Scalability Solutions In Biodegradable Plastics Manufacturing

Biodegradable Plastics Evolution and Objectives

Biodegradable plastics have emerged as a promising solution to address the global plastic pollution crisis. The evolution of these materials can be traced back to the 1980s when the first commercially viable biodegradable plastics were introduced. Initially, these plastics were primarily based on natural polymers such as starch and cellulose. However, their limited performance characteristics restricted widespread adoption.

The 1990s saw significant advancements in biodegradable plastic technology, with the development of synthetic biodegradable polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs). These materials offered improved mechanical properties and processability, making them more suitable for a wider range of applications. Despite these improvements, scalability remained a major challenge due to high production costs and limited raw material availability.

The past decade has seen a surge in innovation within the biodegradable plastics sector. New blends and composites have been developed, combining biodegradable polymers with natural fibers or inorganic fillers to improve performance and reduce costs. Additionally, advancements in biotechnology have led to the production of bio-based monomers, enabling the creation of fully renewable biodegradable plastics.

Current objectives in the field of biodegradable plastics manufacturing focus on addressing scalability challenges. Key goals include reducing production costs, improving material properties to match or exceed those of conventional plastics, and developing more efficient and sustainable manufacturing processes. There is also a strong emphasis on creating biodegradable plastics that can degrade in various environments, including marine ecosystems.

Another critical objective is to establish standardized testing and certification protocols for biodegradability and compostability. This is essential for ensuring consumer confidence and facilitating proper waste management. Additionally, researchers are working on developing "smart" biodegradable plastics that can be programmed to degrade under specific conditions or timeframes.

Looking ahead, the biodegradable plastics industry aims to achieve large-scale production capabilities that can meet the growing global demand for sustainable packaging and consumer goods. This involves optimizing fermentation processes for bio-based monomers, developing more efficient polymerization techniques, and creating innovative recycling and upcycling methods for end-of-life biodegradable products.

Market Demand Analysis for Scalability Solutions In Biodegradable Plastics Manufacturing

The biodegradable plastics manufacturing sector is experiencing a growing demand for scalability solutions, driven by increasing environmental awareness and legislative measures advocating for sustainable alternatives to conventional plastics. The market demand for biodegradable plastics is primarily influenced by their environmental benefits, as these materials can significantly reduce long-term waste and pollution associated with petroleum-based plastics. This increased demand is evident in sectors such as packaging, agriculture, and consumer goods, where companies are under pressure to align with sustainability goals.

In the packaging industry, there is a significant shift towards biodegradable options as businesses aim to reduce their carbon footprint and appeal to eco-conscious consumers. This trend is further bolstered by regulations in various regions mandating the use of environmentally friendly materials. The scalability solutions in manufacturing processes are essential to meet this added demand efficiently while maintaining product integrity and performance standards. As packaging constitutes a large portion of plastic use, the demand for scalable biodegradable solutions is particularly robust in this sector.

Agriculture is another domain where biodegradable plastics are gaining traction. Products such as mulch films, plant pots, and bags used in agricultural practices see a rising adoption of biodegradable variants that decompose naturally, minimizing environmental impact. For such applications, scalability is critical to meet the seasonal and regional variations in demand, ensuring timely availability and cost-effectiveness meeting the needs of farmers and agribusinesses.

The consumer goods market also reflects a growing inclination towards biodegradable plastics, especially in single-use products like utensils, bags, and packaging materials. Consumers increasingly prioritize sustainability in their purchase decisions, compelling manufacturers to seek scalable production methods that do not compromise on quality or aesthetics. This shift is supported by public discourse and media representation that advocate for a reduction in plastic pollution.

Additionally, global market trends show an interest in scalable manufacturing solutions from regions with stringent environmental regulations, such as Europe and North America, which are often early adopters of sustainable practices. Developing economies are also noting increasing demand as they experience socio-economic shifts towards environmental responsibility, although challenges such as cost considerations and infrastructure development persist.

To strategically capitalize on this expanding market, manufacturers must invest in research and development that focuses on improving production technologies and processes. This includes optimizing raw material usage, energy consumption, and waste management within the manufacturing cycle. By addressing these factors, companies can effectively enhance their production scalability, reducing operational costs and increasing market competitiveness.

