Research on liquid metal cooling electromagnetic pump technologies

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Cooling Technology Background and Objectives

Liquid metal cooling technology has evolved significantly over the past decades, transitioning from theoretical concepts to practical applications in various high-performance thermal management systems. Initially developed for nuclear reactor cooling in the 1950s, liquid metals such as sodium, gallium, and their alloys have gained renewed attention due to their exceptional thermal conductivity properties—typically 10-100 times higher than conventional coolants like water or oils. This superior thermal performance enables more efficient heat transfer in compact spaces, making liquid metal cooling increasingly relevant in today's high-power density electronic systems.

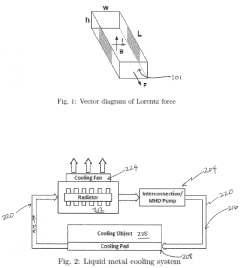

The electromagnetic pump (EMP) represents a critical advancement in liquid metal cooling technology, offering a non-mechanical method to circulate these conductive fluids. Unlike conventional pumps with moving parts, EMPs leverage the principles of magnetohydrodynamics to generate flow through the interaction of magnetic fields and electric currents within the liquid metal itself. This approach eliminates mechanical seals, bearings, and other components that would otherwise be vulnerable to corrosion or failure when exposed to high-temperature liquid metals.

The evolution of this technology has been driven by increasing thermal management demands across multiple industries. Modern computing systems, power electronics, and concentrated solar power installations all generate unprecedented heat loads that conventional cooling technologies struggle to address efficiently. The miniaturization trend in electronics has further exacerbated these challenges, creating scenarios where thermal bottlenecks limit overall system performance.

Current research objectives in liquid metal cooling electromagnetic pump technologies focus on several key areas. First, improving pump efficiency remains paramount, as traditional EMPs typically operate at 10-40% efficiency—significantly lower than mechanical alternatives. Second, researchers aim to develop novel liquid metal alloys with optimized properties for specific applications, balancing thermal conductivity with other considerations such as melting point, chemical compatibility, and cost. Third, addressing the challenges of oxide formation and material compatibility continues to be critical for long-term system reliability.

The integration of advanced control systems represents another important research direction, enabling precise flow modulation in response to varying thermal loads. This adaptive capability is particularly valuable in applications with fluctuating power profiles. Additionally, miniaturization of EMP systems for microelectronic cooling applications presents unique design challenges that researchers are actively addressing through innovative electromagnetic configurations and materials.

As global energy efficiency standards become increasingly stringent, liquid metal cooling with electromagnetic pumping offers promising pathways to meet these requirements in next-generation thermal management systems. The technology's potential to enable higher operating temperatures in power conversion systems could significantly improve overall energy efficiency across multiple sectors.

The electromagnetic pump (EMP) represents a critical advancement in liquid metal cooling technology, offering a non-mechanical method to circulate these conductive fluids. Unlike conventional pumps with moving parts, EMPs leverage the principles of magnetohydrodynamics to generate flow through the interaction of magnetic fields and electric currents within the liquid metal itself. This approach eliminates mechanical seals, bearings, and other components that would otherwise be vulnerable to corrosion or failure when exposed to high-temperature liquid metals.

The evolution of this technology has been driven by increasing thermal management demands across multiple industries. Modern computing systems, power electronics, and concentrated solar power installations all generate unprecedented heat loads that conventional cooling technologies struggle to address efficiently. The miniaturization trend in electronics has further exacerbated these challenges, creating scenarios where thermal bottlenecks limit overall system performance.

Current research objectives in liquid metal cooling electromagnetic pump technologies focus on several key areas. First, improving pump efficiency remains paramount, as traditional EMPs typically operate at 10-40% efficiency—significantly lower than mechanical alternatives. Second, researchers aim to develop novel liquid metal alloys with optimized properties for specific applications, balancing thermal conductivity with other considerations such as melting point, chemical compatibility, and cost. Third, addressing the challenges of oxide formation and material compatibility continues to be critical for long-term system reliability.

