Liquid metal cooling scalability in industrial-scale heat exchangers

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Cooling Technology Evolution and Objectives

Liquid metal cooling technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in various industrial settings. Initially developed for nuclear reactor cooling systems in the 1950s, liquid metals such as sodium, NaK alloys, and later gallium-based alloys were recognized for their exceptional thermal conductivity properties. The fundamental advantage of liquid metals lies in their ability to transfer heat at rates significantly higher than conventional coolants while maintaining relatively low operating pressures.

The evolution of liquid metal cooling technology has been marked by several key milestones. In the 1960s and 1970s, significant research focused on sodium-cooled fast breeder reactors, establishing fundamental principles for liquid metal heat transfer systems. The 1980s and 1990s witnessed expanded applications beyond nuclear power, with aerospace and defense industries exploring liquid metal cooling for high-performance electronics and propulsion systems. The early 2000s brought renewed interest in liquid metal cooling for computing applications, particularly for high-performance processors and data centers.

Recent technological advancements have focused on addressing historical challenges associated with liquid metal cooling systems. These include developing corrosion-resistant materials and containment solutions, improving pumping mechanisms for high-density fluids, and enhancing safety protocols for handling reactive liquid metals. The introduction of gallium-indium-tin alloys (Galinstan) and other low-melting-point alloys has significantly expanded the practical application range by reducing operational hazards associated with earlier liquid metal coolants.

The current trajectory of liquid metal cooling technology is directed toward scalability in industrial heat exchangers, which represents a significant frontier for innovation. As power densities in industrial processes continue to increase, conventional cooling methods are approaching their physical limitations. Liquid metal cooling offers a promising alternative with heat transfer coefficients 10-100 times greater than water-based systems, potentially enabling more compact and efficient heat exchanger designs.

The primary objectives for advancing liquid metal cooling in industrial-scale heat exchangers include: developing cost-effective manufacturing techniques for corrosion-resistant components; creating reliable pumping and flow control systems capable of handling the unique fluid dynamics of liquid metals; establishing standardized safety protocols and containment strategies; and optimizing heat exchanger geometries specifically for liquid metal properties. Additionally, there is significant focus on reducing the environmental footprint through closed-loop systems and exploring applications in waste heat recovery and renewable energy systems.

The evolution of liquid metal cooling technology has been marked by several key milestones. In the 1960s and 1970s, significant research focused on sodium-cooled fast breeder reactors, establishing fundamental principles for liquid metal heat transfer systems. The 1980s and 1990s witnessed expanded applications beyond nuclear power, with aerospace and defense industries exploring liquid metal cooling for high-performance electronics and propulsion systems. The early 2000s brought renewed interest in liquid metal cooling for computing applications, particularly for high-performance processors and data centers.

Recent technological advancements have focused on addressing historical challenges associated with liquid metal cooling systems. These include developing corrosion-resistant materials and containment solutions, improving pumping mechanisms for high-density fluids, and enhancing safety protocols for handling reactive liquid metals. The introduction of gallium-indium-tin alloys (Galinstan) and other low-melting-point alloys has significantly expanded the practical application range by reducing operational hazards associated with earlier liquid metal coolants.

The current trajectory of liquid metal cooling technology is directed toward scalability in industrial heat exchangers, which represents a significant frontier for innovation. As power densities in industrial processes continue to increase, conventional cooling methods are approaching their physical limitations. Liquid metal cooling offers a promising alternative with heat transfer coefficients 10-100 times greater than water-based systems, potentially enabling more compact and efficient heat exchanger designs.

The primary objectives for advancing liquid metal cooling in industrial-scale heat exchangers include: developing cost-effective manufacturing techniques for corrosion-resistant components; creating reliable pumping and flow control systems capable of handling the unique fluid dynamics of liquid metals; establishing standardized safety protocols and containment strategies; and optimizing heat exchanger geometries specifically for liquid metal properties. Additionally, there is significant focus on reducing the environmental footprint through closed-loop systems and exploring applications in waste heat recovery and renewable energy systems.

Industrial Heat Exchanger Market Analysis

The global industrial heat exchanger market is experiencing robust growth, valued at approximately $17.86 billion in 2022 with projections to reach $24.32 billion by 2028, representing a compound annual growth rate of 5.3%. This growth is primarily driven by increasing industrialization across developing economies, stringent energy efficiency regulations, and the rising demand for sustainable cooling solutions in energy-intensive industries.

