Biodegradable Plastic Applications: Revolutionizing Waste Management

Biodegradable Plastics Evolution and Objectives

Biodegradable plastics have emerged as a promising solution to the global plastic waste crisis, marking a significant milestone in the evolution of sustainable materials. The journey of biodegradable plastics began in the 1980s with the development of polyhydroxyalkanoates (PHAs), naturally occurring polymers produced by bacteria. This initial breakthrough paved the way for further research and development in the field of eco-friendly plastics.

As environmental concerns grew in the 1990s and early 2000s, the focus shifted towards creating biodegradable alternatives to conventional plastics. Polylactic acid (PLA), derived from renewable resources such as corn starch or sugarcane, gained prominence as a viable biodegradable option. Concurrently, the development of starch-based plastics and cellulose-derived materials expanded the range of biodegradable options available to manufacturers and consumers.

The evolution of biodegradable plastics has been driven by the urgent need to address the environmental impact of plastic pollution. With millions of tons of plastic waste accumulating in landfills and oceans each year, the objective of biodegradable plastics is to provide a sustainable alternative that can decompose naturally, reducing long-term environmental damage.

Recent advancements in biodegradable plastic technology have focused on improving the material properties to match or exceed those of conventional plastics. This includes enhancing durability, heat resistance, and barrier properties while maintaining biodegradability. The development of multi-layer biodegradable plastics and blends has opened up new possibilities for applications in packaging, agriculture, and consumer goods.

The primary objectives of biodegradable plastics research and development are multifaceted. Firstly, there is a push to increase the range of applications where biodegradable plastics can effectively replace traditional plastics. This involves tailoring the properties of biodegradable materials to meet specific industry requirements. Secondly, researchers aim to optimize the biodegradation process, ensuring that these materials break down efficiently in various environments without leaving harmful residues.

Another crucial objective is to reduce the production costs of biodegradable plastics, making them more economically viable for widespread adoption. This involves improving manufacturing processes and exploring new sources of raw materials. Additionally, there is a focus on developing standardized testing methods and certification processes to ensure the authenticity and effectiveness of biodegradable claims.

Looking ahead, the field of biodegradable plastics is poised for further innovation. Emerging areas of research include the development of marine-degradable plastics to address ocean pollution, the creation of smart biodegradable materials that can respond to environmental stimuli, and the exploration of novel biodegradable polymers from unconventional sources such as algae or agricultural waste.

Market Demand Analysis for Eco-friendly Packaging

Biodegradable plastics hold significant potential in transforming waste management, particularly within the context of eco-friendly packaging. The market demand for such sustainable packaging solutions is particularly driven by increasing environmental consciousness among consumers and stricter regulatory policies aimed at reducing plastic pollution.

Insights reveal that the demand for biodegradable plastics in eco-friendly packaging is primarily fueled by consumer preferences shifting towards sustainable consumption. This shift is noticeable across various demographics, who now favor products that minimize environmental impact. Brands adopting biodegradable packaging are increasingly perceived as responsible and forward-thinking, which not only enhances their market appeal but also drives sales.

Simultaneously, regulatory environments worldwide are becoming more stringent regarding the use of non-degradable plastics. Many governments have introduced or are considering policies that ban or heavily tax single-use plastics. Such legislative measures are creating a direct push for industries to transition towards biodegradable alternatives. Companies responding to this by adopting biodegradable plastics in their operations can not only avoid potential legal repercussions but also align themselves with future regulatory trends.

Furthermore, advancements in technology have reduced the cost barriers associated with producing biodegradable plastics, making it more economically viable. Companies can now integrate these materials into their packaging strategies without significant financial burdens. Enhanced materials, which offer similar performance characteristics to traditional plastics, also contribute to this substitution, supporting broader market acceptance and implementation.

The potential market size for biodegradable plastic packaging is vast, covering a variety of sectors including food and beverage, personal care, and healthcare. These sectors are particularly sensitive to sustainability practices due to their direct interactions with consumers and their substantial impact on environmental health. Adoption in these areas is expected to grow as businesses increasingly prioritize sustainability in their operational models.

There is also a notable trend towards innovation in biodegradable materials. Companies are investing in research and development to create more effective, durable, and diverse biodegradable options that can meet complex packaging needs while ensuring environmental safety. This ongoing innovation is further stimulating market demand, as enhanced products can cater to a wider range of applications, making them more attractive to diverse industrial sectors.

Overall, the market demand for eco-friendly packaging using biodegradable plastics is influenced by a confluence of consumer behavior, regulatory changes, cost reductions, and technological advancements. Industries that proactively embrace these trends are likely to experience increased market share and customer loyalty, as they navigate the evolving landscape of sustainable packaging solutions.

Current Challenges in Biodegradable Plastic Technology

Despite significant advancements in biodegradable plastic technology, several challenges persist in its widespread adoption and effective implementation. One of the primary obstacles is the higher production cost compared to conventional plastics. The complex manufacturing processes and specialized materials required for biodegradable plastics contribute to increased expenses, making them less economically viable for many applications.