The integration of advanced control systems represents another important research direction, enabling precise flow modulation in response to varying thermal loads. This adaptive capability is particularly valuable in applications with fluctuating power profiles. Additionally, miniaturization of EMP systems for microelectronic cooling applications presents unique design challenges that researchers are actively addressing through innovative electromagnetic configurations and materials.

As global energy efficiency standards become increasingly stringent, liquid metal cooling with electromagnetic pumping offers promising pathways to meet these requirements in next-generation thermal management systems. The technology's potential to enable higher operating temperatures in power conversion systems could significantly improve overall energy efficiency across multiple sectors.

Market Analysis for Liquid Metal Cooling Solutions

The liquid metal cooling solutions market is experiencing significant growth driven by increasing demands for efficient thermal management systems across multiple industries. The global market for advanced cooling technologies, including liquid metal solutions, is projected to reach $20 billion by 2027, with a compound annual growth rate of approximately 7.5%. This growth is primarily fueled by the expanding data center industry, high-performance computing applications, and the electric vehicle sector, where thermal management challenges are becoming increasingly critical.

In the data center segment, the need for more efficient cooling solutions has become paramount as processing densities continue to rise. Traditional air and water cooling systems are reaching their practical limits, creating a substantial market opportunity for liquid metal cooling technologies. Data centers currently account for approximately 40% of the liquid metal cooling market, with this share expected to increase as heat dissipation requirements become more demanding.

The consumer electronics industry represents another significant market segment, particularly for high-performance computing devices and gaming systems. As manufacturers continue to pack more processing power into smaller form factors, the thermal management challenges intensify, driving interest in advanced cooling solutions like electromagnetic pump-driven liquid metal systems.

Geographically, North America currently leads the market with approximately 35% share, followed by Asia-Pacific at 30% and Europe at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, increasing data center construction, and the strong presence of electronics manufacturing.

From a competitive landscape perspective, the market remains relatively fragmented with a mix of established cooling solution providers and emerging startups specializing in liquid metal technologies. Key market players include thermal management solution providers, specialized liquid metal technology developers, and system integrators who incorporate these solutions into end products.

Customer adoption barriers include concerns about long-term reliability, initial implementation costs, and compatibility with existing systems. The average implementation cost for liquid metal cooling systems remains 30-40% higher than conventional cooling solutions, though this gap is narrowing as technology matures and production scales increase.

Market forecasts indicate that electromagnetic pump technologies for liquid metal cooling will see accelerated adoption in the next 3-5 years as technical challenges are overcome and costs decrease. Industries with high cooling demands and performance requirements, such as AI computing centers, aerospace applications, and advanced manufacturing, represent the most promising near-term growth opportunities.

In the data center segment, the need for more efficient cooling solutions has become paramount as processing densities continue to rise. Traditional air and water cooling systems are reaching their practical limits, creating a substantial market opportunity for liquid metal cooling technologies. Data centers currently account for approximately 40% of the liquid metal cooling market, with this share expected to increase as heat dissipation requirements become more demanding.

The consumer electronics industry represents another significant market segment, particularly for high-performance computing devices and gaming systems. As manufacturers continue to pack more processing power into smaller form factors, the thermal management challenges intensify, driving interest in advanced cooling solutions like electromagnetic pump-driven liquid metal systems.

Geographically, North America currently leads the market with approximately 35% share, followed by Asia-Pacific at 30% and Europe at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, increasing data center construction, and the strong presence of electronics manufacturing.

From a competitive landscape perspective, the market remains relatively fragmented with a mix of established cooling solution providers and emerging startups specializing in liquid metal technologies. Key market players include thermal management solution providers, specialized liquid metal technology developers, and system integrators who incorporate these solutions into end products.