Overall, the market demand for scalable solutions in biodegradable plastics manufacturing is responding to an unprecedentedly strong drive for environmental sustainability, influenced by legislative mandates, consumer preferences, and industry innovation. This demand outlines the necessity for industry players to adopt advanced technologies and scalable production methods to accommodate growing needs efficiently and sustainably.s of biodegradable plastics. The development of new feedstocks, such as agricultural waste and algae, holds promise for more sustainable and scalable production methods. As consumer awareness grows and regulatory pressures increase, the demand for biodegradable packaging solutions is likely to accelerate across various industries, presenting significant opportunities for manufacturers and investors in this sector.

Current Challenges in Large-scale Production

The large-scale production of biodegradable plastics faces several significant challenges that hinder widespread adoption and commercialization. One of the primary obstacles is the high production cost compared to conventional plastics. The raw materials and processing techniques required for biodegradable plastics are often more expensive, making it difficult to compete with traditional petroleum-based plastics on price.

Another major challenge is the inconsistency in material properties and performance. Biodegradable plastics can exhibit variations in strength, durability, and degradation rates, which can lead to quality control issues in large-scale manufacturing. This inconsistency makes it challenging to meet the stringent requirements of various industries and applications.

The limited availability of suitable raw materials poses another significant hurdle. Many biodegradable plastics rely on specific agricultural feedstocks, which can be subject to supply chain disruptions, seasonal variations, and competition with food production. This dependency on agricultural resources can lead to fluctuations in raw material costs and availability, impacting the stability of large-scale production.

Scaling up production processes while maintaining product quality and consistency is a complex task. The transition from laboratory-scale to industrial-scale production often requires significant modifications to equipment and processes, which can be both time-consuming and costly. Additionally, optimizing these processes to achieve high efficiency and yield at scale remains a challenge for many manufacturers.

The lack of standardized testing methods and certification processes for biodegradability and compostability further complicates large-scale production. Different regions and markets may have varying requirements and standards, making it difficult for manufacturers to develop products that comply with global regulations. This regulatory complexity can slow down product development and market entry.

Infrastructure limitations also present challenges in the production and disposal of biodegradable plastics. Many existing plastic processing facilities are not equipped to handle biodegradable materials, requiring significant investments in new equipment and technologies. Similarly, the lack of widespread industrial composting facilities limits the proper disposal and degradation of these materials at the end of their lifecycle.

Addressing these challenges requires a multifaceted approach involving technological innovations, policy support, and market development. Advances in material science and processing technologies are needed to improve the performance and consistency of biodegradable plastics while reducing production costs. Collaborative efforts between industry, academia, and government bodies are essential to overcome these hurdles and enable the successful scaling of biodegradable plastics manufacturing.

Existing Scalable Manufacturing Solutions

01 Production methods for scalable biodegradable plastics

Various production methods have been developed to enhance the scalability of biodegradable plastics. These include improved fermentation processes, novel polymer blending techniques, and optimized extrusion methods. These advancements aim to increase production efficiency and reduce costs, making biodegradable plastics more competitive with traditional plastics on an industrial scale.- Production methods for scalable biodegradable plastics: Various production methods have been developed to enhance the scalability of biodegradable plastics. These include improved fermentation processes, novel polymer blending techniques, and optimized extrusion methods. These advancements aim to increase production efficiency and reduce costs, making biodegradable plastics more competitive with traditional plastics on a large scale.

- Enhancing material properties for industrial applications: Researchers are focusing on improving the mechanical and thermal properties of biodegradable plastics to make them suitable for a wider range of industrial applications. This includes developing new additives, reinforcing agents, and polymer modifications that enhance strength, flexibility, and heat resistance without compromising biodegradability.

- Biodegradable plastic composites for increased versatility: The development of biodegradable plastic composites combines different biodegradable materials or incorporates natural fibers to create products with enhanced properties. These composites aim to improve scalability by offering a wider range of applications and potentially reducing production costs through the use of readily available natural materials.

- Optimizing biodegradation rates for various environments: Research is being conducted to fine-tune the biodegradation rates of plastics for different environments and applications. This involves developing formulations that can degrade efficiently in various conditions such as industrial composting facilities, marine environments, or soil. The goal is to create scalable solutions that meet both performance requirements and environmental standards.

