Application of Raman spectroscopy in detecting malachite impurities

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Raman Spectroscopy Background and Objectives

Raman spectroscopy, a powerful analytical technique, has evolved significantly since its discovery by C.V. Raman in 1928. This non-destructive method relies on the inelastic scattering of monochromatic light, typically from a laser source, to provide detailed information about molecular vibrations and crystal structures. Over the decades, Raman spectroscopy has found applications across various scientific disciplines, including chemistry, physics, and materials science.

The technology behind Raman spectroscopy has seen remarkable advancements, particularly in recent years. The development of more powerful lasers, improved detectors, and sophisticated data processing algorithms has greatly enhanced the sensitivity and resolution of Raman measurements. These improvements have expanded the technique's capabilities, allowing for the analysis of increasingly complex materials and trace impurities.

In the context of detecting malachite impurities, Raman spectroscopy offers a unique set of advantages. Malachite, a copper carbonate hydroxide mineral, possesses distinct vibrational modes that can be readily identified through its Raman spectrum. The ability to detect and characterize malachite impurities is crucial in various fields, including geology, archaeology, and quality control in industries such as mining and gemology.

The primary objective of applying Raman spectroscopy to malachite impurity detection is to develop a reliable, efficient, and non-destructive method for identifying and quantifying malachite in various matrices. This goal encompasses several key aspects, including improving the sensitivity of detection to trace levels of malachite, enhancing the specificity of identification to distinguish malachite from other similar minerals, and developing robust analytical protocols for diverse sample types.

Another critical objective is to explore the potential for in-situ and real-time analysis of malachite impurities. This capability would be particularly valuable in field applications, such as geological surveys or on-site quality control in mining operations. Achieving this goal requires advancements in portable Raman spectrometers and the development of rapid data analysis techniques.

Furthermore, the integration of Raman spectroscopy with other analytical methods, such as X-ray diffraction or infrared spectroscopy, is an important area of development. This multi-modal approach aims to provide a more comprehensive characterization of materials containing malachite impurities, offering complementary information that can enhance the accuracy and reliability of analysis.

As research in this field progresses, there is also a focus on expanding the application of Raman spectroscopy beyond mere detection to more quantitative analysis of malachite impurities. This involves developing calibration methods and statistical models that can accurately determine the concentration of malachite in complex mixtures, potentially opening new avenues for quality control and process monitoring in industries where malachite presence is a concern.

The technology behind Raman spectroscopy has seen remarkable advancements, particularly in recent years. The development of more powerful lasers, improved detectors, and sophisticated data processing algorithms has greatly enhanced the sensitivity and resolution of Raman measurements. These improvements have expanded the technique's capabilities, allowing for the analysis of increasingly complex materials and trace impurities.

In the context of detecting malachite impurities, Raman spectroscopy offers a unique set of advantages. Malachite, a copper carbonate hydroxide mineral, possesses distinct vibrational modes that can be readily identified through its Raman spectrum. The ability to detect and characterize malachite impurities is crucial in various fields, including geology, archaeology, and quality control in industries such as mining and gemology.

The primary objective of applying Raman spectroscopy to malachite impurity detection is to develop a reliable, efficient, and non-destructive method for identifying and quantifying malachite in various matrices. This goal encompasses several key aspects, including improving the sensitivity of detection to trace levels of malachite, enhancing the specificity of identification to distinguish malachite from other similar minerals, and developing robust analytical protocols for diverse sample types.

Another critical objective is to explore the potential for in-situ and real-time analysis of malachite impurities. This capability would be particularly valuable in field applications, such as geological surveys or on-site quality control in mining operations. Achieving this goal requires advancements in portable Raman spectrometers and the development of rapid data analysis techniques.

Furthermore, the integration of Raman spectroscopy with other analytical methods, such as X-ray diffraction or infrared spectroscopy, is an important area of development. This multi-modal approach aims to provide a more comprehensive characterization of materials containing malachite impurities, offering complementary information that can enhance the accuracy and reliability of analysis.

