Application of Solenoid Valves in Industrial Refrigeration: Performance Analysis

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution

The evolution of solenoid valves in industrial refrigeration systems has been marked by significant technological advancements and design improvements over the years. Initially developed in the early 20th century, solenoid valves have undergone a transformation from simple on-off devices to sophisticated, precision-controlled components that play a crucial role in modern refrigeration systems.

In the 1950s and 1960s, the first generation of solenoid valves for refrigeration applications emerged. These early models were primarily focused on basic functionality, offering rudimentary control over refrigerant flow. They were characterized by their robust construction, typically featuring brass or steel bodies, and simple electromagnetic coils. However, these valves often suffered from issues such as slow response times and limited durability under extreme temperature conditions.

The 1970s and 1980s saw significant improvements in solenoid valve design, driven by the need for greater energy efficiency and reliability in industrial refrigeration systems. During this period, manufacturers introduced valves with enhanced sealing mechanisms and more efficient coil designs. The introduction of synthetic materials for valve seats and seals improved resistance to corrosion and wear, extending the operational life of these components.

The 1990s marked a turning point in solenoid valve technology with the integration of electronic controls. This advancement allowed for more precise regulation of refrigerant flow, enabling better temperature control and system efficiency. Pulse width modulation (PWM) techniques were introduced, allowing for variable flow control rather than simple on-off operation. This period also saw the development of valves specifically designed for use with new, environmentally friendly refrigerants as the industry moved away from CFCs and HCFCs.

In the early 2000s, the focus shifted towards miniaturization and increased energy efficiency. Compact solenoid valve designs emerged, offering the same performance as their larger predecessors but with reduced size and weight. This trend was particularly beneficial for applications where space was at a premium. Additionally, low-power solenoid valves were developed, significantly reducing the energy consumption of refrigeration systems.

The most recent developments in solenoid valve technology have centered around smart and connected systems. Modern valves now incorporate sensors and microprocessors, enabling real-time monitoring and adjustment of valve performance. These smart valves can communicate with central control systems, providing valuable data for predictive maintenance and system optimization. Furthermore, advancements in materials science have led to the use of high-performance polymers and composites in valve construction, offering improved chemical resistance and thermal stability.

Looking ahead, the evolution of solenoid valves in industrial refrigeration is likely to continue along the path of increased intelligence and integration. Future developments may include self-diagnostic capabilities, further miniaturization, and even greater energy efficiency. As industrial refrigeration systems become more complex and demands for sustainability increase, solenoid valves will undoubtedly play a critical role in meeting these challenges.

In the 1950s and 1960s, the first generation of solenoid valves for refrigeration applications emerged. These early models were primarily focused on basic functionality, offering rudimentary control over refrigerant flow. They were characterized by their robust construction, typically featuring brass or steel bodies, and simple electromagnetic coils. However, these valves often suffered from issues such as slow response times and limited durability under extreme temperature conditions.

The 1970s and 1980s saw significant improvements in solenoid valve design, driven by the need for greater energy efficiency and reliability in industrial refrigeration systems. During this period, manufacturers introduced valves with enhanced sealing mechanisms and more efficient coil designs. The introduction of synthetic materials for valve seats and seals improved resistance to corrosion and wear, extending the operational life of these components.

The 1990s marked a turning point in solenoid valve technology with the integration of electronic controls. This advancement allowed for more precise regulation of refrigerant flow, enabling better temperature control and system efficiency. Pulse width modulation (PWM) techniques were introduced, allowing for variable flow control rather than simple on-off operation. This period also saw the development of valves specifically designed for use with new, environmentally friendly refrigerants as the industry moved away from CFCs and HCFCs.

In the early 2000s, the focus shifted towards miniaturization and increased energy efficiency. Compact solenoid valve designs emerged, offering the same performance as their larger predecessors but with reduced size and weight. This trend was particularly beneficial for applications where space was at a premium. Additionally, low-power solenoid valves were developed, significantly reducing the energy consumption of refrigeration systems.