The market segmentation reveals distinct categories based on application requirements. Shell and tube heat exchangers dominate with roughly 38% market share due to their versatility and reliability in high-pressure applications. Plate heat exchangers follow at 27%, gaining popularity for their compact design and higher thermal efficiency. Air-cooled heat exchangers constitute about 19% of the market, while specialized types including liquid metal-based systems account for the remaining 16%.

Geographically, Asia-Pacific leads the market with 35% share, fueled by rapid industrialization in China and India. North America and Europe follow with 28% and 24% respectively, where the focus is increasingly on energy-efficient and environmentally sustainable solutions. The Middle East and Africa region, though smaller at 13%, is witnessing accelerated growth due to expanding oil and gas operations.

Key industry verticals driving demand include chemical processing (26%), oil and gas (22%), power generation (18%), HVAC (14%), and food and beverage (11%), with other applications comprising the remaining 9%. The chemical processing sector particularly shows strong interest in advanced cooling technologies like liquid metal systems due to their superior thermal conductivity and potential for handling extreme temperature conditions.

Market dynamics indicate a shift toward more efficient cooling technologies, with liquid metal cooling gaining attention for applications requiring high heat transfer rates. Despite representing less than 3% of current heat exchanger installations, liquid metal cooling systems are projected to grow at twice the market rate over the next five years, particularly in sectors dealing with extreme thermal management challenges.

Customer requirements are evolving toward solutions offering higher energy efficiency, reduced maintenance costs, and extended operational lifespans. This trend aligns favorably with liquid metal cooling technologies, which offer theoretical thermal efficiency improvements of 30-45% compared to conventional water-based systems in high-temperature industrial applications.

The market segmentation reveals distinct categories based on application requirements. Shell and tube heat exchangers dominate with roughly 38% market share due to their versatility and reliability in high-pressure applications. Plate heat exchangers follow at 27%, gaining popularity for their compact design and higher thermal efficiency. Air-cooled heat exchangers constitute about 19% of the market, while specialized types including liquid metal-based systems account for the remaining 16%.

Geographically, Asia-Pacific leads the market with 35% share, fueled by rapid industrialization in China and India. North America and Europe follow with 28% and 24% respectively, where the focus is increasingly on energy-efficient and environmentally sustainable solutions. The Middle East and Africa region, though smaller at 13%, is witnessing accelerated growth due to expanding oil and gas operations.

Key industry verticals driving demand include chemical processing (26%), oil and gas (22%), power generation (18%), HVAC (14%), and food and beverage (11%), with other applications comprising the remaining 9%. The chemical processing sector particularly shows strong interest in advanced cooling technologies like liquid metal systems due to their superior thermal conductivity and potential for handling extreme temperature conditions.

Market dynamics indicate a shift toward more efficient cooling technologies, with liquid metal cooling gaining attention for applications requiring high heat transfer rates. Despite representing less than 3% of current heat exchanger installations, liquid metal cooling systems are projected to grow at twice the market rate over the next five years, particularly in sectors dealing with extreme thermal management challenges.

Customer requirements are evolving toward solutions offering higher energy efficiency, reduced maintenance costs, and extended operational lifespans. This trend aligns favorably with liquid metal cooling technologies, which offer theoretical thermal efficiency improvements of 30-45% compared to conventional water-based systems in high-temperature industrial applications.

Current Limitations and Technical Barriers in Liquid Metal Cooling

Despite the promising thermal properties of liquid metals, their widespread adoption in industrial-scale heat exchangers faces significant technical barriers. One primary limitation is the corrosive nature of liquid metals, particularly gallium-based alloys, which can aggressively attack conventional heat exchanger materials like aluminum, copper, and certain steels. This corrosion mechanism accelerates at elevated temperatures, creating a challenging trade-off between thermal performance and system longevity.

Material compatibility issues extend beyond corrosion to include embrittlement phenomena, where liquid metals penetrate grain boundaries of structural materials, compromising mechanical integrity. This is particularly problematic in high-stress regions of industrial heat exchangers where thermal cycling is common, potentially leading to catastrophic failures without adequate materials selection and protective measures.

