Liquid metal cooling environmental and regulatory considerations

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Cooling Technology Background and Objectives

Liquid metal cooling technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in various industries. Initially developed for nuclear reactors in the 1950s, liquid metals such as sodium, NaK alloys, and gallium-based alloys were utilized for their exceptional thermal conductivity properties. The historical progression of this technology demonstrates a continuous refinement of materials, safety protocols, and application methodologies to address the inherent challenges associated with highly reactive cooling media.

The current technological landscape features both traditional liquid metals (sodium, potassium) and emerging alternatives such as gallium-indium-tin (GaInSn) alloys and liquid metal composites that offer improved safety profiles while maintaining superior thermal performance. These advanced materials have expanded potential applications beyond nuclear energy into electronics cooling, concentrated solar power systems, and high-performance computing infrastructure.

Environmental considerations represent a critical dimension of liquid metal cooling technology development. Traditional liquid metals pose significant environmental hazards due to their reactivity with water and air, potential for fire or explosion, and toxicity concerns. Modern research aims to develop environmentally benign alternatives that minimize these risks while maintaining thermal efficiency advantages over conventional coolants.

Regulatory frameworks governing liquid metal cooling systems vary globally but generally focus on containment integrity, leak detection systems, emergency response protocols, and end-of-life disposal considerations. The evolution of these regulations reflects growing environmental awareness and increasingly stringent safety standards across industries. Compliance with these regulations represents a significant technical challenge that influences design choices and implementation strategies.

The primary technological objectives in this field include developing liquid metal cooling systems with enhanced safety features, reduced environmental impact, and improved compatibility with existing infrastructure. Specific goals encompass the creation of non-toxic, low-reactivity liquid metal formulations, advanced containment materials resistant to corrosion, and sophisticated monitoring systems capable of detecting potential failures before they result in environmental contamination.

Research initiatives are increasingly focused on lifecycle assessment approaches that consider the environmental impact of liquid metal coolants from production through disposal. This holistic perspective aims to identify and mitigate potential environmental risks at each stage of technology deployment, aligning with broader sustainability objectives and regulatory trends toward more comprehensive environmental protection frameworks.

The current technological landscape features both traditional liquid metals (sodium, potassium) and emerging alternatives such as gallium-indium-tin (GaInSn) alloys and liquid metal composites that offer improved safety profiles while maintaining superior thermal performance. These advanced materials have expanded potential applications beyond nuclear energy into electronics cooling, concentrated solar power systems, and high-performance computing infrastructure.

Environmental considerations represent a critical dimension of liquid metal cooling technology development. Traditional liquid metals pose significant environmental hazards due to their reactivity with water and air, potential for fire or explosion, and toxicity concerns. Modern research aims to develop environmentally benign alternatives that minimize these risks while maintaining thermal efficiency advantages over conventional coolants.

Regulatory frameworks governing liquid metal cooling systems vary globally but generally focus on containment integrity, leak detection systems, emergency response protocols, and end-of-life disposal considerations. The evolution of these regulations reflects growing environmental awareness and increasingly stringent safety standards across industries. Compliance with these regulations represents a significant technical challenge that influences design choices and implementation strategies.

The primary technological objectives in this field include developing liquid metal cooling systems with enhanced safety features, reduced environmental impact, and improved compatibility with existing infrastructure. Specific goals encompass the creation of non-toxic, low-reactivity liquid metal formulations, advanced containment materials resistant to corrosion, and sophisticated monitoring systems capable of detecting potential failures before they result in environmental contamination.

Research initiatives are increasingly focused on lifecycle assessment approaches that consider the environmental impact of liquid metal coolants from production through disposal. This holistic perspective aims to identify and mitigate potential environmental risks at each stage of technology deployment, aligning with broader sustainability objectives and regulatory trends toward more comprehensive environmental protection frameworks.

