Biodegradable Plastics in Space Exploration: The Next Frontier

Space Plastics Evolution

The evolution of plastics in space exploration has been a journey of innovation and adaptation. In the early days of space travel, traditional petroleum-based plastics were the primary materials used due to their lightweight properties and versatility. However, these materials posed significant challenges in the harsh environment of space, including degradation from radiation exposure and the potential for off-gassing harmful chemicals.

As space missions became more complex and long-duration, the need for more durable and space-resistant materials grew. This led to the development of specialized space-grade plastics, such as polyimides and fluoropolymers, which offered improved thermal stability and radiation resistance. These advanced materials played crucial roles in spacecraft construction, insulation, and component protection.

The turn of the 21st century marked a shift towards sustainability in space exploration. With growing concerns about space debris and environmental impact, the focus turned to developing biodegradable plastics for space applications. This new frontier in material science aimed to create plastics that could withstand the rigors of space travel while also being environmentally friendly at the end of their lifecycle.

Recent advancements have seen the emergence of bio-based polymers derived from renewable resources, such as cellulose and starch. These materials offer promising alternatives to traditional space plastics, combining biodegradability with the necessary performance characteristics for space applications. Researchers are now exploring ways to enhance these bio-based materials to match or exceed the properties of conventional space-grade plastics.

The latest developments in space plastics include smart materials that can self-heal or adapt to changing environmental conditions. These innovations are paving the way for more resilient and efficient spacecraft components. Additionally, 3D printing technologies are revolutionizing the production of plastic parts in space, allowing for on-demand manufacturing and reducing the need for Earth-based supply chains.

As we look to the future of space exploration, the evolution of plastics continues to play a critical role. The focus is now on developing multi-functional materials that can serve multiple purposes, such as radiation shielding, thermal management, and structural support, while still maintaining biodegradability. This ongoing evolution reflects the space industry's commitment to innovation, sustainability, and the responsible exploration of our solar system and beyond.

Space Waste Reduction

Space exploration has long been associated with the generation of significant amounts of waste, particularly in the form of non-biodegradable plastics. These materials, while essential for various space missions, pose a growing threat to the sustainability of space operations and the preservation of the space environment. The accumulation of space debris, including discarded plastic components, has become a critical concern for space agencies and private companies alike.

The introduction of biodegradable plastics in space exploration represents a promising solution to this pressing issue. These innovative materials are designed to break down naturally over time, reducing the long-term impact of space waste on orbital environments. By incorporating biodegradable plastics into spacecraft components, payload packaging, and other space-related applications, the space industry can significantly mitigate its environmental footprint beyond Earth's atmosphere.

One of the primary advantages of biodegradable plastics in space waste reduction is their ability to decompose without leaving harmful residues. Traditional plastics can persist in the space environment for centuries, contributing to the growing problem of space debris. In contrast, biodegradable alternatives can be engineered to break down into harmless compounds within a specified timeframe, effectively reducing the volume of long-lasting waste in orbit.

Moreover, the use of biodegradable plastics aligns with the broader goals of sustainable space exploration. As space agencies and private companies plan for long-term missions and potential colonization efforts, the need for environmentally responsible practices becomes increasingly crucial. By adopting biodegradable materials, the space industry can demonstrate its commitment to preserving the pristine nature of celestial bodies and minimizing the impact of human activities beyond Earth.

The implementation of biodegradable plastics in space applications also offers potential cost savings in the long run. While the initial investment in developing and manufacturing these materials may be higher, the reduced need for debris mitigation and cleanup operations can lead to significant economic benefits over time. Additionally, as regulations surrounding space debris become more stringent, the adoption of biodegradable materials may help space organizations comply with future environmental standards and avoid potential penalties.

However, the transition to biodegradable plastics in space exploration is not without challenges. These materials must meet the rigorous performance requirements of space applications, including resistance to extreme temperatures, radiation, and vacuum conditions. Ongoing research and development efforts are focused on enhancing the durability and reliability of biodegradable plastics while maintaining their environmentally friendly properties.