The high surface tension of liquid metals presents another significant challenge for industrial scalability. This property creates wetting difficulties with many common engineering surfaces, reducing effective heat transfer area and creating thermal contact resistance. While surface modification techniques exist, maintaining these treatments over extended operational periods in industrial environments remains problematic.

Pumping and flow control of liquid metals introduce additional complexities. Their high density necessitates robust pumping systems capable of handling increased loads, while their electrical conductivity introduces magnetohydrodynamic (MHD) effects when flowing through electromagnetic fields. These MHD interactions can create flow instabilities and pressure drops that are difficult to predict and control at industrial scales.

Safety considerations present further barriers to widespread adoption. Many liquid metal coolants, particularly those containing sodium or lithium, pose significant fire and explosion hazards when exposed to air or water. Implementing adequate containment, leak detection, and emergency response systems adds substantial complexity and cost to industrial installations.

Economic factors also limit scalability, with high-purity liquid metals representing a significant capital investment. The specialized equipment required for safe handling, monitoring, and maintenance further increases total cost of ownership compared to conventional cooling solutions. Additionally, the lack of standardized design methodologies and limited operational experience in industrial settings creates uncertainty in performance predictions and reliability assessments.

Regulatory frameworks for liquid metal cooling systems in industrial applications remain underdeveloped in many jurisdictions, creating compliance uncertainties and potential approval delays for new installations. This regulatory ambiguity, combined with the technical challenges outlined above, has restricted liquid metal cooling primarily to specialized applications rather than mainstream industrial heat exchange processes.

Material compatibility issues extend beyond corrosion to include embrittlement phenomena, where liquid metals penetrate grain boundaries of structural materials, compromising mechanical integrity. This is particularly problematic in high-stress regions of industrial heat exchangers where thermal cycling is common, potentially leading to catastrophic failures without adequate materials selection and protective measures.

The high surface tension of liquid metals presents another significant challenge for industrial scalability. This property creates wetting difficulties with many common engineering surfaces, reducing effective heat transfer area and creating thermal contact resistance. While surface modification techniques exist, maintaining these treatments over extended operational periods in industrial environments remains problematic.

Pumping and flow control of liquid metals introduce additional complexities. Their high density necessitates robust pumping systems capable of handling increased loads, while their electrical conductivity introduces magnetohydrodynamic (MHD) effects when flowing through electromagnetic fields. These MHD interactions can create flow instabilities and pressure drops that are difficult to predict and control at industrial scales.

Safety considerations present further barriers to widespread adoption. Many liquid metal coolants, particularly those containing sodium or lithium, pose significant fire and explosion hazards when exposed to air or water. Implementing adequate containment, leak detection, and emergency response systems adds substantial complexity and cost to industrial installations.

Economic factors also limit scalability, with high-purity liquid metals representing a significant capital investment. The specialized equipment required for safe handling, monitoring, and maintenance further increases total cost of ownership compared to conventional cooling solutions. Additionally, the lack of standardized design methodologies and limited operational experience in industrial settings creates uncertainty in performance predictions and reliability assessments.

Regulatory frameworks for liquid metal cooling systems in industrial applications remain underdeveloped in many jurisdictions, creating compliance uncertainties and potential approval delays for new installations. This regulatory ambiguity, combined with the technical challenges outlined above, has restricted liquid metal cooling primarily to specialized applications rather than mainstream industrial heat exchange processes.

Existing Liquid Metal Cooling Implementation Strategies

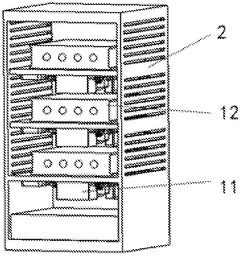

01 Liquid metal cooling systems for electronic devices

Liquid metal cooling systems are used in electronic devices to efficiently dissipate heat. These systems utilize the high thermal conductivity of liquid metals to transfer heat away from critical components. The scalability of these systems allows for implementation in various device sizes, from small consumer electronics to larger computing systems, providing effective thermal management solutions that can be adapted to different power requirements and form factors.- Liquid metal cooling systems for electronic devices: Liquid metal cooling systems are used in electronic devices to efficiently dissipate heat. These systems utilize the high thermal conductivity of liquid metals to transfer heat away from critical components. The scalability of these systems allows for implementation in various device sizes, from small consumer electronics to larger computing systems, providing effective thermal management while maintaining performance.