Market Demand Analysis for Advanced Thermal Management Solutions

The global thermal management market is experiencing unprecedented growth, driven primarily by the increasing power densities in electronic devices and the continuous miniaturization trend across industries. Current market valuations place the advanced cooling solutions sector at approximately 15 billion USD in 2023, with projections indicating a compound annual growth rate of 8.2% through 2030. Within this expanding market, liquid metal cooling technologies are emerging as a high-potential segment due to their superior thermal conductivity compared to traditional cooling methods.

Data centers represent the largest demand driver, consuming over 2% of global electricity and requiring increasingly efficient cooling solutions to manage their thermal output. The transition toward edge computing and high-performance computing (HPC) facilities has intensified this need, with operators seeking solutions that can reduce cooling-related energy consumption by at least 30% while maintaining reliability standards.

The electric vehicle (EV) sector presents another significant market opportunity for liquid metal cooling systems. As battery technologies evolve toward faster charging capabilities and higher energy densities, thermal management becomes critical for safety, performance, and longevity. Industry analysts report that effective thermal management can extend EV battery life by up to 15% and improve fast-charging efficiency by 20%, representing substantial value for manufacturers and consumers alike.

Consumer electronics manufacturers are increasingly exploring liquid metal solutions for high-performance devices. The gaming and professional computing segments show particular interest, with thermal constraints often limiting performance in compact form factors. Market research indicates consumers are willing to pay a 15-25% premium for devices offering superior thermal performance that translates to tangible performance improvements.

Industrial applications in sectors such as aerospace, defense, and advanced manufacturing represent emerging markets with specialized requirements. These sectors value reliability and performance under extreme conditions over initial cost considerations, making them ideal early adopters for advanced liquid metal cooling technologies.

Regulatory trends are significantly influencing market demand patterns. Environmental regulations targeting energy efficiency, particularly in North America, Europe, and developed Asian markets, are creating incentives for adoption of more efficient cooling technologies. Additionally, restrictions on certain refrigerants and cooling fluids are driving research into alternatives with lower environmental impact, positioning environmentally compatible liquid metal solutions favorably in the regulatory landscape.

Customer requirements are evolving toward solutions that offer not only superior thermal performance but also reduced maintenance requirements, longer operational lifespans, and compatibility with existing infrastructure. This represents both a challenge and opportunity for liquid metal cooling technologies as they mature and seek broader market adoption.

Data centers represent the largest demand driver, consuming over 2% of global electricity and requiring increasingly efficient cooling solutions to manage their thermal output. The transition toward edge computing and high-performance computing (HPC) facilities has intensified this need, with operators seeking solutions that can reduce cooling-related energy consumption by at least 30% while maintaining reliability standards.

The electric vehicle (EV) sector presents another significant market opportunity for liquid metal cooling systems. As battery technologies evolve toward faster charging capabilities and higher energy densities, thermal management becomes critical for safety, performance, and longevity. Industry analysts report that effective thermal management can extend EV battery life by up to 15% and improve fast-charging efficiency by 20%, representing substantial value for manufacturers and consumers alike.

Consumer electronics manufacturers are increasingly exploring liquid metal solutions for high-performance devices. The gaming and professional computing segments show particular interest, with thermal constraints often limiting performance in compact form factors. Market research indicates consumers are willing to pay a 15-25% premium for devices offering superior thermal performance that translates to tangible performance improvements.

Industrial applications in sectors such as aerospace, defense, and advanced manufacturing represent emerging markets with specialized requirements. These sectors value reliability and performance under extreme conditions over initial cost considerations, making them ideal early adopters for advanced liquid metal cooling technologies.

Regulatory trends are significantly influencing market demand patterns. Environmental regulations targeting energy efficiency, particularly in North America, Europe, and developed Asian markets, are creating incentives for adoption of more efficient cooling technologies. Additionally, restrictions on certain refrigerants and cooling fluids are driving research into alternatives with lower environmental impact, positioning environmentally compatible liquid metal solutions favorably in the regulatory landscape.

