Biodegradable Plastics In Pet Product Safety

Biodegradable Plastics in Pet Products: Background and Objectives

Biodegradable plastics have emerged as a promising solution to address the growing environmental concerns associated with conventional plastic waste. In the field of pet products, this technology holds significant potential to revolutionize the industry while ensuring the safety and well-being of companion animals. The development of biodegradable plastics for pet products stems from the increasing awareness of plastic pollution and its detrimental effects on ecosystems worldwide.

The primary objective of this research is to explore the application of biodegradable plastics in pet product manufacturing, with a specific focus on ensuring product safety. This involves investigating the various types of biodegradable materials suitable for pet products, their degradation processes, and their potential impact on animal health. The study aims to identify innovative solutions that can replace traditional plastics without compromising the quality, durability, or functionality of pet products.

The evolution of biodegradable plastics in the pet industry is closely tied to advancements in material science and polymer technology. Early attempts to introduce biodegradable materials in pet products faced challenges related to durability, cost-effectiveness, and scalability. However, recent breakthroughs in biopolymer synthesis and processing techniques have paved the way for more viable alternatives to conventional plastics.

One of the key drivers behind this technological pursuit is the growing consumer demand for environmentally friendly pet products. Pet owners are increasingly conscious of their ecological footprint and seek sustainable options for their animal companions. This shift in consumer behavior has prompted manufacturers to invest in research and development of biodegradable alternatives for a wide range of pet products, including toys, feeding accessories, grooming tools, and packaging materials.

The technical goals of this research encompass several critical aspects. Firstly, it aims to develop biodegradable plastics that exhibit comparable mechanical properties to traditional plastics, ensuring the durability and functionality of pet products. Secondly, the research focuses on optimizing the degradation rate of these materials to strike a balance between product lifespan and environmental impact. Lastly, a crucial objective is to ensure that the degradation byproducts are non-toxic and safe for both pets and the environment.

As the field of biodegradable plastics continues to evolve, researchers are exploring various approaches to enhance the performance and safety of these materials in pet products. This includes investigating novel polymer blends, incorporating natural fibers or additives, and developing advanced manufacturing processes. The ultimate goal is to create a new generation of pet products that not only meet the functional requirements but also contribute to a more sustainable and eco-friendly pet care industry.

Market Analysis for Eco-friendly Pet Products

The market for eco-friendly pet products has experienced significant growth in recent years, driven by increasing consumer awareness of environmental issues and a desire for sustainable alternatives. This trend aligns closely with the research on biodegradable plastics in pet product safety, as pet owners seek products that are both safe for their animals and environmentally responsible.

The global pet care market, valued at approximately $190 billion in 2022, is projected to grow at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. Within this market, the eco-friendly pet product segment is emerging as a key growth driver, with consumers showing a strong preference for sustainable and biodegradable options.

Pet owners are increasingly concerned about the environmental impact of traditional plastic pet products, such as toys, food containers, and waste management solutions. This concern has led to a surge in demand for biodegradable alternatives, with market research indicating that over 60% of pet owners are willing to pay a premium for eco-friendly pet products.

The biodegradable pet product market is particularly strong in North America and Europe, where stringent environmental regulations and high consumer awareness drive adoption. However, emerging markets in Asia-Pacific and Latin America are also showing rapid growth, as urbanization and rising disposable incomes fuel pet ownership and environmental consciousness.

Key product categories within the eco-friendly pet market include biodegradable toys, compostable waste bags, sustainable bedding, and recyclable food packaging. The biodegradable pet toy segment, in particular, is expected to see substantial growth, with a projected CAGR of 7.2% from 2023 to 2028.

Consumer preferences in this market are shifting towards products that offer both environmental benefits and enhanced safety for pets. This trend aligns perfectly with research on biodegradable plastics in pet product safety, as consumers seek assurance that eco-friendly alternatives are non-toxic and durable enough for pet use.

Market analysis reveals that major pet product manufacturers are investing heavily in research and development of biodegradable materials. This investment is driven by the potential for significant market share gains and the need to comply with increasingly strict environmental regulations in many countries.

