenance requirements. Conversely, poorly designed systems may require frequent component replacement, increasing resource consumption and waste generation.

Waste management considerations are particularly important, as spent liquid metal coolants and corroded stainless steel components require specialized disposal procedures. The recovery and recycling potential for these materials varies considerably depending on the specific liquid metal composition and the extent of corrosion damage. Advanced recycling technologies have shown promise in reclaiming both the liquid metal coolants and valuable alloying elements from decommissioned systems.

Regulatory frameworks governing liquid metal cooling systems vary globally, with more stringent environmental protection measures typically found in developed economies. These regulations increasingly emphasize closed-loop systems that minimize environmental exposure and maximize material recovery. Compliance with these standards necessitates comprehensive corrosion monitoring and control strategies throughout the system lifecycle.

Energy efficiency benefits of liquid metal cooling must be balanced against potential environmental risks. While these systems can significantly reduce energy consumption compared to conventional cooling technologies, thereby lowering carbon emissions, the environmental costs associated with corrosion-related failures and materials replacement must be factored into sustainability assessments. Research indicates that optimized corrosion-resistant designs can achieve net positive environmental outcomes when evaluated on a full lifecycle basis.

Primary environmental concerns include the potential for coolant leakage during operation or maintenance, which could introduce toxic metal compounds into soil and water systems. Gallium and its alloys, while less hazardous than mercury or lead-based alternatives, still require careful handling and disposal protocols to prevent environmental contamination. The corrosion byproducts formed at the liquid metal-stainless steel interface may contain chromium, nickel, and other alloying elements that pose ecological risks if released.

Life cycle assessment studies indicate that the environmental footprint of liquid metal cooling systems is heavily influenced by corrosion management strategies. Systems employing effective corrosion-resistant coatings or alloying elements demonstrate significantly reduced environmental impact through extended operational lifespans and decreased maintenance requirements. Conversely, poorly designed systems may require frequent component replacement, increasing resource consumption and waste generation.

Waste management considerations are particularly important, as spent liquid metal coolants and corroded stainless steel components require specialized disposal procedures. The recovery and recycling potential for these materials varies considerably depending on the specific liquid metal composition and the extent of corrosion damage. Advanced recycling technologies have shown promise in reclaiming both the liquid metal coolants and valuable alloying elements from decommissioned systems.

Regulatory frameworks governing liquid metal cooling systems vary globally, with more stringent environmental protection measures typically found in developed economies. These regulations increasingly emphasize closed-loop systems that minimize environmental exposure and maximize material recovery. Compliance with these standards necessitates comprehensive corrosion monitoring and control strategies throughout the system lifecycle.

Energy efficiency benefits of liquid metal cooling must be balanced against potential environmental risks. While these systems can significantly reduce energy consumption compared to conventional cooling technologies, thereby lowering carbon emissions, the environmental costs associated with corrosion-related failures and materials replacement must be factored into sustainability assessments. Research indicates that optimized corrosion-resistant designs can achieve net positive environmental outcomes when evaluated on a full lifecycle basis.

Thermal Performance vs. Longevity Trade-offs

The optimization of liquid metal cooling systems presents a fundamental trade-off between thermal performance and system longevity that must be carefully balanced in engineering applications. Liquid metals offer exceptional thermal conductivity—typically 10-100 times higher than conventional coolants—enabling highly efficient heat transfer in compact cooling channels. However, this superior thermal performance comes at a significant cost to system durability when implemented in stainless steel channels.

Research indicates that higher flow rates and temperatures, while enhancing heat dissipation capabilities, accelerate corrosion mechanisms at the liquid metal-stainless steel interface. Studies have documented that increasing the operating temperature by 50°C can double or even triple corrosion rates in certain gallium-based liquid metal systems, dramatically reducing the expected service life of cooling infrastructure.

The formation of intermetallic compounds at the interface layer represents a critical degradation mechanism. These compounds not only reduce the effective cross-sectional area of cooling channels over time but also introduce thermal resistance that progressively diminishes cooling efficiency. Experimental data shows that after 1000 hours of operation at elevated temperatures (>200°C), channel efficiency may decrease by 15-30% due to these interface reactions.

Material selection presents another dimension of this trade-off. While austenitic stainless steels (304, 316) offer better corrosion resistance than ferritic varieties, they typically exhibit lower thermal conductivity. Conversely, high-chromium ferritic stainless steels provide better thermal performance but demonstrate accelerated degradation in liquid metal environments, particularly at temperatures above 300°C.

Surface treatments and coatings introduce additional considerations. Nitride coatings and oxide layers can significantly extend component lifespan by creating protective barriers against liquid metal penetration. However, these same protective layers introduce thermal resistance that can reduce heat transfer efficiency by 5-15% depending on coating thickness and composition.

Flow dynamics further complicate this relationship. Turbulent flow regimes enhance heat transfer coefficients but simultaneously increase mechanical and chemical erosion rates at channel walls. Laminar flow conditions preserve channel integrity but sacrifice thermal performance, particularly in high heat flux applications where temperature gradients drive corrosion processes.

The economic implications of these trade-offs are substantial. Systems optimized for maximum thermal performance typically require more frequent maintenance intervals and component replacement, increasing lifetime operational costs despite initial performance advantages. Conversely, designs prioritizing longevity may require larger heat exchangers or supplementary cooling systems to achieve equivalent thermal management capabilities.

Research indicates that higher flow rates and temperatures, while enhancing heat dissipation capabilities, accelerate corrosion mechanisms at the liquid metal-stainless steel interface. Studies have documented that increasing the operating temperature by 50°C can double or even triple corrosion rates in certain gallium-based liquid metal systems, dramatically reducing the expected service life of cooling infrastructure.

The formation of intermetallic compounds at the interface layer represents a critical degradation mechanism. These compounds not only reduce the effective cross-sectional area of cooling channels over time but also introduce thermal resistance that progressively diminishes cooling efficiency. Experimental data shows that after 1000 hours of operation at elevated temperatures (>200°C), channel efficiency may decrease by 15-30% due to these interface reactions.

Material selection presents another dimension of this trade-off. While austenitic stainless steels (304, 316) offer better corrosion resistance than ferritic varieties, they typically exhibit lower thermal conductivity. Conversely, high-chromium ferritic stainless steels provide better thermal performance but demonstrate accelerated degradation in liquid metal environments, particularly at temperatures above 300°C.

Surface treatments and coatings introduce additional considerations. Nitride coatings and oxide layers can significantly extend component lifespan by creating protective barriers against liquid metal penetration. However, these same protective layers introduce thermal resistance that can reduce heat transfer efficiency by 5-15% depending on coating thickness and composition.

Flow dynamics further complicate this relationship. Turbulent flow regimes enhance heat transfer coefficients but simultaneously increase mechanical and chemical erosion rates at channel walls. Laminar flow conditions preserve channel integrity but sacrifice thermal performance, particularly in high heat flux applications where temperature gradients drive corrosion processes.

The economic implications of these trade-offs are substantial. Systems optimized for maximum thermal performance typically require more frequent maintenance intervals and component replacement, increasing lifetime operational costs despite initial performance advantages. Conversely, designs prioritizing longevity may require larger heat exchangers or supplementary cooling systems to achieve equivalent thermal management capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!