- Scalable data center cooling with liquid metal: Liquid metal cooling solutions for data centers offer scalable thermal management for high-density computing environments. These systems can be designed to accommodate growing computational demands while maintaining optimal operating temperatures. The scalability features include modular components, expandable heat exchange networks, and adaptive control systems that can be deployed across various sizes of data center installations.

- Manufacturing and production scaling of liquid metal cooling systems: Manufacturing processes for liquid metal cooling systems can be scaled to meet market demands. This includes techniques for mass production of liquid metal heat exchangers, pumps, and other components. Advanced manufacturing methods enable consistent quality while scaling production volumes, addressing challenges such as material compatibility, containment of liquid metals, and integration with existing cooling infrastructures.

- Thermal performance scaling of liquid metal cooling solutions: Liquid metal cooling solutions can be scaled to address varying thermal loads across different applications. The thermal performance can be adjusted through parameters such as flow rate, heat exchanger design, and liquid metal composition. This scalability enables these cooling systems to be effective in applications ranging from low-power devices to high-performance computing systems with significant heat generation.

- System integration and compatibility for scalable liquid metal cooling: Scalable liquid metal cooling systems require careful integration with existing infrastructure and compatibility with various hardware configurations. This includes considerations for electrical isolation, material compatibility, and maintenance procedures. Standardized interfaces and modular designs enable these systems to scale across different platforms while maintaining safety and reliability throughout the deployment lifecycle.

02 Scalable liquid metal cooling for data centers

Liquid metal cooling solutions for data centers offer scalable thermal management for high-density computing environments. These systems can be implemented at various scales, from rack-level to facility-wide deployments, allowing for modular expansion as computing needs grow. The superior heat transfer properties of liquid metals enable more efficient cooling of server farms, reducing energy consumption while accommodating increasing power densities in modern data centers.Expand Specific Solutions03 Manufacturing and material considerations for scalable liquid metal cooling

The manufacturing processes and material selection for liquid metal cooling systems significantly impact their scalability. Considerations include compatibility between liquid metals and containment materials to prevent corrosion, techniques for mass production of cooling components, and methods for ensuring consistent thermal performance across different scales. Advanced manufacturing approaches enable the production of complex cooling geometries that maintain efficiency when scaled up or down for various applications.Expand Specific Solutions04 Thermal modeling and simulation for liquid metal cooling scalability

Thermal modeling and simulation tools are essential for designing scalable liquid metal cooling systems. These computational methods help predict heat transfer performance across different system sizes and configurations, enabling engineers to optimize designs before physical implementation. Simulation approaches account for fluid dynamics, phase changes, and thermal interfaces, allowing for accurate scaling of cooling solutions from prototype to production while maintaining thermal efficiency.Expand Specific Solutions05 Integration of liquid metal cooling with power management systems

The integration of liquid metal cooling with power management systems enhances overall energy efficiency and scalability. These integrated approaches dynamically adjust cooling capacity based on real-time thermal loads, allowing systems to scale performance according to demand. The coordination between cooling and power management enables more efficient operation across varying workloads, extending the scalability of liquid metal cooling solutions to accommodate fluctuating thermal requirements in complex computing environments.Expand Specific Solutions

Leading Companies and Research Institutions in Thermal Management

Liquid metal cooling in industrial-scale heat exchangers is currently in a growth phase, with increasing market adoption driven by demands for more efficient thermal management solutions. The market is expanding rapidly, projected to reach significant scale as industries seek sustainable cooling alternatives. Technologically, companies like Siemens AG and MANN+HUMMEL are leading development with advanced implementations, while Asetek Danmark and Iceotope Group are pioneering innovative liquid cooling solutions specifically for data centers. Research institutions including CNRS and Louisiana State University are advancing fundamental understanding of liquid metal properties. Established industrial players such as Modine Manufacturing and Tranter GmbH are integrating these technologies into their heat exchanger portfolios, indicating the technology's transition from experimental to commercially viable solutions.