As research in this field progresses, there is also a focus on expanding the application of Raman spectroscopy beyond mere detection to more quantitative analysis of malachite impurities. This involves developing calibration methods and statistical models that can accurately determine the concentration of malachite in complex mixtures, potentially opening new avenues for quality control and process monitoring in industries where malachite presence is a concern.

Market Demand for Malachite Impurity Detection

The market demand for malachite impurity detection has been steadily growing, driven by several key factors in the gemstone and mineral industry. Malachite, a copper carbonate hydroxide mineral, is highly valued for its vibrant green color and distinctive banding patterns. However, the presence of impurities can significantly affect its quality and value, making accurate detection crucial for both suppliers and buyers.

In the gemstone market, there is an increasing emphasis on authenticity and quality assurance. High-end jewelry retailers and collectors are demanding more sophisticated methods to verify the purity and origin of malachite specimens. This has created a substantial market for advanced detection technologies, with Raman spectroscopy emerging as a preferred method due to its non-destructive nature and high accuracy.

The mining industry also contributes significantly to the demand for malachite impurity detection. As copper ore deposits become more complex and lower-grade, efficient identification of malachite and its impurities is essential for optimizing extraction processes and ensuring the economic viability of mining operations. This has led to a growing interest in on-site Raman spectroscopy solutions that can provide real-time analysis of mineral compositions.

Environmental regulations and sustainability concerns have further fueled the need for precise impurity detection in malachite. As the awareness of potential toxic elements in minerals increases, there is a rising demand for technologies that can identify and quantify harmful impurities. This is particularly relevant in the context of recycling and waste management of copper-based materials, where accurate identification of malachite and its impurities is crucial for proper handling and processing.

The global market for gemstone and mineral testing equipment, including Raman spectroscopy devices for malachite impurity detection, has been expanding. This growth is particularly pronounced in regions with significant gemstone trading and mining activities, such as Asia-Pacific, Africa, and South America. The increasing adoption of advanced analytical techniques in these markets is driving innovation and competition among equipment manufacturers.

Furthermore, the rise of e-commerce in the gemstone trade has created new challenges in quality assurance, leading to an increased demand for portable and user-friendly impurity detection solutions. This trend is expected to continue as online marketplaces for minerals and gemstones become more prevalent, necessitating reliable methods for remote authentication and quality assessment of malachite specimens.

In the gemstone market, there is an increasing emphasis on authenticity and quality assurance. High-end jewelry retailers and collectors are demanding more sophisticated methods to verify the purity and origin of malachite specimens. This has created a substantial market for advanced detection technologies, with Raman spectroscopy emerging as a preferred method due to its non-destructive nature and high accuracy.

The mining industry also contributes significantly to the demand for malachite impurity detection. As copper ore deposits become more complex and lower-grade, efficient identification of malachite and its impurities is essential for optimizing extraction processes and ensuring the economic viability of mining operations. This has led to a growing interest in on-site Raman spectroscopy solutions that can provide real-time analysis of mineral compositions.

Environmental regulations and sustainability concerns have further fueled the need for precise impurity detection in malachite. As the awareness of potential toxic elements in minerals increases, there is a rising demand for technologies that can identify and quantify harmful impurities. This is particularly relevant in the context of recycling and waste management of copper-based materials, where accurate identification of malachite and its impurities is crucial for proper handling and processing.

The global market for gemstone and mineral testing equipment, including Raman spectroscopy devices for malachite impurity detection, has been expanding. This growth is particularly pronounced in regions with significant gemstone trading and mining activities, such as Asia-Pacific, Africa, and South America. The increasing adoption of advanced analytical techniques in these markets is driving innovation and competition among equipment manufacturers.

Furthermore, the rise of e-commerce in the gemstone trade has created new challenges in quality assurance, leading to an increased demand for portable and user-friendly impurity detection solutions. This trend is expected to continue as online marketplaces for minerals and gemstones become more prevalent, necessitating reliable methods for remote authentication and quality assessment of malachite specimens.