The most recent developments in solenoid valve technology have centered around smart and connected systems. Modern valves now incorporate sensors and microprocessors, enabling real-time monitoring and adjustment of valve performance. These smart valves can communicate with central control systems, providing valuable data for predictive maintenance and system optimization. Furthermore, advancements in materials science have led to the use of high-performance polymers and composites in valve construction, offering improved chemical resistance and thermal stability.

Looking ahead, the evolution of solenoid valves in industrial refrigeration is likely to continue along the path of increased intelligence and integration. Future developments may include self-diagnostic capabilities, further miniaturization, and even greater energy efficiency. As industrial refrigeration systems become more complex and demands for sustainability increase, solenoid valves will undoubtedly play a critical role in meeting these challenges.

Refrigeration Market Trends

The global industrial refrigeration market has been experiencing steady growth, driven by increasing demand for cold storage and food preservation across various sectors. This growth is particularly pronounced in emerging economies, where rapid urbanization and changing consumer preferences are fueling the need for advanced refrigeration solutions. The market is also benefiting from technological advancements, with a growing emphasis on energy efficiency and environmental sustainability.

One of the key trends shaping the refrigeration market is the shift towards natural refrigerants. As environmental regulations become more stringent, there is a growing preference for refrigerants with lower global warming potential (GWP). This has led to increased adoption of ammonia, carbon dioxide, and hydrocarbons in industrial refrigeration systems. These natural refrigerants not only offer improved environmental performance but also provide enhanced energy efficiency in many applications.

The food and beverage industry remains the largest end-user segment in the industrial refrigeration market. With the rise of e-commerce and changing consumer habits, there is a growing demand for cold chain logistics and refrigerated warehouses. This trend is expected to continue, driving further growth in the refrigeration market. Additionally, the pharmaceutical and healthcare sectors are emerging as significant contributors to market growth, particularly in light of the increased need for vaccine storage and distribution.

Energy efficiency has become a critical focus in the refrigeration industry. As energy costs continue to rise and environmental regulations tighten, there is a growing demand for refrigeration systems that can deliver optimal performance while minimizing energy consumption. This has led to innovations in compressor technology, heat recovery systems, and smart control systems that can optimize refrigeration cycles based on real-time demand.

The integration of Internet of Things (IoT) and artificial intelligence (AI) technologies is another significant trend in the refrigeration market. These technologies enable remote monitoring, predictive maintenance, and automated control of refrigeration systems, leading to improved efficiency and reduced downtime. The ability to collect and analyze data from refrigeration systems is also driving the development of more sophisticated energy management strategies.

In terms of regional trends, Asia-Pacific is expected to be the fastest-growing market for industrial refrigeration. This growth is driven by rapid industrialization, increasing food production, and the expansion of cold chain infrastructure in countries like China and India. North America and Europe, while mature markets, continue to see growth driven by the need to replace aging infrastructure and adopt more environmentally friendly refrigeration solutions.

One of the key trends shaping the refrigeration market is the shift towards natural refrigerants. As environmental regulations become more stringent, there is a growing preference for refrigerants with lower global warming potential (GWP). This has led to increased adoption of ammonia, carbon dioxide, and hydrocarbons in industrial refrigeration systems. These natural refrigerants not only offer improved environmental performance but also provide enhanced energy efficiency in many applications.

The food and beverage industry remains the largest end-user segment in the industrial refrigeration market. With the rise of e-commerce and changing consumer habits, there is a growing demand for cold chain logistics and refrigerated warehouses. This trend is expected to continue, driving further growth in the refrigeration market. Additionally, the pharmaceutical and healthcare sectors are emerging as significant contributors to market growth, particularly in light of the increased need for vaccine storage and distribution.

Energy efficiency has become a critical focus in the refrigeration industry. As energy costs continue to rise and environmental regulations tighten, there is a growing demand for refrigeration systems that can deliver optimal performance while minimizing energy consumption. This has led to innovations in compressor technology, heat recovery systems, and smart control systems that can optimize refrigeration cycles based on real-time demand.