Siemens AG

Technical Solution: Siemens has developed a comprehensive liquid metal cooling solution for industrial-scale heat exchangers that leverages gallium-indium-tin alloys with thermal conductivity exceeding 60 W/mK. Their system employs a dual-circuit design where liquid metal serves as the primary coolant in direct contact with heat sources, while a secondary conventional coolant handles heat rejection to the environment. Siemens' proprietary electromagnetic pumping technology eliminates mechanical wear components when circulating liquid metal, significantly enhancing system reliability and longevity. The company's heat exchangers incorporate specialized nickel-based coatings that prevent liquid metal embrittlement of structural components, allowing for safe long-term operation. Their digital twin technology enables real-time monitoring and predictive maintenance of liquid metal cooling systems, optimizing performance across varying thermal loads. Siemens has demonstrated this technology in power generation applications, achieving cooling capacities of up to 75MW per unit with temperature differentials as low as 5°C across the heat exchanger.

Strengths: Electromagnetic pumping eliminates mechanical failure points; digital twin technology enables predictive maintenance and optimization; exceptional thermal performance allows for compact heat exchanger designs. Weaknesses: High initial capital investment; requires specialized expertise for installation and maintenance; limited deployment history compared to conventional cooling technologies.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed an innovative liquid metal cooling technology for industrial heat exchangers based on extensive fundamental research into two-phase flow dynamics of liquid metals. Their approach utilizes a sodium-potassium (NaK) alloy that remains liquid at room temperature while offering thermal conductivity approximately 25 times higher than water. The CNRS system incorporates a novel electromagnetic flow control mechanism that precisely regulates liquid metal circulation without mechanical pumps, eliminating potential failure points. Their heat exchanger design features specially engineered surface textures that enhance wetting properties of liquid metals, reducing thermal contact resistance by up to 60% compared to conventional interfaces. The technology includes an advanced safety containment system with multiple redundant barriers and real-time monitoring to address the reactive nature of alkali metal coolants. CNRS researchers have demonstrated this technology at pilot scale, achieving heat flux densities exceeding 500 W/cm² with minimal temperature gradients across the heat exchange surface.

Strengths: Extremely high thermal conductivity enables exceptional heat transfer rates; electromagnetic flow control eliminates mechanical wear components; fundamental research approach has yielded novel surface engineering techniques. Weaknesses: NaK alloy presents significant safety challenges requiring sophisticated containment systems; technology remains primarily at research/pilot scale; higher implementation complexity compared to conventional cooling solutions.

Key Patents and Innovations in Liquid Metal Heat Transfer

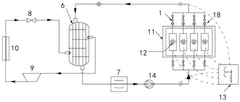

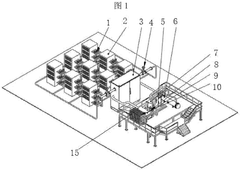

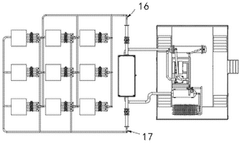

High-efficiency microcircuit thermal control system based on liquid metal cooling

PatentWO2025148566A1

Innovation

- Liquid metal is used as the cold-carrying working fluid, combined with the vapor compression refrigeration system, a multi-system online platform is designed, and the high thermal conductivity and low viscosity characteristics of liquid metal are used to set up a ridge-shaped micro-ribbing structure arranged in the fork arrangement inside the chip cooling platform to achieve efficient heat exchange between liquid metal and the chip, and the working status of each system is accurately monitored and regulated through an intelligent control system.

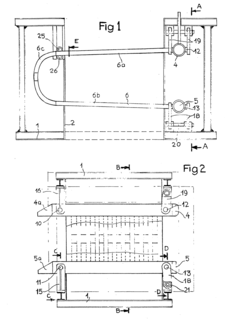

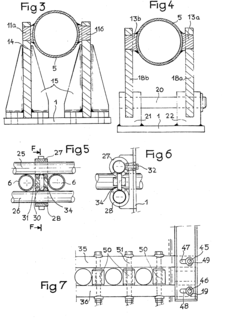

Heat exchanger for cooling a liquid metal by air

PatentInactiveEP0165840A1

Innovation

- A heat exchanger design featuring straight hot and cooled liquid metal collector pipes with U-shaped tubes, supported by coaxial trunnions and cylindrical rods that allow for longitudinal expansion and movement, preventing excessive stress through articulated and rotational support mechanisms.