Current Challenges in Malachite Analysis

The detection of malachite impurities using Raman spectroscopy faces several significant challenges that hinder its widespread adoption and reliability. One of the primary obstacles is the complexity of sample matrices in which malachite may be present. Natural minerals often contain a diverse array of compounds, making it difficult to isolate and accurately identify malachite-specific Raman signals. This complexity can lead to spectral interference and overlapping peaks, reducing the accuracy of impurity detection.

Another challenge lies in the sensitivity of Raman spectroscopy when dealing with low concentrations of malachite impurities. In many cases, the impurity levels may be below the detection limit of conventional Raman systems, necessitating the development of more sensitive instrumentation or advanced signal processing techniques. This limitation can result in false negatives, potentially allowing contaminated materials to pass quality control measures.

The variability in malachite's crystalline structure and composition also poses a significant hurdle. Depending on its formation conditions and geological history, malachite can exhibit slight variations in its Raman spectrum. This variability complicates the establishment of a universal reference spectrum for malachite, making it challenging to create robust and widely applicable detection algorithms.

Furthermore, the presence of fluorescence in many mineral samples can severely interfere with Raman measurements. Fluorescence can overwhelm the relatively weak Raman signals, making it difficult to discern the characteristic peaks of malachite. This issue often requires the use of specialized techniques such as time-resolved spectroscopy or surface-enhanced Raman spectroscopy (SERS) to mitigate fluorescence effects.

The need for sample preparation and the potential for sample alteration during analysis also present challenges. Raman spectroscopy typically requires minimal sample preparation, but factors such as particle size, surface roughness, and orientation can affect the quality and reproducibility of spectra. Additionally, laser-induced heating during analysis can potentially alter the sample's structure or composition, leading to inaccurate results.

Lastly, the interpretation of Raman spectra for complex mineral mixtures demands significant expertise and often relies on advanced chemometric techniques. The development of reliable automated analysis methods that can accurately identify and quantify malachite impurities in diverse sample types remains an ongoing challenge. Overcoming these obstacles is crucial for enhancing the applicability and reliability of Raman spectroscopy in malachite impurity detection across various industries and research fields.

Another challenge lies in the sensitivity of Raman spectroscopy when dealing with low concentrations of malachite impurities. In many cases, the impurity levels may be below the detection limit of conventional Raman systems, necessitating the development of more sensitive instrumentation or advanced signal processing techniques. This limitation can result in false negatives, potentially allowing contaminated materials to pass quality control measures.

The variability in malachite's crystalline structure and composition also poses a significant hurdle. Depending on its formation conditions and geological history, malachite can exhibit slight variations in its Raman spectrum. This variability complicates the establishment of a universal reference spectrum for malachite, making it challenging to create robust and widely applicable detection algorithms.

Furthermore, the presence of fluorescence in many mineral samples can severely interfere with Raman measurements. Fluorescence can overwhelm the relatively weak Raman signals, making it difficult to discern the characteristic peaks of malachite. This issue often requires the use of specialized techniques such as time-resolved spectroscopy or surface-enhanced Raman spectroscopy (SERS) to mitigate fluorescence effects.

The need for sample preparation and the potential for sample alteration during analysis also present challenges. Raman spectroscopy typically requires minimal sample preparation, but factors such as particle size, surface roughness, and orientation can affect the quality and reproducibility of spectra. Additionally, laser-induced heating during analysis can potentially alter the sample's structure or composition, leading to inaccurate results.

Lastly, the interpretation of Raman spectra for complex mineral mixtures demands significant expertise and often relies on advanced chemometric techniques. The development of reliable automated analysis methods that can accurately identify and quantify malachite impurities in diverse sample types remains an ongoing challenge. Overcoming these obstacles is crucial for enhancing the applicability and reliability of Raman spectroscopy in malachite impurity detection across various industries and research fields.