Another critical challenge lies in the performance limitations of current biodegradable plastics. These materials often struggle to match the durability, strength, and versatility of traditional plastics, particularly in demanding applications such as food packaging or long-term storage. This performance gap hinders their adoption in various industries where reliability and longevity are crucial factors.

The degradation process itself presents challenges, as the rate and conditions for biodegradation can vary significantly depending on environmental factors. Many biodegradable plastics require specific conditions, such as industrial composting facilities, to break down effectively. This requirement often leads to confusion among consumers and inadequate disposal practices, limiting the environmental benefits of these materials.

Standardization and certification pose another hurdle in the biodegradable plastics industry. The lack of universally accepted standards for biodegradability and compostability creates uncertainty for manufacturers and consumers alike. This absence of clear guidelines makes it difficult to assess and compare the environmental impact of different biodegradable plastic products.

The recycling infrastructure presents a significant challenge for biodegradable plastics. Current recycling systems are primarily designed for conventional plastics, and the introduction of biodegradable materials can disrupt established recycling processes. This incompatibility often results in biodegradable plastics being diverted to landfills or incineration, negating their potential environmental benefits.

Furthermore, there are concerns about the potential for microplastic formation during the degradation process of some biodegradable plastics. While these materials are designed to break down, there is ongoing research to understand the long-term environmental impacts of their degradation products, particularly in aquatic ecosystems.

Lastly, the scalability of production remains a significant challenge. As demand for biodegradable plastics grows, manufacturers face difficulties in scaling up production while maintaining consistent quality and properties. This limitation hampers the ability to meet increasing market demands and compete effectively with traditional plastic production on a large scale.

Existing Biodegradable Plastic Solutions

01 Biodegradable plastic composition and production

Development of new biodegradable plastic compositions using various natural and synthetic materials. These compositions are designed to break down more easily in the environment, reducing long-term waste accumulation. The production methods focus on creating plastics that maintain desired properties while ensuring biodegradability.- Biodegradable plastic composition and production: Development of new biodegradable plastic compositions and methods for their production. These materials are designed to break down naturally in the environment, reducing long-term waste accumulation. The compositions may include various biodegradable polymers, additives, and fillers to enhance degradation properties while maintaining desired physical characteristics.

- Waste management systems for biodegradable plastics: Implementation of specialized waste management systems tailored for biodegradable plastics. These systems may include collection methods, sorting technologies, and processing facilities designed to handle and properly dispose of biodegradable plastic waste. The focus is on optimizing the degradation process and minimizing environmental impact.

- Recycling and upcycling of biodegradable plastics: Development of techniques for recycling and upcycling biodegradable plastics to extend their lifecycle and reduce waste. This may involve processes for breaking down the materials into their component parts for reuse, or transforming them into new products with different applications, thereby reducing the overall environmental footprint.

- Biodegradation acceleration techniques: Methods and technologies to accelerate the biodegradation process of biodegradable plastics. This may include the use of specific microorganisms, enzymes, or environmental conditions to speed up the breakdown of the materials. The aim is to reduce the time required for complete degradation and minimize the accumulation of plastic waste in the environment.

- Environmental impact assessment and monitoring: Development of tools and methodologies for assessing and monitoring the environmental impact of biodegradable plastics throughout their lifecycle. This includes studying their degradation patterns in various ecosystems, potential effects on wildlife, and long-term environmental consequences. The goal is to ensure that biodegradable plastics truly offer environmental benefits over traditional plastics.

02 Waste management systems for biodegradable plastics

Implementation of specialized waste management systems designed specifically for biodegradable plastics. These systems include collection, sorting, and processing methods that optimize the breakdown of biodegradable materials. The focus is on creating efficient and environmentally friendly disposal processes that maximize the benefits of biodegradable plastics.Expand Specific Solutions03 Recycling and upcycling of biodegradable plastics

Development of innovative recycling and upcycling techniques for biodegradable plastics. These methods aim to extend the lifecycle of biodegradable materials by repurposing them into new products or raw materials. The focus is on minimizing waste and maximizing resource efficiency in the use of biodegradable plastics.Expand Specific Solutions04 Biodegradation acceleration techniques

Research and development of methods to accelerate the biodegradation process of plastics. This includes the use of specific microorganisms, enzymes, or environmental conditions that can speed up the breakdown of biodegradable materials. The goal is to reduce the time it takes for these plastics to decompose in various waste management scenarios.Expand Specific Solutions05 Environmental impact assessment of biodegradable plastics

Studies and methodologies for assessing the environmental impact of biodegradable plastics throughout their lifecycle. This includes evaluating their production, use, disposal, and degradation processes. The aim is to ensure that biodegradable plastics offer genuine environmental benefits compared to traditional plastics and to guide improvements in their design and waste management.Expand Specific Solutions

Key Players in Biodegradable Plastics Industry

The biodegradable plastic industry is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, biodegradable plastics are advancing, but still face challenges in performance and cost-effectiveness. Companies like Kaneka Corp., Mitsui Chemicals, and Danimer IPCo LLC are at the forefront, developing innovative solutions. Other players such as Stratasys, Inc. and Medtronic, Inc. are exploring applications in specialized sectors. Research institutions like Industrial Technology Research Institute and Beijing Forestry University are contributing to technological advancements. The competitive landscape is diverse, with both established chemical companies and emerging startups vying for market share in this promising field.