The market for eco-friendly pet products faces some challenges, including higher production costs and the need for consumer education on proper disposal methods. However, these challenges are offset by the strong growth potential and positive brand perception associated with sustainable product offerings.

Current State and Challenges in Biodegradable Plastics for Pet Product

The current state of biodegradable plastics in pet products is characterized by a growing interest and adoption, driven by increasing environmental concerns and consumer demand for sustainable alternatives. However, the industry faces several significant challenges in widespread implementation and ensuring product safety.

Biodegradable plastics for pet products have seen notable advancements in recent years. Materials such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based plastics are being increasingly utilized in pet toys, food packaging, and accessories. These materials offer the potential to reduce plastic waste and environmental impact associated with traditional petroleum-based plastics.

Despite progress, the adoption of biodegradable plastics in pet products remains limited due to several technical and practical challenges. One major hurdle is the balance between biodegradability and durability. Pet products often require materials that can withstand chewing, scratching, and exposure to moisture, which can be difficult to achieve with current biodegradable formulations without compromising their eco-friendly properties.

Safety concerns present another significant challenge. While biodegradable plastics are generally considered safe, there are ongoing studies to ensure they do not pose any risks when ingested or when they break down in the environment. The potential for these materials to release harmful substances during degradation or to create microplastics is a subject of ongoing research and debate.

Cost remains a substantial barrier to widespread adoption. Biodegradable plastics are often more expensive to produce than conventional plastics, leading to higher prices for end products. This price differential can be a deterrent for both manufacturers and consumers, particularly in a competitive market.

The regulatory landscape for biodegradable pet products is still evolving. There is a lack of standardized testing and certification processes specifically for pet product applications, which creates uncertainty for manufacturers and consumers alike. This regulatory gap also makes it challenging to verify claims of biodegradability and safety.

Technical challenges in manufacturing processes also persist. Adapting existing production lines to work with biodegradable materials can be complex and costly. Additionally, ensuring consistent quality and performance across different batches of biodegradable plastics remains a challenge for many manufacturers.

The disposal and recycling infrastructure for biodegradable plastics is another area of concern. Many biodegradable plastics require specific conditions to break down effectively, which are not always available in standard waste management systems. This can lead to these materials ending up in landfills or contaminating recycling streams, potentially negating their environmental benefits.

Existing Biodegradable Solutions for Pet Product Safety

01 Biodegradable plastic composition and safety

Biodegradable plastics are developed with specific compositions to ensure safety and environmental friendliness. These compositions often include natural polymers, such as starch or cellulose, combined with synthetic biodegradable polymers. The safety of these materials is evaluated through various tests, including toxicity assessments and environmental impact studies.- Biodegradable plastic composition and safety: Biodegradable plastics are developed using various compositions to ensure safety and environmental friendliness. These compositions often include natural polymers, additives, and fillers that enhance biodegradability while maintaining product integrity and safety for consumers and the environment.

- Safety testing and certification of biodegradable plastics: Rigorous safety testing and certification processes are implemented to ensure biodegradable plastics meet safety standards. These processes involve evaluating the materials' toxicity, environmental impact, and degradation characteristics to guarantee their safety for various applications.

- Environmental impact and degradation of biodegradable plastics: Research focuses on the environmental impact and degradation mechanisms of biodegradable plastics. Studies examine how these materials break down in different environments, their effects on ecosystems, and potential residual impacts to ensure they are truly safe and eco-friendly alternatives to conventional plastics.

- Production methods for safe biodegradable plastics: Innovative production methods are developed to manufacture safe biodegradable plastics. These methods focus on using non-toxic raw materials, environmentally friendly processing techniques, and quality control measures to ensure the final products are safe for both consumers and the environment.

- Applications and safety considerations for biodegradable plastics: Various applications of biodegradable plastics are explored, with a focus on safety considerations for each use case. This includes evaluating their suitability for food packaging, medical devices, and other consumer products, ensuring they meet specific safety requirements for different industries and applications.