Material Compatibility and Corrosion Management

Material compatibility represents a critical challenge in liquid metal cooling systems for industrial-scale heat exchangers. Liquid metals such as gallium, indium, and their alloys exhibit aggressive corrosive behavior when in contact with conventional structural materials. This corrosivity stems from their ability to dissolve metals through intermetallic compound formation and grain boundary penetration, particularly at elevated temperatures common in industrial applications.

The compatibility matrix between liquid metals and containment materials varies significantly. Refractory metals like tungsten, molybdenum, and tantalum demonstrate superior resistance to liquid metal corrosion but present challenges in manufacturing and cost. Stainless steels, while more economical, suffer from accelerated corrosion in liquid metal environments, especially in the presence of temperature gradients that exacerbate mass transfer corrosion.

Surface engineering approaches have emerged as promising strategies for corrosion management. Oxide layer formation through controlled oxidation processes can create protective barriers against liquid metal attack. Advanced coating technologies, including ceramic-based coatings (Al2O3, ZrO2) and composite metal-ceramic systems, have demonstrated enhanced protection in laboratory settings but require further validation at industrial scales.

Corrosion inhibition through alloying elements represents another viable approach. The addition of oxygen, nitrogen, or carbon at controlled concentrations to liquid metals can significantly reduce their corrosivity by forming passive films on container surfaces. However, precise concentration control remains challenging in large-scale systems where temperature gradients can alter solubility dynamics.

Monitoring and maintenance protocols constitute essential components of corrosion management strategies. Real-time corrosion monitoring using electrochemical impedance spectroscopy and ultrasonic thickness measurements enables early detection of material degradation. Predictive modeling tools incorporating computational fluid dynamics with corrosion kinetics help optimize system design and maintenance schedules.

The economic implications of material selection and corrosion management significantly impact the overall viability of liquid metal cooling systems. Life-cycle cost analyses indicate that while initial investments in corrosion-resistant materials may be substantial, they often result in lower total ownership costs through extended service life and reduced maintenance requirements.

Standardization efforts for material compatibility testing and qualification protocols remain underdeveloped for industrial-scale liquid metal systems. Establishing industry-wide standards for accelerated testing methodologies and acceptance criteria would facilitate technology adoption and risk management across various industrial sectors implementing liquid metal cooling solutions.

The compatibility matrix between liquid metals and containment materials varies significantly. Refractory metals like tungsten, molybdenum, and tantalum demonstrate superior resistance to liquid metal corrosion but present challenges in manufacturing and cost. Stainless steels, while more economical, suffer from accelerated corrosion in liquid metal environments, especially in the presence of temperature gradients that exacerbate mass transfer corrosion.

Surface engineering approaches have emerged as promising strategies for corrosion management. Oxide layer formation through controlled oxidation processes can create protective barriers against liquid metal attack. Advanced coating technologies, including ceramic-based coatings (Al2O3, ZrO2) and composite metal-ceramic systems, have demonstrated enhanced protection in laboratory settings but require further validation at industrial scales.

Corrosion inhibition through alloying elements represents another viable approach. The addition of oxygen, nitrogen, or carbon at controlled concentrations to liquid metals can significantly reduce their corrosivity by forming passive films on container surfaces. However, precise concentration control remains challenging in large-scale systems where temperature gradients can alter solubility dynamics.

Monitoring and maintenance protocols constitute essential components of corrosion management strategies. Real-time corrosion monitoring using electrochemical impedance spectroscopy and ultrasonic thickness measurements enables early detection of material degradation. Predictive modeling tools incorporating computational fluid dynamics with corrosion kinetics help optimize system design and maintenance schedules.

The economic implications of material selection and corrosion management significantly impact the overall viability of liquid metal cooling systems. Life-cycle cost analyses indicate that while initial investments in corrosion-resistant materials may be substantial, they often result in lower total ownership costs through extended service life and reduced maintenance requirements.

Standardization efforts for material compatibility testing and qualification protocols remain underdeveloped for industrial-scale liquid metal systems. Establishing industry-wide standards for accelerated testing methodologies and acceptance criteria would facilitate technology adoption and risk management across various industrial sectors implementing liquid metal cooling solutions.