Customer adoption barriers include concerns about long-term reliability, initial implementation costs, and compatibility with existing systems. The average implementation cost for liquid metal cooling systems remains 30-40% higher than conventional cooling solutions, though this gap is narrowing as technology matures and production scales increase.

Market forecasts indicate that electromagnetic pump technologies for liquid metal cooling will see accelerated adoption in the next 3-5 years as technical challenges are overcome and costs decrease. Industries with high cooling demands and performance requirements, such as AI computing centers, aerospace applications, and advanced manufacturing, represent the most promising near-term growth opportunities.

Current State and Challenges of Electromagnetic Pump Technologies

Electromagnetic pumps (EMPs) for liquid metal cooling systems have evolved significantly over the past decades, with current technologies broadly categorized into conduction, induction, and magnetohydrodynamic (MHD) types. Conduction EMPs, utilizing the Lorentz force principle through direct current application, remain prevalent in smaller-scale applications due to their structural simplicity and reliability. Induction EMPs, employing alternating current to generate traveling magnetic fields, have gained prominence in larger industrial settings where higher flow rates are required.

The global landscape of EMP technology development shows distinct regional specialization. Countries with advanced nuclear programs such as Russia, France, and Japan have made substantial progress in developing high-efficiency EMPs for liquid metal-cooled fast reactors. China has recently accelerated research efforts, particularly focusing on sodium-cooled systems, while the United States maintains expertise primarily through national laboratories and specialized engineering firms.

Despite significant advancements, electromagnetic pump technologies face several critical challenges. Efficiency limitations represent a primary concern, with most current designs operating at 30-45% efficiency—substantially lower than conventional mechanical pumps. This inefficiency stems from inherent energy losses due to Joule heating and magnetic flux leakage, particularly pronounced when pumping high-temperature liquid metals like sodium or lead-bismuth eutectic.

Material degradation presents another significant hurdle. The combination of high temperatures (often exceeding 500°C), corrosive liquid metals, and intense electromagnetic fields accelerates material fatigue and corrosion. Current materials struggle to maintain structural integrity and electrical properties under these extreme conditions over extended operational periods, limiting pump lifespan and reliability.

Flow instability issues persist across various EMP designs. Magnetohydrodynamic effects can create uneven flow distributions, vortices, and pressure fluctuations that compromise system performance and potentially damage downstream components. These instabilities become particularly problematic at higher flow rates and when scaling up pump dimensions.

Power supply requirements pose both technical and economic challenges. Large-scale EMPs demand sophisticated power conditioning systems to provide precisely controlled high-current inputs, adding complexity and cost to overall system implementation. The need for specialized power electronics capable of withstanding industrial environments further complicates deployment.

Monitoring and control technologies remain underdeveloped compared to conventional pumping systems. The opaque nature of liquid metals and the interference from strong electromagnetic fields complicate flow measurement and real-time performance monitoring, making advanced control strategies difficult to implement effectively.

The global landscape of EMP technology development shows distinct regional specialization. Countries with advanced nuclear programs such as Russia, France, and Japan have made substantial progress in developing high-efficiency EMPs for liquid metal-cooled fast reactors. China has recently accelerated research efforts, particularly focusing on sodium-cooled systems, while the United States maintains expertise primarily through national laboratories and specialized engineering firms.

Despite significant advancements, electromagnetic pump technologies face several critical challenges. Efficiency limitations represent a primary concern, with most current designs operating at 30-45% efficiency—substantially lower than conventional mechanical pumps. This inefficiency stems from inherent energy losses due to Joule heating and magnetic flux leakage, particularly pronounced when pumping high-temperature liquid metals like sodium or lead-bismuth eutectic.

Material degradation presents another significant hurdle. The combination of high temperatures (often exceeding 500°C), corrosive liquid metals, and intense electromagnetic fields accelerates material fatigue and corrosion. Current materials struggle to maintain structural integrity and electrical properties under these extreme conditions over extended operational periods, limiting pump lifespan and reliability.