Customer requirements are evolving toward solutions that offer not only superior thermal performance but also reduced maintenance requirements, longer operational lifespans, and compatibility with existing infrastructure. This represents both a challenge and opportunity for liquid metal cooling technologies as they mature and seek broader market adoption.

Current State and Technical Challenges of Liquid Metal Cooling

Liquid metal cooling technology has evolved significantly over the past decade, with applications expanding from nuclear reactors to high-performance computing systems. Currently, gallium-based alloys such as Galinstan (gallium-indium-tin) and GaIn (gallium-indium) dominate the commercial landscape due to their low toxicity and melting points below room temperature. These properties make them viable alternatives to mercury, which has been largely phased out due to environmental concerns.

The thermal conductivity of liquid metals significantly outperforms traditional coolants, with gallium alloys offering 10-30 times higher thermal conductivity than water. This superior performance enables more efficient heat dissipation in compact electronic systems where thermal management is increasingly critical. However, widespread adoption faces several technical barriers that require innovative solutions.

Corrosion remains the primary technical challenge for liquid metal cooling systems. Gallium-based alloys are particularly aggressive toward aluminum, rapidly degrading structural components through dissolution and embrittlement. This necessitates the use of protective coatings or alternative materials such as stainless steel, titanium, or specialized ceramics, which increases system complexity and cost.

Oxidation presents another significant hurdle, as liquid metals readily form oxide layers when exposed to oxygen. These layers can impede thermal performance and potentially cause system blockages in microchannels. Current solutions involve operating systems in inert environments or incorporating oxygen getters, both adding complexity to system design and maintenance requirements.

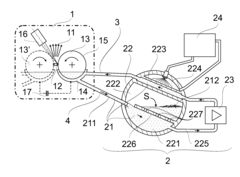

Pump reliability constitutes a persistent challenge in liquid metal cooling systems. The high density and surface tension of liquid metals create unique fluid dynamics that conventional pumping mechanisms struggle to handle efficiently. Electromagnetic pumps offer a solution by eliminating moving parts, but they introduce additional power requirements and electromagnetic interference concerns.

Regulatory frameworks governing liquid metal coolants vary significantly across regions, creating compliance challenges for global deployment. While gallium alloys are generally recognized as less hazardous than mercury, comprehensive standards for their handling, containment, and disposal remain underdeveloped in many jurisdictions. This regulatory uncertainty impedes investment and standardization efforts.

Environmental considerations include the mining impact of gallium production, potential for workplace exposure during maintenance, and end-of-life recycling protocols. The limited global supply of gallium, primarily obtained as a byproduct of aluminum and zinc production, raises sustainability concerns as demand increases across electronics, solar, and cooling applications.

The thermal conductivity of liquid metals significantly outperforms traditional coolants, with gallium alloys offering 10-30 times higher thermal conductivity than water. This superior performance enables more efficient heat dissipation in compact electronic systems where thermal management is increasingly critical. However, widespread adoption faces several technical barriers that require innovative solutions.

Corrosion remains the primary technical challenge for liquid metal cooling systems. Gallium-based alloys are particularly aggressive toward aluminum, rapidly degrading structural components through dissolution and embrittlement. This necessitates the use of protective coatings or alternative materials such as stainless steel, titanium, or specialized ceramics, which increases system complexity and cost.

Oxidation presents another significant hurdle, as liquid metals readily form oxide layers when exposed to oxygen. These layers can impede thermal performance and potentially cause system blockages in microchannels. Current solutions involve operating systems in inert environments or incorporating oxygen getters, both adding complexity to system design and maintenance requirements.

Pump reliability constitutes a persistent challenge in liquid metal cooling systems. The high density and surface tension of liquid metals create unique fluid dynamics that conventional pumping mechanisms struggle to handle efficiently. Electromagnetic pumps offer a solution by eliminating moving parts, but they introduce additional power requirements and electromagnetic interference concerns.