- Scaling up through improved processing technologies: Advancements in processing technologies are crucial for scaling up biodegradable plastic production. This includes developing more efficient reactors, improving purification methods, and creating novel processing techniques that can handle large volumes of biodegradable materials. These technological improvements aim to reduce production costs and increase output, making biodegradable plastics more competitive in the market.

02 Enhancing material properties for industrial applications

Research focuses on improving the mechanical and thermal properties of biodegradable plastics to make them suitable for a wider range of industrial applications. This includes developing new polymer formulations, incorporating reinforcing agents, and modifying the molecular structure of biodegradable polymers to enhance their strength, flexibility, and heat resistance.Expand Specific Solutions03 Biodegradable additives and fillers for large-scale production

The use of biodegradable additives and fillers is being explored to improve the processability and reduce the cost of biodegradable plastics in large-scale production. These additives can enhance properties such as flow characteristics, mold release, and overall performance, making the materials more suitable for existing plastic processing equipment.Expand Specific Solutions04 Recycling and circular economy approaches

Developing efficient recycling methods and implementing circular economy principles are crucial for the scalability of biodegradable plastics. This includes creating closed-loop systems for collection and reprocessing, as well as designing products for easy disassembly and recycling. These approaches aim to reduce waste and improve the overall sustainability of biodegradable plastic production.Expand Specific Solutions05 Standardization and regulatory frameworks

Establishing standardized testing methods and regulatory frameworks is essential for the widespread adoption and scalability of biodegradable plastics. This includes developing consistent definitions of biodegradability, creating uniform labeling systems, and implementing regulations that promote the use of these materials. Such standardization efforts aim to increase consumer confidence and facilitate market growth.Expand Specific Solutions

Key Players in Biodegradable Plastics Industry

The scalability solutions in biodegradable plastics manufacturing are in a rapidly evolving phase, with the market experiencing significant growth due to increasing environmental concerns. The industry is transitioning from early-stage development to commercial scaling, with a projected market size reaching billions of dollars in the coming years. Technological maturity varies among key players, with companies like BASF SE, Stratasys Ltd., and Danimer IPCo LLC leading in innovation and production capacity. Research institutions such as Fraunhofer-Gesellschaft eV and Korea Research Institute of Chemical Technology are contributing to advancements in material science and processing techniques. Emerging players like Toraphene Ltd and Anpoly, Inc. are introducing novel approaches, intensifying competition and driving technological progress in the sector.

Stratasys, Inc.

BASF SE

Innovative Materials and Processes

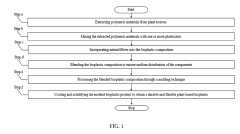

- A method involving the extraction of polymeric materials from renewable plant sources, mixing with plasticizers, incorporation of natural fibers, and processing through standard molding techniques to produce biodegradable and compostable bioplastics with enhanced mechanical properties and thermal stability.

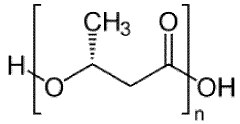

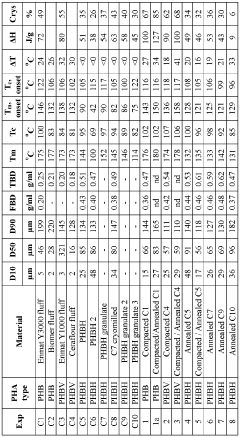

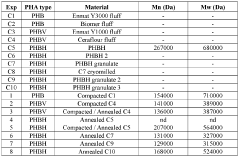

- A method involving compacting and annealing a homopolymer or copolymer of 3-hydroxy butyric acid to create a PHA powder with controlled particle size and density, enhancing its sinterability region and flowability, which involves compacting the starting material with pressures above 5 kN/cm², heating to prevent sticking, and milling to achieve a D50 particle size between 20 to 100 microns.

Environmental Impact Assessment

The environmental impact assessment of scalability solutions in biodegradable plastics manufacturing is a critical aspect of evaluating the sustainability and viability of these technologies. As production scales up to meet growing demand, it is essential to consider the potential environmental consequences and benefits throughout the entire lifecycle of biodegradable plastics.