The integration of Internet of Things (IoT) and artificial intelligence (AI) technologies is another significant trend in the refrigeration market. These technologies enable remote monitoring, predictive maintenance, and automated control of refrigeration systems, leading to improved efficiency and reduced downtime. The ability to collect and analyze data from refrigeration systems is also driving the development of more sophisticated energy management strategies.

In terms of regional trends, Asia-Pacific is expected to be the fastest-growing market for industrial refrigeration. This growth is driven by rapid industrialization, increasing food production, and the expansion of cold chain infrastructure in countries like China and India. North America and Europe, while mature markets, continue to see growth driven by the need to replace aging infrastructure and adopt more environmentally friendly refrigeration solutions.

Technical Challenges

The application of solenoid valves in industrial refrigeration systems presents several technical challenges that require careful consideration and innovative solutions. One of the primary issues is the precise control of refrigerant flow, which is crucial for maintaining optimal system performance and energy efficiency. Solenoid valves must operate with high accuracy and responsiveness to ensure proper refrigerant distribution throughout the system, especially during varying load conditions.

Another significant challenge is the durability and reliability of solenoid valves in harsh industrial environments. These valves are often exposed to extreme temperatures, high pressures, and corrosive refrigerants, which can lead to premature wear, leakage, or failure. Developing materials and designs that can withstand these conditions while maintaining consistent performance over extended periods is a critical area of focus for manufacturers and engineers.

The integration of solenoid valves with advanced control systems and IoT technologies presents both opportunities and challenges. While these integrations can enhance system monitoring and optimization, they also introduce complexities in terms of compatibility, data security, and the need for specialized training for maintenance personnel. Ensuring seamless communication between valves and control systems is essential for realizing the full potential of smart refrigeration systems.

Energy efficiency remains a paramount concern in industrial refrigeration. Solenoid valves must be designed to minimize pressure drops and energy losses while still providing rapid and precise control. This challenge is compounded by the industry's shift towards more environmentally friendly refrigerants, which often have different thermodynamic properties and may require redesigns of valve components and control strategies.

The size and weight of solenoid valves can also pose challenges, particularly in applications where space is limited or weight is a critical factor. Miniaturization of valve components without compromising performance or reliability is an ongoing area of research and development. Additionally, the noise generated by solenoid valves during operation can be problematic in certain industrial settings, necessitating the development of quieter valve designs.

Maintenance and serviceability of solenoid valves in industrial refrigeration systems present their own set of challenges. The need for regular maintenance to prevent issues such as coil burnout, plunger sticking, or seal degradation must be balanced against the operational demands of continuous refrigeration processes. Developing valves with improved diagnostics, easier access for repairs, and longer service intervals is crucial for reducing downtime and maintenance costs.

Lastly, the cost-effectiveness of solenoid valve solutions in industrial refrigeration remains a significant challenge. While advanced valve technologies can offer improved performance and efficiency, they must also be economically viable for widespread adoption. Striking the right balance between functionality, reliability, and cost is an ongoing challenge for manufacturers and system designers in the industrial refrigeration sector.

Another significant challenge is the durability and reliability of solenoid valves in harsh industrial environments. These valves are often exposed to extreme temperatures, high pressures, and corrosive refrigerants, which can lead to premature wear, leakage, or failure. Developing materials and designs that can withstand these conditions while maintaining consistent performance over extended periods is a critical area of focus for manufacturers and engineers.

The integration of solenoid valves with advanced control systems and IoT technologies presents both opportunities and challenges. While these integrations can enhance system monitoring and optimization, they also introduce complexities in terms of compatibility, data security, and the need for specialized training for maintenance personnel. Ensuring seamless communication between valves and control systems is essential for realizing the full potential of smart refrigeration systems.

Energy efficiency remains a paramount concern in industrial refrigeration. Solenoid valves must be designed to minimize pressure drops and energy losses while still providing rapid and precise control. This challenge is compounded by the industry's shift towards more environmentally friendly refrigerants, which often have different thermodynamic properties and may require redesigns of valve components and control strategies.