Biodegradable Challenges

The development of biodegradable plastics for space exploration faces numerous challenges that must be addressed to ensure their effectiveness and safety in extraterrestrial environments. One of the primary obstacles is the extreme temperature fluctuations encountered in space, which can range from -150°C to +150°C. These temperature variations can significantly affect the structural integrity and degradation rates of biodegradable materials, potentially compromising their intended functionality.

Radiation exposure presents another critical challenge for biodegradable plastics in space applications. The high levels of cosmic and solar radiation can accelerate the degradation process or alter the material properties in unpredictable ways. This necessitates the development of radiation-resistant biodegradable polymers that can maintain their structural integrity and controlled degradation rates despite prolonged exposure to harsh radiation environments.

The vacuum conditions of space pose unique challenges for biodegradable plastics. Traditional biodegradation processes often rely on microorganisms and environmental factors that are absent in the vacuum of space. This requires the development of novel degradation mechanisms that can function effectively in the absence of atmospheric pressure and oxygen, while still ensuring controlled and predictable breakdown of the materials.

The need for long-term stability during space missions conflicts with the inherent nature of biodegradable materials. Balancing the requirements for durability during use with the ability to degrade after the mission presents a significant engineering challenge. Researchers must develop innovative approaches to trigger or control the degradation process at specific times or under certain conditions.

Weight considerations are paramount in space exploration, and this applies to biodegradable plastics as well. Developing lightweight yet durable biodegradable materials that can withstand the rigors of space travel while minimizing payload weight is a crucial challenge. This requires careful material selection and engineering to optimize the strength-to-weight ratio of biodegradable plastics for space applications.

The potential for off-gassing and contamination is another significant concern. As biodegradable materials break down, they may release gases or particles that could interfere with sensitive equipment or experiments. Ensuring that the degradation products are non-toxic and do not pose risks to astronauts or scientific instruments is essential for the successful implementation of biodegradable plastics in space exploration.

Lastly, the economic viability of biodegradable plastics for space applications presents a considerable challenge. The high costs associated with space-grade materials and the extensive testing required for space certification can make the development and adoption of biodegradable alternatives financially prohibitive. Overcoming these economic barriers while meeting the stringent performance requirements of space exploration is a significant hurdle that researchers and industry must address.

Current Space Plastics

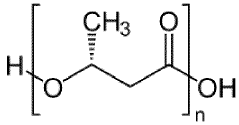

01 Composition of biodegradable plastics

Biodegradable plastics are composed of materials that can break down naturally in the environment. These plastics often incorporate natural polymers, such as starch or cellulose, or synthetic biodegradable polymers. The composition may also include additives to enhance biodegradability or improve material properties.- Composition of biodegradable plastics: Biodegradable plastics are composed of materials that can break down naturally in the environment. These may include natural polymers, synthetic biodegradable polymers, or blends of both. The composition often includes additives to enhance biodegradability and improve material properties.

- Manufacturing processes for biodegradable plastics: Various manufacturing processes are employed to produce biodegradable plastics, including extrusion, injection molding, and film blowing. These processes may be adapted to accommodate the unique properties of biodegradable materials and ensure consistent product quality.

- Applications of biodegradable plastics: Biodegradable plastics find applications in various industries, including packaging, agriculture, consumer goods, and medical devices. These materials are particularly useful in single-use products and in environments where traditional plastic waste poses significant environmental concerns.

- Biodegradation mechanisms and testing: Understanding the mechanisms of biodegradation and developing standardized testing methods are crucial for assessing the environmental impact of biodegradable plastics. This includes studying the role of microorganisms, environmental conditions, and time factors in the breakdown process.

- Enhancing biodegradability and material properties: Research focuses on improving the biodegradability of plastics while maintaining or enhancing their mechanical and functional properties. This may involve the use of novel additives, polymer blends, or surface treatments to optimize performance and environmental impact.