Flow instability issues persist across various EMP designs. Magnetohydrodynamic effects can create uneven flow distributions, vortices, and pressure fluctuations that compromise system performance and potentially damage downstream components. These instabilities become particularly problematic at higher flow rates and when scaling up pump dimensions.

Power supply requirements pose both technical and economic challenges. Large-scale EMPs demand sophisticated power conditioning systems to provide precisely controlled high-current inputs, adding complexity and cost to overall system implementation. The need for specialized power electronics capable of withstanding industrial environments further complicates deployment.

Monitoring and control technologies remain underdeveloped compared to conventional pumping systems. The opaque nature of liquid metals and the interference from strong electromagnetic fields complicate flow measurement and real-time performance monitoring, making advanced control strategies difficult to implement effectively.

Current Electromagnetic Pump Design Solutions

01 Electromagnetic pump design for liquid metal cooling

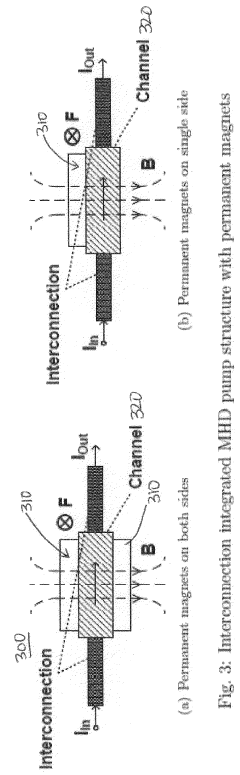

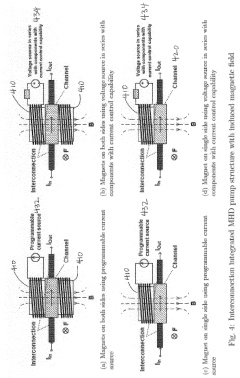

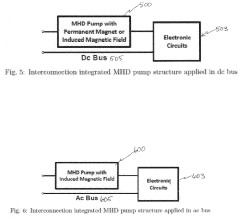

Electromagnetic pumps are specifically designed for circulating liquid metals in cooling systems. These pumps utilize electromagnetic forces to move conductive liquid metals without mechanical parts, making them ideal for high-temperature applications. The design typically includes magnetic coils, flow channels, and specialized materials that can withstand the corrosive nature of liquid metals while maintaining efficient heat transfer properties.- Electromagnetic pump design for liquid metal cooling: Electromagnetic pumps are specifically designed for circulating liquid metals in cooling systems. These pumps utilize electromagnetic forces to move conductive liquid metals without mechanical parts, making them ideal for high-temperature applications. The design typically includes magnetic coils, flow channels, and specialized materials that can withstand the corrosive nature of liquid metals while maintaining efficient heat transfer properties.

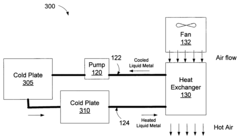

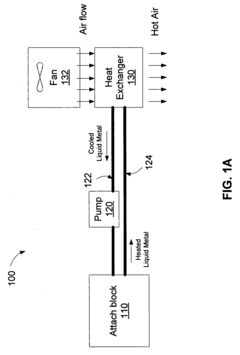

- Cooling systems for electronic devices using liquid metal: Liquid metal cooling systems are implemented in electronic devices to manage heat dissipation more efficiently than traditional cooling methods. These systems utilize the high thermal conductivity of liquid metals to transfer heat away from critical components. The electromagnetic pumps in these systems ensure continuous circulation of the liquid metal coolant without mechanical wear, extending the lifespan of cooling systems in high-performance computing, power electronics, and other heat-intensive applications.

- Temperature control mechanisms in liquid metal cooling systems: Advanced temperature control mechanisms are integrated into liquid metal cooling systems to maintain optimal operating conditions. These mechanisms include temperature sensors, flow rate controllers, and feedback systems that adjust the electromagnetic pump performance based on real-time thermal requirements. The precise temperature control ensures that electronic components operate within safe temperature ranges while maximizing system efficiency and preventing overheating or thermal cycling damage.