The size and weight of solenoid valves can also pose challenges, particularly in applications where space is limited or weight is a critical factor. Miniaturization of valve components without compromising performance or reliability is an ongoing area of research and development. Additionally, the noise generated by solenoid valves during operation can be problematic in certain industrial settings, necessitating the development of quieter valve designs.

Maintenance and serviceability of solenoid valves in industrial refrigeration systems present their own set of challenges. The need for regular maintenance to prevent issues such as coil burnout, plunger sticking, or seal degradation must be balanced against the operational demands of continuous refrigeration processes. Developing valves with improved diagnostics, easier access for repairs, and longer service intervals is crucial for reducing downtime and maintenance costs.

Lastly, the cost-effectiveness of solenoid valve solutions in industrial refrigeration remains a significant challenge. While advanced valve technologies can offer improved performance and efficiency, they must also be economically viable for widespread adoption. Striking the right balance between functionality, reliability, and cost is an ongoing challenge for manufacturers and system designers in the industrial refrigeration sector.

Current Solenoid Solutions

01 Improved valve design for enhanced performance

Solenoid valve performance can be improved through innovative design features. These may include optimized flow paths, reduced friction, and enhanced sealing mechanisms. Such designs can lead to better flow control, increased efficiency, and longer operational life of the valve.- Improved valve design for enhanced performance: Solenoid valve performance can be improved through innovative design features. These may include optimized flow paths, reduced friction in moving parts, and enhanced sealing mechanisms. Such designs can lead to faster response times, increased reliability, and improved overall efficiency of the valve.

- Advanced materials for solenoid valve components: The use of advanced materials in solenoid valve construction can significantly enhance performance. Materials with superior magnetic properties can improve the valve's response to electrical signals, while corrosion-resistant and wear-resistant materials can extend the valve's lifespan and maintain consistent performance over time.

- Electronic control systems for precise valve operation: Integration of sophisticated electronic control systems can greatly enhance solenoid valve performance. These systems can provide precise timing and control of valve operations, allow for adaptive responses to changing conditions, and enable real-time monitoring and diagnostics of valve performance.

- Energy-efficient solenoid valve designs: Improving the energy efficiency of solenoid valves is crucial for enhancing overall performance. This can be achieved through designs that minimize power consumption during operation, utilize energy recovery mechanisms, or incorporate low-power holding circuits to maintain valve position with reduced energy input.

- Performance testing and quality control methods: Implementing rigorous performance testing and quality control methods is essential for ensuring consistent and reliable solenoid valve performance. This includes developing standardized testing procedures, utilizing advanced measurement techniques, and implementing statistical process control to identify and address performance variations.

02 Advanced materials for solenoid valve components

The use of advanced materials in solenoid valve construction can significantly impact performance. Materials with improved magnetic properties, wear resistance, and thermal stability can enhance valve response times, durability, and overall efficiency. This can result in valves that operate more reliably under various conditions.Expand Specific Solutions03 Electronic control systems for precise valve operation

Integration of sophisticated electronic control systems can greatly enhance solenoid valve performance. These systems can provide precise timing, variable control, and adaptive responses to changing conditions. This results in improved accuracy, reduced energy consumption, and optimized valve operation across different applications.Expand Specific Solutions04 Energy-efficient solenoid valve designs

Developing energy-efficient solenoid valve designs is crucial for improving overall performance. This can involve optimizing the electromagnetic circuit, reducing power consumption during operation, and implementing smart power management features. Such designs can lead to valves that are more cost-effective and environmentally friendly.Expand Specific Solutions05 Performance testing and quality control methods

Implementing rigorous performance testing and quality control methods is essential for ensuring consistent solenoid valve performance. This can include advanced diagnostic tools, automated testing procedures, and real-time monitoring systems. These methods help identify potential issues early, ensure reliability, and maintain high standards of valve performance.Expand Specific Solutions

Key Industry Players

The application of solenoid valves in industrial refrigeration is in a mature stage, with a growing market driven by increasing demand for efficient cooling systems. The global industrial refrigeration market is expected to reach significant size in the coming years, propelled by technological advancements and stringent energy efficiency regulations. Key players like Zhejiang Sanhua Intelligent Controls, Festo SE & Co. KG, and Parker-Hannifin Corp. are at the forefront of innovation, offering high-performance solenoid valves. These companies, along with others such as Emerson Electric Co. and Danfoss Group, are continuously improving valve designs to enhance reliability, energy efficiency, and control precision in industrial refrigeration systems.