Regulatory frameworks governing liquid metal coolants vary significantly across regions, creating compliance challenges for global deployment. While gallium alloys are generally recognized as less hazardous than mercury, comprehensive standards for their handling, containment, and disposal remain underdeveloped in many jurisdictions. This regulatory uncertainty impedes investment and standardization efforts.

Environmental considerations include the mining impact of gallium production, potential for workplace exposure during maintenance, and end-of-life recycling protocols. The limited global supply of gallium, primarily obtained as a byproduct of aluminum and zinc production, raises sustainability concerns as demand increases across electronics, solar, and cooling applications.

Current Liquid Metal Cooling Implementation Approaches

01 Environmental impact of liquid metal coolants

Liquid metal coolants, while efficient for heat transfer, pose environmental concerns due to their potential toxicity and disposal challenges. These coolants may contain elements like gallium, indium, or mercury that require careful handling to prevent environmental contamination. Proper containment systems and disposal protocols are necessary to mitigate ecological risks associated with leakage or end-of-life management of cooling systems using liquid metals.- Environmental impact of liquid metal coolants: Liquid metal coolants, while efficient for heat transfer, pose environmental concerns due to their potential toxicity and disposal challenges. Some liquid metals like mercury and gallium alloys require special handling procedures to prevent environmental contamination. Regulatory frameworks mandate proper containment systems, disposal protocols, and environmental impact assessments for facilities using liquid metal cooling technologies to minimize ecological risks and ensure sustainable operation.

- Safety regulations and compliance standards: Liquid metal cooling systems must adhere to strict safety regulations and compliance standards across different jurisdictions. These include requirements for containment systems, leak detection mechanisms, emergency response protocols, and regular safety inspections. Manufacturers and operators must obtain necessary permits and certifications, implement risk assessment procedures, and maintain documentation of compliance with applicable standards to ensure safe operation of liquid metal cooling technologies.

- Alternative eco-friendly liquid metal formulations: Research has focused on developing environmentally friendly alternatives to traditional liquid metal coolants. These include non-toxic gallium-based alloys, bismuth-tin compositions, and other innovative formulations designed to maintain high thermal conductivity while reducing environmental and health risks. These alternative coolants feature lower toxicity profiles, biodegradability considerations, and reduced environmental persistence compared to conventional options, making them more compliant with evolving environmental regulations.

- Recycling and waste management protocols: Proper recycling and waste management of liquid metal coolants are critical environmental considerations governed by specific regulations. Systems must be designed with end-of-life considerations, including methods for safely recovering, recycling, or disposing of used liquid metals. Closed-loop systems that minimize waste generation, specialized containment for transportation of waste materials, and partnerships with certified disposal facilities are essential components of environmentally responsible liquid metal cooling system management.

- Monitoring and reporting requirements: Regulatory frameworks mandate comprehensive monitoring and reporting systems for liquid metal cooling installations. These include continuous monitoring of potential leaks, emissions tracking, temperature and pressure surveillance, and regular reporting to regulatory authorities. Advanced sensor technologies, automated alert systems, and detailed documentation procedures are implemented to ensure early detection of potential environmental or safety issues and facilitate transparent compliance with regulatory requirements.

02 Regulatory compliance for liquid metal cooling systems

Liquid metal cooling systems must adhere to various international and national regulations governing hazardous materials, electronic waste, and thermal management solutions. Compliance requirements include proper labeling, transportation restrictions, usage limitations in certain applications, and documentation of safety measures. Manufacturers must obtain necessary certifications and permits while ensuring their cooling solutions meet evolving environmental standards across different jurisdictions.Expand Specific Solutions03 Safety measures for handling liquid metal coolants