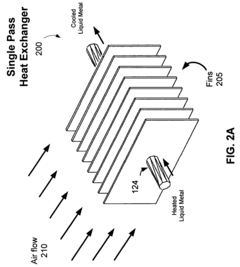

- Structural innovations for electromagnetic pump efficiency: Structural innovations in electromagnetic pumps focus on improving efficiency and reliability for liquid metal cooling applications. These innovations include optimized channel geometries, enhanced magnetic circuit designs, and specialized electrode configurations that reduce energy consumption while increasing pumping capacity. Advanced materials and manufacturing techniques are employed to create compact, lightweight pumps that can be integrated into various cooling system architectures while maintaining high performance under demanding operating conditions.

- Safety and reliability features in liquid metal cooling systems: Safety and reliability features are critical in liquid metal cooling systems due to the potentially hazardous nature of liquid metals. These features include leak detection systems, redundant cooling paths, emergency shutdown mechanisms, and specialized containment materials. The electromagnetic pumps are designed with fail-safe operations to prevent system failures that could lead to overheating or liquid metal leakage. Isolation systems and monitoring technologies ensure continuous operation while protecting both the cooled equipment and surrounding environment from potential hazards.

02 Cooling systems for electronic devices using liquid metal

Liquid metal cooling systems are implemented in electronic devices to manage heat dissipation more efficiently than traditional cooling methods. These systems utilize the high thermal conductivity of liquid metals to transfer heat away from critical components. The electromagnetic pumps in these systems ensure continuous circulation of the liquid metal coolant without mechanical wear, resulting in improved cooling performance and extended lifespan of electronic components.Expand Specific Solutions03 Temperature control mechanisms in liquid metal cooling systems

Advanced temperature control mechanisms are integrated into liquid metal cooling systems to maintain optimal operating conditions. These mechanisms include temperature sensors, feedback control systems, and variable electromagnetic field strength to adjust the flow rate of liquid metal coolant. By precisely controlling the temperature, these systems can prevent overheating of sensitive components while maximizing the efficiency of heat transfer in various operating conditions.Expand Specific Solutions04 Structural innovations for electromagnetic pump efficiency

Structural innovations in electromagnetic pumps focus on improving efficiency and reliability for liquid metal cooling applications. These innovations include optimized channel geometries, enhanced magnetic field configurations, and specialized materials that reduce energy consumption while increasing pumping capacity. The designs often incorporate features to minimize flow resistance, prevent liquid metal oxidation, and ensure uniform cooling across the target components.Expand Specific Solutions05 Integration of liquid metal cooling in nuclear applications

Liquid metal cooling systems with electromagnetic pumps are extensively used in nuclear applications due to their ability to handle high heat loads and operate in radiation environments. These systems circulate liquid metals such as sodium, lead, or lead-bismuth eutectic to transfer heat from nuclear reactor cores. The electromagnetic pumps provide reliable, seal-free operation critical for nuclear safety, while the liquid metal coolants offer superior heat transfer capabilities compared to conventional coolants.Expand Specific Solutions

Key Industry Players in Electromagnetic Pump Development

The liquid metal cooling electromagnetic pump technology market is currently in a growth phase, characterized by increasing adoption in nuclear power and advanced cooling applications. The market is expanding due to rising demand for efficient thermal management solutions in high-performance computing and nuclear energy sectors. China dominates the competitive landscape with key players including China Institute of Atomic Energy, China Nuclear Power Technology Research Institute, and China General Nuclear Power Corp leading research efforts. International competition comes from established technology corporations like Toshiba, Intel, and Fujitsu, who are leveraging their expertise in thermal management. Academic institutions such as Xi'an Jiaotong University and Zhejiang University are driving innovation through fundamental research, while specialized companies like Pierburg Pump Technology and Prime Photonics are developing niche applications for this emerging technology.