Zhejiang Sanhua Commercial Refrigeration Co., Ltd.

Technical Solution: Sanhua has developed advanced solenoid valves for industrial refrigeration applications, focusing on energy efficiency and precise control. Their latest models incorporate electronic expansion valve (EEV) technology, which allows for more accurate refrigerant flow control compared to traditional mechanical valves. These valves use pulse width modulation (PWM) to achieve stepless adjustment of refrigerant flow, resulting in improved system stability and energy savings of up to 15% in some applications[1][3]. Sanhua's solenoid valves also feature a high-efficiency coil design that reduces power consumption by up to 30% compared to conventional models[2]. The company has implemented a patented sealing technology that enhances the valve's reliability and extends its service life, addressing common issues such as refrigerant leakage in industrial refrigeration systems[4].

Strengths: High energy efficiency, precise control, and improved system stability. Weaknesses: May require more complex control systems and initial investment compared to traditional mechanical valves.

Eaton Corp.

Technical Solution: Eaton has developed a range of solenoid valves specifically designed for industrial refrigeration applications, focusing on reliability and versatility. Their valves feature a robust construction with stainless steel bodies and high-quality elastomers, ensuring compatibility with various refrigerants, including natural options like ammonia and CO2. Eaton's solenoid valves incorporate a balanced poppet design, which allows for high flow rates and reduces the risk of valve sticking, a common issue in refrigeration systems[5]. The company has also introduced smart solenoid valves with integrated sensors and diagnostic capabilities, enabling predictive maintenance and real-time performance monitoring. These valves can operate in a wide temperature range (-40°C to +120°C) and pressure range (up to 150 bar), making them suitable for diverse industrial refrigeration applications[6].

Strengths: Robust construction, compatibility with various refrigerants, and smart diagnostic features. Weaknesses: Potentially higher cost due to advanced features and materials.

Innovative Valve Designs

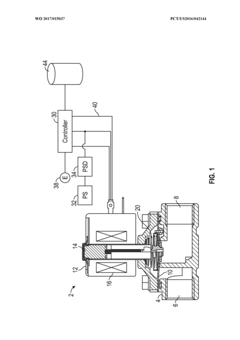

Compensated performance of a solenoid valve based on environmental conditions and product life

PatentWO2017015037A1

Innovation

- A solenoid valve control system that uses a controller, environmental sensor, and database to proactively optimize solenoid coil power consumption based on predetermined adjustments for temperature and operating cycles, reducing power consumption under normal conditions and selectively increasing power as needed without continuous monitoring.

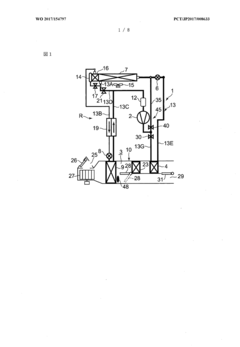

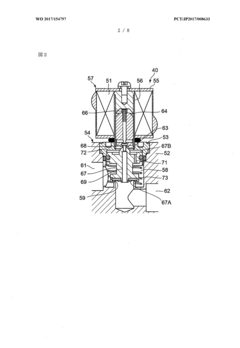

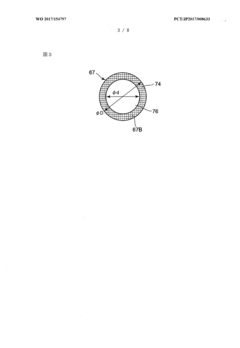

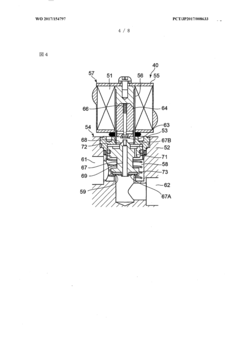

Solenoid valve, refrigeration device using same, and air conditioning device for vehicles, using same

PatentWO2017154797A1

Innovation

- The solenoid valve design incorporates a removed portion on the inner side of the main valve body's end face, with a contact area ratio between the outer and inner diameters optimized to reduce sticking, and the end surfaces are shaped to facilitate easier separation, including diagonal cuts and annular non-contact portions to minimize contact with the valve holder.