Working with liquid metal coolants requires specific safety protocols to protect both workers and the environment. These include specialized containment systems to prevent leakage, temperature monitoring to avoid overheating, proper ventilation in case of vaporization, and emergency response procedures for spills. Personal protective equipment and training for personnel handling these materials are essential to minimize exposure risks and ensure safe operation throughout the coolant lifecycle.Expand Specific Solutions04 Alternative eco-friendly liquid metal formulations

Research into environmentally safer liquid metal coolants focuses on developing formulations with reduced toxicity and environmental impact. These alternatives include gallium-based alloys that remain liquid at low temperatures, bismuth-containing compounds with lower environmental persistence, and novel metal mixtures designed for easier recycling. These formulations aim to maintain the superior thermal conductivity of liquid metals while addressing environmental and regulatory concerns.Expand Specific Solutions05 Recycling and disposal considerations for liquid metal cooling systems

End-of-life management of liquid metal cooling systems presents unique challenges requiring specialized recycling and disposal methods. Proper procedures involve separating the liquid metal from other components, reclaiming valuable elements through refinement processes, and ensuring hazardous constituents are neutralized or securely contained. Closed-loop recycling systems and take-back programs are being developed to minimize environmental impact and comply with waste management regulations.Expand Specific Solutions

Key Industry Players in Liquid Metal Cooling Market

The liquid metal cooling market is currently in a growth phase, characterized by increasing adoption in high-performance computing and industrial applications. The global market size is expanding rapidly, driven by demands for more efficient thermal management solutions in electronics and energy sectors. From a technological maturity perspective, the field shows varying levels of development across applications. Leading players like Siemens AG, Mitsubishi Heavy Industries, and Toshiba Corp. have established strong positions in industrial applications, while companies such as MAHLE International and Honda Motor are advancing automotive implementations. Research institutions including Huazhong University of Science & Technology and China Nuclear Power Research & Design Institute are addressing environmental and regulatory challenges related to toxicity, disposal, and safety standards that currently constrain broader market adoption.

Toshiba Corp.

Technical Solution: Toshiba has developed innovative liquid metal cooling solutions primarily for electronics and energy applications, focusing on gallium-indium-tin alloys with low toxicity profiles. Their environmental approach incorporates hermetically sealed cooling modules with multi-layer containment systems that prevent environmental release throughout the product lifecycle. Toshiba's liquid metal thermal interface materials achieve thermal conductivity up to 40 W/m·K while maintaining compliance with RoHS and REACH regulations[6]. For data center applications, their liquid metal cooling systems include automated monitoring that detects potential leaks and initiates containment protocols before environmental exposure occurs. Toshiba has pioneered recyclable packaging systems for liquid metal coolants that facilitate safe transportation, storage, and end-of-life processing. Their regulatory compliance strategy includes comprehensive material safety data documentation and third-party verification of environmental performance claims. Toshiba has also developed specialized training programs for maintenance personnel handling liquid metal cooling systems, ensuring proper procedures are followed to prevent workplace exposure and environmental contamination[8].

Strengths: Excellent thermal performance in compact electronic applications; systems designed for compatibility with existing regulatory frameworks; comprehensive safety features integrated into product design; solutions optimized for commercial deployment. Weaknesses: Limited to specific application scenarios; requires specialized handling procedures; higher initial cost compared to conventional cooling solutions; potential compatibility issues with certain materials.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed proprietary liquid metal cooling technologies for automotive applications, focusing on gallium-based alloys with enhanced thermal properties. Their environmental approach centers on fully sealed cooling systems with specialized alloy formulations that minimize toxicity concerns while maximizing heat transfer efficiency. Honda's liquid metal cooling solutions for electric vehicle battery systems achieve up to 30% better thermal management compared to conventional coolants, while meeting stringent automotive safety standards[9]. Their environmental compliance strategy includes comprehensive lifecycle management from manufacturing through vehicle end-of-life, with specialized recovery processes for liquid metal coolants during vehicle recycling. Honda has pioneered fail-safe containment systems that prevent environmental release even in severe collision scenarios, utilizing multi-layer encapsulation technologies and rapid solidification properties of their proprietary alloys. For regulatory compliance, Honda has developed detailed safety protocols and documentation packages that address transportation regulations, service procedures, and emergency response guidelines specific to vehicles equipped with liquid metal cooling systems. Their approach also includes specialized training programs for service technicians and first responders to ensure proper handling in maintenance and accident scenarios[10].