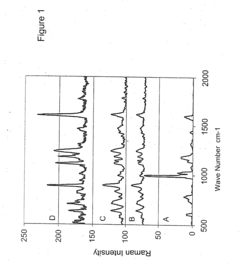

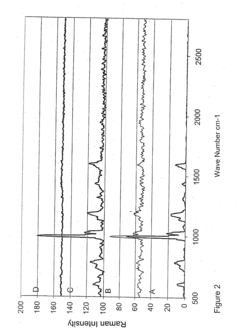

Existing Raman Methods for Malachite Detection

01 Raman spectroscopy for impurity detection in pharmaceuticals

Raman spectroscopy is utilized for detecting impurities in pharmaceutical products. This non-destructive technique can identify and quantify impurities at low concentrations, ensuring drug quality and safety. The method is particularly useful for analyzing both active pharmaceutical ingredients and finished dosage forms.- Raman spectroscopy for impurity detection in pharmaceuticals: Raman spectroscopy is utilized for detecting impurities in pharmaceutical products. This technique allows for non-destructive analysis of drug formulations, enabling the identification and quantification of contaminants or unwanted substances. The method is particularly useful for quality control in pharmaceutical manufacturing processes.

- Surface-enhanced Raman spectroscopy (SERS) for trace impurity detection: Surface-enhanced Raman spectroscopy (SERS) is employed to detect trace impurities with high sensitivity. This technique uses nanostructured metal surfaces to amplify Raman signals, allowing for the detection of extremely low concentrations of impurities in various samples. SERS is particularly useful in environmental monitoring and food safety applications.

- Raman imaging for spatial distribution of impurities: Raman imaging techniques are used to visualize the spatial distribution of impurities in materials. This approach combines spectroscopic analysis with microscopy to create detailed maps of impurity locations within a sample. It is particularly useful for analyzing heterogeneous materials and identifying localized contamination.

- Portable Raman systems for on-site impurity detection: Portable Raman spectroscopy systems are developed for on-site impurity detection. These compact devices allow for rapid analysis in field conditions, enabling real-time quality control and impurity screening. They are particularly useful in industries such as pharmaceuticals, food production, and environmental monitoring.

- Machine learning integration with Raman spectroscopy for impurity analysis: Machine learning algorithms are integrated with Raman spectroscopy to enhance impurity detection and analysis. These advanced data processing techniques improve the accuracy and speed of impurity identification, enabling automated analysis of complex spectral data. This approach is particularly useful for handling large datasets and identifying subtle spectral features indicative of impurities.

02 Surface-enhanced Raman spectroscopy (SERS) for trace impurity detection

Surface-enhanced Raman spectroscopy (SERS) is employed to detect trace impurities with high sensitivity. This technique uses nanostructured metal surfaces to enhance the Raman signal, allowing for the detection of extremely low concentrations of impurities in various materials, including environmental samples and industrial products.Expand Specific Solutions03 Raman imaging for spatial distribution of impurities

Raman imaging techniques are used to map the spatial distribution of impurities in materials. This approach combines spectroscopic data with spatial information, allowing for the visualization of impurity locations within a sample. It is particularly useful for analyzing heterogeneous materials and identifying localized contamination.Expand Specific Solutions04 Portable Raman systems for on-site impurity detection

Portable Raman spectrometers are developed for on-site impurity detection in various industries. These compact devices enable real-time analysis of materials outside the laboratory, facilitating quality control and process monitoring in manufacturing, environmental monitoring, and field-based research applications.Expand Specific Solutions05 Machine learning integration with Raman spectroscopy for impurity analysis

Machine learning algorithms are integrated with Raman spectroscopy to enhance impurity detection and analysis. These advanced data processing techniques improve the accuracy of impurity identification, enable automated spectral interpretation, and facilitate the handling of complex spectral data sets for more efficient and reliable impurity detection.Expand Specific Solutions

Key Players in Raman Spectroscopy Industry

The application of Raman spectroscopy in detecting malachite impurities is in a growth phase, with increasing market size and technological advancements. The market is driven by the need for precise impurity detection in various industries. While the technology is maturing, there's still room for innovation. Key players like HP Development Co. LP, Excelitas Technologies Corp., and Intel Corp. are contributing to the field's development. Academic institutions such as MIT, Shanghai Jiao Tong University, and Columbia University are also advancing research in this area. The collaboration between industry and academia is accelerating the technology's progress and expanding its applications.