Energy Efficiency Impact

The implementation of solenoid valves in industrial refrigeration systems has a significant impact on energy efficiency. These valves play a crucial role in controlling refrigerant flow, which directly affects the overall system performance and energy consumption. By precisely regulating the flow of refrigerant, solenoid valves can optimize the cooling process, reducing energy waste and improving system efficiency.

One of the primary ways solenoid valves contribute to energy efficiency is through their rapid response times. Unlike manual valves, solenoid valves can quickly open and close, allowing for more precise control of refrigerant flow. This responsiveness enables better temperature regulation and reduces the energy required to maintain desired cooling levels. Additionally, the ability to rapidly shut off refrigerant flow when cooling is not needed prevents unnecessary energy expenditure.

Solenoid valves also enable more effective defrost cycles in industrial refrigeration systems. By controlling the flow of hot gas or refrigerant during defrost operations, these valves can minimize the time required for defrosting, thereby reducing energy consumption. This efficiency is particularly important in large-scale industrial applications where frequent defrosting is necessary to maintain optimal system performance.

Furthermore, the integration of solenoid valves with advanced control systems and sensors allows for intelligent refrigeration management. These smart systems can adjust valve operations based on real-time data, such as temperature fluctuations and cooling demand. This dynamic control ensures that the refrigeration system operates at peak efficiency, using only the necessary amount of energy to meet cooling requirements.

The energy-saving potential of solenoid valves extends to their role in preventing refrigerant leakage. By providing a tight seal when closed, these valves minimize the loss of refrigerant, which not only conserves energy but also reduces the environmental impact of the refrigeration system. This aspect is particularly crucial in industrial settings where large quantities of refrigerant are used.

In terms of system design, the strategic placement of solenoid valves can optimize refrigerant distribution throughout the system. This optimization leads to more efficient heat transfer and reduces the workload on compressors and other components, resulting in lower overall energy consumption. The ability to isolate specific sections of the refrigeration system also allows for targeted maintenance and repairs without shutting down the entire system, further contributing to energy conservation.

One of the primary ways solenoid valves contribute to energy efficiency is through their rapid response times. Unlike manual valves, solenoid valves can quickly open and close, allowing for more precise control of refrigerant flow. This responsiveness enables better temperature regulation and reduces the energy required to maintain desired cooling levels. Additionally, the ability to rapidly shut off refrigerant flow when cooling is not needed prevents unnecessary energy expenditure.

Solenoid valves also enable more effective defrost cycles in industrial refrigeration systems. By controlling the flow of hot gas or refrigerant during defrost operations, these valves can minimize the time required for defrosting, thereby reducing energy consumption. This efficiency is particularly important in large-scale industrial applications where frequent defrosting is necessary to maintain optimal system performance.

Furthermore, the integration of solenoid valves with advanced control systems and sensors allows for intelligent refrigeration management. These smart systems can adjust valve operations based on real-time data, such as temperature fluctuations and cooling demand. This dynamic control ensures that the refrigeration system operates at peak efficiency, using only the necessary amount of energy to meet cooling requirements.

The energy-saving potential of solenoid valves extends to their role in preventing refrigerant leakage. By providing a tight seal when closed, these valves minimize the loss of refrigerant, which not only conserves energy but also reduces the environmental impact of the refrigeration system. This aspect is particularly crucial in industrial settings where large quantities of refrigerant are used.

In terms of system design, the strategic placement of solenoid valves can optimize refrigerant distribution throughout the system. This optimization leads to more efficient heat transfer and reduces the workload on compressors and other components, resulting in lower overall energy consumption. The ability to isolate specific sections of the refrigeration system also allows for targeted maintenance and repairs without shutting down the entire system, further contributing to energy conservation.