One of the primary environmental advantages of biodegradable plastics is their ability to decompose naturally, reducing long-term pollution and accumulation in ecosystems. However, the scalability of production processes may introduce new environmental challenges. Large-scale manufacturing often requires increased energy consumption, which could lead to higher greenhouse gas emissions if not managed properly. It is crucial to assess the carbon footprint of expanded production facilities and implement energy-efficient technologies to mitigate these impacts.

Water usage is another significant factor to consider in the environmental impact assessment. Scaling up production may result in increased water consumption for processing and cooling. Implementing closed-loop water systems and water-saving technologies can help minimize the strain on local water resources. Additionally, proper wastewater treatment and management are essential to prevent pollution of nearby water bodies.

The sourcing of raw materials for biodegradable plastics production is a key environmental consideration. As production scales up, there may be increased pressure on agricultural land and resources. It is important to evaluate the potential impacts on biodiversity, soil health, and food security. Sustainable sourcing practices and the development of alternative feedstocks, such as agricultural waste or algae-based materials, can help mitigate these concerns.

Waste management and end-of-life considerations are crucial aspects of the environmental impact assessment. While biodegradable plastics offer advantages in terms of decomposition, proper disposal infrastructure and consumer education are necessary to ensure these benefits are realized. Scaling up production should be accompanied by efforts to develop and expand composting facilities and recycling programs tailored to biodegradable plastics.

The potential for unintended environmental consequences must also be carefully evaluated. For instance, the increased production of biodegradable plastics may lead to changes in consumer behavior, potentially resulting in increased littering or overconsumption. Comprehensive life cycle assessments (LCAs) should be conducted to compare the environmental impacts of biodegradable plastics with traditional plastics and other alternatives across various scenarios and scales of production.

In conclusion, the environmental impact assessment of scalability solutions in biodegradable plastics manufacturing must take a holistic approach, considering factors such as energy use, water consumption, raw material sourcing, waste management, and potential behavioral changes. By identifying and addressing these environmental challenges, the industry can work towards sustainable scalability that maximizes the benefits of biodegradable plastics while minimizing negative impacts on the environment.

Economic Viability Analysis

The economic viability of scalable biodegradable plastics manufacturing is a critical factor in determining the long-term success and widespread adoption of these environmentally friendly materials. As production scales up, several key economic considerations come into play.

Firstly, the cost of raw materials remains a significant challenge. While traditional plastics rely on inexpensive petroleum-based feedstocks, biodegradable plastics often require more costly bio-based materials. However, as production volumes increase, economies of scale can help reduce these input costs. Bulk purchasing agreements and improved supply chain efficiencies can lead to substantial savings, making biodegradable plastics more cost-competitive.

Manufacturing processes for biodegradable plastics are generally more complex and energy-intensive than those for conventional plastics. This translates to higher production costs, which can be a barrier to market entry. However, technological advancements and process optimizations are gradually reducing these expenses. Investments in more efficient equipment and automation can significantly lower per-unit production costs as manufacturing scales up.

The market demand for biodegradable plastics is growing rapidly, driven by increasing environmental awareness and stricter regulations on single-use plastics. This expanding market creates opportunities for economies of scale, allowing manufacturers to spread fixed costs over larger production volumes. As production capacity increases, the average cost per unit decreases, improving overall economic viability.

Pricing strategies play a crucial role in the economic feasibility of biodegradable plastics. Initially, these materials may command a premium price due to their environmental benefits. However, as production scales up and costs decrease, manufacturers can potentially lower prices to compete more effectively with traditional plastics, further driving market adoption.

Government incentives and regulations can significantly impact the economic viability of biodegradable plastics manufacturing. Subsidies, tax breaks, and favorable policies can help offset higher production costs and encourage investment in scaling up manufacturing capabilities. As more countries implement plastic reduction policies, the demand for biodegradable alternatives is likely to increase, further improving economic prospects.

The development of more efficient recycling and composting infrastructure is crucial for the long-term economic viability of biodegradable plastics. As these systems become more widespread and cost-effective, the overall value chain for biodegradable plastics will improve, potentially leading to additional revenue streams from recycled materials and reduced waste management costs.

In conclusion, while challenges remain, the economic viability of scalable biodegradable plastics manufacturing is improving. As production volumes increase, costs decrease, and market demand grows, the industry is moving towards a more sustainable and economically viable future. Continued technological innovation and supportive policies will be key drivers in this transition.