Excelitas Technologies Corp.

Technical Solution: Excelitas has developed advanced photonic components specifically optimized for Raman spectroscopy applications, including malachite impurity detection. Their product line includes high-performance laser sources, specialized optical filters, and sensitive detectors designed to enhance Raman signal collection and analysis[5]. Excelitas' lasers feature narrow linewidth and excellent wavelength stability, critical for precise Raman measurements. Their avalanche photodiodes (APDs) and silicon photomultipliers (SiPMs) offer high quantum efficiency and low noise, enabling detection of weak Raman signals from trace malachite impurities. Excelitas also provides customized optical subsystems that integrate these components for optimal performance in Raman spectroscopy instruments[6].

Strengths: High-performance photonic components, customized solutions for instrument manufacturers, expertise in low-light detection. Weaknesses: Focused on components rather than complete Raman systems, may require integration efforts by end-users or instrument makers.

Smiths Detection Ltd.

Technical Solution: Smiths Detection has developed a handheld Raman spectrometer specifically designed for rapid identification of malachite and other mineral impurities. Their system utilizes a proprietary library of Raman spectra and advanced chemometric algorithms to provide fast, accurate results in field conditions[3]. The device incorporates a high-resolution 785 nm laser and cooled CCD detector to maximize sensitivity while minimizing fluorescence interference. Smiths Detection's approach also includes automated sample preparation techniques to ensure consistent results across different sample types. The system is ruggedized for use in harsh environments and features an intuitive user interface for operation by non-specialists[4].

Strengths: Rugged, portable design for field use, extensive spectral library, user-friendly operation. Weaknesses: May have lower sensitivity compared to lab-based systems, potentially limited to pre-programmed compounds in the spectral library.

Core Innovations in Raman-based Mineral Analysis

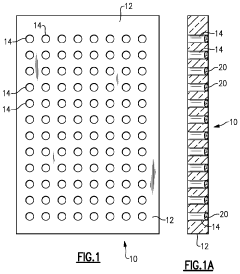

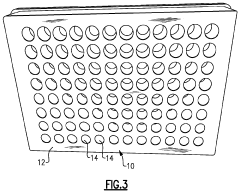

Methods of using and fabricating a supporting substrate for the deposition, automated recognition, and spectroscopic identification of particles

PatentInactiveUS20060017919A1

Innovation

- A supporting substrate with a smooth, metal-coated filter membrane of defined pore width, which absorbs minimal laser energy at the selected wavelength, allowing for reliable identification of microparticles without damage, suitable for both liquid and gaseous media, and enabling precise Raman spectroscopy analysis.

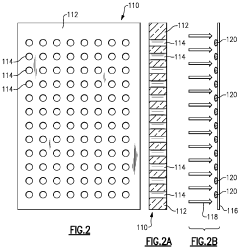

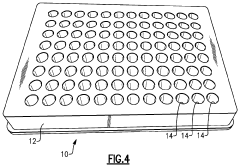

Chemically and Biologically Reactive Microplate Assembly and Manufacture Thereof for Raman Spectroscopy and Other Applications

PatentInactiveUS20210102899A1

Innovation

- A microplate with nano-structured metal-coated copper oxide dendrites on the floor and/or walls of its wells, created through processes like galvanic or electrochemical deposition, followed by noble metal coating, to facilitate enhanced analytical techniques by creating reactive surfaces that aid in sample analysis.

Environmental Impact of Malachite Impurities

The environmental impact of malachite impurities is a critical consideration in the application of Raman spectroscopy for their detection. Malachite, a copper carbonate hydroxide mineral, can have significant ecological consequences when present as an impurity in various materials and environments.

One of the primary concerns is the potential for copper contamination in water systems. When malachite impurities leach into aquatic environments, they can release copper ions, which are toxic to many aquatic organisms even at low concentrations. This can lead to disruptions in aquatic ecosystems, affecting fish populations, algae growth, and the overall balance of freshwater habitats.