Environmental Regulations

Environmental regulations play a crucial role in shaping the application of solenoid valves in industrial refrigeration systems. As global concerns about climate change and environmental protection continue to grow, governments and international organizations have implemented increasingly stringent regulations to reduce the environmental impact of refrigeration technologies.

One of the primary focuses of these regulations is the phase-out of ozone-depleting substances (ODS) and high global warming potential (GWP) refrigerants. The Montreal Protocol, an international treaty designed to protect the ozone layer, has mandated the gradual elimination of chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs). This has led to the development and adoption of alternative refrigerants, such as hydrofluorocarbons (HFCs) and natural refrigerants like ammonia and carbon dioxide.

The Kigali Amendment to the Montreal Protocol, which came into effect in 2019, further extends these efforts by targeting the reduction of HFCs. This amendment requires countries to cut the production and consumption of HFCs by more than 80% over the next 30 years. As a result, manufacturers of solenoid valves for industrial refrigeration systems must adapt their designs to be compatible with new, low-GWP refrigerants.

Energy efficiency is another key aspect of environmental regulations affecting solenoid valve applications in industrial refrigeration. Many countries have implemented minimum energy performance standards (MEPS) for refrigeration equipment. These standards often require the use of high-efficiency components, including solenoid valves, to minimize energy consumption and reduce greenhouse gas emissions associated with power generation.

Leak detection and prevention regulations have also become more stringent in recent years. The European Union's F-Gas Regulation, for example, mandates regular leak checks for refrigeration systems containing fluorinated greenhouse gases. This has led to increased demand for solenoid valves with improved sealing capabilities and integrated leak detection features.

Furthermore, regulations concerning the disposal and recycling of refrigeration equipment have implications for solenoid valve design and materials selection. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations in other regions require manufacturers to consider the entire lifecycle of their products, including end-of-life disposal and recycling.

As environmental regulations continue to evolve, manufacturers of solenoid valves for industrial refrigeration must stay informed and adapt their products accordingly. This may involve developing new materials and designs that are compatible with low-GWP refrigerants, improving energy efficiency, enhancing leak prevention capabilities, and considering the environmental impact of the entire product lifecycle.

One of the primary focuses of these regulations is the phase-out of ozone-depleting substances (ODS) and high global warming potential (GWP) refrigerants. The Montreal Protocol, an international treaty designed to protect the ozone layer, has mandated the gradual elimination of chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs). This has led to the development and adoption of alternative refrigerants, such as hydrofluorocarbons (HFCs) and natural refrigerants like ammonia and carbon dioxide.

The Kigali Amendment to the Montreal Protocol, which came into effect in 2019, further extends these efforts by targeting the reduction of HFCs. This amendment requires countries to cut the production and consumption of HFCs by more than 80% over the next 30 years. As a result, manufacturers of solenoid valves for industrial refrigeration systems must adapt their designs to be compatible with new, low-GWP refrigerants.

Energy efficiency is another key aspect of environmental regulations affecting solenoid valve applications in industrial refrigeration. Many countries have implemented minimum energy performance standards (MEPS) for refrigeration equipment. These standards often require the use of high-efficiency components, including solenoid valves, to minimize energy consumption and reduce greenhouse gas emissions associated with power generation.

Leak detection and prevention regulations have also become more stringent in recent years. The European Union's F-Gas Regulation, for example, mandates regular leak checks for refrigeration systems containing fluorinated greenhouse gases. This has led to increased demand for solenoid valves with improved sealing capabilities and integrated leak detection features.

Furthermore, regulations concerning the disposal and recycling of refrigeration equipment have implications for solenoid valve design and materials selection. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations in other regions require manufacturers to consider the entire lifecycle of their products, including end-of-life disposal and recycling.

As environmental regulations continue to evolve, manufacturers of solenoid valves for industrial refrigeration must stay informed and adapt their products accordingly. This may involve developing new materials and designs that are compatible with low-GWP refrigerants, improving energy efficiency, enhancing leak prevention capabilities, and considering the environmental impact of the entire product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!