02 Manufacturing processes for biodegradable plastics

Various manufacturing processes are employed to produce biodegradable plastics, including extrusion, injection molding, and film blowing. These processes may require specific modifications to accommodate the unique properties of biodegradable materials. Some methods focus on blending biodegradable polymers with conventional plastics to improve overall biodegradability.Expand Specific Solutions03 Applications of biodegradable plastics

Biodegradable plastics find applications in various industries, including packaging, agriculture, and consumer goods. They are used to produce items such as food packaging, disposable cutlery, agricultural films, and compostable bags. The growing demand for environmentally friendly alternatives to traditional plastics drives the development of new applications.Expand Specific Solutions04 Biodegradation mechanisms and testing

Understanding the mechanisms of biodegradation is crucial for developing effective biodegradable plastics. This includes studying the role of microorganisms, environmental conditions, and material properties in the breakdown process. Standardized testing methods are employed to assess the biodegradability and compostability of plastic materials under various conditions.Expand Specific Solutions05 Enhancing biodegradability and material properties

Research focuses on improving the biodegradability of plastics while maintaining or enhancing their mechanical and functional properties. This may involve the development of new polymer blends, incorporation of biodegradation-promoting additives, or modification of existing polymers. Balancing biodegradability with durability and performance is a key challenge in this field.Expand Specific Solutions

Space Industry Players

The biodegradable plastics market in space exploration is in its early stages, with significant growth potential as the industry seeks sustainable solutions. The market size is expanding, driven by increasing space missions and environmental concerns. Technologically, it's still evolving, with companies like Stratasys, Inc. and DSM IP Assets BV leading in advanced materials development. Danimer IPCo LLC and Tipa Corp. Ltd. are pioneering biodegradable packaging solutions, while research institutions like Zhejiang University and Beijing Forestry University are contributing to material innovations. The competitive landscape is diverse, with both established aerospace companies and specialized material manufacturers vying for market share in this emerging field.

Danimer IPCo LLC

Tipa Corp. Ltd.

Key Biodegradable Tech

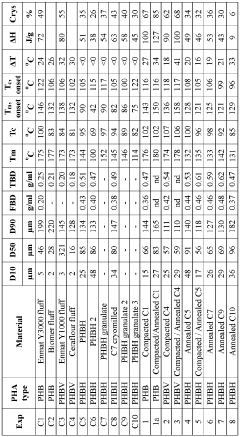

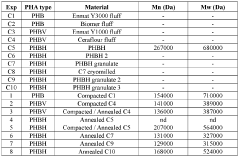

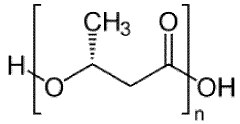

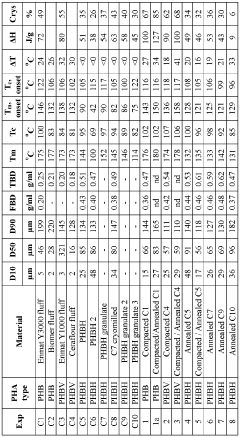

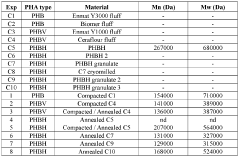

- A method involving compacting and annealing a homopolymer or copolymer of 3-hydroxy butyric acid to create a PHA powder with enhanced sinterability, characterized by a specific particle size distribution and increased sinterability region, allowing for improved flowability and mechanical properties in additive manufacturing.

- A method involving compacting and annealing a homopolymer or copolymer of 3-hydroxy butyric acid to create a PHA powder with controlled particle size and density, enhancing its sinterability region and flowability, which involves compacting the starting material with pressures above 5 kN/cm², heating to prevent sticking, and milling to achieve a D50 particle size between 20 to 100 microns.

Space Debris Mitigation

Space debris mitigation has become a critical concern in the context of space exploration, particularly with the increasing use of biodegradable plastics in spacecraft and satellite components. As the number of objects in Earth's orbit continues to grow, the risk of collisions and the generation of additional debris pose significant threats to operational satellites and future space missions. Biodegradable plastics offer a promising solution to this problem by reducing the long-term presence of debris in orbit.