Soil contamination is another important aspect of malachite impurities' environmental impact. The presence of malachite in soil can alter its pH and chemical composition, potentially affecting plant growth and soil microbial communities. This can have cascading effects on terrestrial ecosystems, including reduced biodiversity and altered nutrient cycles.

The mining and processing of materials containing malachite impurities can also contribute to air pollution. Dust particles containing malachite can be released into the atmosphere during extraction and refining processes, potentially leading to respiratory issues in both humans and animals in the surrounding areas.

Furthermore, the accumulation of malachite impurities in the food chain poses risks to higher-level consumers, including humans. Through bioaccumulation, copper from malachite can concentrate in the tissues of organisms at higher trophic levels, potentially causing long-term health effects and ecological imbalances.

The detection of malachite impurities using Raman spectroscopy plays a crucial role in environmental monitoring and protection. By enabling rapid and accurate identification of these impurities, it allows for timely intervention and mitigation strategies. This can include improved water treatment processes, more targeted soil remediation efforts, and enhanced pollution control measures in industrial settings.

Additionally, the use of Raman spectroscopy in detecting malachite impurities contributes to the development of more sustainable mining and manufacturing practices. By providing a non-destructive and highly sensitive method for impurity detection, it enables better quality control and resource management, potentially reducing the overall environmental footprint of industries dealing with malachite-containing materials.

In conclusion, understanding and addressing the environmental impact of malachite impurities is essential for sustainable resource management and ecosystem protection. The application of Raman spectroscopy in this context represents a significant advancement in environmental monitoring technology, offering a powerful tool for identifying and mitigating the potential ecological risks associated with malachite impurities.

One of the primary concerns is the potential for copper contamination in water systems. When malachite impurities leach into aquatic environments, they can release copper ions, which are toxic to many aquatic organisms even at low concentrations. This can lead to disruptions in aquatic ecosystems, affecting fish populations, algae growth, and the overall balance of freshwater habitats.

Soil contamination is another important aspect of malachite impurities' environmental impact. The presence of malachite in soil can alter its pH and chemical composition, potentially affecting plant growth and soil microbial communities. This can have cascading effects on terrestrial ecosystems, including reduced biodiversity and altered nutrient cycles.

The mining and processing of materials containing malachite impurities can also contribute to air pollution. Dust particles containing malachite can be released into the atmosphere during extraction and refining processes, potentially leading to respiratory issues in both humans and animals in the surrounding areas.

Furthermore, the accumulation of malachite impurities in the food chain poses risks to higher-level consumers, including humans. Through bioaccumulation, copper from malachite can concentrate in the tissues of organisms at higher trophic levels, potentially causing long-term health effects and ecological imbalances.

The detection of malachite impurities using Raman spectroscopy plays a crucial role in environmental monitoring and protection. By enabling rapid and accurate identification of these impurities, it allows for timely intervention and mitigation strategies. This can include improved water treatment processes, more targeted soil remediation efforts, and enhanced pollution control measures in industrial settings.

Additionally, the use of Raman spectroscopy in detecting malachite impurities contributes to the development of more sustainable mining and manufacturing practices. By providing a non-destructive and highly sensitive method for impurity detection, it enables better quality control and resource management, potentially reducing the overall environmental footprint of industries dealing with malachite-containing materials.

In conclusion, understanding and addressing the environmental impact of malachite impurities is essential for sustainable resource management and ecosystem protection. The application of Raman spectroscopy in this context represents a significant advancement in environmental monitoring technology, offering a powerful tool for identifying and mitigating the potential ecological risks associated with malachite impurities.

Regulatory Framework for Mineral Analysis Methods

The regulatory framework for mineral analysis methods plays a crucial role in ensuring the accuracy, reliability, and standardization of techniques used to detect impurities in minerals, including the application of Raman spectroscopy for malachite analysis. This framework encompasses a range of international, national, and industry-specific standards and guidelines that govern the use of analytical methods in the mineral industry.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Union of Pure and Applied Chemistry (IUPAC) have established comprehensive standards for analytical methods in mineral analysis. These standards provide guidelines for sample preparation, instrument calibration, data analysis, and reporting of results, ensuring consistency and comparability across different laboratories and jurisdictions.