Kingfa Sci. & Tech. Co., Ltd.

Kaneka Corp.

Core Innovations in Biodegradable Polymer Science

- A biodegradable plasticizer comprising bio-molecules and monomers or oligomers of biodegradable polymers, thermal-treated between 50 to 160°C, is used to enhance the tenacity, impact-tolerance, adhesion, and ductility of biodegradable materials, allowing for improved properties such as water-resistance, oil-resistance, and microwave-tolerance, and enabling thermal-compression adhesion between substrates.

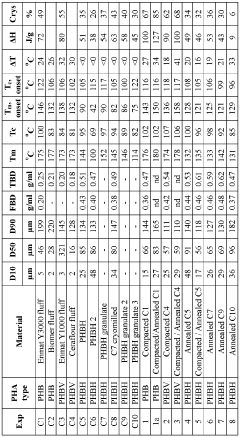

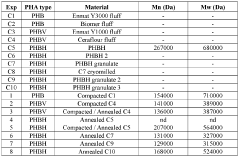

- A method involving compacting and annealing a homopolymer or copolymer of 3-hydroxy butyric acid to create a PHA powder with controlled particle size and density, enhancing its sinterability region and flowability, which involves compacting the starting material with pressures above 5 kN/cm², heating to prevent sticking, and milling to achieve a D50 particle size between 20 to 100 microns.

Environmental Impact Assessment

The environmental impact assessment of biodegradable plastic applications in waste management reveals both promising benefits and potential challenges. These innovative materials offer a significant reduction in long-term plastic pollution, as they decompose more rapidly than conventional plastics. This decomposition process helps mitigate the accumulation of plastic waste in landfills, oceans, and terrestrial ecosystems, potentially reducing harm to wildlife and marine life.

Biodegradable plastics also contribute to a decrease in greenhouse gas emissions associated with waste incineration, as they can be composted or naturally degraded instead of being burned. This shift in waste management practices aligns with circular economy principles, promoting resource efficiency and reducing the overall carbon footprint of plastic products.

However, the environmental benefits of biodegradable plastics are not without caveats. The degradation process often requires specific conditions, such as industrial composting facilities, which are not universally available. In suboptimal conditions, these materials may persist in the environment for extended periods, potentially causing similar issues to conventional plastics.

Furthermore, the production of biodegradable plastics may have its own environmental impacts. Some biodegradable plastics are derived from agricultural crops, raising concerns about land use, water consumption, and potential competition with food production. The use of genetically modified organisms in the production of certain bioplastics also presents potential ecological risks that require careful consideration.

The end-of-life management of biodegradable plastics poses additional challenges. Improper disposal or mixing with conventional plastics in recycling streams can contaminate recycling processes, potentially reducing the overall efficiency of plastic waste management systems. This highlights the need for clear labeling, consumer education, and separate collection systems to maximize the environmental benefits of biodegradable plastics.

Despite these challenges, the potential for biodegradable plastics to revolutionize waste management remains significant. As technology advances and infrastructure adapts, these materials could play a crucial role in reducing plastic pollution and promoting more sustainable consumption patterns. Ongoing research and development efforts are focused on improving the degradation properties, expanding the range of applications, and minimizing the environmental footprint of production processes.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in shaping the development, production, and adoption of biodegradable plastics. As governments and international organizations increasingly recognize the importance of sustainable waste management, they have implemented various policies and standards to govern the use of biodegradable materials.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards for biodegradable plastics. ISO 17088, for instance, specifies requirements for the labeling of plastics as compostable in municipal and industrial composting facilities. These standards provide a common language and set of criteria for manufacturers and consumers alike.

In the European Union, the EN 13432 standard is widely used to certify compostable and biodegradable packaging materials. This standard requires that at least 90% of the material breaks down into CO2 within six months, and that the remaining share degrades within three months. The EU has also introduced directives aimed at reducing single-use plastics and promoting the use of biodegradable alternatives.

The United States has a more fragmented approach, with regulations varying at the state and local levels. The Federal Trade Commission (FTC) provides guidelines for environmental marketing claims, including those related to biodegradability. Some states, like California, have enacted stricter regulations on biodegradable plastic labeling to prevent greenwashing and misleading claims.

Developing countries are also beginning to implement regulations on biodegradable materials. India, for example, has banned certain single-use plastics and is promoting the use of biodegradable alternatives. However, the lack of standardized testing and certification processes in many developing nations remains a challenge.

One of the key issues in the regulatory framework is the distinction between biodegradability and compostability. While all compostable materials are biodegradable, not all biodegradable materials are compostable in industrial facilities. This distinction has led to the development of separate standards and certifications for each category.

As the field of biodegradable plastics continues to evolve, regulatory frameworks are adapting to keep pace. There is a growing emphasis on life cycle assessments to ensure that biodegradable materials truly offer environmental benefits over their conventional counterparts. Additionally, regulations are beginning to address the end-of-life management of biodegradable plastics, including proper disposal and recycling methods.