The implementation of biodegradable plastics in space applications requires careful consideration of their degradation mechanisms in the unique space environment. Unlike terrestrial conditions, space presents challenges such as extreme temperature fluctuations, intense radiation, and the absence of microorganisms that typically facilitate biodegradation on Earth. Researchers are developing specialized formulations of biodegradable plastics that can withstand the harsh conditions of space while still maintaining their ability to break down over time.

One approach to space debris mitigation using biodegradable plastics involves the design of satellite components that degrade after their operational lifetime. These components could include structural elements, thermal insulation, and even solar panel substrates. By engineering these parts to break down into smaller, less harmful fragments, the risk of creating large, dangerous debris is significantly reduced. Additionally, the degradation process can be tailored to coincide with the satellite's planned de-orbiting, further minimizing its environmental impact.

Another innovative application of biodegradable plastics in space debris mitigation is the development of "self-cleaning" orbits. This concept involves deploying small, biodegradable devices that can actively capture and remove existing debris. These devices could be designed to attach to larger pieces of space junk, gradually breaking them down into smaller, less hazardous particles that will eventually burn up upon re-entry into Earth's atmosphere.

The integration of biodegradable plastics into space debris mitigation strategies also aligns with the growing emphasis on sustainable space practices. As space agencies and private companies increasingly focus on reducing their environmental footprint, the use of materials that minimize long-term orbital pollution becomes more attractive. This shift towards eco-friendly space technologies not only addresses the immediate concern of debris but also sets a precedent for responsible space exploration in the future.

However, the successful implementation of biodegradable plastics in space debris mitigation faces several challenges. These include ensuring the reliability and performance of biodegradable components throughout their intended operational life, predicting and controlling the degradation process in the unpredictable space environment, and developing cost-effective manufacturing processes for these specialized materials. Overcoming these hurdles will require continued research, testing, and collaboration between materials scientists, aerospace engineers, and space policy experts.

Extraterrestrial Impact

The exploration of biodegradable plastics in space environments presents a unique set of challenges and opportunities that extend beyond terrestrial applications. In the harsh conditions of outer space, these materials face extreme temperature fluctuations, intense radiation, and vacuum environments, which can significantly alter their degradation processes and overall performance.

One of the primary concerns in extraterrestrial applications is the potential for biodegradable plastics to contribute to space debris. While these materials are designed to break down over time, the lack of microorganisms and moisture in space may significantly slow or alter their degradation process. This could lead to the accumulation of partially degraded plastic particles in orbit, potentially exacerbating the existing space debris problem.

However, the use of biodegradable plastics in space exploration also offers potential benefits. For instance, these materials could be engineered to degrade in specific ways when exposed to solar radiation or other space-specific conditions, potentially reducing the long-term impact of human-made objects in space. This controlled degradation could be particularly useful for temporary structures or packaging materials used in space missions.

The impact of biodegradable plastics on extraterrestrial environments, such as the surface of Mars or the Moon, is another critical consideration. As space exploration missions become more ambitious, the possibility of contaminating other celestial bodies with Earth-based materials becomes a growing concern. Biodegradable plastics could offer a solution by minimizing the long-term presence of human-made materials on these surfaces.

Furthermore, the development of biodegradable plastics for space applications could drive innovation in material science. The need for materials that can withstand extreme space conditions while maintaining biodegradability may lead to breakthroughs in polymer chemistry and engineering. These advancements could potentially have spin-off applications in terrestrial industries, contributing to more sustainable practices on Earth.

The use of biodegradable plastics in space exploration also intersects with the concept of in-situ resource utilization (ISRU). As missions to other planets and moons become more feasible, the ability to produce biodegradable materials from local resources could be crucial. This approach could reduce the need for Earth-launched supplies and support the development of self-sustaining extraterrestrial habitats.

In conclusion, the extraterrestrial impact of biodegradable plastics in space exploration is a multifaceted issue that requires careful consideration of both the challenges and opportunities presented. As space agencies and private companies continue to push the boundaries of exploration, the role of these materials in shaping our approach to sustainable space operations will likely become increasingly significant.