Safety Protocols and Operational Risk Assessment

The implementation of liquid metal cooling systems in industrial-scale heat exchangers necessitates comprehensive safety protocols and operational risk assessment frameworks. Liquid metals such as gallium alloys, sodium, and NaK present unique hazards including chemical reactivity, high operating temperatures, and potential for rapid oxidation when exposed to air or moisture.

Primary safety considerations must address the handling of liquid metals during system filling, operation, and maintenance. Personnel require specialized training and appropriate personal protective equipment including thermal-resistant gloves, face shields, and chemical-resistant clothing. Operational areas must be equipped with emergency response stations including chemical neutralizers specific to the liquid metal in use and specialized fire suppression systems.

Environmental containment represents a critical safety component, with secondary and tertiary containment systems mandatory for industrial installations. These systems must be designed to withstand thermal cycling and potential chemical reactions between the liquid metal and containment materials. Regular integrity testing of these systems should be conducted using non-destructive evaluation techniques such as ultrasonic testing and radiographic inspection.

Risk assessment methodologies for liquid metal cooling systems should incorporate Failure Mode and Effects Analysis (FMEA) with particular attention to pump failures, heat exchanger breaches, and instrumentation malfunctions. Computational fluid dynamics modeling can predict potential failure scenarios and inform the development of mitigation strategies. Quantitative risk assessment should establish acceptable risk thresholds based on industry standards and regulatory requirements.

Operational protocols must include continuous monitoring systems for leak detection, temperature anomalies, and pressure fluctuations. Real-time monitoring using distributed sensor networks enables early detection of potential system failures. Automated emergency shutdown procedures should be implemented with redundant activation mechanisms to ensure system safety during critical failures.

Maintenance procedures require specialized protocols including system drainage, inert gas purging, and controlled solidification techniques for certain liquid metals. Maintenance personnel must be trained in these specialized procedures and understand the chemical compatibility issues between liquid metals and cleaning agents or lubricants.

Regulatory compliance presents additional considerations, with requirements varying significantly across jurisdictions. Industrial facilities implementing liquid metal cooling systems must navigate regulations related to hazardous materials handling, worker safety, and environmental protection. Documentation of safety protocols, risk assessments, and emergency response procedures is essential for regulatory approval and operational authorization.

Primary safety considerations must address the handling of liquid metals during system filling, operation, and maintenance. Personnel require specialized training and appropriate personal protective equipment including thermal-resistant gloves, face shields, and chemical-resistant clothing. Operational areas must be equipped with emergency response stations including chemical neutralizers specific to the liquid metal in use and specialized fire suppression systems.

Environmental containment represents a critical safety component, with secondary and tertiary containment systems mandatory for industrial installations. These systems must be designed to withstand thermal cycling and potential chemical reactions between the liquid metal and containment materials. Regular integrity testing of these systems should be conducted using non-destructive evaluation techniques such as ultrasonic testing and radiographic inspection.

Risk assessment methodologies for liquid metal cooling systems should incorporate Failure Mode and Effects Analysis (FMEA) with particular attention to pump failures, heat exchanger breaches, and instrumentation malfunctions. Computational fluid dynamics modeling can predict potential failure scenarios and inform the development of mitigation strategies. Quantitative risk assessment should establish acceptable risk thresholds based on industry standards and regulatory requirements.

Operational protocols must include continuous monitoring systems for leak detection, temperature anomalies, and pressure fluctuations. Real-time monitoring using distributed sensor networks enables early detection of potential system failures. Automated emergency shutdown procedures should be implemented with redundant activation mechanisms to ensure system safety during critical failures.

Maintenance procedures require specialized protocols including system drainage, inert gas purging, and controlled solidification techniques for certain liquid metals. Maintenance personnel must be trained in these specialized procedures and understand the chemical compatibility issues between liquid metals and cleaning agents or lubricants.

Regulatory compliance presents additional considerations, with requirements varying significantly across jurisdictions. Industrial facilities implementing liquid metal cooling systems must navigate regulations related to hazardous materials handling, worker safety, and environmental protection. Documentation of safety protocols, risk assessments, and emergency response procedures is essential for regulatory approval and operational authorization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!