02 Production methods for safe biodegradable plastics

Safe production methods for biodegradable plastics involve careful selection of raw materials and processing techniques. These methods often focus on minimizing the use of harmful additives and ensuring the final product meets safety standards. Advanced manufacturing processes are employed to enhance the biodegradability while maintaining the desired physical properties of the plastic.Expand Specific Solutions03 Safety testing and certification of biodegradable plastics

Rigorous safety testing protocols are implemented for biodegradable plastics to ensure they meet regulatory standards. These tests evaluate the materials for potential toxicity, allergenicity, and environmental impact. Certification processes are established to verify the safety and biodegradability claims of these plastics, providing assurance to consumers and regulatory bodies.Expand Specific Solutions04 Environmental impact and degradation safety

The safety of biodegradable plastics extends to their environmental impact during and after degradation. Research focuses on understanding the breakdown products and their effects on ecosystems. Studies are conducted to ensure that the degradation process does not release harmful substances into the environment and that the resulting materials are safe for soil and aquatic life.Expand Specific Solutions05 Applications of safe biodegradable plastics

Safe biodegradable plastics find applications in various industries, including packaging, agriculture, and medical devices. These applications are developed with a focus on both functionality and safety. Special attention is given to ensuring that the biodegradable plastics used in food packaging and medical applications meet stringent safety standards to protect consumer health.Expand Specific Solutions

Key Players in Biodegradable Pet Product Manufacturing

The research on biodegradable plastics in pet product safety is in a growth phase, with increasing market demand driven by environmental concerns and pet owner awareness. The global market for biodegradable pet products is expanding, though still relatively small compared to traditional plastics. Technologically, the field is advancing rapidly, with companies like CJ CheilJedang Corp., LOTTE Chemical Corp., and Kaneka Corp. leading in bioplastic innovations. These firms are developing more sophisticated biodegradable materials that balance safety, durability, and environmental impact. However, challenges remain in scaling production and matching the performance of conventional plastics, indicating that the technology is still evolving towards full maturity.

Kaneka Corp.

LOTTE Chemical Corp.

Core Innovations in Pet-safe Biodegradable Materials

- A biodegradable and biocompostible packaging material comprising at least one biopolymer, such as gellan, pectin, or alginate, combined with polyvinyl alcohol, and optionally coated with waxes or chitosan, is prepared through a film casting process, offering tunable moisture permeability and enhanced tensile strength.

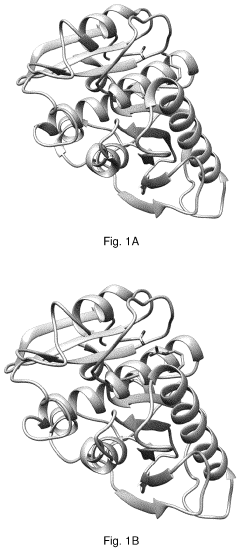

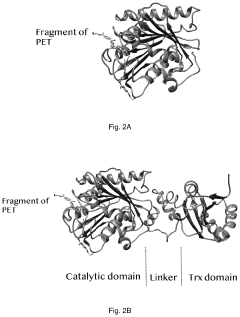

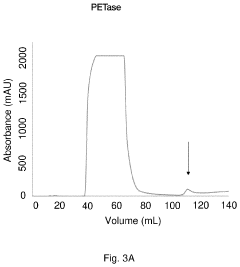

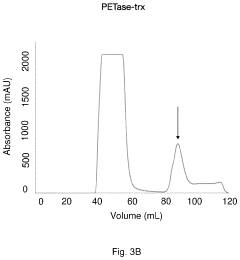

- Development of mutant PETase variants with specific amino acid mutations, such as S93R and S93K, that form stabilizing interactions like salt bridges, enhancing thermostability and activity by maintaining enzyme stability at elevated temperatures.

Environmental Impact Assessment of Biodegradable Pet Products

The environmental impact assessment of biodegradable pet products is a critical aspect of evaluating the sustainability and safety of these innovative materials. As the pet industry increasingly adopts biodegradable plastics, it is essential to comprehensively analyze their effects on ecosystems and natural resources throughout their lifecycle.