Strengths: Superior thermal management for electric vehicle applications; comprehensive safety systems designed for automotive use cases; fully integrated lifecycle management approach; solutions optimized for mass production. Weaknesses: Higher component costs compared to conventional cooling systems; requires specialized service procedures; potential compatibility challenges with certain manufacturing processes; limited to applications where performance benefits justify added complexity.

Critical Patents and Technical Innovations in Liquid Metal Cooling

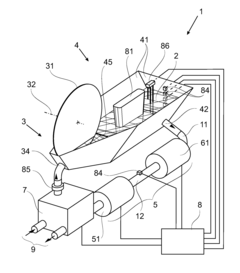

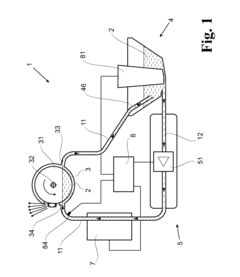

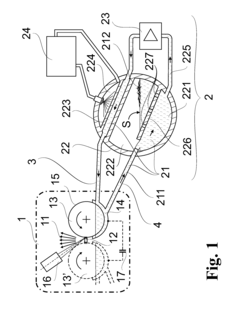

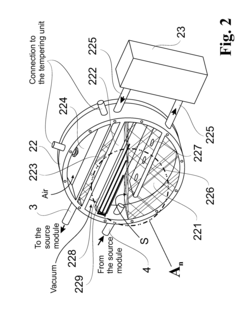

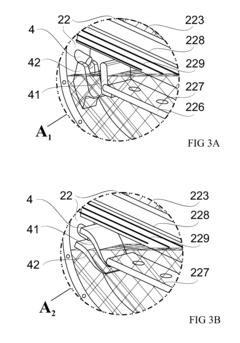

Arrangement for Cooling a Plasma-Based Radiation Source with a Metal Cooling Liquid and Method for Starting Up a Cooling Arrangement of This Type

PatentActiveUS20150247679A1

Innovation

- A cooling arrangement that includes a pump unit with induction pumps in a pipe portion connected to the reservoir, allowing for temporary operation in a direction opposite to the conventional flow to generate a heating effect, combined with a control unit for temperature monitoring and adjustment, and a heat exchanger for maintaining the metal cooling liquid above its melting temperature.

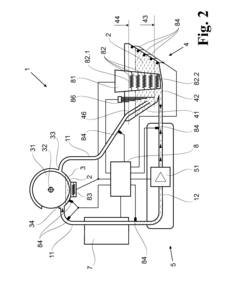

Arrangement for the Handling of a Liquid Metal for Cooling Revolving Components of a Radiation Source Based on a Radiation-Emitting Plasma

PatentActiveUS20140307857A1

Innovation

- A cooling system design that includes a reservoir for the liquid metal, a pump unit for circulation, and a return pipe with a gradient to facilitate laminar flow and minimize erosion, combined with corrosion-resistant coatings and materials, and a slag separator to manage impurities, ensuring efficient heat management and extended system life.

Environmental Impact Assessment of Liquid Metal Coolants

The environmental impact assessment of liquid metal coolants requires comprehensive analysis due to their unique properties and potential ecological footprint. Liquid metals such as gallium, sodium, and lead-bismuth eutectic (LBE) present distinct environmental considerations compared to conventional coolants.

When released into aquatic ecosystems, liquid metal coolants can undergo various transformation processes including oxidation and compound formation with environmental constituents. Gallium-based coolants typically exhibit lower toxicity profiles than mercury or lead alternatives, but their long-term persistence in sediments remains concerning. Sodium-based coolants react violently with water, creating potential for localized pH alterations and thermal damage to aquatic habitats.