China Institute of Atomic Energy

Technical Solution: China Institute of Atomic Energy has developed advanced electromagnetic pump technologies specifically for liquid metal cooling systems in nuclear reactors. Their approach utilizes a flat linear induction pump (FLIP) design with optimized magnetic field distribution to enhance flow stability and reduce MHD effects. The institute has conducted extensive research on sodium-cooled fast reactors where liquid sodium serves as the primary coolant, requiring specialized electromagnetic pumping solutions. Their technology incorporates high-temperature resistant materials and specialized magnetic core designs that can withstand the harsh operating conditions of liquid metal environments. Recent innovations include the development of dual-frequency excitation methods that significantly reduce flow instabilities and improve pumping efficiency by approximately 15-20% compared to conventional single-frequency designs[1]. The institute has also pioneered fault-tolerant control systems that can maintain operation during partial power failures, critical for nuclear safety applications.

Strengths: Extensive experience with nuclear-grade safety requirements and radiation-resistant designs; strong integration with China's nuclear power program providing real-world implementation opportunities. Weaknesses: Potentially limited international collaboration due to nuclear technology restrictions; higher costs associated with nuclear-grade certification requirements.

Toshiba Corp.

Technical Solution: Toshiba has developed sophisticated electromagnetic pump technologies for liquid metal cooling applications, particularly for next-generation nuclear reactors. Their proprietary design incorporates a double-stator annular linear induction pump (ALIP) configuration that generates a traveling magnetic field to propel liquid metals like sodium or lead-bismuth eutectic without mechanical moving parts. Toshiba's technology features advanced power supply systems with variable frequency drives that enable precise flow control across a wide operating range. Their pumps utilize specialized magnetic core materials with low core losses at high temperatures (up to 550°C) and incorporate radiation-resistant insulation materials for long-term operation in nuclear environments[2]. Toshiba has demonstrated pump efficiencies exceeding 45% in large-scale prototypes, significantly higher than conventional electromagnetic pumps. Their design also includes innovative cooling channels for the stator windings that prevent overheating during continuous operation, extending the service life to over 40 years with minimal maintenance requirements.

Strengths: Extensive experience in nuclear applications with proven reliability; advanced manufacturing capabilities for large-scale electromagnetic systems; strong integration with their broader nuclear technology portfolio. Weaknesses: High initial capital costs compared to mechanical pumping alternatives; technology heavily optimized for nuclear applications which may limit flexibility for other industrial uses.

Core Patents and Technical Literature on Liquid Metal Pumping

Utilization of interconnections in electronic circuits as magnetohydrodynamic pumps for liquid metal based cooling

PatentPendingUS20230371203A1

Innovation

- A Magnetohydrodynamic (MHD) Pump system using liquid metal coolant, where a magnet provides a perpendicular magnetic field to generate Lorentz force for coolant flow, eliminating the need for auxiliary power supplies and leveraging current flow from main power electronic circuits to adjust flow rates.

Pumped liquid cooling for computer systems using liquid metal coolant

PatentInactiveUS20050099775A1

Innovation

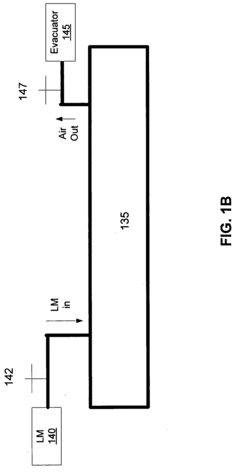

- A liquid cooling system employing a closed-loop system with liquid metal coolant, a pump, and a remote heat exchanger, along with techniques to prevent oxidation such as air evacuation and filling methods, and the use of cold plates and heat spreaders to enhance heat transfer, replaces traditional heat pipes with thermally conductive tubes and utilizes single or multi-pass heat exchangers for efficient heat rejection.