One of the primary benefits of biodegradable pet products is their potential to reduce plastic pollution. Traditional plastic pet products can persist in the environment for hundreds of years, contributing to the accumulation of microplastics in soil and water systems. Biodegradable alternatives offer a promising solution by decomposing into natural elements over time, potentially mitigating long-term environmental damage.

However, the environmental impact of biodegradable pet products is not uniformly positive. The production process of these materials often requires significant energy inputs and may involve the use of chemical additives to enhance degradability. This can lead to increased greenhouse gas emissions and potential chemical pollution during manufacturing, offsetting some of the environmental benefits gained at the end-of-life stage.

The degradation process itself warrants careful consideration. While biodegradable plastics break down more readily than conventional plastics, the rate and completeness of degradation can vary widely depending on environmental conditions. In landfills, where many pet products ultimately end up, the lack of oxygen and proper microbial activity may significantly slow or even halt the biodegradation process.

Water consumption is another critical factor in the environmental assessment. Some biodegradable plastics, particularly those derived from plant-based sources, require substantial water resources for raw material cultivation. This can strain local water supplies and potentially contribute to habitat loss if not managed sustainably.

The impact on soil quality is a double-edged sword. As biodegradable pet products decompose, they can potentially enrich soil with organic matter. However, if the degradation process releases harmful additives or creates microplastic particles, it may negatively affect soil ecosystems and potentially enter the food chain.

Biodegradable pet products also intersect with waste management systems. While they offer the potential to reduce landfill volume over time, they can complicate recycling processes if not properly sorted. Mixing biodegradable plastics with conventional recycling streams can compromise the quality of recycled materials, potentially leading to increased waste.

In conclusion, the environmental impact assessment of biodegradable pet products reveals a complex interplay of benefits and challenges. While these materials offer promising solutions to plastic pollution, their overall environmental footprint must be carefully evaluated across the entire lifecycle. Future research and development should focus on optimizing production processes, enhancing degradation efficiency, and ensuring compatibility with existing waste management infrastructure to maximize the environmental benefits of biodegradable pet products.

Regulatory Framework for Pet Product Safety Standards

The regulatory framework for pet product safety standards plays a crucial role in ensuring the safety and quality of biodegradable plastics used in pet products. As the demand for eco-friendly pet products grows, regulatory bodies worldwide are adapting their guidelines to address the unique challenges posed by biodegradable materials.

In the United States, the Food and Drug Administration (FDA) oversees the safety of pet products, including those made from biodegradable plastics. The FDA's Center for Veterinary Medicine (CVM) has established guidelines for the evaluation of materials used in pet products, focusing on their potential toxicity and environmental impact. These guidelines require manufacturers to provide comprehensive data on the composition, degradation process, and potential byproducts of biodegradable plastics used in pet products.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in biodegradable plastics for pet products. REACH mandates that manufacturers assess and manage the risks associated with these materials, ensuring their safety for both pets and the environment.

In addition to national and regional regulations, international standards organizations have developed specific guidelines for biodegradable plastics. The International Organization for Standardization (ISO) has published ISO 17088, which outlines the requirements for compostable plastics. This standard is often referenced in pet product safety regulations to ensure that biodegradable materials meet specific degradation and environmental impact criteria.

The pet product industry has also taken proactive steps to establish self-regulatory measures. The Pet Industry Joint Advisory Council (PIJAC) has developed voluntary standards for pet product safety, including guidelines for the use of biodegradable materials. These industry-led initiatives complement government regulations and help ensure a comprehensive approach to pet product safety.

As research on biodegradable plastics in pet products advances, regulatory frameworks are evolving to keep pace with new developments. Many regulatory bodies are now focusing on the long-term effects of biodegradable plastics, including their impact on pet health and the environment throughout their lifecycle. This includes assessing the potential for microplastic formation during degradation and the bioaccumulation of any residual substances in pets or ecosystems.

To address these concerns, some jurisdictions are implementing more stringent testing requirements for biodegradable plastics used in pet products. These may include accelerated aging tests to simulate long-term exposure, as well as ecotoxicity studies to evaluate potential environmental impacts. Manufacturers are increasingly required to provide detailed information on the degradation pathways of their materials and any potential intermediate compounds formed during the process.