National regulatory bodies, such as the United States Geological Survey (USGS) and the European Committee for Standardization (CEN), have also developed specific protocols and standards for mineral analysis. These national standards often incorporate international guidelines while addressing unique regional requirements and industry practices.

In the context of Raman spectroscopy for malachite impurity detection, regulatory frameworks typically outline specific requirements for instrument specifications, sample preparation procedures, and data interpretation methodologies. These guidelines ensure that the results obtained from Raman spectroscopic analysis are reliable and can be used for quality control, mineral grading, and regulatory compliance purposes.

The regulatory framework also addresses the validation and verification of analytical methods, including Raman spectroscopy. This involves rigorous testing and inter-laboratory comparisons to demonstrate the accuracy, precision, and reproducibility of the method. Validation protocols often require the analysis of certified reference materials and the participation in proficiency testing programs to ensure the ongoing reliability of the analytical results.

Furthermore, the regulatory framework encompasses guidelines for the training and qualification of personnel involved in mineral analysis. This includes requirements for education, experience, and ongoing professional development to ensure that analysts are competent in using advanced techniques like Raman spectroscopy for impurity detection.

Data management and reporting standards are also integral components of the regulatory framework. These standards dictate how analytical results should be recorded, stored, and communicated, ensuring transparency and traceability in the mineral analysis process. This is particularly important for applications involving malachite impurity detection, where accurate reporting of impurity levels can have significant economic and environmental implications.

As analytical technologies continue to evolve, regulatory frameworks must adapt to incorporate new methods and techniques. In the case of Raman spectroscopy for malachite analysis, ongoing research and development efforts are likely to lead to updates in regulatory guidelines, reflecting advancements in instrumentation, data processing algorithms, and understanding of spectral signatures associated with malachite impurities.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Union of Pure and Applied Chemistry (IUPAC) have established comprehensive standards for analytical methods in mineral analysis. These standards provide guidelines for sample preparation, instrument calibration, data analysis, and reporting of results, ensuring consistency and comparability across different laboratories and jurisdictions.

National regulatory bodies, such as the United States Geological Survey (USGS) and the European Committee for Standardization (CEN), have also developed specific protocols and standards for mineral analysis. These national standards often incorporate international guidelines while addressing unique regional requirements and industry practices.

In the context of Raman spectroscopy for malachite impurity detection, regulatory frameworks typically outline specific requirements for instrument specifications, sample preparation procedures, and data interpretation methodologies. These guidelines ensure that the results obtained from Raman spectroscopic analysis are reliable and can be used for quality control, mineral grading, and regulatory compliance purposes.

The regulatory framework also addresses the validation and verification of analytical methods, including Raman spectroscopy. This involves rigorous testing and inter-laboratory comparisons to demonstrate the accuracy, precision, and reproducibility of the method. Validation protocols often require the analysis of certified reference materials and the participation in proficiency testing programs to ensure the ongoing reliability of the analytical results.

Furthermore, the regulatory framework encompasses guidelines for the training and qualification of personnel involved in mineral analysis. This includes requirements for education, experience, and ongoing professional development to ensure that analysts are competent in using advanced techniques like Raman spectroscopy for impurity detection.

Data management and reporting standards are also integral components of the regulatory framework. These standards dictate how analytical results should be recorded, stored, and communicated, ensuring transparency and traceability in the mineral analysis process. This is particularly important for applications involving malachite impurity detection, where accurate reporting of impurity levels can have significant economic and environmental implications.

As analytical technologies continue to evolve, regulatory frameworks must adapt to incorporate new methods and techniques. In the case of Raman spectroscopy for malachite analysis, ongoing research and development efforts are likely to lead to updates in regulatory guidelines, reflecting advancements in instrumentation, data processing algorithms, and understanding of spectral signatures associated with malachite impurities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!