Thermal Management Applications and Use Cases

Liquid metal cooling electromagnetic pumps have found significant applications across various thermal management scenarios due to their unique capabilities. In data centers, these pumps enable efficient heat dissipation for high-density server racks, addressing the growing thermal challenges posed by increasingly powerful computing hardware. The non-mechanical pumping mechanism allows for reliable operation in these critical environments where system downtime can result in substantial financial losses.

In the electric vehicle industry, liquid metal cooling systems powered by electromagnetic pumps provide superior thermal management for battery packs and power electronics. This technology helps maintain optimal operating temperatures during fast charging and high-performance driving scenarios, extending battery life and improving overall vehicle reliability. The compact design of these pumping systems also contributes to space optimization in EV architectures where packaging constraints are significant.

Advanced electronics manufacturing benefits from precise temperature control offered by liquid metal cooling systems. Semiconductor fabrication processes require extremely stable thermal conditions, which electromagnetic pumps can deliver without the vibration issues associated with mechanical pumps. This precision contributes to higher yields and better quality in chip production.

Nuclear power applications represent another critical use case, where liquid metal coolants like sodium or lead-bismuth eutectic are circulated using electromagnetic pumps. These systems offer inherent safety advantages through simplified designs with fewer moving parts, reducing maintenance requirements and potential failure points in reactor cooling systems.

Aerospace thermal management systems increasingly incorporate liquid metal cooling with electromagnetic pumps for satellite and spacecraft applications. The absence of moving parts enhances reliability in the harsh space environment, while the high thermal conductivity of liquid metals enables efficient heat transfer from sensitive electronics and propulsion systems.

Renewable energy installations, particularly concentrated solar power plants, utilize liquid metal heat transfer systems for thermal energy storage. Electromagnetic pumps facilitate the movement of high-temperature liquid metals between solar receivers and storage tanks, enabling electricity generation even when the sun isn't shining.

Medical applications are emerging as well, with liquid metal cooling systems providing precise temperature control for advanced imaging equipment and therapeutic devices. The electromagnetic pumping technology ensures silent operation and minimal vibration, creating a better environment for both patients and sensitive diagnostic procedures.

In the electric vehicle industry, liquid metal cooling systems powered by electromagnetic pumps provide superior thermal management for battery packs and power electronics. This technology helps maintain optimal operating temperatures during fast charging and high-performance driving scenarios, extending battery life and improving overall vehicle reliability. The compact design of these pumping systems also contributes to space optimization in EV architectures where packaging constraints are significant.

Advanced electronics manufacturing benefits from precise temperature control offered by liquid metal cooling systems. Semiconductor fabrication processes require extremely stable thermal conditions, which electromagnetic pumps can deliver without the vibration issues associated with mechanical pumps. This precision contributes to higher yields and better quality in chip production.

Nuclear power applications represent another critical use case, where liquid metal coolants like sodium or lead-bismuth eutectic are circulated using electromagnetic pumps. These systems offer inherent safety advantages through simplified designs with fewer moving parts, reducing maintenance requirements and potential failure points in reactor cooling systems.

Aerospace thermal management systems increasingly incorporate liquid metal cooling with electromagnetic pumps for satellite and spacecraft applications. The absence of moving parts enhances reliability in the harsh space environment, while the high thermal conductivity of liquid metals enables efficient heat transfer from sensitive electronics and propulsion systems.

Renewable energy installations, particularly concentrated solar power plants, utilize liquid metal heat transfer systems for thermal energy storage. Electromagnetic pumps facilitate the movement of high-temperature liquid metals between solar receivers and storage tanks, enabling electricity generation even when the sun isn't shining.

Medical applications are emerging as well, with liquid metal cooling systems providing precise temperature control for advanced imaging equipment and therapeutic devices. The electromagnetic pumping technology ensures silent operation and minimal vibration, creating a better environment for both patients and sensitive diagnostic procedures.