Atmospheric emissions during manufacturing, maintenance, or disposal phases constitute another environmental pathway requiring assessment. Vapor pressure characteristics of different liquid metals determine their volatilization potential, with mercury-based coolants presenting significant inhalation risks compared to gallium or sodium alternatives. Particulate emissions containing liquid metal residues can contribute to air quality degradation in surrounding communities.

Soil contamination represents a persistent concern, particularly for facilities utilizing liquid metal cooling systems. Migration through soil profiles depends on specific metal properties, with some compounds demonstrating high mobility in acidic conditions. Bioaccumulation potential varies significantly among liquid metal variants, with lead-bismuth eutectic showing greater propensity for uptake in terrestrial food chains compared to gallium-based alternatives.

Life cycle assessment methodologies reveal that environmental impacts extend beyond operational phases. Raw material extraction for liquid metals often involves energy-intensive mining operations with substantial carbon footprints. Manufacturing processes require specialized containment systems and safety protocols that increase embodied energy compared to conventional coolants.

Waste management considerations present significant challenges, as spent liquid metal coolants often qualify as hazardous materials under regulatory frameworks. Recovery and recycling technologies have advanced significantly, with gallium reclamation achieving efficiency rates exceeding 85% in specialized facilities. However, contaminated components and maintenance waste still require specialized disposal protocols.

Comparative environmental impact analyses demonstrate that while liquid metal coolants offer superior thermal performance, their ecological footprint must be carefully managed through engineered containment systems, monitoring protocols, and emergency response capabilities. The environmental risk profile varies substantially based on specific metal composition, with newer gallium-indium formulations showing promising reductions in ecotoxicity compared to traditional alternatives.

When released into aquatic ecosystems, liquid metal coolants can undergo various transformation processes including oxidation and compound formation with environmental constituents. Gallium-based coolants typically exhibit lower toxicity profiles than mercury or lead alternatives, but their long-term persistence in sediments remains concerning. Sodium-based coolants react violently with water, creating potential for localized pH alterations and thermal damage to aquatic habitats.

Atmospheric emissions during manufacturing, maintenance, or disposal phases constitute another environmental pathway requiring assessment. Vapor pressure characteristics of different liquid metals determine their volatilization potential, with mercury-based coolants presenting significant inhalation risks compared to gallium or sodium alternatives. Particulate emissions containing liquid metal residues can contribute to air quality degradation in surrounding communities.

Soil contamination represents a persistent concern, particularly for facilities utilizing liquid metal cooling systems. Migration through soil profiles depends on specific metal properties, with some compounds demonstrating high mobility in acidic conditions. Bioaccumulation potential varies significantly among liquid metal variants, with lead-bismuth eutectic showing greater propensity for uptake in terrestrial food chains compared to gallium-based alternatives.

Life cycle assessment methodologies reveal that environmental impacts extend beyond operational phases. Raw material extraction for liquid metals often involves energy-intensive mining operations with substantial carbon footprints. Manufacturing processes require specialized containment systems and safety protocols that increase embodied energy compared to conventional coolants.

Waste management considerations present significant challenges, as spent liquid metal coolants often qualify as hazardous materials under regulatory frameworks. Recovery and recycling technologies have advanced significantly, with gallium reclamation achieving efficiency rates exceeding 85% in specialized facilities. However, contaminated components and maintenance waste still require specialized disposal protocols.

Comparative environmental impact analyses demonstrate that while liquid metal coolants offer superior thermal performance, their ecological footprint must be carefully managed through engineered containment systems, monitoring protocols, and emergency response capabilities. The environmental risk profile varies substantially based on specific metal composition, with newer gallium-indium formulations showing promising reductions in ecotoxicity compared to traditional alternatives.