Safety and Material Compatibility Considerations

The safety considerations for liquid metal cooling electromagnetic pumps are paramount due to the inherent risks associated with high-temperature liquid metals and electromagnetic fields. Liquid metals commonly used in these systems, such as sodium, NaK alloys, lead, and gallium-based alloys, present significant hazards including chemical reactivity, toxicity, and fire risks. Sodium and NaK alloys react violently with water and air, necessitating stringent containment measures and inert gas environments. Lead-based coolants pose serious health risks through potential exposure, requiring robust handling protocols and monitoring systems.

Material compatibility represents another critical aspect of electromagnetic pump design. The corrosive nature of liquid metals at elevated temperatures can compromise structural integrity over time. Austenitic stainless steels (316L, 304) are widely employed for their resistance to liquid metal corrosion, though they may experience mass transfer effects during long-term operation. Advanced materials such as ferritic-martensitic steels and refractory alloys offer enhanced performance in high-temperature liquid metal environments but present challenges in fabrication and joining processes.

Electromagnetic compatibility must be addressed to prevent interference with surrounding systems and instrumentation. The strong electromagnetic fields generated during pump operation can affect nearby electronic components, sensors, and control systems. Proper shielding, grounding, and isolation techniques are essential to maintain operational integrity of the entire cooling system.

Thermal cycling and thermal shock present additional challenges, as temperature fluctuations can induce mechanical stresses at material interfaces. This is particularly concerning at joints between dissimilar materials where differential thermal expansion can lead to fatigue and eventual failure. Careful selection of compatible materials with similar thermal expansion coefficients and implementation of flexible connections can mitigate these risks.

Maintenance considerations must be integrated into the initial design phase. The radioactive environment in nuclear applications adds complexity to maintenance procedures, requiring remotely operated tools and specialized handling equipment. Non-destructive testing methods such as ultrasonic testing and eddy current inspection are valuable for monitoring system integrity without disassembly.

Regulatory compliance represents the final critical safety consideration. Electromagnetic pumps used in nuclear cooling applications must adhere to stringent nuclear safety standards including ASME BPVC Section III, NQA-1, and country-specific nuclear regulations. Documentation of material traceability, quality assurance processes, and comprehensive safety analyses are mandatory for regulatory approval and operational licensing.

Material compatibility represents another critical aspect of electromagnetic pump design. The corrosive nature of liquid metals at elevated temperatures can compromise structural integrity over time. Austenitic stainless steels (316L, 304) are widely employed for their resistance to liquid metal corrosion, though they may experience mass transfer effects during long-term operation. Advanced materials such as ferritic-martensitic steels and refractory alloys offer enhanced performance in high-temperature liquid metal environments but present challenges in fabrication and joining processes.

Electromagnetic compatibility must be addressed to prevent interference with surrounding systems and instrumentation. The strong electromagnetic fields generated during pump operation can affect nearby electronic components, sensors, and control systems. Proper shielding, grounding, and isolation techniques are essential to maintain operational integrity of the entire cooling system.

Thermal cycling and thermal shock present additional challenges, as temperature fluctuations can induce mechanical stresses at material interfaces. This is particularly concerning at joints between dissimilar materials where differential thermal expansion can lead to fatigue and eventual failure. Careful selection of compatible materials with similar thermal expansion coefficients and implementation of flexible connections can mitigate these risks.

Maintenance considerations must be integrated into the initial design phase. The radioactive environment in nuclear applications adds complexity to maintenance procedures, requiring remotely operated tools and specialized handling equipment. Non-destructive testing methods such as ultrasonic testing and eddy current inspection are valuable for monitoring system integrity without disassembly.

Regulatory compliance represents the final critical safety consideration. Electromagnetic pumps used in nuclear cooling applications must adhere to stringent nuclear safety standards including ASME BPVC Section III, NQA-1, and country-specific nuclear regulations. Documentation of material traceability, quality assurance processes, and comprehensive safety analyses are mandatory for regulatory approval and operational licensing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!