Regulatory Compliance Framework for Liquid Metal Cooling Systems

The regulatory landscape for liquid metal cooling systems is complex and multifaceted, requiring careful navigation to ensure compliance across different jurisdictions. At the international level, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) have established baseline standards that influence regional and national regulations. These standards typically address safety requirements, performance metrics, and environmental considerations specific to cooling technologies.

In the United States, liquid metal cooling systems fall under the purview of multiple regulatory bodies. The Environmental Protection Agency (EPA) regulates the disposal and potential environmental impact of liquid metals under the Resource Conservation and Recovery Act (RCRA). Meanwhile, the Occupational Safety and Health Administration (OSHA) establishes workplace safety standards for handling potentially hazardous materials like gallium, indium, and other metals commonly used in advanced cooling solutions.

The European Union implements more stringent regulations through directives such as the Restriction of Hazardous Substances (RoHS) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH). These frameworks impose specific limitations on the use of certain metals and compounds, potentially affecting the composition and design of liquid metal cooling systems. Manufacturers must obtain proper certification and documentation to demonstrate compliance with these directives.

Asian markets present varying regulatory requirements. Japan's regulatory framework emphasizes recycling and proper disposal through its Home Appliance Recycling Law and the Law for Promotion of Effective Utilization of Resources. China has implemented the China RoHS and China REACH, which mirror European standards but with distinct compliance procedures and documentation requirements.

Emerging economies are developing their regulatory frameworks, often adopting modified versions of established international standards. This creates a complex patchwork of requirements that manufacturers must navigate when deploying liquid metal cooling technologies globally.

Industry-specific regulations add another layer of complexity. Data centers, for instance, must comply with additional standards related to energy efficiency and thermal management, such as those established by ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers). The medical and aerospace sectors impose particularly stringent reliability and safety requirements on cooling technologies.

Compliance strategies typically involve comprehensive documentation, regular testing, and certification processes. Organizations must establish robust internal compliance programs that include regular audits, staff training, and monitoring of regulatory developments. As environmental concerns grow globally, regulatory frameworks are likely to evolve toward stricter controls on materials used in cooling systems, emphasizing recyclability and reduced environmental impact.

In the United States, liquid metal cooling systems fall under the purview of multiple regulatory bodies. The Environmental Protection Agency (EPA) regulates the disposal and potential environmental impact of liquid metals under the Resource Conservation and Recovery Act (RCRA). Meanwhile, the Occupational Safety and Health Administration (OSHA) establishes workplace safety standards for handling potentially hazardous materials like gallium, indium, and other metals commonly used in advanced cooling solutions.

The European Union implements more stringent regulations through directives such as the Restriction of Hazardous Substances (RoHS) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH). These frameworks impose specific limitations on the use of certain metals and compounds, potentially affecting the composition and design of liquid metal cooling systems. Manufacturers must obtain proper certification and documentation to demonstrate compliance with these directives.

Asian markets present varying regulatory requirements. Japan's regulatory framework emphasizes recycling and proper disposal through its Home Appliance Recycling Law and the Law for Promotion of Effective Utilization of Resources. China has implemented the China RoHS and China REACH, which mirror European standards but with distinct compliance procedures and documentation requirements.

Emerging economies are developing their regulatory frameworks, often adopting modified versions of established international standards. This creates a complex patchwork of requirements that manufacturers must navigate when deploying liquid metal cooling technologies globally.

Industry-specific regulations add another layer of complexity. Data centers, for instance, must comply with additional standards related to energy efficiency and thermal management, such as those established by ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers). The medical and aerospace sectors impose particularly stringent reliability and safety requirements on cooling technologies.

Compliance strategies typically involve comprehensive documentation, regular testing, and certification processes. Organizations must establish robust internal compliance programs that include regular audits, staff training, and monitoring of regulatory developments. As environmental concerns grow globally, regulatory frameworks are likely to evolve toward stricter controls on materials used in cooling systems, emphasizing recyclability and reduced environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!